SECOP 101N07 Series User manual

CONTROLLER FOR

BD COMPRESSORS

Flexible control settings

TOOL COOL

4

OPERATING INSTRUCTIONS

101N07xx Series, 48 V DC

WE HAVE MORE THAN 30

YEARS OF EXPERIENCE,

DEVELOPING DIRECT

CURRENT COMPRESSORS

AND HELPING CUSTOMERS

BENEFIT FROM THE

OPPORTUNITIES OF

MOBILE REFRIGERATION

TECHNOLOGY.

WITH A DEEP INSIGHT OF

THE USAGE ACROSS VARIOUS

APPLICATIONS WE HAVE

EARNED A POSITION AS

MARKET LEADER, WORKING

WITH OEM-CUSTOMERS .

www.secop.com SETTING THE STANDARD

2

Operating

Instructions

Operating

Instructions

3

Operating

Instructions

3

1. Introduction ..............................................................................................5

1.1 Applications............................................................................................5

1.2 Capability................................................................................................5

1.3 Functions................................................................................................5

1.4 Programming Interface .........................................................................5

2. Installation ..............................................................................................6

2.1 Checklist ................................................................................................6

2.2 Connect Cables ......................................................................................7

2.3 Install and Configure Software ..............................................................9

3. TOOL4COOL

®

Software Interface ............................................................. 15

3.1 User Interface ......................................................................................15

3.2 Operation ..............................................................................................15

4. Parameters ............................................................................................ 16

4.1 Parameter Overview ............................................................................16

4.2 Description of Parameters ..................................................................18

5. Ordering ............................................................................................ 26

TABLE OF CONTENTS

4

Operating

Instructions

Operating

Instructions

5

1.

INTRODUCTION

The cooling capacities of the compressors are approx. 480 Watt (BD250GH.2) and 900 Watt

(BD350GH) @ Pe/Pc ~+15/+55°C

The system is able to operate in ambient temperatures up to +55 ºC (131 F).

The operating conditions are High Back Pressure (HBP).

The main functions of the controllers are:

• Motor / Compressor speed control

• Thermostat control (ON / OFF or electronic via NTC temperature sensor)

• ECO function to optimize compressor speed for minimum power consumption

• Condenser fan control

• Evaporator fan control

• Communication interface

• Monitoring function

• Error & event log

• Battery protection functions

• Main Switch

• Log of specific parameters

• Optimization of specific parameters via PC software before commencing mass production

The controller can be accessed using either

• The Secop software tool, Tool4Cool

®

LabEdition, or

• A custom interface. Please contact Secop for further information regarding custom interfaces.

The BD 48 V DC compressor systems are intended mainly for shelter cooling and cooling of bat-

teries in radio stations for cellular phones.

Secondary applications could be

• Spot cooling in golf carts, forklifts, etc

• Air cargo cooling

1.1

Applications

1.2

Capability

1.3

Functions

1.4

Programming

Interface

6

Operating

Instructions

BD electronic controller

101N07xx Series 48V DC

• 101N0720 or

• 101N0732

Tool4Cool

®

LabEdition software download:

www.secop.com/tool4cool.html

NTC temperature sensor

(alternative: mechanical thermostat)

Product key for BD compressor controller - on request -

Secop One Wire/LIN gateway with

connection cables

• Gateway

• One Wire/LIN gateway

communication cable

• USB 2.0 A/B cable

2.

INSTALLATION

Installation involves the following steps:

• Checklist

• Cable connection

• Software installation and configuration

2.1

Checklist

Ordering: See section 5

Check that you have the following:

Operating

Instructions

7

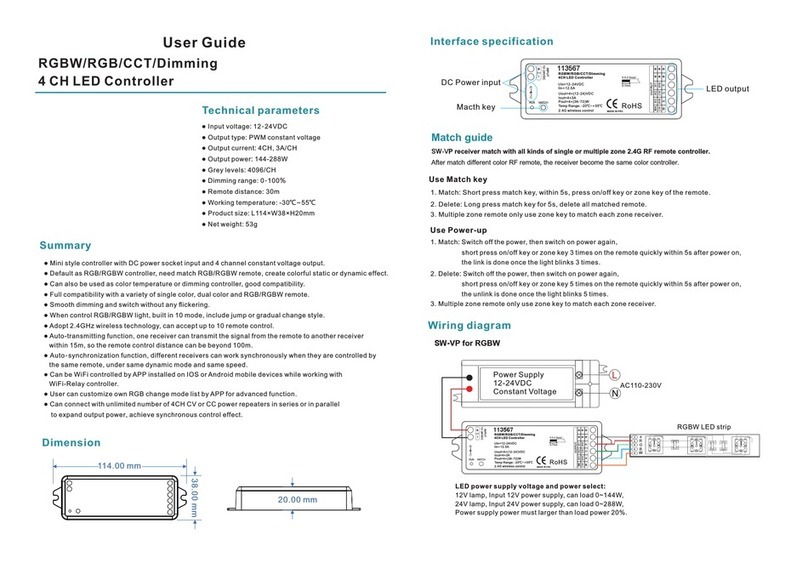

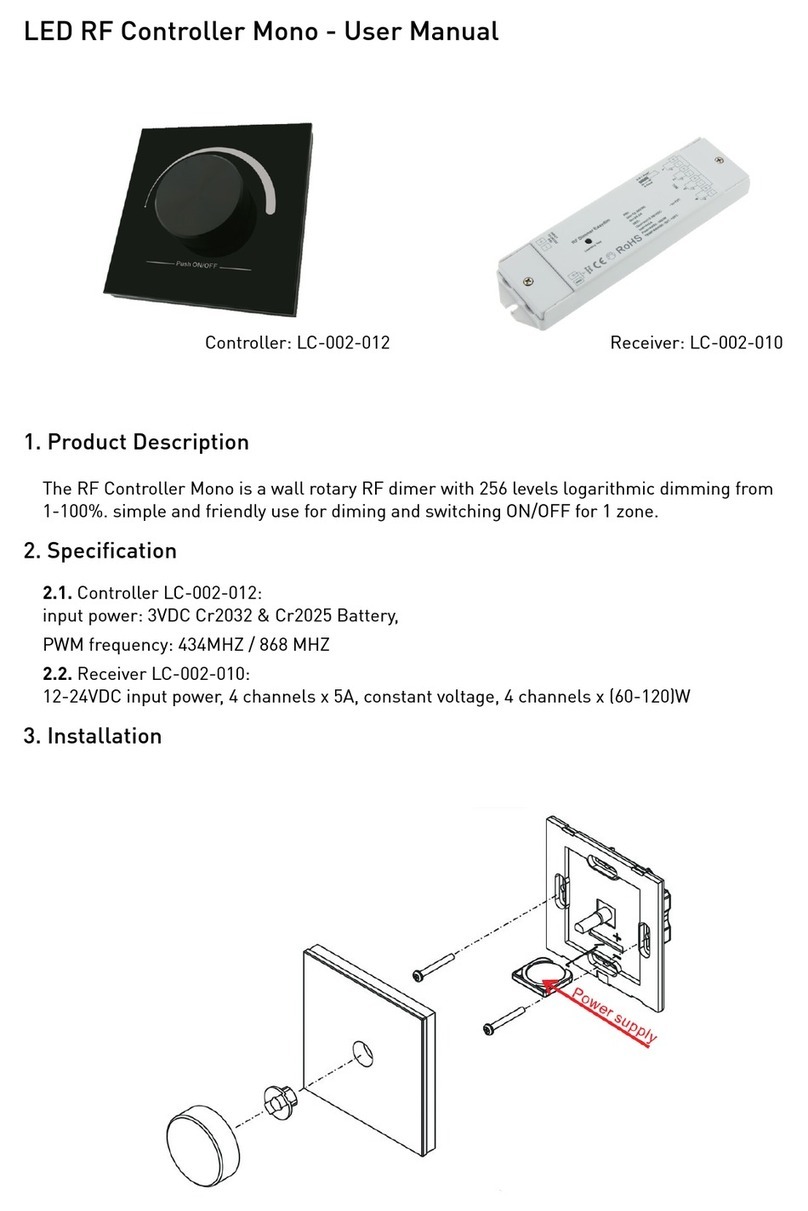

Wiring diagram 101N0732 and 101N0720 (below)

2.2

Connect Cables

8

Operating

Instructions

Wire dimensions

The compressor control unit has the following connections:

I, C, + Modbus data communication. I = communication C & + power supply.

C, T Thermostat connection. A Secop NTC temperature sensor (option 2) can be connected

or a mechanical ON/OFF thermostat (option 1)

Fe, + Evaporator fan (Optional) 48 V DC, 32-60 V, max 60 Watt power output, pulse width

modulated.

Fc, + Condenser fan (optional) 48 V DC, 32-60 V max, 60 Watt power output, pulse width

modulated.

-, + Main supply voltage. Nominal voltage 48 V DC, range: 32 to 60 V DC

* Length between battery and electronic unit

Size Max. length*

48 V DC operation

Cross

section

AWG

[mm2]

[Gauge]

[m] [ft.]

2 x 4 11 1.5 4.92

2 x 6 9 2 6.60

2 x 10 7 4 13.12

Operating

Instructions

9

2.3.1 Install Software

1. Check that you have the latest update of .NET Framework from www.windowsupdate.com.

2. Insert the Tool4Cool

®

installation CD.

This view will appear:

2.3

Install and Configure

Software

10

Operating

Instructions

3. Double-click Tool4Cool

®

Software Installation. Run the file setup.exe. Then follow the

instructions in the Setup Wizard.

For detailed instructions please refer to Tool4Cool

®

LabEdition Operating Instructions.

This manual is supplied with the Tool4Cool

®

software.

12

34

5

Operating

Instructions

11

2.3.2 Install Product Key

1. Start Tool4Cool

®

LabEditon by double clicking on the icon on the desktop:

2. Select Help in the menu bar.

3. Select Product Keys from the drop-down menu:

4. This dialog box will open:

In the Add Product Key field, type the Product Key shown in Section 2.1: Checklist.

Click the Add Key button. The Product Key is now active.

12

Operating

Instructions

2.3.3 Connect Network

1. Select File in the menu bar.

2. Select Connect Network in the drop-down menu:

3. This dialog box will open:

Operating

Instructions

13

In the Connect using field, select the COM port to which the gateway is connected.

Fill in Description (optional).

Press OK.

Wait a short time. The LEDs on the gateway will flash, then a red arrow will appear in front of the

description (COM1).

The controller is now accessible via Tool4Cool

®

.

14

Operating

Instructions

2.3.4 Ready to Operate

Click the red arrows to view the controller and its parameter groups:

Click a parameter group name to view details to the right of the screen:

Operating

Instructions

15

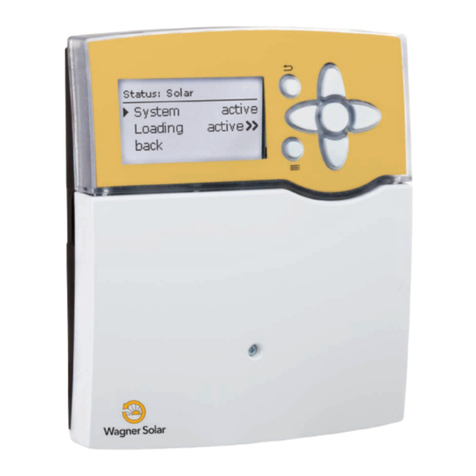

The controller can be programmed and optimized from a PC using the Tool4Cool

®

software

An example of the Tool4Cool

®

user interface showing the main parameter groups of the BD Con-

troller 101N07xx Series 48V DC is shown below.

Example:

The Tool4Cool

®

software enables the user to observe and document certain aspects of the com-

pressor operation via the controller. The output of the software is in the form of data logs and

plots.

Using Tool4Cool

®

the user can also change the settings of the controller parameters, and copy

settings from one controller to another.

Please refer to the Tool4Cool

®

LabEdition Operating Instructions for operation instructions.

3.1

User Interface

3.2

Operation

3.

TOOL4COOL

®

SOFTWARE INTERFACE

16

Operating

Instructions

4.

PARAMETERS

The user can change settings and observe real-time measurements (read-only)

in the following parameters.

The table in 4.1 Parameter Overview is intended for easy reference.

For more detail, please refer to 4.2 Description of Parameter Groups.

Parameter

Group

Parameter Description Default Max va-

lue

Min value Step Unit Type

Main functions Main switch On/Off regulation of power supply to

controller ON ON OFF 1

Battery

protection Battery cutout level Battery protection cut-out voltage

level 36 60 32 0.1 Volt Setting

Battery cutin diff. Voltage difference between battery

cut-in and cut-out 4 10 0.5 0.1 Volt Setting

Cutout delay Time to cut-out when non-critical

battery protection implemented 3 60 0 1 Seconds Setting

Cut-in level Calculated value.

Cutin = Cutout + Diff. 0.1 Volt Measurement

Supply voltage Real-time voltage measured

on + & - terminals 0.1 Volt Measurement

Compressor

BD250GH.2 Requested speed Compressor speed and therefore

capacity definition 4400 4400 2500 100 rpm Setting

Compressor

BD350GH Requested speed Compressor speed and therefore

capacity definition 4000 4000 2500 100 rpm Setting

Start delay Time to start after

compressor is switched ON 4 240 2 1 Seconds Setting

Start time

Period of time elapsing after startup

of compressor until Requested speed

is reached

30 600 30 1 Seconds Setting

Compressor speed Real-time speed (+/- 10%) 1 rpm Measurement

Condenser fan Cond. Fan voltage Supply voltage to the

condenser fan. 48 60 32 1 Volt Setting

Fan speed Condenser fan speed synchronized

with compressor operation 100 100 40 10 % Setting

Fan start delay Time to start as a function of

Thermostat 0 240 0 1 Seconds Setting

Fan stop delay Time to stop as a function of

Thermostat 0 240 0 1 Seconds Setting

Fan forced ON Force condenser fan continuously

ON or OFF OFF ON OFF 1 Setting

Detect missing fan Detect whether condenser fan is

connected OFF ON OFF 1 Setting

Fan speed Real-time condenser fan speed 1 % Measurement

Evaporator fan Evap. Fan voltage Supply voltage to the evaporator fan. 48 60 32 1 Volt Setting

Fan speed

Evaporator fan speed

synchronized with

compressor operation.

100 100 40 10 % Setting

Fan start delay Time to fan start as a

function of Thermostat 6 240 0 1 Seconds Setting

Fan stop delay Time to fan stop as a

function of Thermostat 0 240 0 1 Seconds Setting

Fan forced ON Force evaporator fan

continuously ON or OFF OFF ON OFF 1 Setting

Detect missing fan Detect whether evaporator fan is

connected OFF ON OFF 1 Setting

Fan speed Real-time evaporator fan speed 1 % Measurement

4.1

Parameter Overview

Operating

Instructions

17

Customer

register Register 1 Custom-designed interface parameter 65535 65535 0 1 Setting

Register 2 Custom-designed interface parameter 65535 65535 0 1 Setting

Register 3 Custom-designed interface parameter 65535 65535 0 1 Setting

Register 4 Custom-designed interface parameter 65535 65535 0 1 Setting

Register 5 Custom-designed interface parameter 65535 65535 0 1 Setting

Register 6 Custom-designed interface parameter 65535 65535 0 1 Setting

Register 7 Custom-designed interface parameter 65535 65535 0 1 Setting

Register 8 Custom-designed interface parameter 65535 65535 0 1 Setting

Register 9 Custom-designed interface parameter 65535 65535 0 1 Setting

Register 10 Custom-designed interface parameter 65535 65535 0 1 Setting

Actual error Actual error

0 = No error

1 = Voltage failure

2 = Fan failure

3 = Motor failure

4 = Min. speed failure

5 = Max. speed failure

6 = Thermal failure

7 = NTC Sensor Failure

Measurement

Inverter

temperature

(PCB)

Inverter temperature

(PCB) Controller overheating protection ºC Measurement

Compressor restart

delay Delay before restart after failure 60 120 60 1 Seconds Setting

Parameter

Group

Parameter Description Default Max va-

lue

Min value Step Unit Type

Thermostat Thermostat type Detect mechanical or NTC sensor

thermostat Auto Electronic Setting

Cutout temperature Compressor cuts out below cutout

temperature +25 +40 -40 1 Celsius

(ºC) Setting

Difference 3 15 1 1 Kelvin (K) Setting

Forced ON Force thermostat operation to conti-

nuously ON or OFF OFF ON OFF 1 Setting

Runtime

During cooling OFF (Thermostat cut-

out), the Runtime will show the time

for the last cooling period. Runtime is

reset at cooling ON period. At power-up

the reading is reset.

1 Minutes Measurement

Actual temperature

Real-time air temperature when an

NTC sensor is used. When a mechani-

cal thermostat is used, only thermostat

status ON or OFF is displayed.

ºC Measurement

ECO mode Turns the ECO mode on and off 0 0 1 1 Setting

ECO speed BD250GH.2 Speed applied when temperature falls

below ECO temperature 2500 4400 2500 1 rpm Setting

ECO speed BD350GH Speed applied when temperature falls

below ECO temperature 2500 4000 2500 1 rpm Setting

ECO temperature Temperature where ECO speed

is applied 26.5 -40 40 40 ˚C Setting

Automatic

ECO temperature cut-out + cut-in / 2 1 0 1 1 0 = OFF

1 = ON Setting

Compressor

safety

Compressor restart

time Delay before restart after short cycling 60 120 60 1 Seconds Setting

Communication Node Number Modbus address 1 247 1 1 Setting

Bits per seconds Communication speed 19200 9600 19200 9600 bps Setting

Communication options 0 = Disabled

1 = Enabled 0 1 0 1 Setting

Communication ti-

meout

Maximum duration of each communi-

cation attempt 900 15 7200 1 seconds Setting

Setting protection code

& status

Privacy function code must be entered

twice 0 9999 0 1 Setting

Product

information Unit name The user’s own identification name for

the unit can be entered here (optional) Setting

Vendor name Vendor name Measurement

Product code no Secop product code number Measurement

Software version Controller software version Measurement

Unit ID Secop unit ID Measurement

Production date Secop production date Measurement

Lot no Secop lot no. Measurement

Serial no Secop serial no. Measurement

18

Operating

Instructions

4.2.1 Main Functions

In order to start and stop the compressor the Main Switch can be set to ON or OFF .

OEMs making an interface with custom design electronics via Modbus must be able to control

the CCU ON / OFF via the Main Switch (CCU = Compressor Control Unit)

ON: All functions are active.

OFF: All main functions are inactive, however

• Battery monitoring active

• NTC temperature sensor monitoring active

• PCB inverter temperature monitoring active

Settings:

4.2.2 Battery Protection

The battery protection serves to avoid permanent damage to the battery by discharge.

The setting range is from 32 to 60 V DC.

Critical stop without delay if voltage drops below 28 V DC

Tolerances are ± 0.30 V DC

ON

OFF

OFF

ON

Alarm state

Comp. state

Cut-out level

Cut-in level

Max limit 60 V DC

0-60 sec

60-120 sec

Battery Protection

Critical stop

(Restart delay)(Cut-outdelay)

(Voltage failure)

Name Default Max value Min value Step Unit

Main switch ON ON OFF 1 -

Settings

Name Default Max value Min value Step Unit

Battery cutout level 36 60 32 0.1 Volt

Battery cutin diff. 4.0 10 0.5 0.1 Volt

Cutout delay 3 60 0 1 Seconds

4.2

Description of

Parameters

Operating

Instructions

19

4.2.3 Compressor

The speed and thereby the capacity of the compressor is set using the Requested speed

parameter. During start up, the compressor can be run at a lower speed, Start speed, than

Requested speed. The duration of the period running at Start speed is set using the Start time

parameter.

The compressor is protected against operation below minimum speed. Lubrication of the com-

pressor will be very poor at excessively low speed and therefore low speed operation can lead to

destruction of the compressor.

Speed limits are: min 1850 rpm; max speed 4700 rpm (BD250GH.2) & 4300 rpm (BD350GH).

If the compressor speed falls below the minimum or exceeds the maximum speed, the compres-

sor will stop and an alarm Min speed failure or Max. speed failure will be sent. The compressor

will try to restart after the set Restart time. The Restart time default is 60 sec.

The fans will continue to run.

Min & Max. Compressor Speed Protection

Max. speed 4300 rpm (BD350GH)

Max. speed 4700 rpm (BD250GH)

Min. speed 1850 rpm

Comp. state

Alarm state

ON

OFF

OFF OFF

ON

(Min speed failure)

ON

(Max speed failure)

60-120 sec

(Restart delay)

60-120 sec

(Restart delay)

Name Default Max value Min value Step Unit

Requested speed (BD250GH.2) 4400 4400 2500 100 rpm

Requested speed (BD350GH) 4000 4000 2500 100 rpm

Start delay 4 240 2 1 Seconds

Start time 30 600 0 1 Seconds

Settings

Measurements

Name Description Step Unit

Compressor speed Real-time compressor speed(+/-10%) 1 rpm

Measurements

Name Description Step Unit

Cut-in level Calculated value. Cutin = Cutout + Diff. 0.1 Volt

Supply voltage Real-time - voltage measured on + & - terminals 0.1 Volt

20

Operating

Instructions

4.2.4 Condenser Fan

The speed of the condenser fan can be controlled in order to save energy, reduce noise and

optimize the fan operation.

The fan is synchronized with the compressor operation.

Start and stop delays can be set up as a function of the state of the parameter Thermostat.

Furthermore, the fan can be set to run continuously (forced ON operation).

Some fan defects are detectable, and are displayed in the parameter Error.

The speed of the fan can be controlled in the range from 40% to 100%.

Settings

Measurements

Name Default Max value Min value Step Unit

Cond. Fan voltage 48 60 32 1 Volt

Fan speed 100 100 40 10 %

Fan start delay 0 240 0 1 Seconds

Fan stop delay 0 240 0 1 Seconds

Fan forced ON OFF ON OFF 1 -

Detect missing fan OFF ON OFF 1 -

Name Description Step Unit

Fan speed Actual fan speed 1 %

4.2.5 Evaporator Fan

The speed of the evaporator fan can be controlled in order to save energy, reduce noise and opti-

mize the fan operation.

The fan is synchronized with the compressor operation.

Start and stop delays can be set up as a function of the state of the parameter Thermostat.

Furthermore, the fan can be set to run continuously (forced ON operation).

Some fan defects are detectable, and are displayed in the parameter Error.

The speed of the fan can be controlled in the range from 40% to 100%.

Settings

Measurements

Name Default Max value Min value Step Unit

Evap. Fan voltage 48 60 32 1 Volt

Fan speed 100 100 40 10 %

Fan start delay 0 240 0 1 Seconds

Fan stop delay 0 240 0 1 Seconds

Fan forced ON OFF ON OFF 1 -

Detect missing fan OFF ON OFF 1 -

Name Description Step Unit

Fan speed Real-time fan speed 1 %

Table of contents

Other SECOP Controllers manuals