ImageQuest Q770 Operating manual

Multiscanning Color Monitor

TECHNICAL SERVICE MANUAL

Q770

http: monitor.hei.co.kr

http: ImageQuest.co.kr

ImageQuest Q770 TECHNICAL SERVICE MANUAL

Q770 Technical Service Manual

--1--

Safety Precaution

WARNING

Service should not be attempted by anyone unfamiliar with the necessary precautions on this monitor.

The followings are the necessary precautions to be observed before servicing.

1. Always discharge the high voltage to the CRT conductive coating before handling the CRT. The

picture tube is highly evacuated and if broken, glass fragments will be violently exploded. Use

shatter proof goggles and keep picture tube away from the bare body while handling.

2. When replacing a chassis in the cabinet, always be certain that all the protective devices are put back

in place, such as nonmetallic control knobs, insulating covers, shields, isolation resistor capacitor

network etc.

3. Before returning the monitor to the customer, always perform an AC leakage current check on the

exposed metallic parts of the cabinet, such as signal connectors, terminals, screw heads, metal

overlays, control shafts etc, to be sure the monitor is safe to operate without danger of electrical

shock. Plug the AC line cord directly into a AC outlet (do not use a line isolation trasformer during

this check.). Use an AC voltmeter having 1500 ohm per volt or more sensitivity in the following

manner : Connect ground(water pipe, conduit, etc.) and the exposed metallic parts, one at a time.

Measure the AC Voltage across the combination of 1500 ohm resistor and 0.15 capacitor. Reverse

the AC plug at the AC outlet and repeat AC voltage measurements for each exposed metallic part.

The Voltage must not exceed 0.3 volts RMS. This corresponds to 0.2 milliamp AC. Any value

exceeded this limit constitutes a potential shock hazard and must be corrected immediately.

INSTRUCTIONS TO USER

This equipment generates and uses radio frequency energy and if not installed and used properly, that

is, in strict accordance with the manufacturer's instruction, may cause interference to radio and

television. It has been tested and found to comply with the limits for the specifications in Subpart J of

Part 15 FCC Rules, which are designed to provide reasonable protection against such interference in a

residential installation. However, there is no guarantee that interference will not occur in a particular

installation.

If this equipment does cause interference to radio or television reception, which can be determined

by turning the equipment off and on, the user is encouraged to try to correct the interference by one or

more of the following measures.

• reorient the receiving antenna

• relocate the computer with respect to the receiver

• plug the computer into a different outlet so that computer and receiver are on different branch

circuits.

AC VOLTMETER

Good earth ground

such as the water pipe,

conduit, etc

1500 ohm

10 WATT

0.15µF

Place this probe

on each exposed

metallic part.

0.15µF

RODUCT SAFETY NOTICE

Many electrical and mechanical parts in this monitor have special safety-related characteristics.

These characteristics are often not evident from visual inspection.

Replacement parts which have these special safety characteristics are identified in this manual;

electrical components having such features identified by " ! " in the replacement parts list and

schematic diagram.

For continued protection, replacement parts must be identical to those used in the original circuit.

The use of substitute replacement parts which dose not have the same safety characteristics as the

factory recommended replacement parts shown in this service manual, may create shock, fire,

X-RAY RADIATION or other hazards.

--2--

X-Ray Radiation Precaution

1. Excessive high voltage can produce potentially hazardous X-RAY RADIATION. To avoid

such hazards, the high voltage must be under the specified limit. The nominal value of the high

voltage of this monitor is 25KV 1.0KV at zero beam current(minimun brightness) under a 120V AC

power source. The high voltage must not(under any circumstances) exceed30KV. Each time a monitor

requires servicing, the high voltage should be checked.

It is recommended the high voltage be recorded as a part of the service record. It is important to use

an accurate and reliable high voltage meter.

2. This monitor is equipped with a protection circuit which prevents the monitor from producing

excessively high voltage. Each time the monitor is serviced, the protection circuit must be checked to

determine that the circuit is properly functioning.

3. The only source of X-RAY RADIATION in this monitor is the picture-tube.

For continued X-RAY RADIATION protection, the replacement tube must be exactly the same type

tube as specified in the parts list.

4. Some parts in this monitor have special safety-related characteristics for X-RAY RADIATION

protection.

For continued safety, parts replacement should be undertaken only after referring to the product

safety notice.

PRODUCT CDRH NOTICE

Electrical potentiometers which is marked as caution " ! " in parts list are crititial components

of safety & CDRH.

Therefore, for continued protection, replacements parts must be used it which is used in original

PCB ASS’Y.

Q770 Technical Service Manual

--3--

!

General Inforormation

1. Description

This 17" (16" viewable) color display monitor is operated in R, G, B, drive mode input.

2. Operating instructions

2-1. Front

Menu, Select,Down DPMS(Power)LED, Power Switch

2-2. Rear

Input connection AC & SIGNAL CABLE

2-3 Service Instruction(internal controls)

H-Center , H/V Focus

2-4. OSD Controls

Brightness/Contrast, H/V-Position, H/V-Size, Pincushion/Trapezoid, Pin Balance, Parallel,

Top/Botton-Corner, H/V-LinearityRotation, H/V Moire, Degauss, Color Control, Information,

Language, OSD H/V- Position ,Recall

3. Electrical Characteristics

3-1. Power supply

Input Voltage : 100-240 V AC

Input Current : 1.5A Max.

Input Frequency : 50 - 60Hz

Power Consumption : 70W (TYP)

3-2. Video input signal

Input : 0.7 Vp-p analog signal(at 75 ohm terminated to ground)

Polarity : Positive

Rise/Fall time : < 5ns

3-3. Horizontal Synchronization Signal

Level : TTL High : 2.4V min

Low : 0.4V max

Polarity : Negative or Positive

Frequency : 30kHz - 70kHz

Timing Limits : Pulse width (0.1µs Thp 6µs)

3-4. Vertical Synchronization Signal

Level : TTL High : 2.0V min

Low : 0.4V max

Polarity : Negative or Positive

Frequency : 50Hz - 150Hz

Timing Limits : Pulse width (8µs Tvp 2.048ms)

--4--

Video Input Signal

Recommended signals are shown below.

• Video Signal

Video Level : 0 to 700mV

Polarty : Positive

Video Input : RGB separated

Analog level

Sync input : H-Sync ; TTL level

V-Sync ; TTL level

• Waveform

Video input(R, G, B)

• H-Sync • V-Sync

0

1

2

3

4

59

60

61

62

63 700mV

• Signal: 64 level gray scale

• Linear stepping:

(11.1mV-64 Steps)

ACTIVE (4)

Front Porch

(T5) Period (T1)

Sync Width (T2)

Back Porch (T3)

ACTIVE (4)

Front Porch (T5)

Period (T1) Sync Width (T2)

Back Porch (T3)

Power LED Power Switch

Control Desciption

Front View

Q770 Technical Service Manual

--5--

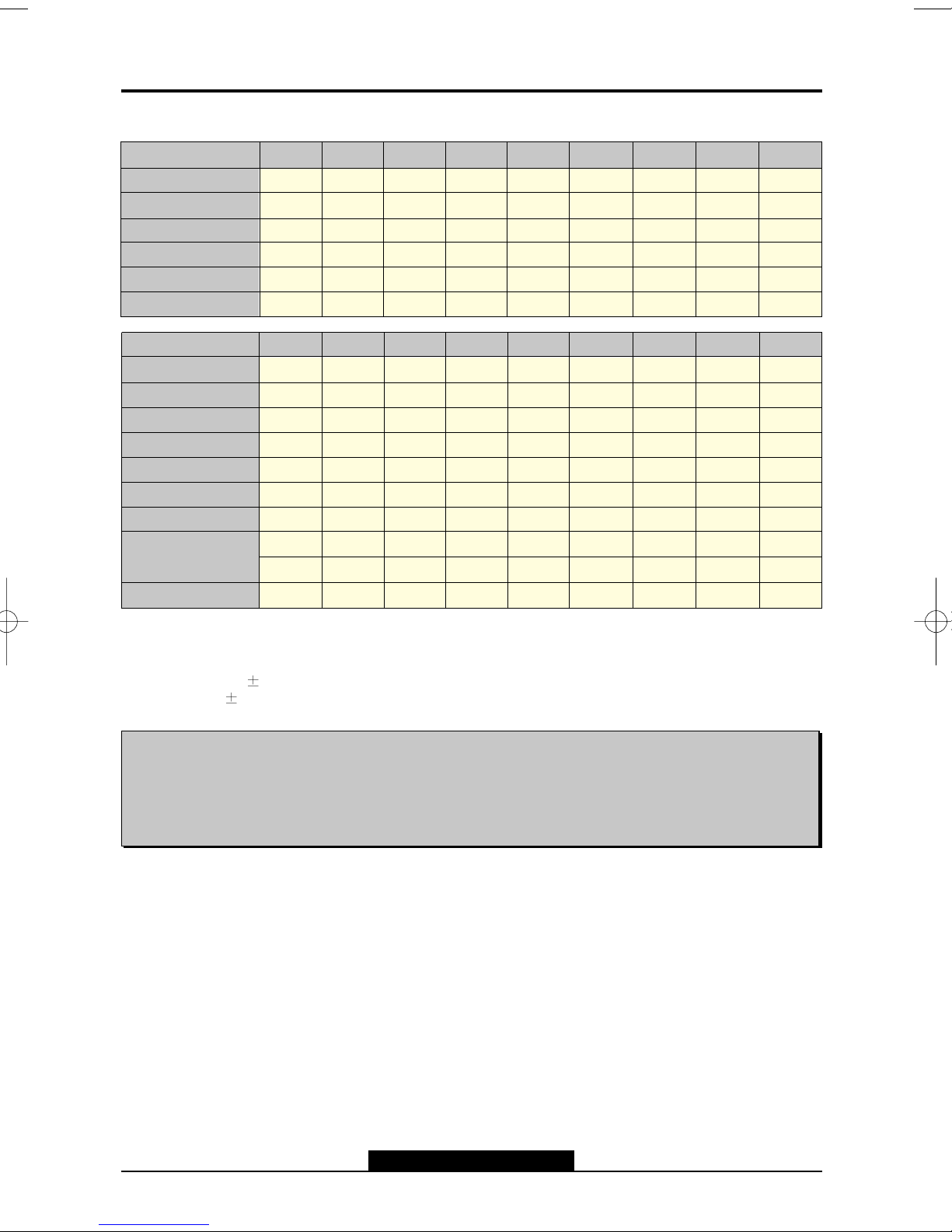

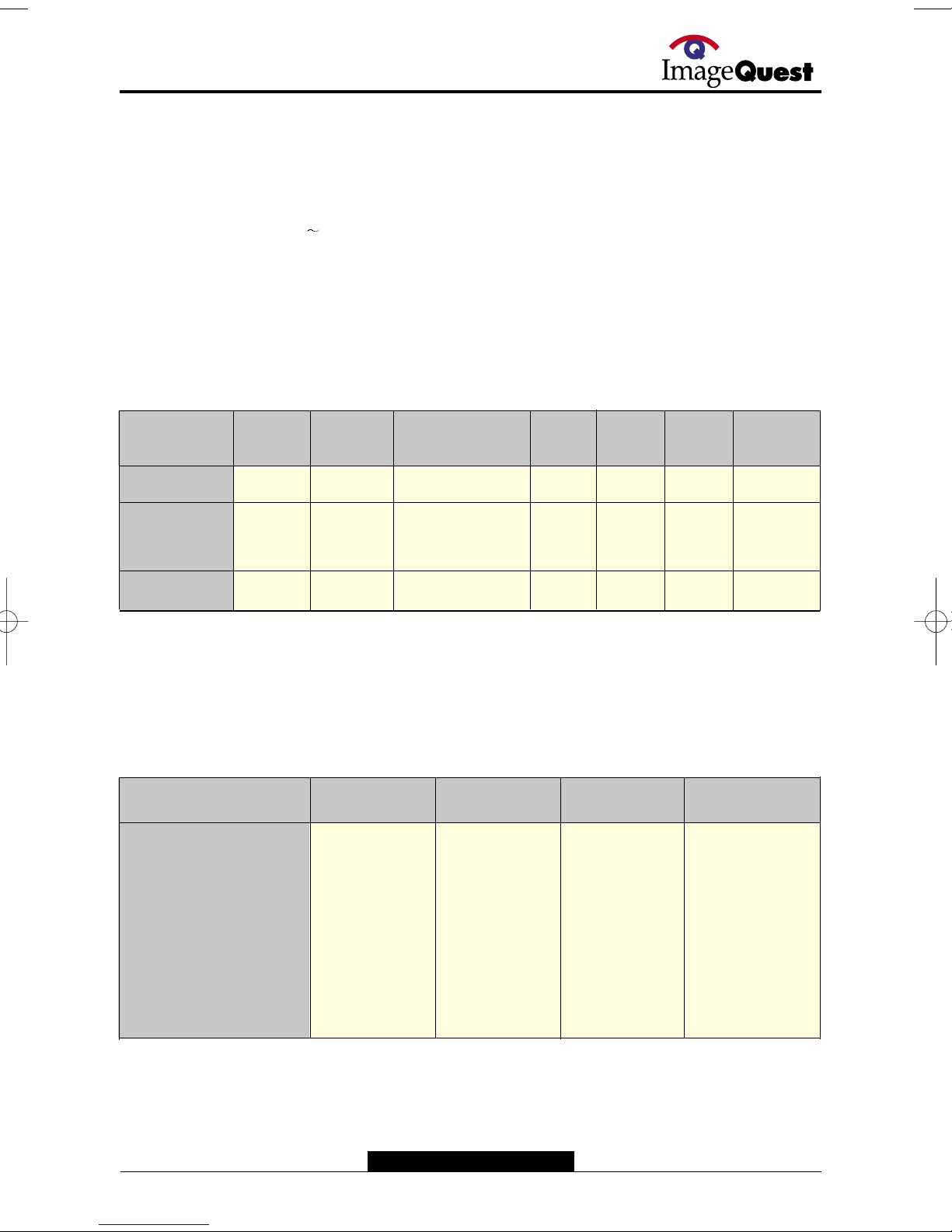

• Timing Table

Horizontal Dot 720

31.469

31.778

3.813

1.907

25.422

0.636

640

43.269

23.111

1.556

2.222

17.778

1.556

640

50.625

19.752

1.580

1.975

15.802

0.395

800

46.875

21.333

1.616

3.232

16.162

0.323

800

53.674

18.631

1.138

2.702

14.222

0.569

800

63.920

15.645

1.185

2.015

11.852

0.593

1024

60.023

16.660

1.219

2.235

13.003

0.203

1024

68.677

14.561

1.016

2.201

10.836

0.508

400

70.080

14.268

0.064

1.081

12.711

0.413

1.577

-

+

Frequency kHz

Period(T1) µs

Sync Width(T2) µs

Back Porch(T3) µs

Active(T4) µs

Front Porch(T5) µs

Vertical Line

Frequency Hz

Period(T1) ms

Sync Width(T2) ms

Back Porch(T3) ms

Active(T4) ms

Front Porch(T5) ms

Interlaced

Sync Polar

ms

N

480

85.008

11.764

0.069

0.570

11.093

0.023

0.671

-

-

N

480

100.05

9.995

0.059

0.435

9.481

0.020

0.514

-

-

N

600

75.000

13.333

0.064

0.448

12.800

0.021

0.553

+

+

N

600

85.061

11.756

0.056

0.503

11.179

0.019

0.577

+

+

N

600

100.03

9.997

0.063

0.501

9.387

0.047

0.610

+

+

N

768

75.029

13.328

0.050

0.466

12.795

0.017

0.533

+

+

N

768

84.997

11.765

0.044

0.524

11.183

0.015

0.582

+

+

NInterlaced Y/N

H

V

The monitor is compatible with additional modes within the specified frequency ranges provided that

they are different at least for one of the following :

Horizontal Freq.: 1.0kHz

Vertical Freq.: 1Hz

Note: Even if the monitor detects the input timing as a factory preset mode, the size

and position may not be able to be set as desired. Check the input timings are under the specifications and

adjust the image as you want.

For better quality of display image, use the timing and polarity shown in the table above. Please see your video

card user's guide to ensure compatibility.

Note: Even if the monitor detects the input timing as a factory preset mode, the size and position

may not be able to be set as desired. Check the input timings are under the specifications and

adjust the image as you want.

For better quality of display image, use the timing and polarity shown in the table above. Please see

your video card user's guide to ensure compatibility.

--6--

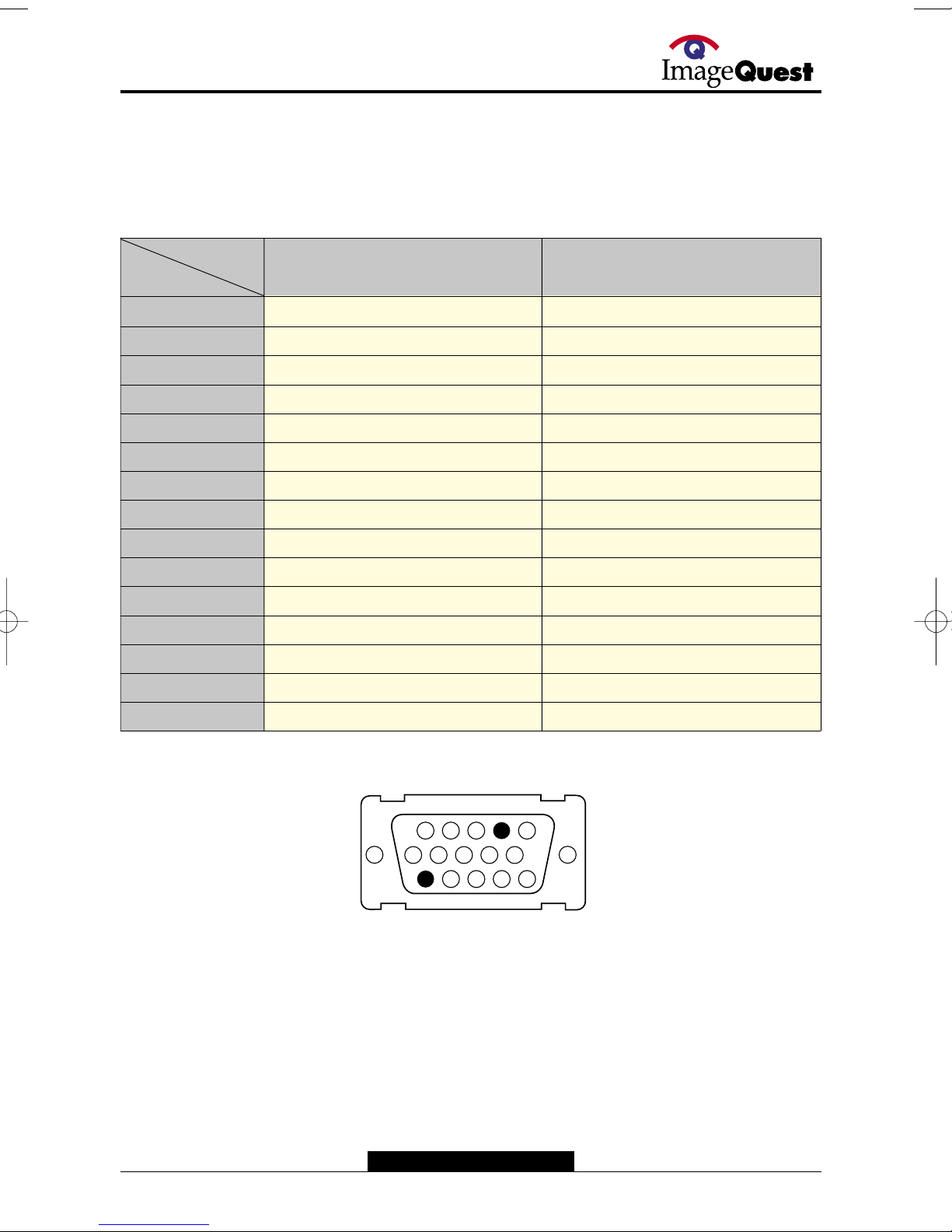

COMPOSITE

SYNC

1

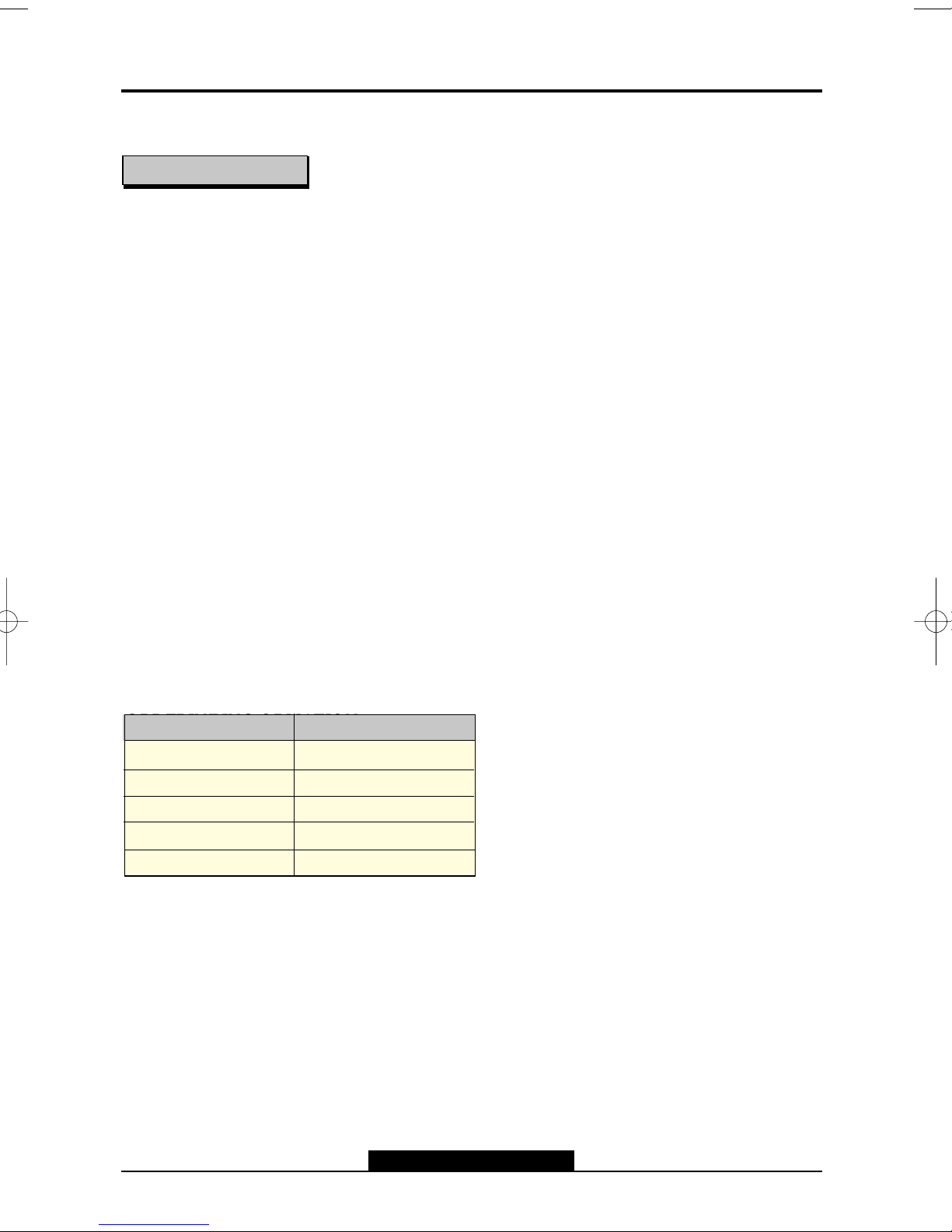

Video Input Terminal

A 15 Pin D-sub male connector is used as the input signal connector.

Pin and input signals are shown in the table below.

Pin Description

D-Sub male connector

12345

6789

11 12 13 14

10

15

SIGNAL

PIN NO. SEPERATE

SYNC

RED

2GREEN

3BLUE

4N.C

5DDC RETURN

6RED GROUND

7GREEN GROUND

8BLUE GROUND

9+5

10 LOGIC GROUND

11 N.C

12 SDA

13 H-SYNC(TTL)

14 V-SYNC(VCLK)

15 SCL

RED

GREEN

BLUE

N.C

DDC RETURN

RED GROUND

GREEN GROUND

BLUE GROUND

+5

LOGIC GROUND

N.C

SDA

(H+V) SYNC

VCLK

SCL

Q770 Technical Service Manual

--7--

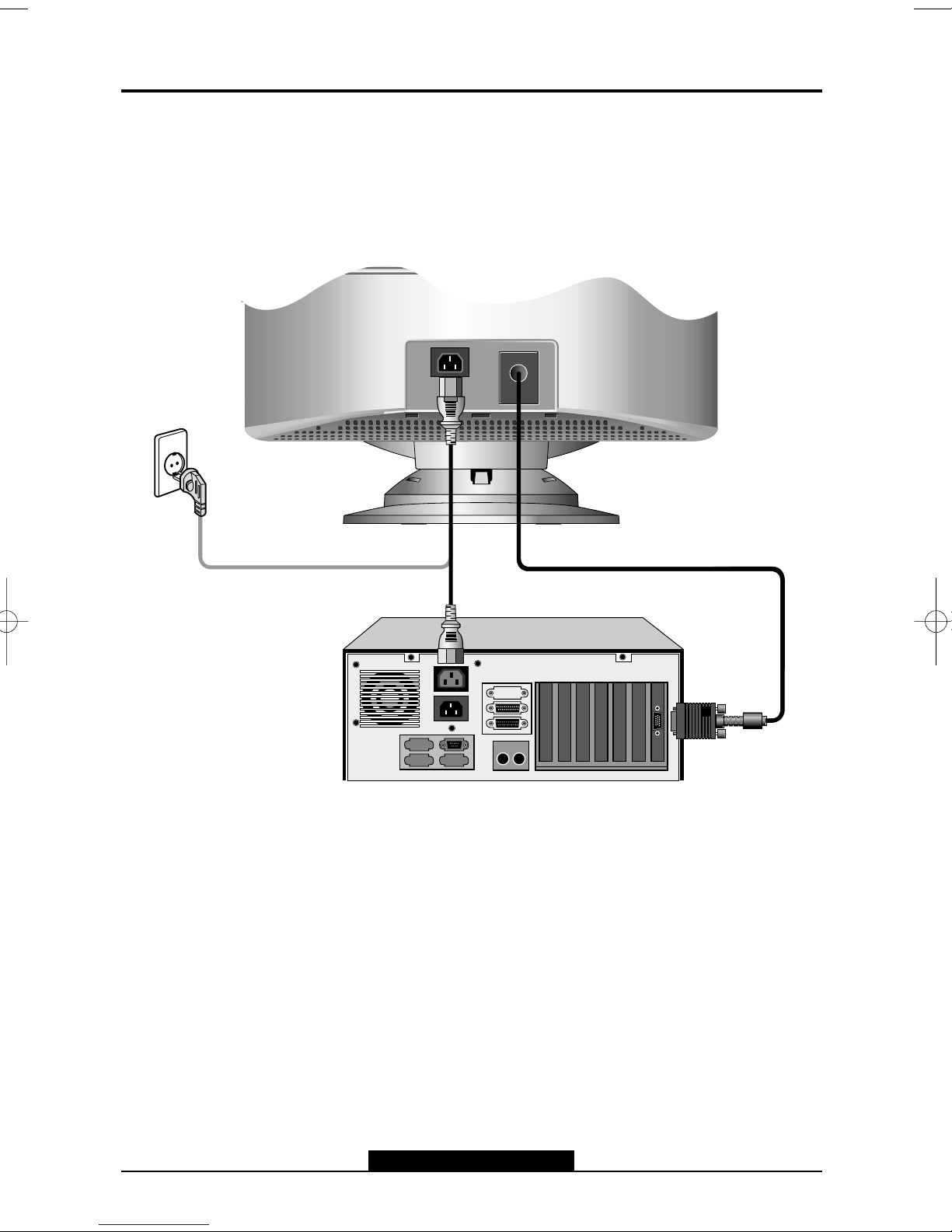

Connecting With External Equipment

Cautions

Be sure to turn off the power of your computer before connecting the monitor.

--8--

3. Signal Processing and MCU Control

The X-TAL resonates at 12MHz.

When the H and V sync or TTL composite sync are input to MCU, MCU can measures the H and V

frequency to detect the video mode.

MCU has digital to analog converter(DACS) control function like ABL, H-LIN, SBU-SIZE, rotation,

brightness. and MCU can control , Recall, H/V-Size, H/V-Position, Pincushion/Trapezoide,

Top/Botton-Corner, H/V-Linearity, Parallel/Pin Balance, H/V Moire, Color Control, Information,

Language, by I2C BUS Line.

The operation of MCU is shown in the table below.

Stage1

Stage2

Self Test

Theory of Operation

1. Power Supply

The AC line voltage range is from 100V to 240V.

The SMPS has +55V, +7.0V, +14V,+5V, -12V

The conducted noise is filtered by X(CP01, CP04) and Y (CP02, CP03, CP32, CP33, CP09)capacitors

and a common mode line filter (LP01).

The input rectifier (DP01 DP04) converts the AC line voltage into a DC voltage to power the SMPS.

The UC3843B (ICP01) drives the power FET(QP04) according to the PWM signals generated by the RT

and CT(RP07, CP10) connected pin 4 of ICP01.

The ICP01 is an integrated current mode PWM.

It consists of an oscillator, error amplifier, current sense comparator, under voltage lock-out and an

MOSFET drive stage.

The switching frequency is locked to horizontal scan frequency by horizontal flyback pulse.

When the monitor is in Stage2 with no pulsed syncs. QP05 and QP07 is turned off. The total power

consumption must be less than 5W in Stage2.

2. DPMS and Self test mode

The power supply supports the DPMS function. Its operation is shown in the table below.

MODE H-SYNC V-SYNC MCU

PIN35

(BRI)

MCU

PIN 10

(Suspend)

Q905

QP07 14V HEATER

O

X

O

X

X

O

O

X

X

X

CONTROL

0

3.5V

H

L

H

ON

OFF

ON

6.3V

2V

6.3V

14V

0V

14V

H-FREQ

(kHz) H-LIN1

PIN 30 H-LIN2

PIN 29 H-LIN3

PIN 28 REMARK

31 < H < 34

34 < H < 36

36.0 < H < 41

41.0 < H < 46

46 < H < 52

52 < H < 59

59< H < 62

62.0<H<66

66.0<H<69

L

L

L

L

H

H

H

H

H

L

L

H

H

L

L

H

H

H

L

H

H

H

L

H

L

L

H

Q770 Technical Service Manual

--9--

4. Horizontal Deflection

TDA9116is an I2C autosync deflection controller for H/V sync and drive processing.

All functions are controlled by I2C bus.

When H-Sync is applied, the internal oscillator is automatically locked.

The duty-cycle of H-output pulse Pin 26 is variable by frequency.

QH08 and TH01 are used to drive the H-output transistor (QH09). QH09 is turned on, it conducts

current through the deflection yoke on the right hand side of the screen.

This current comes from the S correction capacitors (CH27, CH29, CH32, CH34), which have a charge

equal to the effective supply voltage.

When the QH09 is opened up, the damper diode(DH12) allows current for left hand side of the screen

to flow back through the deflection yoke to the S capacitors.

The flyback capacitor (CH23) determines the size and length of the flyback pulse.

The S capacitors correct outside versus center linearity in horizontal scan.

THREE FETs (QH11, QH12, QH13) select the value of S capacitors.

H-centering is controlled by a switch(SWH01). The switch selects DC offset current flow through the

yoke.

A diode modulator is used to control the E-W correction and H-size. ICH01 generates the

E-W parabora wave using vertical amp.

A power buffer (QH02, QH03) drives the diode modulator.

In order to keep the high voltage constant independent of the horizontal scan frequency, the supply

voltage of FBT must increase with increasing scan frequency proportionally. A step-up mode DC-DC

converter with PWM is used to realize this demand.

ICH01 compares high-voltage feedback with reference voltage. Its output pulse switches a

FET(QH07). To adjust the high voltage, TDA9116(ICH01) has a control terminal (Pin14).

5. Vertical Deflection

In vertical section of TDA9116 there is auto-sync processing.

The vertical output stage consists of a power OP-AMP with extra flyback grnerator.

TDA9302H(ICV01) is used as vertical output stage.

6. X-Ray Protection and Beam Current Limiting.

A failure in the horizontal scan control section could cause a dangerous situation; the high voltage

might rise to an unacceptable high level. When the flyback voltage rise to unacceptable level, the

(Pin25) of ICH01 detects these states over 8.0V TDA9116

It causes the H-drive stage and oscillator to be turned off. Then high voltage is shut down until the

power switch is on.

The average anode current is measured at lower side of the High Voltage winding of the FBT.

ABL flows through Connectors(CNM06,CNC01) connected ICC01(LM1267) and through RM07

Connected ICM01 Pin39. and ABL is controlled by ICM01.

7. Video Amplifier and OSD Interface

LM1267(ICC01) is a Very High Freguncy video amplifier with three matched video amplifiers, OSD

Contrast Control SDA, SCL,OSD Interface, OSD BLK drive controls, blanking gate and clamp gate.

H-blank signal is applied to Pin 24. During blanking all three outputs are thrown to the pedestal

level. MCU(ICM01)Pin32 Clamp is used to a clamp signal.

The signal is applied to ICC01 Pin 23.

Three OSD inputs (Pin 1,2,3 of ICC01) are TTL compatible and typical bandwidth is 80MHz.

A fast commutate pin is provided to select either the video or the OSD inputs as a source for

amplification.

gain of three internal variable gain amplifiers through the I2C bus interface. MTV 021 is designed for

monitor application to display built-in characters or fonts on to monitor screen.

The display operation occurs by transferring data and control information from the MCU to RAM

through a serial data interface.

The output stage is made of 3-channel power amplifier (LM2467, ICC03 ). The output is capable of 40

Volts swing in less than 9 nsec?

The three cathodes are AC coupled to the video amplifiers. The DC level on each cathode is set by a

cut-off amplifier and clamp diode. The value of the DC voltage is adjusted by DACS.

--10--

[Ly-Ry] 2.0mm

Data Area Hor.ax.

Ly Ry

Visual Characteristics

1. Test condition

• Resolution : Any of Preset modes

• Input level : 700mV

• Pattern : Central White box covering 20% of the data area

• Brightness Control : Default position (cut off)

• Contrast Control : Adjust to 100 cd/m2 of luminance (Center of the white field)

• Image duty cycle : 10% to 90%

• Magentic field : Horizontal = 0.3 Gauss

Vertical = 0.4 Gauss

• Supply Voltage : 100 240 VAC

• Operating Condition

Temperature (0 to 35)°C

Humidity (35 to 80)% (W/O condensation)

Altitude (0 to 3000)m

• Stroage condition

Temperature (-20 to 60)°C

Humidity (5 to 85)% (W/O condensation)

Altitude (0 to 15,000)m

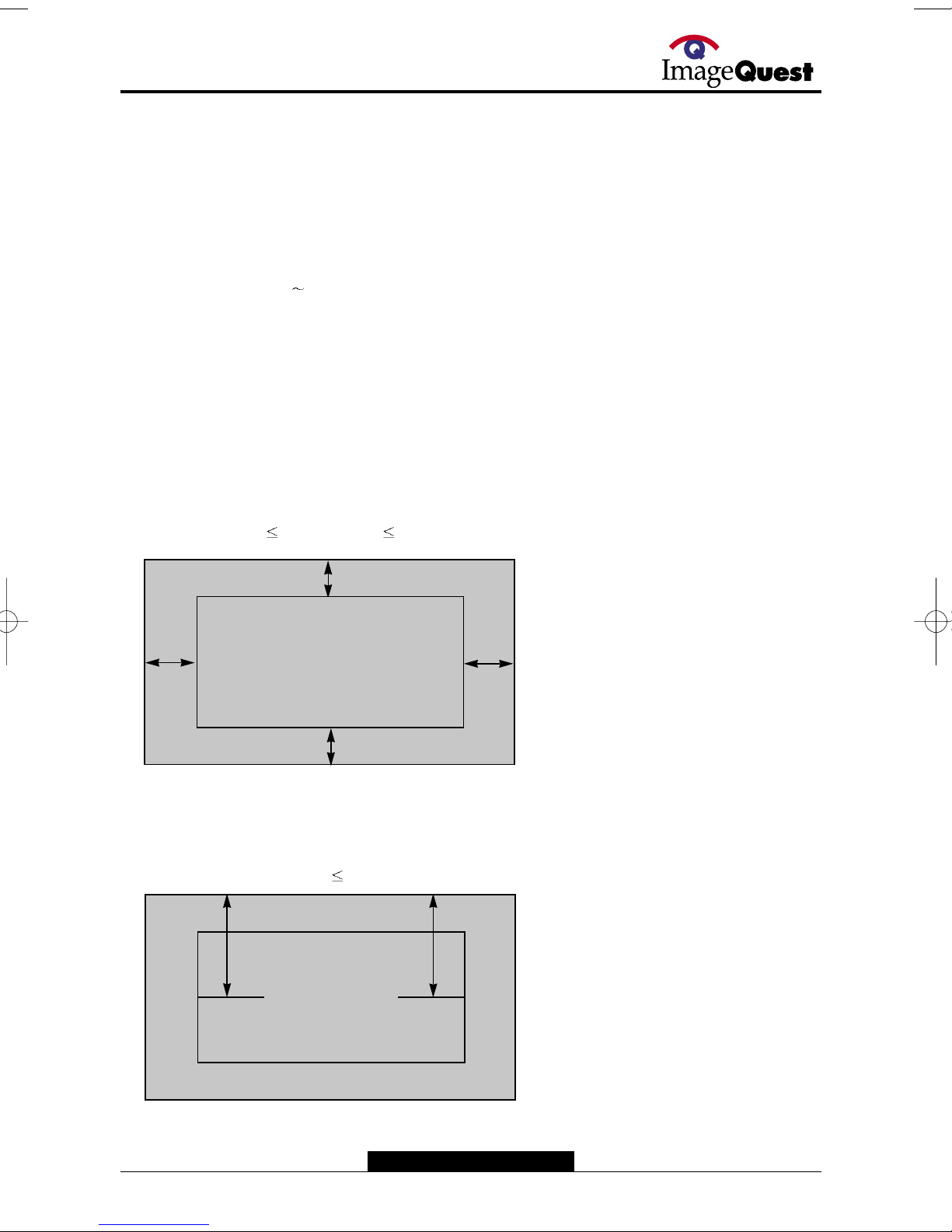

2. Display Centering

The following describes the pattern for this test. Basically it is composed by a single pixel white line

around the perimeter of the data area, with marks for the horizontal and vertical axes, the

background is black.

The display centering shall be met as following specification at adjustied centering function (user’s

control)

[L-R] 4mm [U-D] 4mm

Display Cextering

U

R

D

L

3. Tilt

The maximum variation of the display rotation(tilt) shall be with in 2.0mm based on the following

formula.

Q770 Technical Service Manual

--11--

4. Geometric Distortion

All kind of Geometric Distortion

(Pincushion, Barallel, Parallelogram and Trapezoid) shall be with in 2mm boundary (to tolerance

frame) Refer to belows tolerance frame.

A2mm B 2mm

The tolerance frame sides are parallel to the window of enclosure axes.

B

A

Data Area

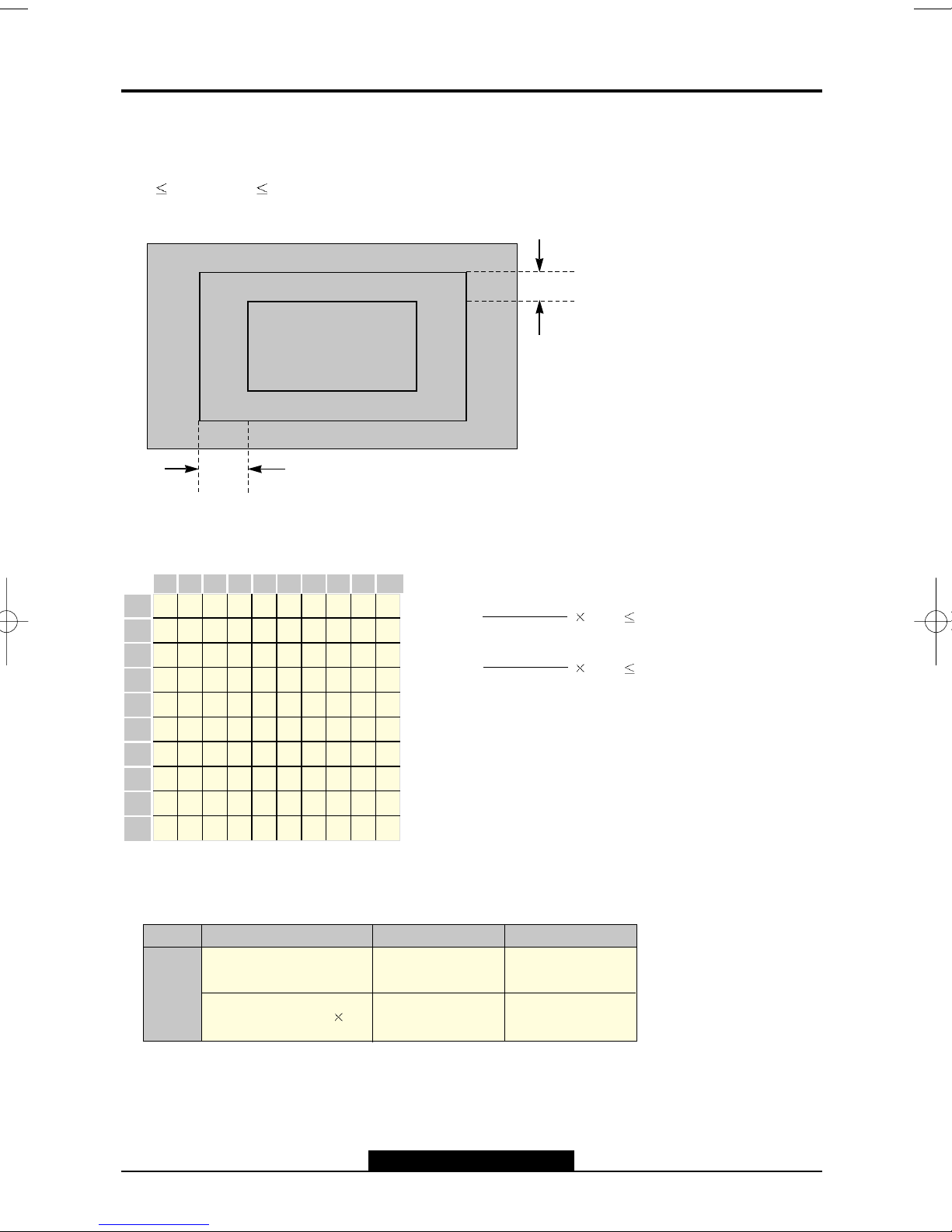

5. Linearity

The linearity of an image displayed on the CRT must meet the following requirements, with

reference to figure for both X and Y axis.

• Formula : 100 = 6% overall

• Where : X1=X2=....X16

Y1=Y2=....Y12

XMax- XMin

XMax+XMin

Y1

X1 ........X16

.

.

.

.

.

.

.

.

Y12

100 = 5% adjacent cells

XMax- XMin

XMax+XMin

6. Misconvergence

The display must confirm to all following requirements:

Maximum convergence error.

Area

MODEL

Q770

Horiz. Direction Vert. Direction

A

Central circle field

of(299) mm diameter 0.3mm 0.3mm

B

All screen Area (305 229)

except Area A 0.4mm 0.4mm

--12--

The maximum convergence error shall be measures for a white spot of line, and represents the

maximum distance between the energy centers of any two primary colors.

Power Management System

The automatic power management function saves electricity and reduces heat. Used in conjunction

with a PC having Power Management function, or a PC running Screen Blanking software, this monitor

automatically reduces its power consumption when the PC is not in use.

This monitor runs in four states:ON(Normal Operating), Stand-by(No Video Signal),

Suspend(Minimum Power for Quick Recovery) and OFF(Non-Operating).

This monitor is in complaince with U.S EPA Energy Star and NUTEK requirements.

Please refer to the following specifications.

(*) ; It is capable to select by user.

State Signals Power

consumption Recovery

time LED

Description

H-Sync V-Sync Video

Stage1 pulses pulses active 70W - Green

Stage1 no pulse pulses blanked

pulses no pulse blanked Less than

5W within

3 sec Orange

no pulse no pulse blanked

305mm

229mm

B

B

A

B

B

Active Area

Q770 Technical Service Manual

--13--

Trouble Shooting

1. Introduction

This trouble shooting guide is arranged by fault conditions. Following each fault condition is a check

for a signal on condition to be answered YES or NO.

For NO answer proceed to the right and continue until the fault is located.

For a YES answer continue in the left column to the next numbered check.

Again followed this procedure until the fault is located.

2. Trouble shooting procedure

When Troubleshooting this monitor, some precaution should be observed.

Use a high quality isolation tranformer is capable of providing 3 Amps or more.

Never connect primary ground and secondary ground together including use with an isolation

transformer.

Measure high voltage with respect to chassing ground only, and with a high impedance prove of 1000

mega-ohm or higher and rated for 30KV DC or higher.

Measure QH09 collector pulse with a high quality 100:1 probe rated for 1500 volts or higher.

3. Troubleshooting procedure

Symptom

a) Image is

scrolling.

b) Image is

unstable.

Check(YES)

1) Check for Vsync at pin 41 of ICM01

2) Check for positive going Vsync at

pin 2 of ICH01.

3) Will V-oscillator is locked with input

signal?

(pin 22 of ICH01)

4) Check V-ramp at pin 23 of ICH01.

5) Check V-out at pin 5 of ICV01.

1) Check for Hsync at pin 40 of ICM01

2) Check for positive going Hsync at

pin 1 of ICH01.

3) Will H-oscillator is locked

with input signal?

(pin 6 of ICH01)

4) Check H-out at pin 26 of ICH01

5) Check for flyback pulse at pin 12 of

ICH01.

Action(NO)

Check 15 pin D-sub connector, cable,

ZDM02.

Check ICM01, ICH01

Check CH01, CH02

Replace ICH01.

Check B+ at pin 2,4 of ICV01.

Check 15 pin D-sub connector, cable,

ZDM01.

Check ICM01 , ICH01

Check CH06, RH06

Replace ICH01

Check RH10

--14--

Symptom

c) Screen is black

but high voltage

is present.

d) Screen is black

with no high

voltage.

e) No power

Check(YES)

1) Check for G2, pin4 of CRT.

Around 500 volts?

2) Check for heater voltage at pin 6 of

CRT. (about 6.3V)

3) Can screen be lit with brightness

control at MAX?

4) Check for video at pin 5, 6, 7 of

ICC01

5) Check for positive pulse for clamp at

pin 23 of ICC01.

6) Check if contrast controls video level

at pin 18,19,20 of ICC01.

7) Check for video at pin 1, 2, 3 of

ICC03.

8) Check if R, G, B cut-off control the

video DC level at pin 6, 8, 11 of CRT.

9) Check CRT.

1) Is the LED01 lighting in Green color.

2) Check for 14V at collector of QP07.

3) Check output pulse at pin 26, 28 of

ICH01.

4) Check Hor-Drive pulse at Base of

QH09.

5) Check B+ at pin 2 of TH04.

1) Check ICP01 pin 4, 7

2) Check switch pulse at Drain of QP04.

3) Check voltage for, 55V at Cathode of

Dp11 and for 7V at Cathode of DP13

and for 14V at cathode of DP15

Check QP01, QP02, DP16, DP07

Check pin 6, 3 of ICP01, RP11

Recheck above Item(d).

Action(NO)

Check DH28, RH96, RH92, CH53, CRT

socket. G2 Wire

Check DP13, RP24, RP25, QP05

CRT socket. RC32, CNC01

Check DH21, DH25, QH18, QH19.

DH26 RH99. CRT socket.

Check 15 pin D-sub connector, cable,

DC4,5,6 Check

Check ICM01, RC13, CNC01

Check ICM01, ICC01, 5VDC (Pin9)of

ICC01

Check ICC03, 75VDC (pin 4)

12VDC(pin 8)

Check ICC04

Check H.V Sync at pin40, 41 of ICM01.

Check pin 8,9 of ICM01.

Check ICM01, ICM02,ICC03

Check QP07, QP08.

Check pin 10 of ICM01.

Check for Vcc at pin 29 of ICH01.

Check oscilation pulse at pin 6 of

ICH01.

Check X-Ray voltage below 8.0V at

pin 25 of ICH01.

Check RH11, RH12, RH13

Check QH08, TH01.

Check DH07, LH01, QH07, QH05

QH06, RH41, RH42, RH39, RH16,

ICH01

Q770 Technical Service Manual

--15--

Adjustment Method

1. Caution

Extremely high voltage are present in the area around the FBT(TH04) and the anode high voltage

Lead.

2. Equipment Required

Digital Voltmeter

Frequency Counter : about 40 Hz to 100 KHz

Color Analyzer

Video Signal Generator

High Voltmeter : up to 30 KV

Alignment Templete : Attachment 1

3. Before Adjustment

Verify that the video output level is 0.7 Vpp at 75 ohm termination and the video timmings are same

as standard timming given in specification. Place the AC power switch to the ON position.

Allow the monitor to stabillize thermally for 15 minutes at least before any adjustment about the

image parameters. The electron optics of the CRT and electronics of system require time of stabillize.

4. Adjustment Procedure

4-1 Horizontal raster center setting

- Video Signal : Back Raster pattern in 60kHz, 768 mode

- Measuring Point : SWH01, main board

- Place the Raster in center of the bezel.

4-2 Factory mode setting

- Turn off the power.

- Keep pressing the menu select key until the power turns on.

- Press the menu select key one more time.

- You can see the “F” message in 5the bottom on the right of the OSD main menu.

- This is the factory mode.

- Turn off the power to save the adjusted state.

- Select the "Mode Information" menu after you exit the factory mode.

4-3 Rotation setting

- Video Signal : Cross Hatch pattern in 31.5kHz, 400 mode

- Adjust the rotation of screen by using the menu select key and UP And Down Key.

4-4 Color setting

- Adhere color Analyzer sensor closely to CRT center.

- Set Factory mode.

- Video mode : 68.677kHz, 768 mode

--16--

1 Color Temperature 9300°K setting

- Select " 93 " by using the menu select key and up/down KEY.

Back Raster Setting

• Video signal : Back Raster Pattern

• Adjust the brightness of back raster by Using up/down KEY in “Bright”

• Limits : 2.5 0.5 cd/m2

Cut-off Setting

• Video signal : Back Raster Pattern

• Select “Cut-off” by using the menu select key and adjustment up/down KEY.

• Press the menu select key to get the desired R, G or B Cut-off.

• Adjust x and y color coord:nate by Using up and down key

• Limits : x=0.283 0.01, y=0.297 0.01

Drive Setting

• Video signal : 20% white box

• Select the "9300" by using the menu select key and R,G or B up/down KEY.

• Press the menu select key to get the desired R or B

• Adjust the x and y color coordinate by Using up and down key

• Limits : x=0.283 0.01, y=0.297 0.01

Contrast Setting

• Video Signal : 20% white box

• Adjust the brightness go to 0.1 cd/m2 by using the adjustment up/down KEY in “Bright”

• Adjust the brightness of 20% white box by using up/down Key in “contrast”

• Limits : 150 3 cd/m2

Back Raster Setting again

• The method of adjustment is same to section

2) Color Temperature 6500°K Setting

- Select " 65 " by using the menu select key and up/down KEY.

Back Raster, Cut-off Setting

• The method of adjustment is same to 9300°K

• The color coordinate is x=0.313 0.01, y=0.329 0.01

Drive, contrast Setting

• The method of adjustment is same to 9300°K

• The color coordinate is x=0.313 0.01, y=0.329 0.01

4-5 Geometry Setting

- Adhere template closely to the CRT surface

- Video Signal : Cross hatch pattern in 31.5kHz to 69kHz expectively.

- Adjust the all items by using the menu/select key .

1) Horizontal Position Setting

- Place the screen in center of the horizontal direction.

2) Horizontal Size Setting

-Adjust the horizontal size of the screen to 305 5 mm

ajust the honitonfal size of the screen to 260 4mm.

3) Vertical Position Setting

- ”Place the screen in center of the vertical direction.

4) Vertical Size Setting

- Adjust the vertical size of the screen to 229 5 mm

5) Pincushion Setting

- Make the straight line to the vertical right and left line of screen.

6) Trapezoid Setting

- Make the same size to the horizontal up and bottom size of screen.

7) Parallelogram & Pin Balance

- Adjust parallerogram until vertical lines are parallel to the vertical vezel.

8) Corner Pin

- Adjust corner pin until 4 corners are parallel to the vertical vezel.

9) Rotation Setting

- Adjust rotate until horizontal lines are parallel to the vezel.

Q770 Technical Service Manual

--17--

4-6 Focus

- Video Signal : Reverse " Full H " character pattern in 64kHz 1024 mode

- Adjust H/V Focus VR on the top and middle of the FBT so that the image of whole screen

looks clear

5. X-Ray Protection Test

- In any signal input condition, short RH12 (main board) by using the JIG.

- At this moment, check out whether raster disappears.

- Remove the JIG.

- After the power switch of the set off and on, check out proper working

6. AGING and Self Test Mode

The monitor has an enhanced level of self-diagonostics.

When the signal cable is removed The monitor is operated to self test mode(Following OSD

Image) and The Signal Isn’t detected, the monitor is operated to OFF-Mode.

Picture A (MODE FOR END USER)

(OSD MESSAGE is moving around the screen)

NO SIGNAL

NO SIGNAL

1024 768/ 75Hz

RGB

--18--

Specification

CRT

SIZE 17"(16" viewable) Diagonal

Dot Pitch 0.20 mm (Horizantal Dot Pitch)

Type Non-glare, Anti-Static & TCO Coated

Input Signal R.G.B Analog

Cable 15 pin D-Type male Connector

SYNC H-F 30 kHz 70 kHz(Automatic)

V-F

Video Bandwidth

50 Hz 150 Hz(Automatic)

108 MHz (-3dB)

Display Area(H V) Color 305 229mm (Max. Over Scan) Infinite

Resolution 1280 1024(64kHz/60Hz)

User Controls

&

OSD Controls

Max.

Recall, Brightness/Contrast, H/V-Position, H/V-Size,

Pincushion/Trapezoid, Rotation, H/V-Moire, Degauss,

Color Control, Parallel, Information, Language, OSD H/V

Poistion, Pin Balpance, Top/Botton-Corner, H/V-Linearity

Power Management As per VESA Standard, Lower than EPA's

recommendation

Compatibility

VESA DDC 1/2B Basic

VESA, 8514/A, XGA, EVGA, MAC II

Power Source 100-240 VAC(Universal Power) 70W 1.5A

Safety &

Regulation

TCO

EMC

Safety

Basic

FCC Class B, CE,EMC

cULus, TÜV-GS, SEMKO, DHHS, PCBC, GOST-R, VCCI

Temperature Storage

0 to 35 degree celsius

Operating

-20 to 60 degree celsius

Humidity Operating 35% to 80% (Non-condensing)

Storage 5% to 85%

Weight Unit : 15.5Kg • Gross Weight :17.5Kg(with carton)

Dimension(W HD mm)

Specification is subject to change without notice for performance improvement.

380 372 411mm

Critical Parts Specification

GENERAL DESCRIPTION

The WT62P1 is a microcontroller for digital controlled monitor with Universal Serial Bus(USB)interface.

It contains an 8-bit CPU, 32k bytes flash memory, 512 bytes RAM, 14 PWMs, parallel I/Os, SYNC signal

processor, time, DDC 1/2B interface, master/slave I2C interface, low speed USB device module, 6-bit

A/D converter and watch-dog timer.

FEATURES

• 8-bit 6502 compatible CPU with 6MHz operating frequency

• 32768 bytes flash memory, 512 bytes SRAM.

• 12 MHz crystal oscillator

• 4 channels processor with H+V separation , H/V frequency counter, H/V polarity

detection/control and clamp pulse output

• Sync signal processor with H+V separation, H/V frequency counter, H/V polarity detection/control

and clamp pulse output

• Six free-running sync signal outputs(Horizontal frequency up to 106KHz)

• Self-test pattern

• DDC 1/2B supported

• Fast mode master slave I2C interface(up to 400KHz)

• Embedded USB function with endpoint 0 and endpoint 1

• Built-In 3.3V regulator for USB tranceiver

• Watch-dog timer

• Maximum 28 progammable I/O pins

• One 8-bit programmable timer

• 6-bit A/D converter with 4 selectable inputs

• One external interrupt request input

• Low VDD reset

ORDERINF ING ORMATION

Q770 Technical Service Manual

--19--

MC68HC705BD7B

WT62P1

Package Type

42-pin PDIP

42-oin shrink PDIP

40-pin PDIP

28-pin skinny PDIP

44--pin SOP

Part Number

WT62P1-N42

WT62P1-K42

WT62P1-N40

WT62P1-N28

WT62P1-S44

Table of contents

Other ImageQuest Monitor manuals