4

Table of Contents

Micro-Trak Warranty.............................................................................................................................................................................3

Table of Contents ..................................................................................................................................................................................4

Component Parts and Assembly.................................................................................................................................................... 5-6

Basic Overview of Installation ............................................................................................................................................................7

MT-2405FTW II System Layout ...........................................................................................................................................................8

MT-2405FTW II Wiring Diagram .........................................................................................................................................................9

Installation......................................................................................................................................................................................10-17

Required Tools.......................................................................................................................................................................................................10

Mounting the Display Console........................................................................................................................................................................10

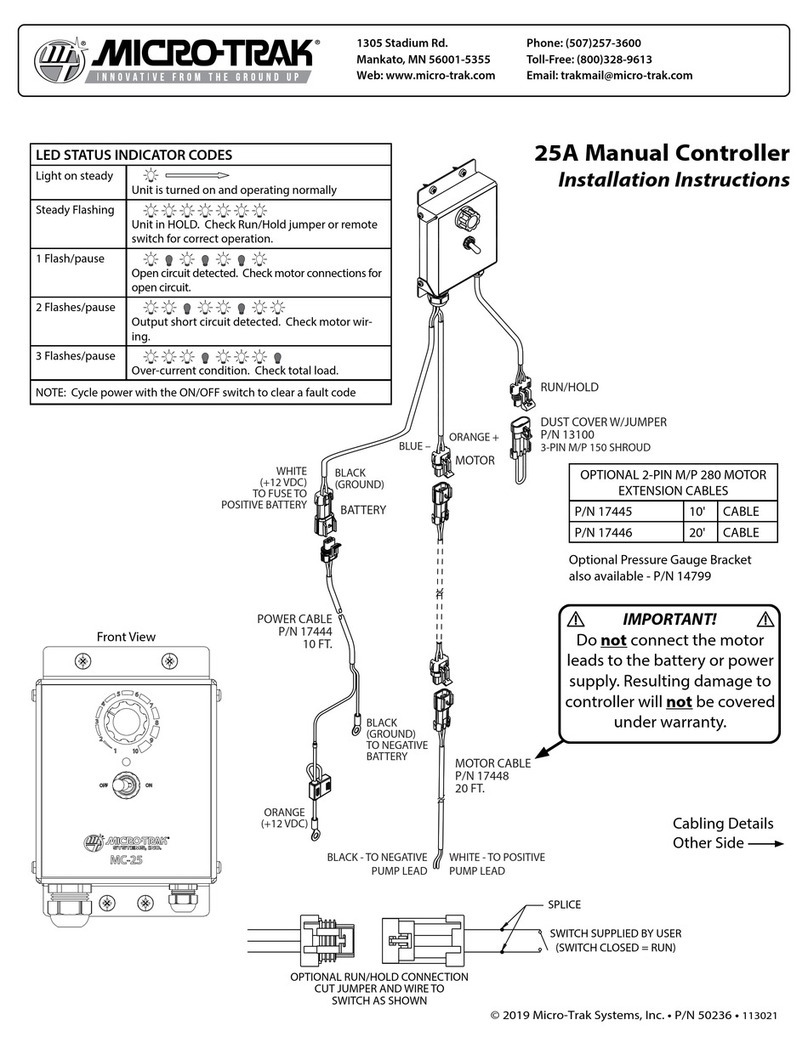

Electrical Installation .....................................................................................................................................................................................11-12

Universal Switch Harness....................................................................................................................................................................11-12

Speed Sensor Installation.................................................................................................................................................................................. 13

Magnets ...................................................................................................................................................................................................................13

Attaching the Speed Sensor............................................................................................................................................................................. 14

Connecting the Speed Sensor Cable ............................................................................................................................................................ 14

Speed Sensor Options ........................................................................................................................................................................................ 14

Mounting and Plumbing Flowmeter ............................................................................................................................................................ 15

Installing Flow Sensor Cable ............................................................................................................................................................................ 15

Manual Pressure Relief Valve ........................................................................................................................................................................... 16

Servo, Throttling Valves ..................................................................................................................................................................................... 16

Remote Run/Hold.................................................................................................................................................................................................17

Care and Maintenance .......................................................................................................................................................................18

Console Functions...............................................................................................................................................................................18

Calibration ......................................................................................................................................................................................19-22

English/Metric Selection.................................................................................................................................................................................... 19

Entering Calibration Values ........................................................................................................................................................................19-22

Radar/GPS Speed Sensor Calibration............................................................................................................................................................21

Determining Speed Calibration ......................................................................................................................................................................21

Drive Shaft Speed Sensor Calibration...........................................................................................................................................................21

Exiting Calibration................................................................................................................................................................................................22

Factory Loaded Calibration Values................................................................................................................................................................22

Special Calibration ........................................................................................................................................................................23-24

Pre-field System Checkout ..........................................................................................................................................................25-26

Bypass....................................................................................................................................................................................................................... 25

In-line ........................................................................................................................................................................................................................26

Operation........................................................................................................................................................................................27-30

Functions...........................................................................................................................................................................................................27-28

Resetting System Counters............................................................................................................................................................................... 29

Clearing System Counters................................................................................................................................................................................. 30

Troubleshooting............................................................................................................................................................................31-35

Messages/Warnings............................................................................................................................................................................................. 31

General .....................................................................................................................................................................................................................32

Checking Individual Components..................................................................................................................................................................33

Console Inputs.......................................................................................................................................................................................................34

Plumbing Troubleshooting Chart ..................................................................................................................................................................35

Plumbing Guidelines ....................................................................................................................................................................36-37

Flowmeter Assemblies .......................................................................................................................................................................38

Appendices.....................................................................................................................................................................................39-50

Appendix A: Boom Shut-off Relay Kit ..........................................................................................................................................................40

Appendix B: Optional Speed Sensor Mounting Installation .........................................................................................................41-42

Appendix c: Fine Tuning Speed/Distance Calibration Value without Run/Hold Switch ..........................................................43

Appendix D: Fine Tuning Speed/Distance Calibration Value with Run/Hold Switch................................................................ 44

Appendix E: Fine Tuning Flowmeter Calibration Value........................................................................................................................ 45

Appendix F: Various Ball Valve Configurations ........................................................................................................................................46

Appendix G: Adjusting By-Pass Valves........................................................................................................................................................ 47

Appendix H: Radar Adapter Cables .............................................................................................................................................................. 48

Appendix I: Conversion Chart......................................................................................................................................................................... 49

Appendix J: Replacement Parts ...................................................................................................................................................................... 50