ILX Lightwave TSC-599 User manual

User’s Guide

Temperature Sensor Converter

TSC-599

ILX Lightwave Corporation P. O. Box 6310 Bozeman, MT, U.S.A.59771 :· · · 1-800-459-9459 · ·

www.ilxlightwave.com

U.S.& Canada International Inquiries: 406-586-1244 Fax 406-586-9405

E-mail: support@ilxlightwave.com

70009602_R00_06/03

TABLE OF CONTENTS

4_03 TSC-599 i

TABLE OF CONTENTS

Safety Information and the Manual . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

General Safety Considerations . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iii

Safety Marking Symbols . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . iv

Comments, Suggestions, and Problems . . . . . . . . . . . . . . . . . . . . . . . . . . . .vii

Chapter 1 Introduction and Specifications

Product Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Specifications . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Chapter 2 Operation

Installation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Possible Sources of Error . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

RTD Non-Linearity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

RTD Self-Heating . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Ambient Temperature Change . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Wire Resistance . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Thermocouple Effects . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Setting the Calibration Constants . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

TABLE OF CONTENTS

ii TSC-599

TSC-599 iii

SAFETY AND WARRANTY INFORMATION

The Safety and Warranty Information section provides details about cautionary

symbols used in the manual, safety markings used on the instrument, and

information about the Warranty including Customer Service contact information.

Safety Information and the Manual

Throughout this manual, you will see the words

Caution

and

Warning

indicating

potentially dangerous or hazardous situations which, if not avoided, could result in

death, serious or minor injury, or damage to the product. Specifically:

Caution indicates a potentially hazardous situation which can result in minor or

moderate injury or damage to the product or equipment.

Warning indicates a potentially dangerous situation which can result in serious injury or

death.

WARNING

Visible and/or invisible laser radiation. Avoid direct exposure to the beam.

General Safety Considerations

If any of the following conditions exist, or are even suspected, do not use the

instrument until safe operation can be verified by trained service personnel:

•Visible damage

•Severe transport stress

•Prolonged storage under adverse conditions

•Failure to perform intended measurements or functions

If necessary, return the instrument to ILX Lightwave, or authorized local ILX

Lightwave distributor, for service or repair to ensure that safety features are

maintained (see the contact information on page vii).

All instruments returned to ILX Lightwave are required to have a Return

Authorization Number assigned by an official representative of ILX Lightwave

Corporation. See Returning an Instrument on page v for more information.

SAFETY SYMBOLS

iv TSC-599

SAFETY SYMBOLS

This section describes the safety symbols and classifications.

Technical specifications including electrical ratings and weight are included within

the manual. See the Table of Contents to locate the specifications and other

product information. The following classifications are standard across all ILX

Lightwave products:

•Indoor use only

•Ordinary Protection: This product is NOT protected against the harmful ingress of moisture.

•Class I Equipment (grounded type)

•Mains supply voltage fluctuations are not to exceed ±10% of the nominal supply voltage.

•Pollution Degree II

•Installation (overvoltage) Category II for transient overvoltages

•Maximum Relative Humidity: <80% RH, non-condensing

•Operating temperature range of 0 °C to 40 °C

•Storage and transportation temperature of –40 °C to 70 °C

•Maximum altitude: 3000 m (9843 ft.)

•This equipment is suitable for continuous operation.

Safety Marking Symbols

This section provides a description of the safety marking symbols that appear on

the instrument. These symbols provide information about potentially dangerous

situations which can result in death, injury, or damage to the instrument and other

components.

Caution,

refer to

manual

Earth

ground

Te r m i n a l

Alternating

current

Visible and/or

invisible laser

radiation

Caution, risk

of electric

shock

Protective

Conductor

Te r m i n a l

Caution, hot

surface

Frame or

chassis

Termin a l

On: In position of a bistable push control.

The slash (I) only denotes that mains are on.

Off: Out position of a bistable push control.

The circle (O) only denotes that mains are off.

or

(I) or

(O)

WARRANTY

06_03 TSC-599 v

WARRANTY

ILX LIGHTWAVE CORPORATION warrants this instrument to be free from

defects in material and workmanship for a period of one year from date of

shipment. During the warranty period, ILX will repair or replace the unit, at our

option, without charge.

Limitations

This warranty does not apply to fuses, lamps, defects caused by abuse,

modifications, or to use of the product for which it was not intended.

This warranty is in lieu of all other warranties, expressed or implied, including any

implied warranty of merchantability or fitness for any particular purpose. ILX

Lightwave Corporation shall not be liable for any incidental, special, or

consequential damages.

If a problem occurs, please contact ILX Lightwave Corporation with the

instrument's serial number, and thoroughly describe the nature of the problem.

Returning an Instrument

If an instrument is to be shipped to ILX Lightwave for repair or service, be sure to:

1Obtain a Return Authorization number (RA) from ILX Customer Service.

2Attach a tag to the instrument identifying the owner and indicating the required service or

repair. Include the instrument serial number from the rear panel of the instrument.

3Attach the anti-static protective caps that were shipped with the instrument and place the

instrument in a protective anti-static bag.

4Place the instrument in the original packing container with at least 3 inches (7.5 cm) of

compressible packaging material. Shipping damage is not covered by this warranty.

5Secure the packing box with fiber reinforced strapping tape or metal bands.

6Send the instrument, transportation pre-paid, to ILX Lightwave. Clearly write the return

authorization number on the outside of the box and on the shipping paperwork. ILX

Lightwave recommends you insure the shipment.

If the original shipping container is not available, place your instrument in a

container with at least 3 inches (7.5 cm) of compressible packaging material on all

sides.

Repairs are made and the instrument returned transportation pre-paid. Repairs

are warranted for the remainder of the original warranty or for 90 days, whichever

is greater.

WARRANTY

vi TSC-599

Claims for Shipping Damage

When you receive the instrument, inspect it immediately for any damage or

shortages on the packing list. If the instrument is damaged, file a claim with the

carrier. The factory will supply you with a quotation for estimated costs of repair.

You must negotiate and settle with the carrier for the amount of damage.

WARRANTY

06_03 TSC-599 vii

Comments, Suggestions, and Problems

To ensure that you get the most out of your ILX Lightwave product, we ask that

you direct any product operation or service related questions or comments to ILX

Lightwave Customer Support. You may contact us in whatever way is most

convenient:

Phone . . . . . . . . . . . . . . . . . . . . . . . . . . . (800) 459-9459 or (406) 586-1244

Fax . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . (406) 586-9405

On the web at: . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .ilx.custhelp.com

Or mail to:

ILX Lightwave Corporation

P. O. Box 6310

Bozeman, Montana, U.S.A 59771

www.ilxlightwave.com

When you contact us, please have the following information:

If ILX Lightwave determines that a return to the factory is necessary, you are

issued a Return Authorization (RA) number. Please mark this number on the

outside of the shipping box.

You or your shipping service are responsible for any shipping damage when

returning the instrument to ILX Lightwave; ILX recommends you insure the

shipment. If the original shipping container is not available, place your instrument

Model Number:

Serial Number:

End-user Name:

Company:

Phone:

Fax:

Description of what is

connected to the ILX

Lightwave instrument:

Description of the problem:

WARRANTY

viii TSC-599

in a container with at least 3 inches (7.5 cm) of compressible packaging material

on all sides.

We look forward to serving you even better in the future!

TSC-599 1

CHAPTER 1

INTRODUCTION AND SPECIFICATIONS

This manual contains information for using the 599 RTD Temperature Sensor

Converter, as well as procedures for optimizing the calibration of your temperature

sensor. By following these procedures, the user will be able to achieve the most

accurate results.

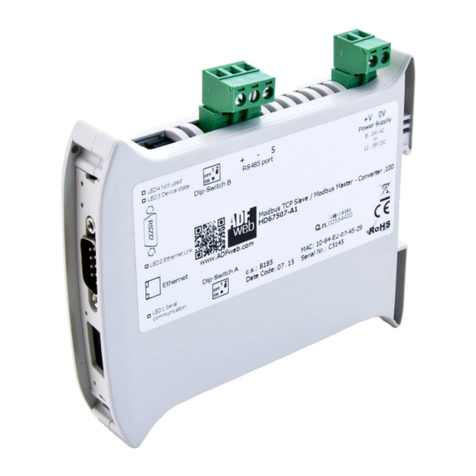

Product Overview

The 599 RTD Temperature Sensor Converter is a device which allows an RTD, or

resistance temperature detector, to be used as a temperature sensor with the ILX

Lightwave LDT-5910B, LDT-5525 Temperature Controllers, ILX Lightwave Laser

Diode Controllers (LDC-3700 Series), and the LPA-9000 Series Laser Parameter

Analyzers. The 599 is designed to be used with 100 ohm, 500 ohm and 1Kohm

two-lead RTDs.

INTRODUCTION AND SPECIFICATIONS

Specifications

2 TSC-599

CHAPTER 1

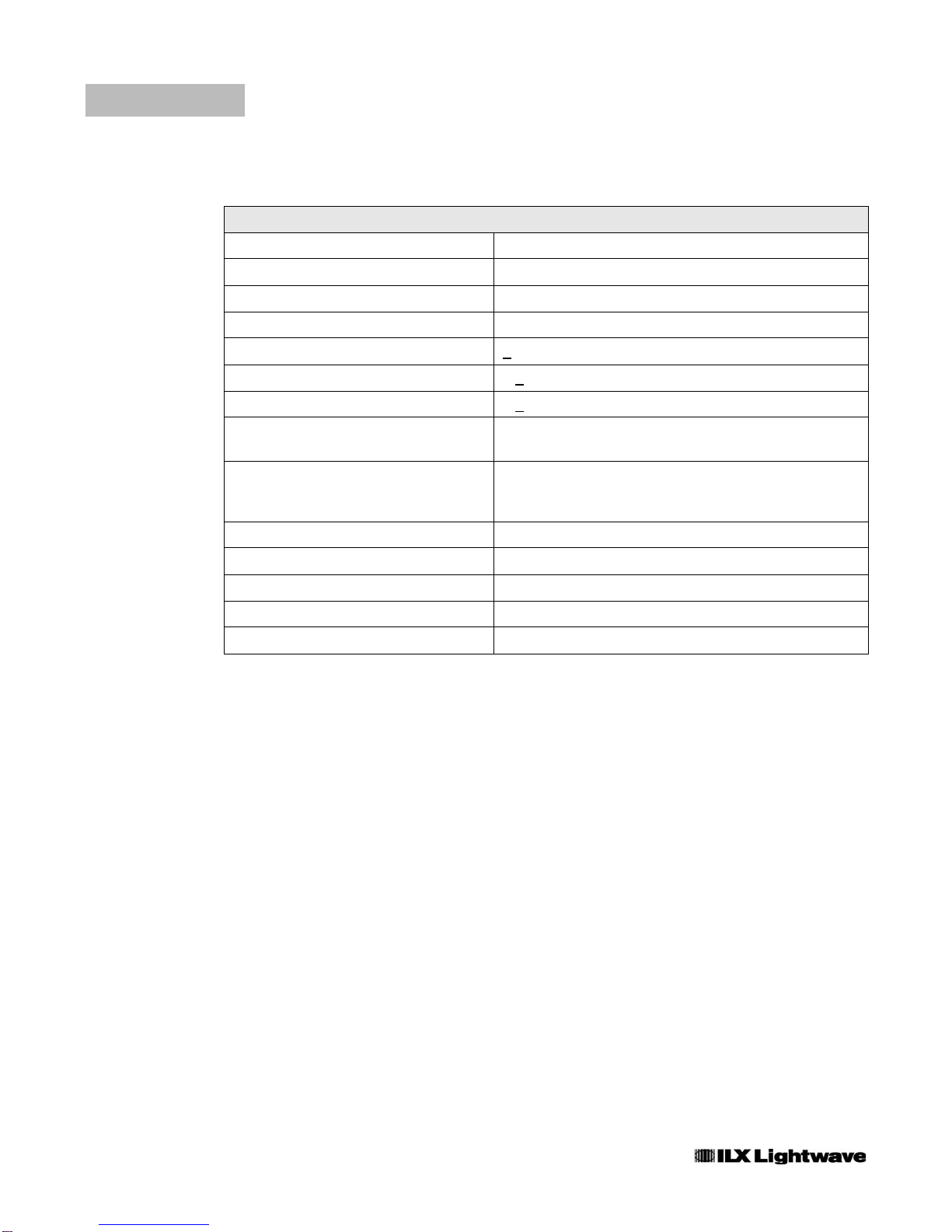

Specifications

1. Input connector pin configuration is compatible with the ILX Lightwave LDT-5910B, LDT-5525 Temperature Controllers, ILX

Lightwave Laser Diode Controllers (LDC-3700 Series) and the LPA-9000 Series Laser Parameter Analyzers.

2. Sensor resistance setting is internally switch selectable.

3. Specification of ILX Lightwave LDT-5910B Temperature Controller used with the 599 RTD Temperature Sensor Converter and a

100 ohm platinum RTD temperature sensor.

4. Typical specification; set-point accuracy depends upon user-defined calibration constants, ambient temperature fluctuations, the

particular temperature sensor used and other factors.

Connectors115-pin D-subminiature

Sensor Type22-wire RTD (1K, 500 and 100 ohm)

Sensor Current (mA) 2.0 mA

Temperature Readout Range -20 oC to +100 oC

RTD Set Point Accuracy3,4 +0.2 oC

Short Term Stability (10 minutes)3< + 0.01 oC

Long Term Stability (24 hours)3< + 0.02 oC

Error Due to a Temperature Change of

Enclosure 0.04% / oC

Typical Temperature Readout Error Due

to RTD Non-Linearity

(-20 oC to + 100 oC)

0.75 oC

Size 0.9” x 2.4” x 3.8”

Weight 6.75 ounces (191 grams)

Operating Temperature 0 oC to 40 oC

Storage Temperature -40 oC to +70 oC

Humidity < 95% relative humity, non-condensing

TSC-599 3

CHAPTER 2

OPERATION

Installation

Prior to installing the 599, the RTD sensor type must be selected. Open the 599

enclosure by removing the two #2 Phillips-head screws. Position the large slide

switch into either the 100 ohm, 500 ohm or 1Kohm position depending on the RTD

sensor type used. (Switch positions are labeled on the printed circuit board.)

Reassemble the 599 enclosure.

Note: Opening the 599 enclosure will NOT void the ILX Lightwave Warranty. However, the

user should not adjust any internal trimpots, as the 599 has been factory calibrated.

To install the 599 Temperature Sensor Converter, first position the sensor select

switch of your ILX Lightwave Temperature Controller to the “AD590” position.

Then plug the 15-pin male D-subminiature connector on the 599 into the 15-pin

female D-subminiature connector on the rear panel of the temperature controller.

The 15-pin female D-sub connector on the 599 will now function the same as the

15-pin D-sub connector on the back of the temperature controller (with the

exception that an RTD temperature sensor, instead of an AD590 sensor, should

be connected to pins seven and eight). Refer to the appropriate ILX Lightwave

Temperature Controller Manual for temperature control operation.

Possible Sources of Error

The following sections outline several factors which may reduce the accuracy of

the 599 RTD Temperature Sensor Converter. ILX suggests that the user follow the

outlined suggestions to minimize the influence of these factors.

RTD Non-Linearity

By a first approximation, the change in resistance of an RTD with respect to

temperature is given by:

R = Ro(1 + αT)

OPERATION

Installation

4 TSC-599

CHAPTER 2

where Rois the resistance of the RTD at 0 oC, T is the temperature in Celsius and

αis a constant. However, this approximation is not completely accurate, as an

RTD is typically about 0.5% non-linear in the range between 0 and 100 oC. The

599 RTD Temperature Sensor Converter gives a linear response for a change in

sensor resistance, R. The formula for the temperature displayed on the

temperature controller (in oC) is given by:

Tdisplay = C1 + C2 * (K * R - 273.15)

where C1 and C2 are the calibration constants set on the temperature controller,

and K is an internally-set constant. To reduce the error due to non-linearity of the

RTD, the calibration constants C1 and C2 should be set using the two-point

calibration method. The two points should be as close together as possible (while

still spanning the region of interest). Refer to a later section for a description of the

two-point calibration.

RTD Self-Heating

The error due to self-heating of the RTD will vary, depending on the size and

shape of the RTD and the thermal environment. To minimize this error, the

calibration constants on the temperature sensor should be set with the RTD in the

same type of thermal environment in which is will be used.

Ambient Temperature Change

The change in ambient temperature surrounding the enclosure will effect the

temperature reading slightly. To minimize this error, the temperature controller and

the 599 should be warmed-up properly prior to calibration (approximately 1 hour is

sufficient) and the room temperature should be fairly stable.

Wire Resistance

The wire used to connect the RTD to the 599 Temperature Converter will add

some small error. However, this error may be offset by properly adjusting the

calibration constant C1.

Thermocouple Effects

This effect is usually quite small and can be minimized by property selecting the

type of wire used to connect the RTD leads to the 599 Temperature Converter. In

addition, these effects may be offset by properly adjusting the calibration constant

C1.

OPERATION

Setting the Calibration Constants

06_03 TSC-599 5

CHAPTER 2

Setting the Calibration Constants

For a firs approximation, the calibration constants C1 and C2 may be set by using

the following equations. This will usually give an accuracy within 1 oC.

C1 = 0

C2 = 1 / 273.15 * α

Here αis a constant dependent upon the particular RTD. Two common values of

αare 0.00385 and 0.00392.

If more accuracy is desired, the two-point calibration method may be used. The

accuracy of this procedure depends upon the accuracy of the known

temperatures, externally measured. It is used to determine the zero offset and the

gain offset (slope) of the RTD device.

The two-point calibration procedure is outlined below:

1Connect the RTD to the 599 Temperature Converter unit. Connect the 599 Temperature

Converter to the Temperature Controller and allow the Temperature Controller to warm up

for at least 1 hour.

2Select the C1 parameter of the Temperature Controller and enter a value for C1. Read

and record the value of C1. Next, select the C2 parameter and enter a value for C2. Read

and record the value of C2. (The user may with to use the formulas for C1 and C2 as a

first approximation.)

3Set up the Temperature Controller for constant temperature operation. Place the sensor at

an accurately known and stable temperature Ta1. Allow the temperature controller to

stabilize and read the displayed temperature, Td1. Record these values.

4Repeat step 3 for another known temperature, Ta2, and the corresponding displayed

temperature, Td2.

Note: The two temperature,Ta1 and Ta2, should be at the bounds of the intended operating

range. For best results, make the range between the two temperatures as small as

possible, while still covering the temperature range of interest.

5Calculate the new values of C1 (C1new) and C2 (C2new) using the following equations:

First, determine the intermediate values of V and U, where:

V = ( Ta1 - Ta2 ) / ( Td1 - Td2 ), and

U = Ta1 - ( Td1 * V )

C1new and C2new can then be determined with the following:

C1new = U + ( V * C1 )

C2new = V * C2

6Replace C1 with C1new by selecting the C1 parameter of the Temperature Controller and

entering the new value, C1new. Similarly, replace C2 with C2new. It is not necessary to

repeat the calibration procedure at this point.

OPERATION

Setting the Calibration Constants

6 TSC-599

CHAPTER 2

Table of contents