Ilford ILFOLAB 2150RC User manual

IL184A

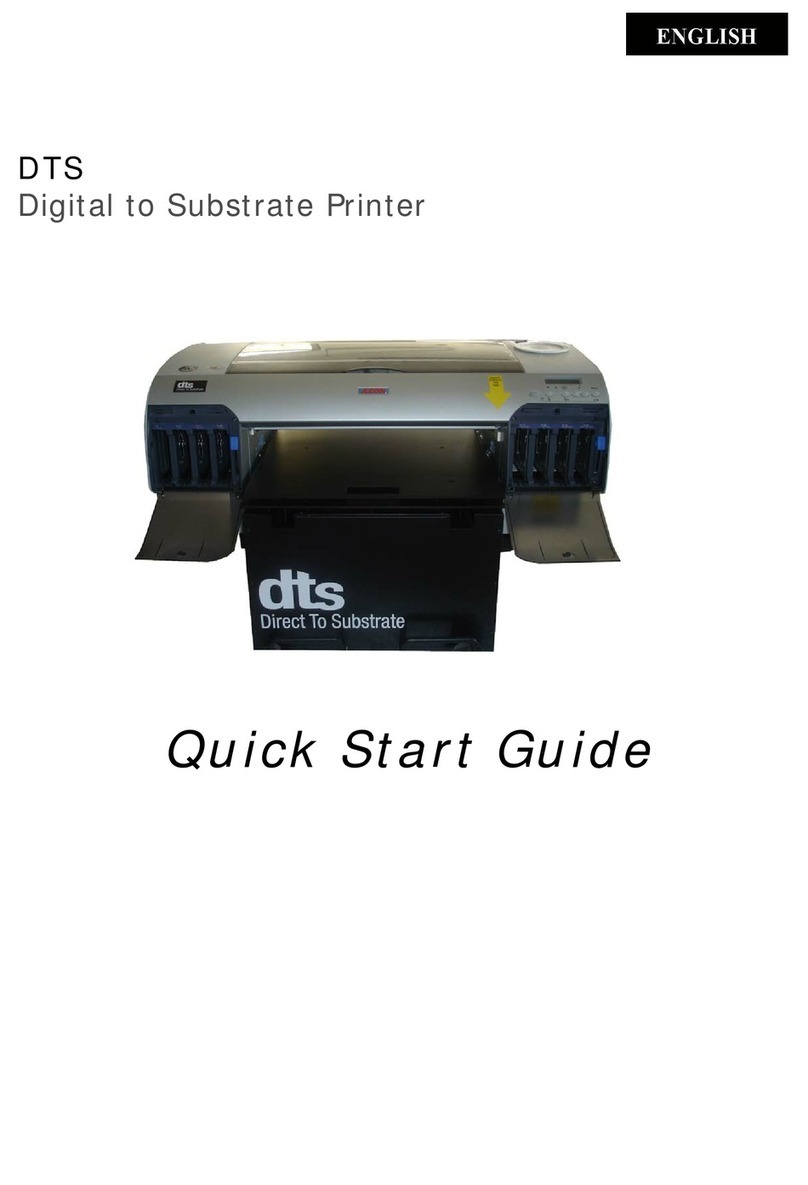

TABLE TOP AUTOMATIC PROCESSING SYSTEM FOR

HIGH QUALITY BLACK AND WHITE PRINT MAKING

50/60Hz OPERATING MANUAL

ILFORD

ILFOLAB

2150RC

1st Proof rev A - March 1997

March 1998 - amended BC address/print date/deleted IP logo

1

2

3

4

5

6

7

8

9

10

11

12

13

SAFETY PRECAUTIONS

Your photographic equipment is powered by mains electricity,

and is designed to comply with international electrical safety

standards. However, basic safety precautions must always be

followed when operating electrical equipment, including the

following, where applicable:

Read and understand all instructions and equipment labels.

Close supervision is necessary when the equipment is being used

by inexperienced personnel.

Take care to avoid burns. Some internal parts of the equipment

can become very hot with continuous use.

Do not operate equipment that has been dropped or damaged,

or has damaged electrical leads. Have the equipment examined

by qualified personnel.

Do not allow any electrical lead to touch hot surfaces.

Ensure the leads are arranged such that they cannot be pulled or

tripped over.

Ensure extension leads are of a suitable current rating to prevent

the lead overheating.

Always unplug or isolate the equipment when it is not in use.

Never pull plugs out by holding the lead.

For equipment connected to the electrical mains supply by a plug

and socket arrangement, ensure the socket is installed near to the

equipment and is easily accessible at all times.

Do not touch electrical components with wet or damp hands.

Ensure the air flow through the vents is not obstructed when

equipment is switched on.

Do not dismantle the equipment unless you are qualified to do

so. Incorrect assembly can cause hazards both to yourself and to

the equipment.

All equipment, no matter how well made, can break down and,

therefore, must not be left unattended for long periods of time

while it is switched on.

14

15

Always unplug or isolate the equipment before connecting or

disconnecting any plugs supplying electrical power to or from the

equipment.

Always obey local codes of practice, particularly for installation

requirements.

Do not destroy these instructions

CONTENTS

1

1.1

2

2.1

2.2

3

3.1

3.1a

3.2

3.3

3.4

3.4a

3.4b

3.5

3.5a

3.6

3.7

4

5

6

7

8

8.1

8.2

8.3

8.4

8.4a

8.4b

8.5

8.6

8.7

8.7a

8.7b

8.8

9

9.1

10

10.1

1

PICTOGRAMS 2

INTRODUCTION 4

Important information 4

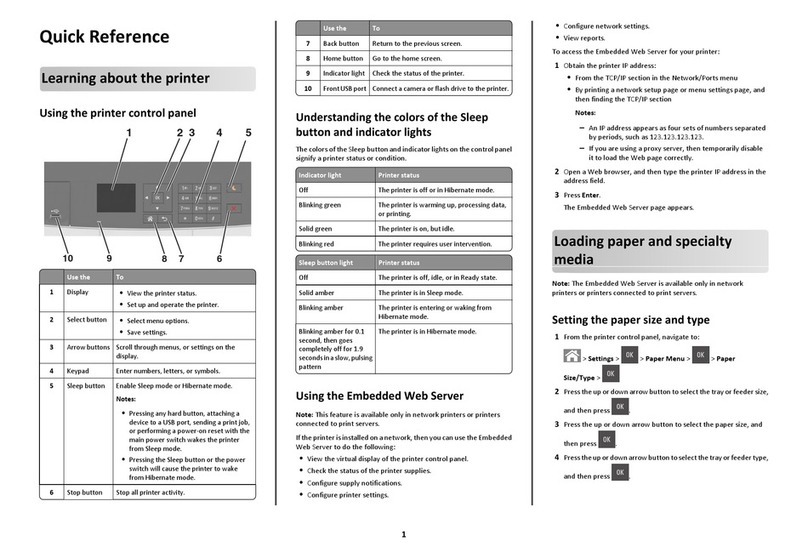

CONTROLS AND INDICATORS 6

Processor 6

Dryer 8

INSTALLATION 10

Processor 10

Levelling adjustments 10

Electrical supply 10

Plumbing 10

ILFOLAB 2150RC installation kit (optional) 11

Drain connections 11

Water supply 12

Dryer 12

Removing yellow transit wedges 14

ILFOLAB 2150RC print exit cover assembly 14

Commissioning a new machine 16

ADDING CHEMICALS 18

PROCESSING 19

SWITCHING OFF 21

DRAINING AND RINSING 22

CLEANING AND SIMPLE REPAIRS 24

Daily routine 24

Routine procedure between chemical changes 24

Monthly routine 24

Three monthly routine 24

Processor - cleaning roller racks 24

Dryer - cleaning the four-roller assembly 26

Replacing a mains fuse 27

Resetting the thermal cut-outs 28

Replacing a roller tension spring 28

Processor 28

Dryer 29

Removing dryer rear rollers/adjusting print exit guide 30

FAULT FINDING 33

Safety features 33

SPECIFICATION 40

Recommended processing capacities 43

PICTOGRAMS

The following pictograms are used on labels fixed to the ILFOLAB

2150RC processing system. Please ensure you understand their

meaning.

2

Electrical hazard - refer to manual

Figure 1.1 ILFOLAB 2150RC processing system - typical installation

ILFORD

OI

ILFOLAB 2150 RC

IL167A

3

1

INTRODUCTION

1.1

4

See figure 1.1.

The ILFOLAB 2150RC table-top processing system is designed for

low to medium volume users of paper. Typically, up to 1000

20˙3x25˙4cm (8x10 inch) prints can be processed on one fill of

chemicals. The system is very easy to install, operate and

maintain, and provides black and white prints on resin coated

papers up to a maximum width of 50.8cm (20 inches). The prints

are fully processed and dried to a very high standard.

This manual gives full instructions for installing and operating the

complete system. By disregarding all references to the dryer, this

manual also describes the processor when used alone.

For ease of description, it is assumed the left and right hand sides

of the processor are determined when facing the processor at the

paper feed (front) end. The left and right hand sides of the dryer

module are determined with the dryer module removed from the

processor and the paper feed side facing (ie the side normally

facing away from the operator). Unless otherwise stated, the

50Hz system is shown.

IMPORTANT INFORMATION

Chemicals

For optimum results always use recommended ILFORD chemicals.

Before handling ILFORD chemicals please ensure you are familiar

with the information detailed in the ILFORD Photochemical Safety

Data Sheets supplied as part of the chemicals pack.

Automatic rinsing

This is a feature designed to simplify regular cleaning operations

and, therefore, to keep major strip-down cleaning to a minimum.

Colour coding

Roller racks are colour coded: red for developer, green for fixer

and white for wash water. Do not interchange the roller racks for

any reason. The same colour coding is used on the drain outlets

at the rear of the processor, the standpipes in the working and

front tanks and the covers on the front tanks.

Operation

A wall chart, which summarises the regular operating procedures,

is supplied with this manual.

Figure 2.1 Controls and indicators

IL168A

OI

1

5

2

CONTROLS AND

INDICATORS

2.1

1

2

3

4

5

6

See figure 2.1.

PROCESSOR

Control switch

The control switch has two positions:

Position ‘0’

The processor and dryer are switched off.

Position ‘|’

The processor and dryer are switched on.

‘Mixing’ light

Illuminates when the processor is automatically mixing fresh

chemicals.

‘Ready’ light

Provides two indications:

Flashing

Indicates the system is not ready for use (chemicals are being

mixed or heated).

Steady on

Indicates the system is ready.

Note

The ‘ready’ light switches off when a sheet is fed into the

processor, and switches on when the processor is ready to

accept the next sheet. In this way, the ‘ready’ light serves as a

visual feed indicator, and is synchronised with the audible feed

indicator (see 7 Audible signals).

‘Power’ light

Illuminates when the processor control switch is set to position |’.

‘Warning’ light

Illuminates when the solution level in either of the front tanks is

low. Under normal operating conditions, the levels will not fall

sufficiently for the ‘warning’ light to switch on.

Figure 2.1

Water feed button1

6

7

7

Water feed button

See figure 2.2.

Located on the processor to the right of the front tanks under the

processor lid. The water feed button controls the water supply for

diluting chemical concentrates, and for rinsing the processor.

Audible signals

There are four different signals:

Feed indicator

A single audible signal is made indicating the processor is ready

to accept the next sheet. This signal is synchronised with the

‘ready’ light (see 3 ‘Ready’ light).

Incorrect feed

A continuous audible signal is made lasting the length of a sheet.

This signal indicates that a sheet has been fed before the ‘ready’

light has stopped flashing (see 3 ‘Ready’ light).

Rinsing cycle complete

Three audible signals are made indicating the rinsing cycle is

complete (see section 7).

Warning indicator

A series of audible signals are made. The warning signal sounds

if the processor lid remains open 30 seconds after pressing the

water feed button, or if the solution level in either of the front

tanks is low. If left unchecked, the signal continues for three

minutes and the processor is then automatically switched off.

IL181

Figure 2.2 Water feed button

8

2.2

1

2

8

Thermal cut-out light

See figure 2.3.

Located between the two thermal cut-out resets in the processor

skirt. The light is switched on if either cut-out is tripped.

DRYER

See figure 2.4.

Dryer control switch

The dryer control switch has two positions, High and Low.

Temperature control

Adjustable over the range 1 (minimum) to 6 (maximum).

IL185

Figure 2.3 Thermal cut-out

IL186A

Figure 2.4 Dryer controls

Figure 3.1 Installation - general

150mm

(6in) 150mm

(6in)

150mm

(6in)

IL169A

4

3

567

8

10

11

2

19

9

3

INSTALLATION

3.1

3.1a

3.2

3.3

a

b

10

PROCESSOR

See figure 3.1.

Position the processor on a firm, level bench or table, at a

convenient working height. Leave a space of at least 15cm

(6 inches) between the processor and any wall to allow

adequate air circulation, to ensure the electrical and plumbing

installations are not impeded and to gain access to the thermal

cut-out resets.

Note

The processor lid support can be fitted to either side of the lid to

suit the installation and ease removal of the roller racks.

Levelling adjustments

CAUTION

For correct operation, it is essential to level the processor

accurately.

With the processor positioned, level the processor by placing a

spirit level first along the dividing wall between two of the

working tanks and then along the left and right hand sides of the

processor. Height adjustments are made by turning the four

levelling feet.

ELECTRICAL SUPPLY

See figure 3.1.

Connect the processor to the electrical mains with the lead

supplied. The lead is supplied with plugs, and fits one way only.

60Hz processors only:

The mains supply must be a correctly wired, grounded, 120 volt,

20 amp supply, with a socket suitable to accept the 20 amp plug

fitted to the mains lead. Do not remove the plug from the lead.

PLUMBING

The plumbing can be installed in one of two ways:

By the use of proprietary fittings (see table 3.1 for the dimensions

of the processor connections).

By the use of the ILFOLAB 2150RC installation kit (see section

3.4).

Figure 3.1

Dryer electrical connection

Electrical mains supply to

processor

Processor mains fuse

Dryer supply fuse

Developer drain connection

Fixer drain connection

Wash water drain connection

Wash water supply

connection

Auxiliary power supply

Drain manifold

Blanking plug - fixer drain

1

2

3

4

5

6

7

8

9

10

11

3.4

3.4a

11

Table 3.1 Plumbing connections

Description Dimension

Developer drain (red) connection 21mm

Fixer drain (green) connection 21mm

Wash water drain connection 21mm

Wash water supply connection 3/4inch BSP

ILFOLAB 2150RC INSTALLATION KIT (OPTIONAL)

See figure 3.1.

An installation kit is available as an optional extra to simplify the

plumbing installation. This kit (part number 6171-4-073 or

QY6714073 in North America) is supplied with full fitting

instructions.

There are four connections at the rear of the processor:

Wash water supply;

Wash water drain;

Developer drain (front and working tanks combined);

Fixer drain (front and working tanks combined).

The wash water drain takes the normal excess from the wash

water tank during processing. The wash water standpipe (see

figure 8.1) is fitted for emergency water overflow, and must be

used when draining the tank.

Drain connections

CAUTION

Ensure your drain arrangements comply with local regulations.

The drain manifold supplied with the installation kit has a

maximum of three inlets. These are connected to the processor

drain outlets by the short lengths of flexible pipe.

The fixer drain inlet on the manifold can be sealed using the plug

provided. If it is necessary for the fixer to be drained separately,

fit the blanking plug to the manifold and connect one of the 2m

(6˙5 feet) lengths of flexible pipe supplied to the processor fixer

drain outlet.

Connect the manifold to the service drain with the other 2m

(6˙5 feet) length of flexible pipe. Secure all pipe connections

with the pipe clips supplied.

3.4b

3.5

1

2

3

4

5

12

CAUTION

To prevent air locks and consequential flooding of the wash

water tank, ensure all drains fall continuously to the service

drain.

When using the drain manifold, drain each tank separately and

always drain the fixer before the developer.

Water supply

Note

The processor automatically regulates the flow of water at all

times.

Secure the water pressure pipe supplied to the processor water

supply connection by tightening the outer ring.

If the water supply contains a high proportion of suspended

solids, connect the water supply via a filter unit.

DRYER

See figure 3.2.

Position the dryer on the processor lid, with the paper feed end

of the dryer facing towards the rear of the processor.

Align the holes in the base of the dryer with the holes in the

processor lid.

Carefully open and support the processor lid.

Secure the dryer by inserting the two fixing screws from the

underside of the processor lid.

Plug the dryer into the power socket (marked ‘dryer’) at the rear

of the processor.

WARNING

Do not plug the dryer into any other power supply. The

processor socket is wired via the processor lid interlock, ensuring

the dryer heaters are automatically switched off when the

processor lid is raised.

Figure 3.2 Installation - dryer

IL170A

1

OI

2

60 Hz

50 Hz

B

A

4

3

3

6

5

6

5

13

3.5a

1

2

3

4

3.6

1

2

14

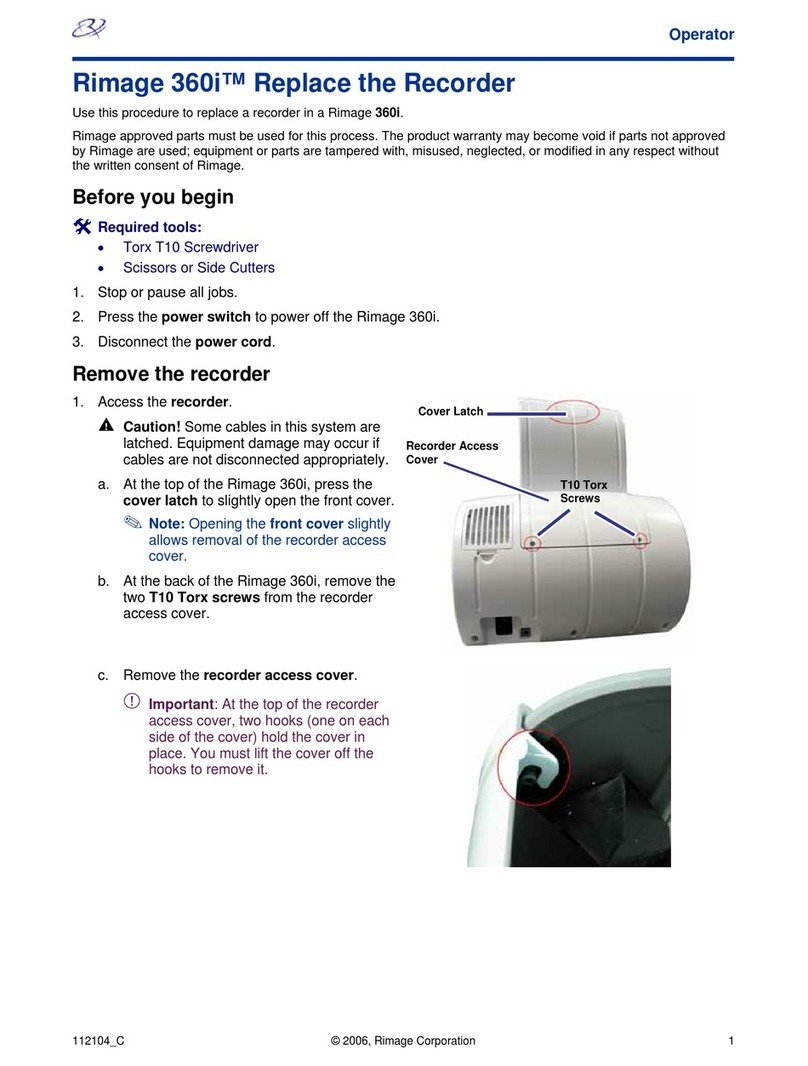

Removing yellow transit wedges

See figures 3.2 and 3.3.

CAUTION

To enable the dryer to operate correctly, it is important to remove

the two yellow transit wedges prior to use.

Removing transit wedges can be done before or after the dryer is

installed.

Press the release button and open the dryer until the lid is held

securely by the restraining arm.

Lift the four-roller assembly away.

Remove the two transit wedges from between the roller bearings.

Re-assemble the dryer and close the lid.

ILFOLAB 2150RC PRINT EXIT COVER ASSEMBLY

See figures 3.4 and 3.5.

The ILFOLAB 2150RC print exit cover assembly is supplied if the

processor is to be operated without the dryer.

Position the print exit cover on the processor lid, as shown, with

the holes in the base of the cover aligned with the holes in the

processor lid.

Carefully open and support the processor lid.

IL886

Figure 3.3 Location of transit wedges

Figure 3.2

Fixing screw

Processor to dryer drive gear

Socket - dryer electrical

supply

Release button - dryer lid

Fuse - processor

Fuse - dryer

Detail A

Location of fixing points

Detail B

Location of transit wedges

1

2

3

4

5

6

Secure the print exit cover by inserting the two fixing screws

from the underside of the processor lid.

Position the dish support at the front edge of the recess in the

processor lid, as shown. To secure the dish support, peel the

backing paper away from the tape fixed to the dish support.

Position the print receive dish in front of the print exit cover so

that the front of the dish rests on the dish support.

Fill the print receive dish with clean, fresh water.

3

4

5

6

Figure 3.4 Installation - print exit cover

OI

IL171

12

3

2

15

3.7

1

2

16

COMMISSIONING A NEW MACHINE

See figure 3.6.

Ensure all packing material has been removed.

Remove the roller rack assemblies from their packaging and

install the racks into the processor. Follow the colour coding (see

section 1.1) and ensure the racks are held secure by the shaft

retainers (see figure 8.1).

IL189

ILFORD

OI

ILFOLAB 2150 RC

Figure 3.5 Location of print receive dish

Figure 3.4

Fixing screw

Print exit cover

Dish support

1

2

3

IL180

ILFORD

ILFOLAB 2150 R C

OI

Figure 3.6 Internal view of processor

3

4

5

6

7

17

With the processor empty, turn on the water and electrical

supplies.

Note

The ‘warning’ light will switch on. This is normal with the front

tanks empty.

Carry out the automatic rinsing procedure (see section 7).

Switch the processor off (see section 6).

Drain the processor by releasing the five standpipes (see figure

8.1), using the standpipe key supplied.

Check for leaks, particularly from the water supply and drain

connections at the rear of the processor.

Table of contents

Other Ilford Printer manuals