Ilford ILFOLAB 1250 RC User manual

IL882

VARIABLE SPEED PRINT DRYER

FOR HIGH QUALITY

BLACK AND WHITE PRINT DRYING

50/60 Hz OPERATING MANUAL

ILFORD

ILFOLAB

12 5 0 R C

1st Proof rev A - March 1997

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

SAFETY PRECAUTIONS

Your photographic equipment is powered by mains electricity,

and is designed to comply with international electrical safety

standards. However, basic safety precautions must always be

followed when operating electrical equipment, including the

following, where applicable:

Read and understand all instructions and equipment labels.

Close supervision is necessary when the equipment is being used

by inexperienced personnel.

Take care to avoid burns. Some internal parts of the equipment

can become very hot with continuous use.

Do not operate equipment that has been dropped or damaged,

or has damaged electrical leads. Have the equipment examined

by qualified personnel.

Do not allow any electrical lead to touch hot surfaces.

Ensure the leads are arranged such that they cannot be pulled or

tripped over.

Ensure extension leads are of a suitable current rating to prevent

the lead overheating.

Always unplug or isolate the equipment when it is not in use.

Never pull plugs out by holding the lead.

For equipment connected to the electrical mains supply by a plug

and socket arrangement, ensure the socket is installed near to the

equipment and is easily accessible at all times.

Do not touch electrical components with wet or damp hands.

Ensure the air flow through the vents is not obstructed when

equipment is switched on.

Do not dismantle the equipment unless you are qualified to do

so. Incorrect assembly can cause hazards both to yourself and to

the equipment.

All equipment, no matter how well made, can break down and,

therefore, must not be left unattended for long periods of time

while it is switched on.

Always unplug or isolate the equipment before connecting or

disconnecting any plugs supplying electrical power to or from the

equipment.

Always obey local codes of practice, particularly for installation

requirements.

Do not destroy these instructions

CONTENTS

1

2

2.1

2.2

2.3

2.4

3

3.1

3.2

3.3

3.4

4

5

6

6.1

6.2

6.3

6.4

6.5

7

8

1

PICTOGRAMS 2

INTRODUCTION 5

CONTROLS AND INDICATORS 7

‘POWER’ light 7

‘READY’ light 7

Dryer control 7

Speed control 7

INSTALLATION 9

Print receive tray 9

Location 9

Electricity supply 9

Removing yellow transit wedges 9

DRYING PRINTS 10

SWITCHING OFF 11

CLEANING AND SIMPLE REPAIRS 13

Daily routine 13

Cleaning the front roller assembly 13

Replacing a mains fuse 14

Replacing a roller tension spring 14

Removing rear rollers/adjusting print exit guide 15

FAULT FINDING 18

SPECIFICATION 21

INSERTS

94031.2A.GB Wall chart - Operating

PICTOGRAMS

2

The following pictograms are used on labels fixed to the dryer.

Please ensure you understand their meaning.

Electrical hazard - refer to manual

Caution moving rollers

IL895

3

Figure 1.1 ILFOLAB 1250RC dryer - typical installation

ILFOLAB

1250 RC

ILFORD

IL883

4

1

INTRODUCTION

5

See figure 1.1.

The ILFOLAB 1250RC variable speed dryer is designed to dry

ILFORD black and white resin coated papers to a very high

standard. The dryer will dry up to 380 20.3x25.4cm

(8x10 inches) prints per hour, and has a maximum feed width of

50.8cm (20 inches).

For uniform drying and greater efficiency, prints are dried by

infra-red, fan assisted heaters. The print transport speed is

variable for precise control of a wide range of drying conditions

and materials.

This manual gives full instructions for installing and operating the

ILFOLAB 1250RC dryer. For ease of description, it is assumed

the left and right hand sides of the dryer are determined when

facing the dryer at the paper feed (front) end.

Figure 2.1 Controls and indicators

IL884A

ILFOLAB

1250 RC

ILFORD

12

6

2

CONTROLS AND

INDICATORS

2.1

2.2

2.3

2.4

7

See figure 2.1.

‘POWER’ LIGHT

The red ‘POWER’light illuminates when the dryer control is

selected to ‘I ‘or ‘RUNDOWN’.

‘READY’LIGHT

The orange ‘READY’light indicates that the machine has warmed

up and is ready for use.

DRYER CONTROL

The dryer control has three positions:

Position ‘O’

The dryer is switched off.

Position ‘RUNDOWN’

In this position the power supply to the heaters is switched off,

but the fans and main drive continue to run. After a pre-set time

(factory set), the fans and main drive are switched off

automatically.

Note

It is recommended that this position is used before switching the

dryer off at the end of the day. Select this position to remove

moist air from the dryer and to prevent excessive heat retention

in the rollers.

Position ‘I ‘

For drying sheets. See section 8 for speed range.

SPEED CONTROL

The speed control adjusts the time taken for sheets to pass

through the dryer and, therefore, the rate of drying. The speed

control operates when the dryer control is selected to ‘I ‘and is

adjustable over the range minimum setting (slowest) to maximum

setting (quickest).

Figure 2.1

Dryer control

Speed control

1

2

Figure 3.1 Installation

IL885A

A

B

300mm

(12in)

300mm

(12in)

350mm

(13.8in)

3

2

2

1

6

10

4

8

9

5

7

8

3

INSTALLATION

3.1

3.2

3.3

3.4

1

2

3

4

9

See figure 3.1.

PRINT RECEIVE TRAY

Secure the tray with the screws supplied, as shown in detail B.

LOCATION

Position the dryer on a firm bench or table at a convenient

working height. The dimensions shown in detail Aare minimum

requirements to allow for adequate air circulation and for the

print receive tray. Position the wet-print dish under the dryer.

ELECTRICITY SUPPLY

Connect the lead supplied to the dryer mains input plug and to a

standard wall socket. The lead fits one way only.

REMOVING YELLOW TRANSIT WEDGES

See figures 3.1 and 3.2.

CAUTION

To enable the dryer to operate correctly, it is important to remove

the two yellow transit wedges prior to use.

Press the release button on the left hand side of the dryer and

open the dryer until the lid is held by the restraining arm.

Lift the four-roller assembly away.

Remove the two transit wedges from between the roller bearings.

Re-assemble the dryer and close the lid.

IL886

Figure 3.2 Location of transit wedges

Figure 3.1

Release button

Yellow transit wedges

Four-roller assembly

Restraining arm

Feed tray

Mains fuse

Electricity supply lead

Print receive tray

Pan head screw

Wet-print dish

1

2

3

4

5

6

7

8

9

10

4

DRYING PRINTS

IL887A

IL888A

IL889

ILFOLAB

1250 RC

ILFORD

10

Fill the wet-print dish with

enough cold water to cover

the washed prints. Switch the

electrical supply on. Turn the

dryer control to ‘I ‘. The red

‘POWER’light illuminates.

1

2

3

Allow about 11/2minutes for

the orange ‘READY’light to

switch on. During this time,

transfer the washed prints to

the wet-print dish. As a

guide, set the speed control

to position 6 to dry resin

coated paper sheets.

Feed prints emulsion side up.

Ensure prints are fed

squarely. Feed small prints

with the short edge leading.

Do not overlap one print with

another - allow 2 seconds

between the trailing edge of

one print and the leading

edge of the next.

5

SWITCHING OFF

IL890A

IL891A

11

Turn the dryer control to

‘RUNDOWN’. If the dryer is

to be used again later the

same day, the control can be

left in this position.

To switch the dryer off

completely, carry out

operation 1 and wait for the

fans and main drive to stop.

Then turn the dryer control to

‘O’. Switch the electrical

supply off.

1

2

Figure 6.1 Adjusting print exit guide

IL892A

AB

10

3

8

9

76

5

4

7

6

8

1

2

12

6

CLEANING AND SIMPLE

REPAIRS

6.1

1

2

6.2

1

2

3

4

5

13

See figure 6.1.

Cleaning is the only regular maintenance required on the

ILFOLAB 1250RC dryer. Regular cleaning will ensure correct

operation and consistently high drying quality.

CAUTION

During the following procedures, do not allow water to enter

areas of the dryer containing electrical components. Please refer

to the Safety Precautions at the front of this manual.

DAILY ROUTINE

Change the water in the wet-print dish daily or more frequently if

necessary.

Wipe the outside of the dryer with a damp cloth.

CLEANING THE FRONT ROLLER ASSEMBLY

See figure 3.1.

CAUTION

When cleaning the roller assembly, always take extreme care

not to damage the roller surfaces. Damaged roller surfaces will

cause marks on subsequent prints.

If the four-roller assembly at the front of the dryer becomes

contaminated, remove and clean it as follows:

Switch the electrical supply off.

Press the release button and open the dryer until the lid is held

securely by the restraining arm.

Lift the four-roller assembly away.

Thoroughly clean the rack with a soft lint free cloth and warm

water. More stubborn deposits on metal and plastic surfaces can

be removed using a soft bristle brush and warm water.

CAUTION

To prevent a reduction in the quality of drying, particularly on

glossy surfaces, do not use soap solutions or other cleaning

agents on the rollers.

Refit the four-roller assembly and close the dryer.

Figure 6.1

Upper roller, rear

Lower roller, rear

Lower cover

Restraining arm

Front roller assembly

Print exit guide

Ventilation grille

Alignment mark

Washer

Nut

1

2

3

4

5

6

7

8

9

10

6.3

1

2

3

4

6.4

1

2

3

14

REPLACING A MAINS FUSE

See figure 6.2.

The mains fuse is located to the right of the dryer mains input

plug.

Switch the electrical supply off.

Remove the fuse by turning the fuseholder anti-clockwise with a

screwdriver.

Replace the fuse with one of the correct value (see section 8).

Refit the fuse by turning the fuseholder clockwise with a

screwdriver.

REPLACING A ROLLER TENSION SPRING

See figure 6.3.

Roller tension springs are fitted on the four-roller assembly only.

Springs are fitted to both ends of the roller pairs, as shown.

Switch the electrical supply off.

Press the release button and open the dryer until the lid is held

securely by the restraining arm.

Lift the four-roller assembly away.

IL893

Figure 6.2 Replacing a mains fuse

4

5

6

7

8

9

6.5

15

To remove a tension spring left hand side, release the socket set

screws and remove the gears and locating plate, as shown on

Detail A.

Unhook and remove the spring from the end of the roller pair.

Fit a new spring around the roller bearings, as shown.

Refit the locating plate and gear. Secure each gear by tightening

the socket set screw against the flat on the roller shaft.

To remove a tension spring right hand side as shown on

Detail B, carry out operations 5 and 6.

Refit the roller assembly and close the dryer.

REMOVING REAR ROLLERS/ADJUSTING

PRINT EXIT GUIDE

See figure 6.1.

The gap between the print exit guide and the rear upper roller is

critical to ensure correct paper transport through the dryer.

Initially, this gap is factory set. Under normal operating

conditions, the print exit guide must not be moved.

If, for any reason, the rear lower roller needs to be removed, the

print exit guide must first be moved to clear the way for the

roller. This means that, when the rollers are replaced, the gap

must be reset as accurately as possible. To help with this

operation, the print exit guide has an alignment mark at each

end as shown in detail A.

IL894

A

B

1

233

Figure 6.3 Replacing a roller tension spring

Figure 6.3

Gear

Locating plate

Spring

1

2

3

1

2

3

4

5

6

1

2

3

4

5

6

16

To remove the rear rollers, proceed as follows:

CAUTION

This operation requires access to the electrical compartment.

Please refer to the Safety Precautions at the front of this manual.

Switch the electrical supply off.

Press the release button and open the dryer until the lid is held

securely by the restraining arm.

Release the four screws and remove the lower cover.

Carefully remove the upper roller, complete with bearings.

Carry out the following operations only if the lower roller is to be

removed.

Slacken the four nuts securing the print exit guide to the

ventilation grille as shown in detail Band push the exit guide

towards the rear of the dryer.

Carefully lift the lower roller, complete with bearings and roller

drive gear, away.

To replace the rear rollers, proceed as follows:

Note

Carry out operations 1, 2, 3, 7 and 8 only if the lower roller is

being replaced.

Ensure the print exit guide is pushed towards the rear of the

dryer and is not obstructing the lower roller.

Replace the lower roller, complete with bearings. Ensure the

roller drive gear meshes with the idler gear.

Replace the upper roller, complete with bearings.

Carefully move the print exit guide towards the front of the dryer

until the rear edge of the mark at each end of the guide is

aligned with the front edge of the ventilation grille. Tighten the

nuts securing the guide to the ventilation grille. Check the

alignment is correct as shown in detail A.

Refit the lower cover. Secure the cover with the four screws and

washers.

Close the dryer.

7

8

17

Switch the electrical supply on.

When the dryer is ready, feed a number of wet sheets through,

ensuring they exit the dryer without obstruction. If the sheets do

not exit correctly, switch the electrical supply off and check the

alignment of the print exit guide. Re-adjust the guide if necessary.

7

FAULT FINDING

18

Sheet fed upside down Feed sheets emulsion side up

Prints pulled from the exit Leave prints to emerge fully

rollers from the dryer before handling

them

Dirty paper guides Remove roller assemblies and

inspect guides. See figure 3.1.

Clean guides as necessary

Dirty feed tray Clean feed tray. See figure 3.1

Paper guides bent Contact your local ILFORD

Selling Company

Dryer speed too high Adjust speed control to a slower

setting

Faulty heater element Contact your local ILFORD

Selling Company

Rollers operating incorrectly Replace any damaged or

missing roller tension springs.

See section 6.4. Clean rollers.

See section 6.2. Ensure the

yellow transit wedges have

been removed. See section 3.4

Symptom Possible cause Remedy

Scratches on prints

Wet or damp prints

1

2

This section provides a list of checks to make should there be any

problems with the dryer. If the problem persists, contact your

nearest ILFORD Selling Company at the address shown on the

back cover of this manual.

CAUTION

If in doubt about making any of the checks consult a competent

engineer. Any further repair work carried out by unqualified

personnel could cause a hazard both to yourself and to the

equipment, and may invalidate any guarantees applicable to the

equipment.

Note

An interlock switches off the fan motor, drive motor and heaters if

the dryer lid is raised.

Table of contents

Other Ilford Printer manuals

Popular Printer manuals by other brands

Canon

Canon LBP113w Getting started

Colorjet

Colorjet Neptune Installation and Troubleshoot Guide

Epson

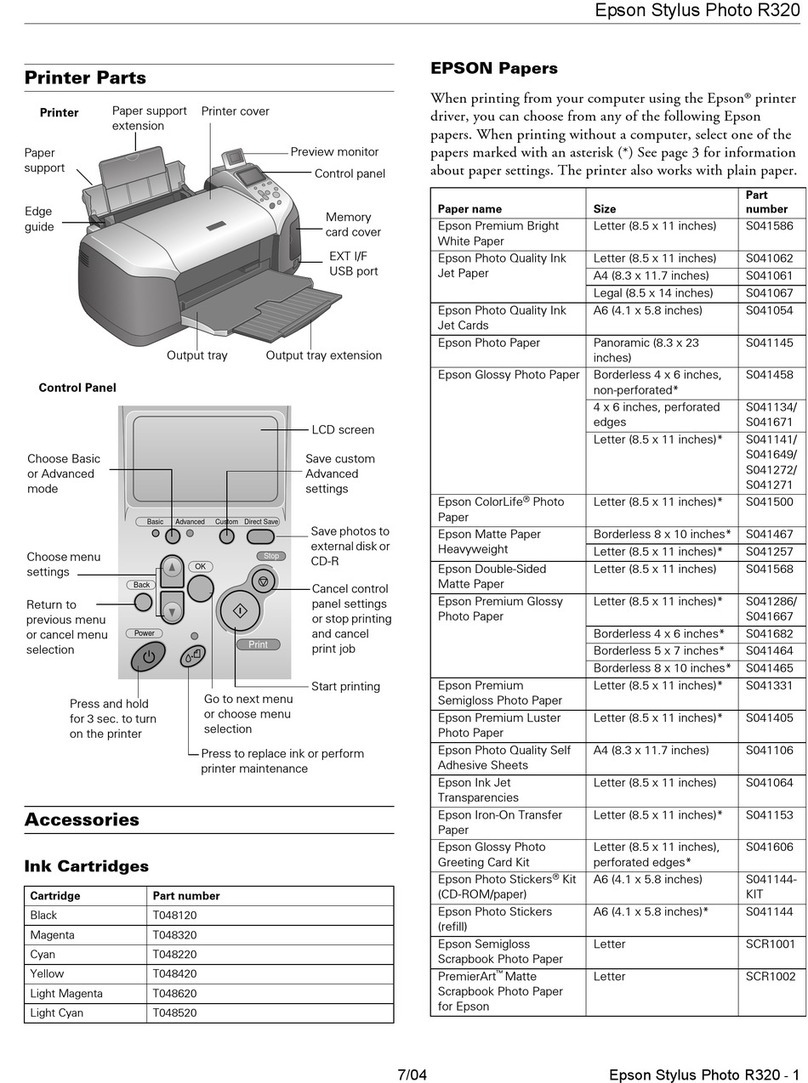

Epson R320 - Stylus Photo Color Inkjet Printer Product information

Kyocera Mita

Kyocera Mita Ecosys FS-6020 Operation guide

LabelTac

LabelTac Pro X user manual

Addressograph

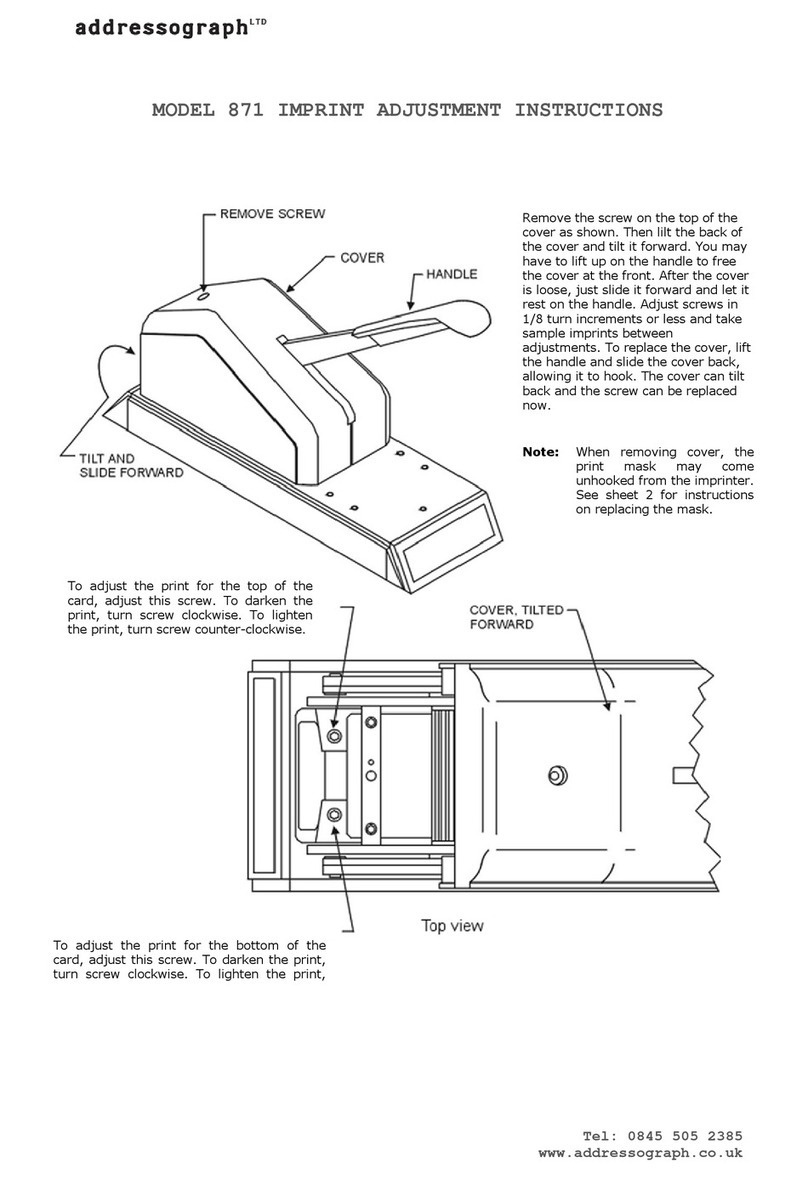

Addressograph 871 Adjustment instructions