Illinois Tool Works SIMCO PulseFlow PFC User manual

2257 North Penn Road

Hatfield, PA 19440

Phone: (215) 997-0590

Fax: (215) 997-0590

Publication 5100941 Rev A

INSTRUCTIONS

Operation / Maintenance

PFC

PulseFlow Controller

SIMCO’s PulseFlow Controller (PFC) DC pulse and steady state ionizer power supply.

SECTION 1. Description

2. Specifications

3. Safety Procedures

4. Installation

5. Operating Instructions

6. Cleaning & Maintenance

7. Customer Service

8. Replacement Parts

9. Warranty

1

PulseFlow Controller

Installation & Operating Instructions

Section 1 Description

The PulseFlow Controller incorporates both Pulse and Steady State DC technologies and is the power

source for the PulseBar line of products. The PulseFlow controller has four operational ranges from

10hz to 1.0hz in pulse mode and SS for Steady State DC operation. One PulseFlow Controller can

power up to 20 electrode pairs of PulseBar. The compact size of the PulseFlow Controller offers

versatile mounting in almost any application.

Section 2 Specifications

Input Power: 4 watts

Nominal Line Voltage: 100 - 120 / 230 VAC 50/60 Hz.

Output Voltage Range: 3.5 kv. to 8.0 kv. D.C. (Pos. & Neg.)

Output Current Range: 3.0 ua to 7.0 ua D.C.

Cycle

Pulse Rate: Sw. Pos. Freq. Time

10Hz 10Hz 100ms.

2.2Hz 2.2Hz. 450ms.

1.3Hz 1.3Hz 750ms.

1.0Hz 1.0Hz. 1000ms.

SS 0Hz Steady State (DC)

Temp. Range: +32ºF to 122ºF (0ºC to +50ºC)

Dimensions: 5.75” x 5.00” x 1.65” (14.60cm x 12.7cm x 4.19cm)

Weight: 20.5 oz (637 gr.)

Emitter Electrodes: 20 pairs (20 Pos. 20 Neg.) maximum.

Fuse: Two 80 ma. (5x20mm) slo-blow type.

Power Terminal: Meets FCC part 15J.MP-4 class B

ITE Standard (VDE 0871106.78).

EMI Radiation: Meets FCC part 15J.MP-4 @ 3 meters.

Section 3 Safety Procedures

CAUTION

The maximum current available at any emitter electrode is less than 100 microamps. A person touching

an electrode may experience a mild nuisance shock.

2

WARNING!

When working on ANY electrical equipment be sure to disconnect the unit from

its power source to prevent any kind of electrical shock.

As with any electrical appliance, do not operate any PulseBar or ionizer system

in an area where flammable vapors, chemicals, or explosives are present.

IMPORTANT

All Simco equipment and power cords MUST be properly grounded to ensure

proper operation and operator safety.

Prior to installation, insure that any outlets being used to power Simco equipment are correctly polarized

and grounded.

Section 4 Installation

The PFC can simply be placed on a benchtop or mounted vertically to a wall, workbench or machine

using the keyhole slots on the back of the case. The keyhole slots can also be used to secure the PFC to

the workbench top. The feet used on the PFC Controller are made of a durable polyurethane so that they

will not mark benchtops or shed particles in a cleanroom environment.

Figure 1. PFC mounting to wall

The PFC Controller can be attached to almost any surface using a variety of screws and wall anchors. Check your particular

installation to determine the type of fastener you should use.

3

Figure 2. A single PulseBar can be attached to a controller or in multiple hookups

using the HV-1 adapter.

PulseBar Installation

For best results, do not block or hinder the flow of ionizing air by placing large objects directly in front

of or below the PulseBar.

Mount the PulseBar at least 4” above the work surface with its adjustable mounting brackets. Refer to

your PulseBar owners manual for details.

Connecting a single PulseBar to the PFC Controller

Plug the two high-voltage cables from the PulseBar into the two connectors located on the rear panel of

the PFC.

Connecting two PulseBars to the PFC Controller

1. Insert one HV-2 (two-to-one) Adapter into the positive output connector and one into the negative

output connector located on the back panel of the PFC. There are two positive and two negative

positions now available.

2. Insert one of the plugs from a PulseBar into one of the positive outputs and the other into one of the

negative outputs. Only one positive and one negative output will now be available.

3. Insert the plugs from the second PulseBar the same as the first. All four output connectors will now

be used.

NOTE!

DO NOT use an MC-2 adapter if only one PulseBar is in use because arcing or contamination buildup

may occur. Consult your PulseBar owners manual for further information.

Ground connection

4

1. Secure the green ground wire and lug to the power supply case using the grounding post located on

the back of the power supply.

Figure 3. PulseFlow Controller Rear Panel

Section 5 Operating Instructions

CAUTION!

Do not turn on any Simco power supply until all PulseBars and other devices are connected to the

completed system assembly.

1. Make sure that all connections are made as outlined above.

2. Plug the PFC Controller power cord into a grounded AC outlet with the appropriate line voltage.

3. Turn the power to the PFC on. The lamps on the front panel will light up after a few moments and

will pulse back and forth when the PFC Controller is in the pulse mode and will light continuously

in the steady state mode.

4. Select the desired Pulse Rate by rotating the Pulse Rate switch with a flatblade screwdriver from

positions 10hz to 1.0hz. Position SS is Steady State DC.

5. Adjust the ion balance with the high voltage adjustment controls located on the front panel. Turning

the high voltage controls clockwise increases the HV output to the emitters.

6. Turn the PFC Controller power switch off when not in use.

If your unit does not operate after turning it on, refer to the section on troubleshooting on page 6.

Avoiding Nuisance Shocks

When an ionizer is disconnected from the controller, a charge may remain in the high voltage wiring.

To avoid a mild nuisance shock from the ionizer plugs, touch the contacts on the plugs together

immediately after removing them from the controller.

Setup and Adjustments

5

Although the PFC Controller is calibrated at the factory, it may require additional adjustments for your

specific work area. Use a Charge Plate Monitor, such as Simco’s EA-2, to check for decay times as well

as ion balance. Refer to the respective Owners Manual for set up and operational procedures. A

complete check of any ionization system should be made before doing any type of calibration or

adjustments. This includes inspection of the emitter assemblies for cleanliness and wear (refer to the

section on Cleaning & Maintenance). Simco recommends that ionizing equipment be tested every

month for ion balance.

Figure 4. PFC PulseFow Controller Front Panel

NOTE!

When the PFC is first turned on one of the lamps will come on and remain on for a few moments.

This is normal operation. After the PFC power supplies stabilize, both lamps will start to flash

at the selected rate.

Section 6 Cleaning & Maintenance

1. Turn the power to the PFC Controller off and unplug the unit prior to any servicing or cleaning.

2. Inspect the electrodes on the PulseBar for excessive wear or particle accumulation every month. A

hissing sound often occurs when the electrodes have become coated with dust.

3. Clean the electrodes every month using a lint-free cleaning swab and denatured alcohol.

4. Replace any worn electrodes approximately once a year, depending on frequency of usage and

environmental conditions.

5. Clean the PFC case and PulseBars using a soft, lint-free cloth and a mild, non-abrasive cleaner.

6

Line Voltage Conversion

To convert the PFC from 115 VAC to 230 VAC or from 230 VAC to 115 VAC, it is necessary to

change a selector switch inside the unit:

1. Turn power to unit off and unplug unit.

2. Turn unit upside down and remove the four screws from bottom of unit. The screws are different

sizes so it is necessary to make sure they get replaced in the same holes.

3. Turn unit right side up and remove cover.

4. The voltage selector switch is located near the power switch on the circuit board. Move selector

switch to desired line voltage (115 VAC or 230 VAC). The voltage is printed on the circuit board.

5. Replace cover and turn unit upside down.

6. Replace the four screws, being careful to get each screw in the proper hole.

7. Use a small label to cover the line voltage on the serial label on bottom of unit and note new line

voltage.

Troubleshooting

Sympton Probable Solution

ÍPFC lamps do not flash or turn on at all ÍCheck that the unit is plugged in.

ÍCheck the fuses and replace if required.

ÍThe PFC lamps do not flash after a reasonable ÍThe Pulse Rate switch is set to position SS,

period (less than a few seconds). Both Stead State DC. Turn the switch to the 10hz to

lamps are turned on. 1.0hz positions.

ÍOne lamp flashes, the other lamp remains ÍReturn the unit to Simco for repair.

turned on after a few seconds operation

ÍOnly one lamp flashes ÍReturn the unit to Simco for repair.

SECTION 7 Customer Service

Should any Simco product require service or if you have any questions regarding its usage, contact our

Customer Service department between the hours of 8:00 a.m. and 6:00 p.m. EST Monday through

Friday at (215) 822-2171.

A Return Authorization (RA) number is required before returning any Simco product for repair, credit

or exchange. Please consult the warranty page of your manual for our shipping address and other

pertinent information regarding specific Simco units or systems.

SECTION 8 Replacement Parts

7

Description Part Number

PFC-2 115 V, 50/60 Hz 4005184

PFC-2 230 V, 50/60 Hz 4005185

PFC, UK, 23OV, 50/60Hz 4009734

Circuit Board w/Connectors 4105828

Wall Bracket 5050718

HV-2 Connector Kit 5050538

HV-4 Connector Kit 5050539

SECTION 9 Warranty Information

Simco warrants the PulseFlow Controller to be free of defects in components, workmanship, or materials for a

period of one year from date of purchase. This warranty does not apply to any physical or electrical damage done

to the product through misuse or abuse or negligence (such as any modifications made to the unit or service work

done by any other than our own technicians). Any unit which has had its serial number altered or removed will be

ineligible for warranty.

Simco will not be liable for loss or damage due directly or indirectly to an occurrence or use for which the product

is not designed or intended. In no event shall Simco be liable for incidental or consequential damages except

where state laws override.

This warranty extends to the original purchaser and is not transferable. No person, agent, distributor, dealer, or

company is authorized to change, modify, or amend the terms of this warranty in any manner whatsoever.

ALL PRODUCTS RETURNED MUST HAVE AN “RA” (RETURN AUTHORIZATION) NUMBER REGARDLESS OF

ITS WARRANTY STATUS. REFER TO THE CUSTOMER SERVICE INFORMATION IN THIS MANUAL.

WARNING!

The following servicing instructions are for use by QUALIFIED PERSONNEL ONLY. To avoid personal injury

or damage to the equipment, do not perform any servicing other than that contained in this manual.

Information in this document is subject to change without notice and does not represent a commitment on the part

of Simco. No part of this manual may be reproduced or transmitted in any form or by any means, electronic or

mechanical, including photocopying and recording, for any purpose other than the purchaser’s personal use

without written permission of Simco.

2257 North Penn Road

Hatfield, PA 19440

Telephone: (215) 822-2171 (800) 538-0750 Fax: (215) 997-3450

http://www.simcoION.biz

8

9

Table of contents

Other Illinois Tool Works Controllers manuals

Popular Controllers manuals by other brands

nVent RAYCHEM

nVent RAYCHEM Elexant 450c Installation and operation manual

RadioMaster

RadioMaster POCKET quick start guide

micro-trak

micro-trak MT-2405FTW II Reference manual

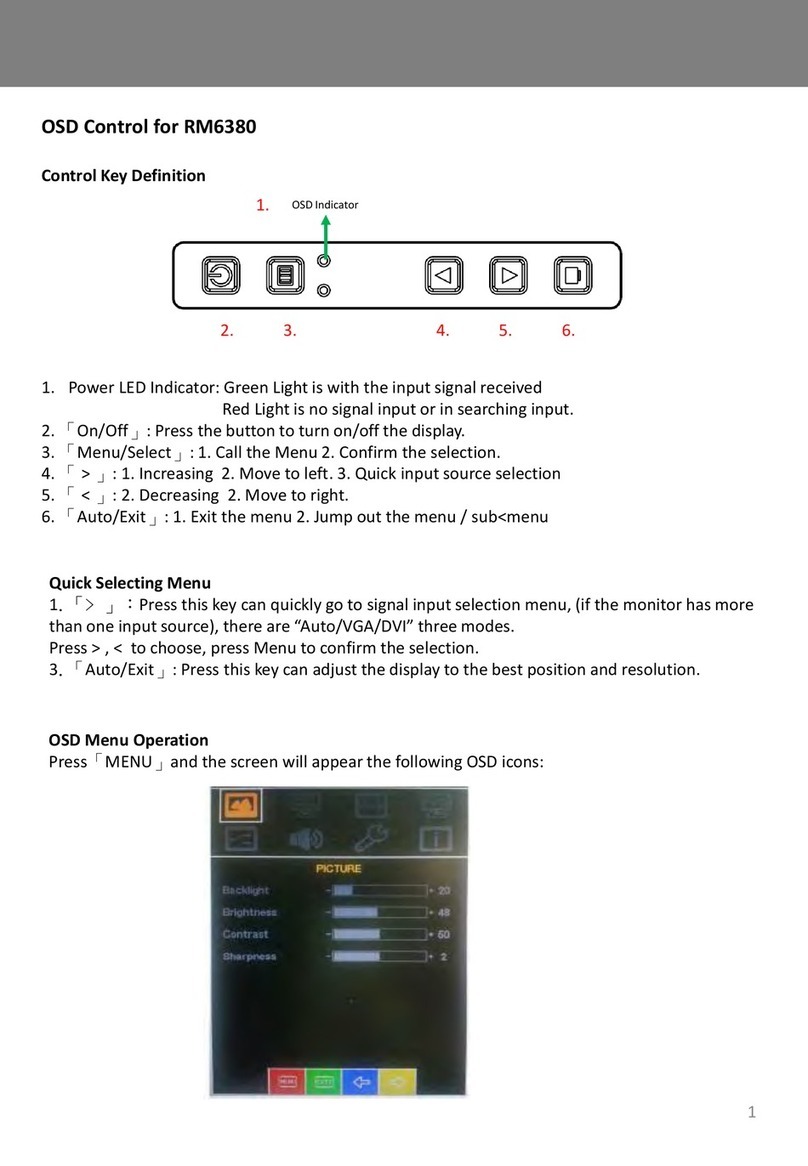

Acnodes

Acnodes RM6380 quick start guide

Digital Equipment

Digital Equipment DEC CT1controller 100 Hardware Use

Vera Controls

Vera Controls VeraEdge manual

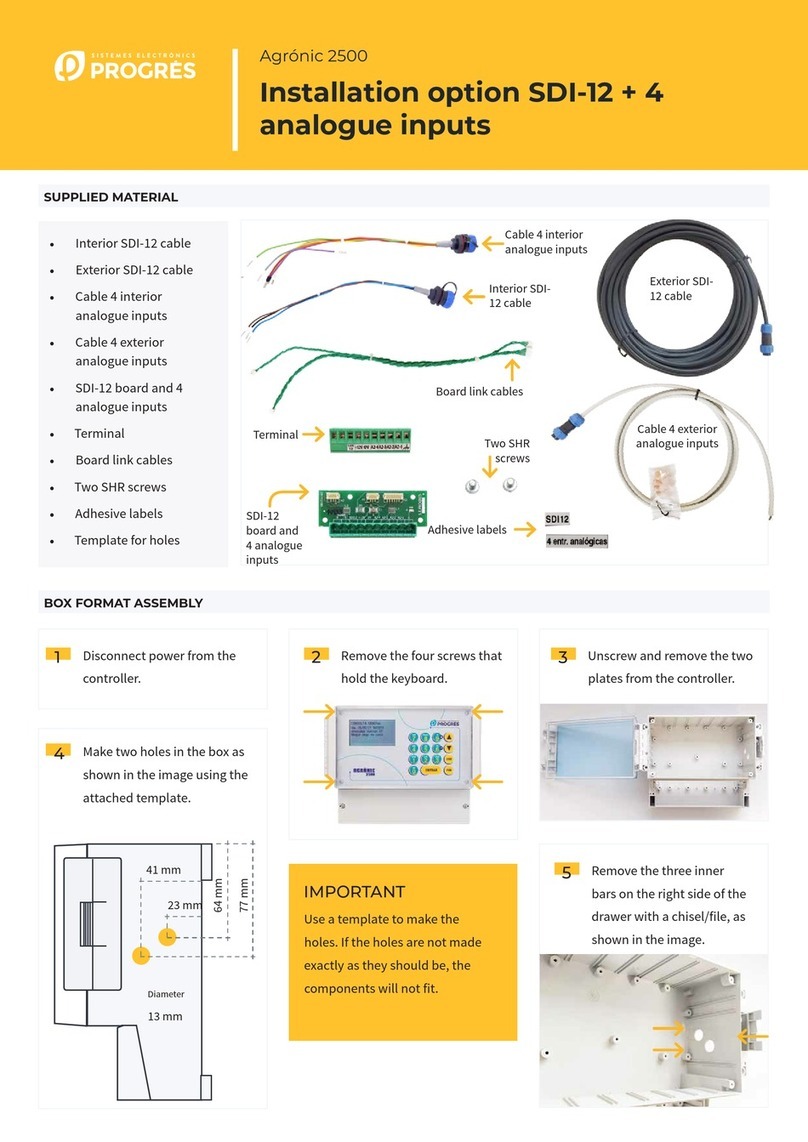

Sistemes Electronics Progres

Sistemes Electronics Progres Agronic 2500 Installation

Siemens

Siemens SICAM TM installation manual

Master

Master CLOUD SYNCRO 230V instruction manual

Smokin-It

Smokin-It #2D User's guide & instructions

IEI Technology

IEI Technology VWBOX-E133 user manual

SmartDHOME

SmartDHOME MyMB user manual