Page 2

MASTER products are specially manufactured in safe materials in

compliance with the requirements of legislation in force. When

correctly mounted, installed and used in accordance with the

present instructions, our products constitute no danger to people,

animals or property.

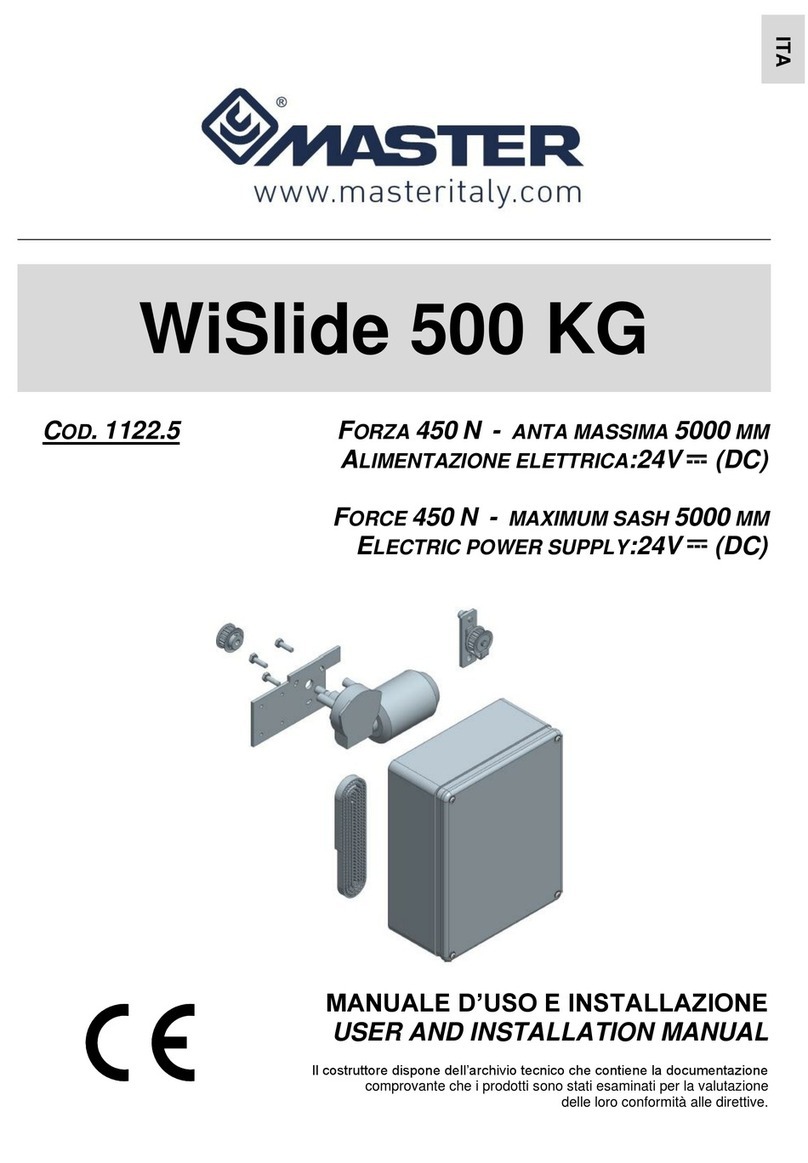

Products subject to EU directives comply with the essential

requirements stipulated by the latter. markings mean that our

products can be sold and installed throughout the European

Union without any further formality.

The mark on our products, packaging and user manuals provided

with the product, indicate “presumed in conformity with directives” issued

by the EU. MASTER holds the technical file with all the documentation to

show that our products have all been inspected to ensure compliance

with directives conformity.

Contents

1. Safety indications .............................................................................................................3

1.1. Formulas and recommendations for installation ....................................................4

1.2. Calculation of opening / closure force ....................................................................4

2. Maximum opening according to height of sash................................................................4

3. Use of Cloud Syncro.........................................................................................................5

3.1. How to recognise it.................................................................................................5

3.2. When it has to be mounted.....................................................................................5

4. Accessories ......................................................................................................................5

5. Technical data..................................................................................................................6

6. Label data and markings..................................................................................................6

7. Electricity supply...............................................................................................................6

7.1. Section choice of supply cables .............................................................................7

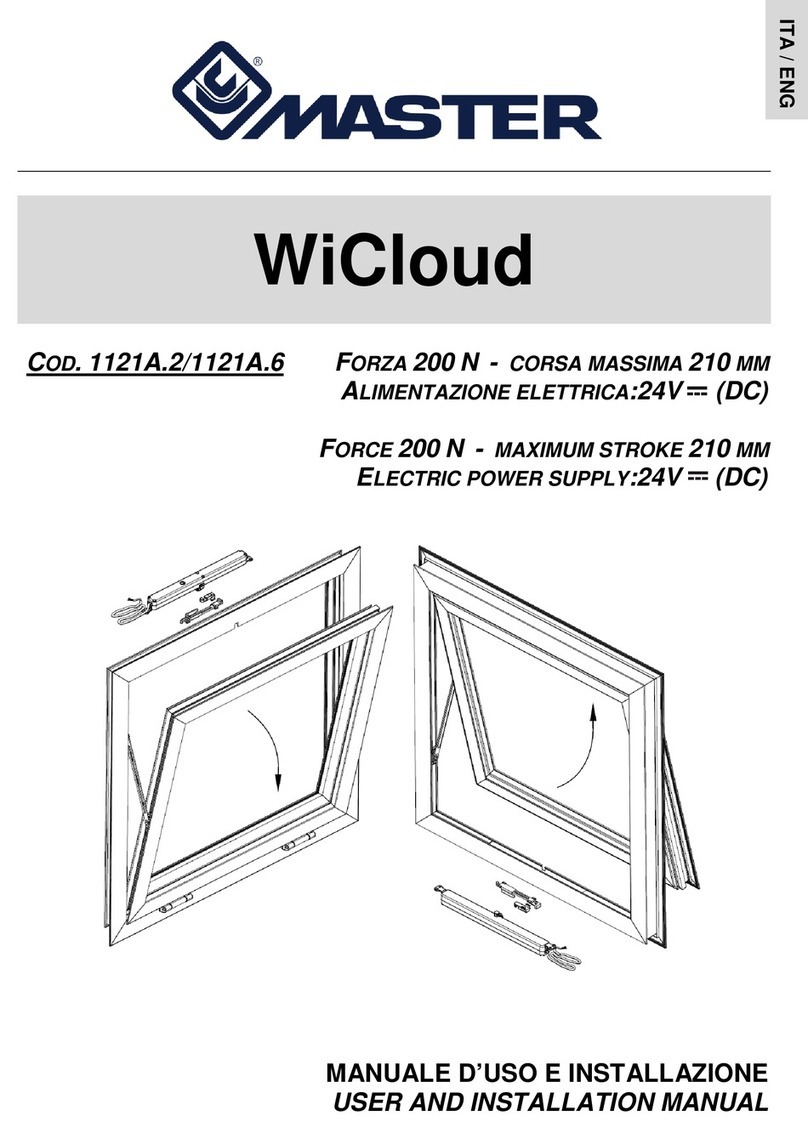

8. Assembly..........................................................................................................................7

8.1. Assembly with outward opening window...............................................................8

8.2. Assembly on transom window................................................................................9

9. Electrical connections.....................................................................................................10

10. Programming the actuator.............................................................................................11

10.1. Limit switches at opening .....................................................................................11

10.2. Limit switches at closure.......................................................................................11

10.3. Setting for SOLO operation of a Syncro...............................................................11

10.4. Setting for synchronized operation (chain alignment and address acquisition)...12

10.5. Light signals of the LED (for Cloud Syncro).........................................................13

11. Checking for correct assembly......................................................................................13

12. Emergency manoeuvres, maintenance and cleaning ...................................................13

13. Troubleshooting ............................................................................................................14

14. Environmental protection...............................................................................................14

15. Warranty........................................................................................................................14

16. Certificate of conformity.................................................................................................15