IMC EAGLE 2 SOLR-2ELC-10 Guide

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

INSTRUMENTS, INC.

®

FREZE-PMP->ON

LOWTEMP-PMP>OF

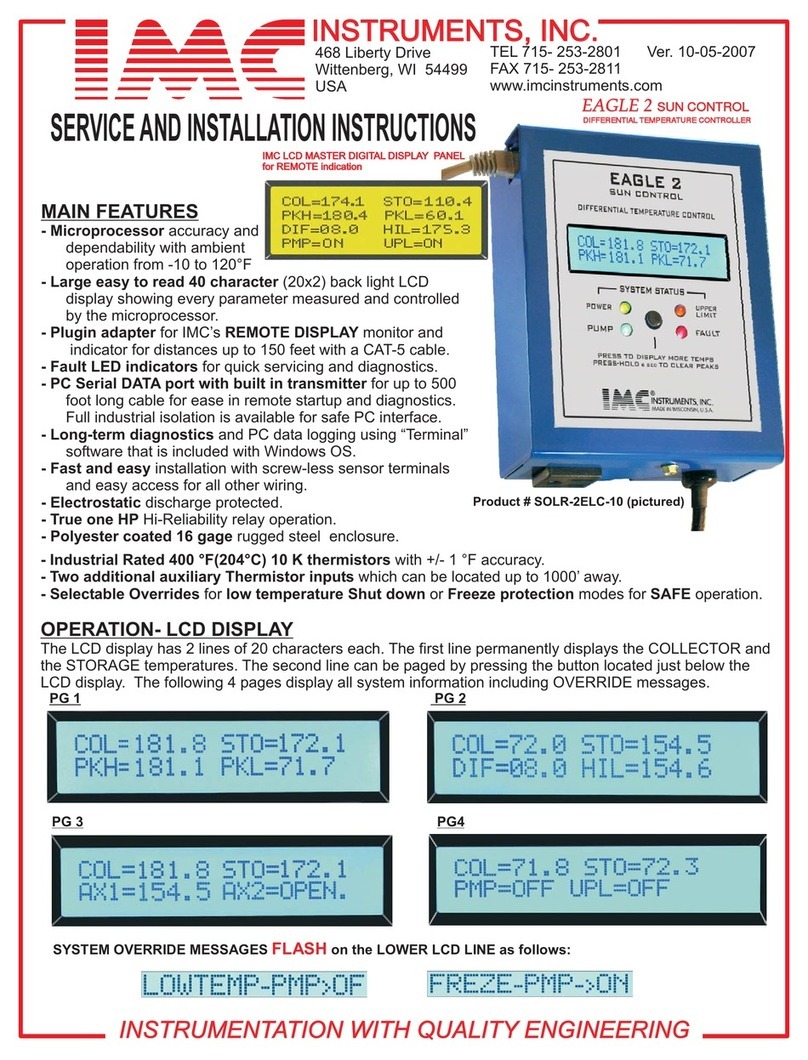

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

DI F=0 8 . 0 H IL= 17 5 . 3

PMP= O N UPL=ON

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

DI F=0 8 . 0 H IL= 17 5 . 3

PMP= O N UPL=ON

SYSTEM OVERRIDE MESSAGES on the LOWER LCD LINE as follows:FLASH

PG 4PG 3

PG 2PG 1

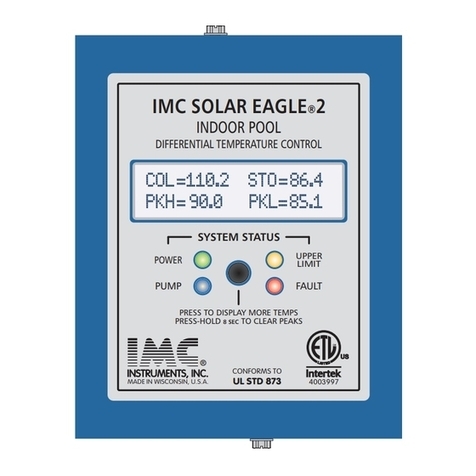

SUN CONTROL

DIFFERENTIAL TEMPERATURE CONTROLLER

SUN CONTROL

EAGLE 2

IMC’S LCD MASTER DIGITAL DISPLAY PANEL

FOR REMOTE INDICATION

P# SOLR-2ELC-10

LCD DISPLAY

The LCD display has 2 lines of 20 characters each. The first line permanently displays the COLLECTOR and the

STORAGE temperatures. The second line can be paged by pressing the button located just below the LCD

display. The following 4 pages display all system information including OVERRIDE messages.

- Two industrial 400°F (204°C) rated 10 K thermistors with +/- 1°F accuracy are included.

- Two auxiliary thermistor inputs for optional sensors that can be located up to 1000’ away.

- Selectable overrides for low temperature shut down or freeze protection modes for safe operation.

MAIN FEATURES

- Microprocessor accuracy and

dependability with ambient

operation from -10 to 120 F

- Large easy-to-read 40 character (20x2) backlit LCD

display showing every parameter measured and

Controlled by the microprocessor.

- PC DATA PORT with built-in transmitter allows optional

adapter and up to 500 ft. cable to interface with computers

for ease in startup and remote diagnostics. Or, for adding

an Optional large 80 character (4x20) backlit LCD display.

Remote-mount up to 150 ft. distances with a CAT-5 cable.

- Long-term diagnostics and data logging is possible using

communications software that is included in Windows’ OS.

- Fault LED indicators for quick servicing and diagnostics

- Features for fast installation and wiring

- Electrostatic discharge protected

- One HP or 20 AMP high reliability relay

- Polyester coated 16 gage rugged steel enclosure

- Model available with receptacle & power cord or with 1/2”

conduit holes for higher current permanent wiring

°

SERVICE AND INSTALLATION INSTRUCTIONS

Tel:715- 253-2801 Ver.11-01-2008

Fax:715- 253-2811

Web: www.solar.imcinstruments.com

468 Liberty Drive

Wittenberg, WI 54499

U.S.A.

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

INSTRUMENTS, INC.

®

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

AX1=-10.5 AX2= 17 5 . 3

PMP= O N UPL=ON

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

AX1=-10.5 AX2= 17 5 . 3

PMP= O N UPL=ON

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

DI F=0 8 . 0 H IL= 17 5 . 3

PMP= O N UPL=ON

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

DI F=0 8 . 0 H IL= 17 5 . 3

PMP= O N UPL=ON

PAGE 2

PAGE 1

An IMC LCD MASTER DIGITAL DISPLAY PANEL can also be connected to the DATA PORT. It has an RJ-45

jack and is supplied with a 3 foot long cable that can be substituted with a standard CAT5 cable up to150 feet long.

These ethernet cables are available at most retail stores. The display panel also has a PEAK RESET button

located on the side to reset previous STORAGE temperature peaks.

The Information on the LCD MASTER DISPLAY PANEL is displayed as follows:

COLLECTOR TEMPERATURE

STORAGE TEMPERATURE

DIFFERENTIAL CONTROL SETTING

HI LIMIT CONTROL SETTING

PUMP STATUS

UPPER LIMIT STATUS

PEAK HI= MAXIMUM TEMPERATURE

PEAK LO= MINIMUM TEMPERATURE

AUXILIARY SENSORS 1 AND 2

This Master LCD has a second page that will

display the auxiliary sensor temperatures.

To display, press and release the PAGE/RESET

button on the side of the display housing.

The auxiliary sensors will be displayed within 2

seconds. To RESET the STORED PEAK

temperatures of the storage tank, press and hold

for 6 seconds the PAGE/RESET button. The

current temperatures will appear after the button

is released. The Master LCD display is updated

every 2 seconds.

DATA-PORT

Requires an IMC Data-Port ADAPTER that will allow interface to a standard computer’s serial RS232 port. The

ADAPTER can also accept a serial to USB converter to connect directly to portable computers that only have

USB ports. If wireless operation is desired for short distances, BLUE TOOTH transceiver can also be

connected. The rate at which the data is sent from the EAGLE solar controller is determined by a jumper in the

controller as show in the CONTROLLER diagram on page 4. If the jumper is placed on position labeled “2S”,

one complete line of “total system information” will be sent to the computer every 2 seconds which is necessary

when performing diagnostics or a system startup. If the same jumper is placed on position labeled ”6M”, then

data will be sent every 6 minutes. This will allow a more suitable data-send rate for long-term DATA LOGGING,

specially when storing the data in a “CAPTURE” file setup in the computer’s communications program such as

“Terminal” or “Hyper Terminal”.

SAMPLE DATA PORT PRINT

RUNTIME COLL-T STOR-T DIFF-T HILI-T AUX-1 AUX-2 PUMP UPLim FAULT

0:00 125.9 73.7 08.0 110.0 212.2 205.4 ON OFF System collecting solar HEAT

0:06 25.9 73.7 08.0 110.0 212.2 205.4 OFF OFF LO-TMP->OFF System in LO TEMP shut down PUMP->OFF

0:12 25.9 73.7 08.0 110.0 212.8 205.4 ON OFF PmpSW! Pump switch ON

0:18 OPEN.S 73.9 08.0 110.0 212.8 205.4 OFF OFF SENS!, PmpSW! Open sensor, pump switch OFF

0:24 -16.0 74.7 08.0 110.0 25.9 184.6 ON OFF FREZE-PMP->ON System in Freeze protect mode PUMP->ON

0:30 SHRT.S 74.9 08.0 110.0 25.9 154.6 OFF OFF Shorted sensor->System OFF

0:36 125.9 173.7 08.0 173.0 112.2 95.4 OFF ON Storage reached UPPER LIMIT

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

INSTRUMENTS, INC.

®

IMPORTANT NOTICE

These EAGLE Series Temperature Controls are intended to control equipment under normal operating

conditions. Where failure or malfunction of EAGLE Series Control could lead to an abnormal operating condition

that could cause personal injury or damage to the equipment or other property, other devices (limit or safety

controls) or systems (alarm or supervisory) intended to warn of or protect against failure or malfunction of the

EAGLE Series Control must be incorporated into and maintained as part of the control system.

°°

°

°

°

°

CONTROLLER OPERATION

TEMPERATURE DIFFERENCE CONTROL- When the temperature difference between the sensor on the

solar collector and the sensor in the storage tank exceeds the dialed temperature difference setting (ON DIF),

the PUMP relay will actuate after a 30 second delay. The BLUE LED indicator will also turn ON. When the

temperature difference decreases and falls below 4 F (2.2 C), the PUMP relay and the BLUE LED indicator will

turn off without delay.

HIGH LIMIT CONTROL- When the temperature in the storage tank exceeds the HI-LIMIT dialed setting, the

PUMP relay will be turned OFF without delay regardless of the status of the temperature difference that exists

between the STORAGE tank and the solar COLLECTOR. The BLUE LED indicator will also turn OFF. When

the storage tank temperature falls 4 degrees below the setting in the HI-LIMT, the controller will then resume

normal operation. The PUMP relay will always have a 30 second delay before switching ON and the BLUE LED

will always show its STATUS condition.

LOW TEMPERATURE SHUT-DOWN OVERRIDE- This feature is available to prevent the system from

operating at low outdoor temperatures. If this feature is enabled, normal operation will stop when the

COLLECTOR temperature falls below 50 F. The PUMP relay will then be turned OFF. Normal control

operation will not resume until the COLLECTOR temperature returns to 70 F or above. To enable this feature,

a jumper must be placed onto the jumper pins marked “LO’ on the circuit board. Only ONE of these two

override features can be enabled.

FREEZE PROTECTION OVERRIDE- This feature is available to prevent a non-drain back “water only” system

from freezing when the outdoor temperature drops too low. If this feature is enabled normal operation will stop

when the COLLECTOR temperature falls below 37 F. The PUMP relay will then be turned ON until the

COLLECTOR temperature reaches 52 F. Normal control operation will resume above this temperature. To

enable this feature, a jumper must be placed onto the jumper pins marked “FZ’ on the circuit board. Only ONE

of these two override features can be enabled.

STATUS INDICATION LEDS- There are four status indication LEDS. The GREEN LED indicates that the

microprocessor is POWERED and the SOLAR controller is running. The BLUE LED indicates PUMP operation.

When ON, the PUMP is operating and solar energy is being stored in the STORAGE tank. The AMBER LED

indicates if the UPPER LIMIT temperature in the storage has been exceeded. The RED LED indicates when

there is a fault condition. The conditions that can cause the fault LED to turn ON are as follows: OPEN or

SHORTED or OUT of RANGE temperature SENSORS, pump RELAY SWITCH NOT set to “AUT” (automatic)

position and internal component malfunctions. The RED LED will always be FLASHING when the FAULT

indication is ON

SENSORS- Industrial 400°F (204°C) rated 10K IMC thermistors have +/- 1°F accuracy. When installed, they

will not exceed ONE degree of additional error for cable distances up to 1000 feet of 18ga., 700 feet of 20ga. or

500 feet of 22ga.

SENSOR SCREW TERMINALS- There are 9 screws on a GREEN block located at the top edge of the board.

These terminals accept solid or stranded wire from 18ga. to 22ga. They are NEC class 2 circuit connections.

POWER AND RELAY TERMINALS- The power terminals are for 120 vac operation (230 vac operation is

optional). Use solid wire in 16 or 18 ga. and stranded (19 max) in 12 or 14 ga. The power RELAY is rated for 20

Amps and is designed to connect directly to PUMPS or FANS not exceeding a total of 1 hp. A 30 amp.

(resistive load) board option is available. Current and voltage ratings will vary for models with cords and

receptacles. See model label for specific ratings.

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

AX1=-10.5 AX2= 17 5 . 3

PMP= O N UPL=ON

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

DI F=0 8 . 0 H IL= 17 5 . 3

PMP= O N UPL=ON

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

INSTRUMENTS, INC.

®

INSTALLATION

MOUNTING- The Eagle line of SOLAR controllers are designed to be mounted indoors, protected from rain and

condensing moisture. Use two #10 screws in the enclosure “keyholes” for mounting.

POWER WIRING- Hard wired models are designed for 120 vac operation unless special ordered. If relay is

wired to switch any voltage other than 120 vac then the “20 AMP RELAY JUMPER” MUST BE REMOVED. Use

solid wire in 16 or 18 ga. and stranded (19 max) in 12 or 14 ga. Same gage and stranding must be used under

both sides of each clamping washer. All wiring must be done in accordance with local codes. Models supplied

with line cords and receptacles are to be connected directly to power outlets without the use of extension cords.

Line and power wires should NOT be bundled with or placed in the same conduit with sensor or data cables.

SENSOR INSTALLATION AND WIRING- Sensor installation should be in a manner as to permit proper sensor

contact of the areas to be measured. Shield and/or insulate the sensors to prevent them from being affected by

the surrounding ambient temperatures. Sensor wiring installed outdoors must be rated for OUTDOOR use.

It is recommended in today’s Radio interference “RICH” environment that all sensor wiring be shielded.

The cable SHIELDS must be brought to the shield grounding terminal that is the rightmost position on the

GREEN terminal block. See controller layout diagram. For ease of shield installation, insert one short wire in

the shield terminal labeled “SHLD” and connect all the shields together with a “wire-nut”or other reliable means.

Ungrounded shields may result in damage to the Solar controller circuits. The shield requires grounding at the

controller side ONLY. DO NOT attempt to ground the collector panel with the sensor shield.

For efficient and reliable wire connections, strip 3/8” (slightly shorter than block width) of insulation from an

undamaged wire end. Use a strip tool that will not nick the conductors. If wire is solid, make sure that the tip is

NOT pinched or deformed so that it will fit into the terminal hole easily. If the wire is stranded, make sure the

strands are tightly twisted. Using a elect the appropriate screw and turn

CCW to open the terminal hole fully. Then guide the wire into the terminal hole and hold while tightening (turn

CW) the screw to clamp the wire.

slip off the

screw and damage any circuit components. If the wire is stranded, make sure that ALL the strands are properly

clamped in the terminal.

COLLECTOR GROUNDING- The Solar collector panel array “must be GROUNDED’ directly to an earth

ground line. This is necessary to prevent damage from nearby lightening strikes which induce very

DAMAGING high voltages in all nearby ungrounded metallic surfaces. Please consult local, state and federal

codes for proper grounding.

DATA LOGGING TO ACOMPUTER- All the EAGLE Solar controllers can be connected to the serial port of a

PC or Laptop computers. An IMC DATA PORT/RS232 adapter is required. The maximum recommended

adapter cable length is 500 feet. All Windows operating systems have a communications programs such as

“Terminal” or “Hyper Terminal” which are used to receive and/or CAPTURE data from the PC’s serial port.

This feature is “EXTREMELY” valuable in starting up newly installed SOLAR systems. Long-term data

logging is now possible which can be very useful in service and diagnostics of intermittent malfunctions.

Complete “system status” including temperature is presented in a line by line format including timer

information. In applications were the computer’s interface is going to be permanent it is recommended that

the EAGLE WEB model be used in order to protect the connecting computer from electrical surges.

Please visit our website for news or more detailed instruction at “www.solar.imcinstruments.com”.

All

connections exposed to the weather must be made with waterproof “outdoor” rated connectors.

Listed

below are a few suggested wire part numbers. Wire selected must also meet local codes and be rated for

indoor/outdoor use by its manufacturer.

1) “PLTC” Belden # 9322 (22ga) or 9320 (20ga) Best specifications

2) “Control” Belden # 8761 (22ga) or 8762 (20ga) Better specifications

3) “Audio” Belden # 9451-10 Black (22ga) Acceptable specifications

1/8" (3mm) wide blade screwdriver, s

WARNING- If a 5/32" (4mm) wide screwdriver blade is used, the screw

retaining edge of the hole will be scraped off allowing the screw to fall out. DO NOT reverse the screw turning

directions and place the wire outside the metal CAGE creating an unreliable connection. DO NOT

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

INSTRUMENTS, INC.

®

HIGH LIMIT DIAL-ADJ.

KNOB STYLE VARIES

POWER INPUT/OUTPUT:

120VAC 10% 50/60 HZ±

CORD WITH 5-15P PLUG

10 A (18AWG CORD)

13 A (16AWG CORD)

15 A (14AWG CORD)

6 ½FT LG.

PR# SOLR-2ELC

MOUNT ENCLOSURE WITH 2 #10 SCREWS SPACED 5.25 IN.

RECEPTACLE 5-15R

SWITCHED UNFUSED:

15 A (1HP) MAX. PER

CORD RATING

DIFFERENTIAL

DIAL-ADJ.

KNOB STYLE VARIES

Product #

SOLR-2ELC-10, -15

With Line Cord &

Receptacle

RJ-45

HIGH LIMIT DIAL-ADJ.

KNOB STYLE VARIES

CIRCUIT POWER (2.4W):

EG- EARTH GROUND

N- NEUTRAL (WHT)

L - 120VAC 10% (BLK)±

MOUNT ENCLOSURE WITH 2 #10 SCREWS SPACED 5.25 IN.

FOUR ½” CONDUIT

HOLES HERE & SIDES

DIFFERENTIAL

DIAL-ADJ.

KNOB STYLE VARIES

120 VAC 20 AMP

RELAY JUMPER

POWER WIRING PER

LOCAL CODES-

USE 16,18 GA. SOLID;

12,14 GA. STRANDED.

1 OR 2 OF SAME GA.

UNDER EACH CLAMP

RELAY (PUMP/FAN):

(UL & CSA LISTED)

WITH 120V JUMPER

NO- 20 A RES; 1 HP

NC- 20 A RES; 1/4 HP

WITHOUT JUMPER

COM- 250 VAC

NO- 20 A RES; 2 HP

NC- 20 A RES; 1/2 HP

TEMPERATURE

SENSORS (4):

SHD- CABLE SHIELDS

COL- COLLECTOR

STO- STORAGE

AX1 & 2- OPTIONAL

USE 1/8” WIDE BLADE

SCREW DRIVER.

TURN CCW TO OPEN

HOLE FOR WIRE

(22 TO 18 GA)

OVERRIDE JUMPERS: (ONE OR NONE)

FZ- FREEZE PROTECT (37 ON 52 OFF)

LO- LOW LIMIT COL (50 OFF 70 ON)

RELAY (PUMP)

OVERRIDE SWITCH

AUT- NORMAL SETTING

DATA PORT:

REMOTE DISPLAY

OR

COMPUTER RS232

UPDATE INTERVAL

6 MIN. 2 SEC.

PR# SOLR-2EHW-20 REV: 10-27-08

Product #

SOLR-2EHW-20

With Conduit Holes

for Hard Wiring

* 230 VAC Input Power is optional

** 120VAC Relay Jumper MUST be removed

*** 30 Amp configured model is available

Relay Action: 30sec delay ON; no delay OFF

Differential: Adjustable 8 to 24 F; fixed 4 F reset

High Limit: Adjustable from 110 to 200 F

Accuracy: +/- 1 F

Sensors: 10K @ 77 F (25 C) Rated to 400 F

Environmental: -10 to 120 F @ 0 to 95 %RH

Dimensions: 5.00”W x 6.12”H x 2.50”D

Weight: Appx. 2.0 lbs without power cord

°°

°

°

°° °

°

Input Power: 2 Watts @ 120VAC*

Relay Contact Ratings:

#832 UL #E88991, CSA #1429333

Common (CM)-

30VDC MAX. or 250VAC MAX.**

Normally Open (NO)-

20A resistive*** @ 120VAC & 250VAC**

1 HP @ 120VAC; 2 HP @ 250VAC**

20A @ 30VDC**; TV-5

Normally Closed (NC)-

20A resistive*** @ 120VAC & 250VAC**

1/4 HP @ 120VAC; 1/2 HP @ 250VAC**

15A @ 30VDC**

SPECIFICATIONS

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

ACTUAL SIZE DISPLAY

when printed booklet size

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

AX1=-10.5 AX2= 17 5 . 3

PMP= O N UPL=ON

ACTUAL SIZE DISPLAY

when printed booklet size

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

INSTRUMENTS, INC.

®

Includes electronic circuits

inside the DB-9 connector

housing.

PC Data-Port Adapter RS-232*: SOLR-DA10

Connects directly to the EAGLE controller DATA-PORT and permits serial PC communication at

2400 BAUD rate. * non-isolated

Adapter has a 7 foot cable terminated with an RJ-45 plug.

EAGLE “web” controller with

a 2500 volt isolated PORT is

recommended for long-term

or permanent installations.

Immersion style:

4"long with 1/4NPT fitting- SOLR-TS04

1/2NPT fitting- SOLR-TS24

8"long with 1/4NPT fitting- SOLR-TS05

1/2NPT fitting- SOLR-TS25

Screw-in style: SOLR-TS03

1/2-NPT threaded plug

Bolt-on style: SOLR-TS02

ACCESSORIES

THERMISTOR TEMPERATURE SENSORS-

O

RATED TO 400 F:

CONTROLLERS(120vac power) RATING PRODUCT #

With line cord & receptacle - 10 Amp SOLR-2ELC-10

15 Amp SOLR-2ELC-15

With conduit holes for permanent wiring - 20 Amp SOLR-2EHW-20

30 Amp SOLR-2EHW-30

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

INSTRUMENTS, INC.

®

ACTUAL SIZE DISPLAY

when printed booklet size

ACTUAL SIZE DISPLAY

when printed booklet size

* IMPORTANT NOTICE

Do NOT attempt to connect any

ETHERNET device or any other non-

IMC devices to the RJ-45 DATA-PORT

of any IMC CONTROLLER or

accessory. This will result in damage

to the connected equipment. Connect

ONLY devices specifically designed by

IMC Instruments to be connected to

these ports.

ACCESSORIES continued

LCD MASTER DIGITAL DISPLAY PANEL- SOLR-RD80

Displays temperature and status indication with 80 characters (4x20) 1/4” high.

Supplied with a 3’ foot CAT-5 cable that connects directly to the EAGLE controller Data-Port*.

Housing dimensions are 4.33” (110mm) wide x 2.34” (82mm) high x 1.73” (44mm) deep.

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

AX1=-10.5 AX2= 17 5 . 3

PMP= O N UPL=ON

COL=174.1 STO= 1 10 . 4

PKH =18 0.4 PKL= 6 0 . 1

AX1=-10.5 AX2= 17 5 . 3

PMP= O N UPL=ON

ACTUAL SIZE DISPLAY

when printed booklet size

ACTUAL SIZE DISPLAY

when printed booklet size

INSTRUMENTATION WITH QUALITY ENGINEERING

INSTRUMENTS, INC.

VER: 11-01-08 PRINTED IN U.S.A.

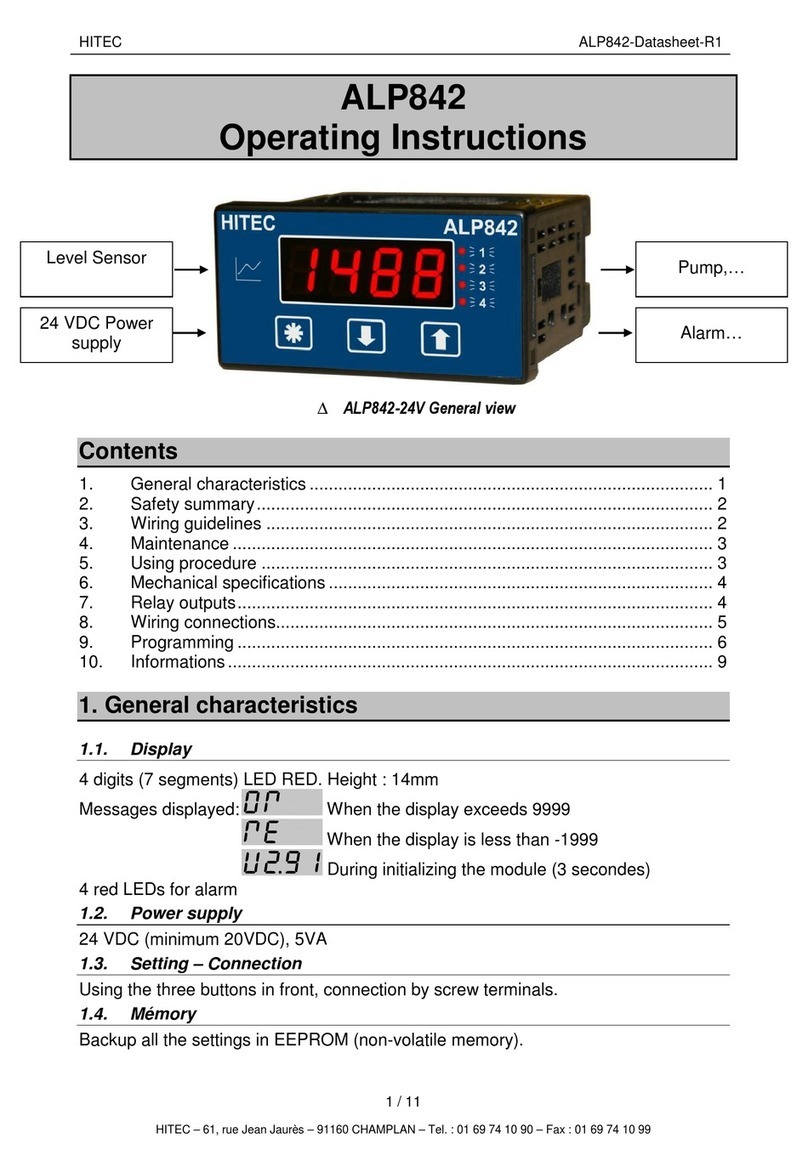

Table of contents

Other IMC Controllers manuals

Popular Controllers manuals by other brands

Hobby-Wing

Hobby-Wing Platinum HV 200A SBEC V4.1 user manual

Hi-Tec

Hi-Tec ALP842 operating instructions

Secu-tech

Secu-tech LC200 Operating instruction

Ink Bird

Ink Bird ITC-2000 user manual

Timeguard

Timeguard SLW360L Installation & operating instructions

COLORKINETICS

COLORKINETICS PDS-60CA installation guide