500 Series Food Waste Disposer 1

GUARANTEE

This machine is guaranteed by IMC for 1 Year from the date of purchase from

IMC or from one of its stockists, dealers or distributors.

The guarantee is limited to the replacement of faulty parts or products and

excludes any consequential loss or expense incurred by purchasers. Defects

which arise from faulty installation, inadequate maintenance, incorrect use,

connection to the wrong electricity supply or fair wear and tear are not

covered by the guarantee.

PLEASE OBSERVE THESE INSTRUCTIONS CAREFULLY

This guarantee applies in this form to installations within the UK only.

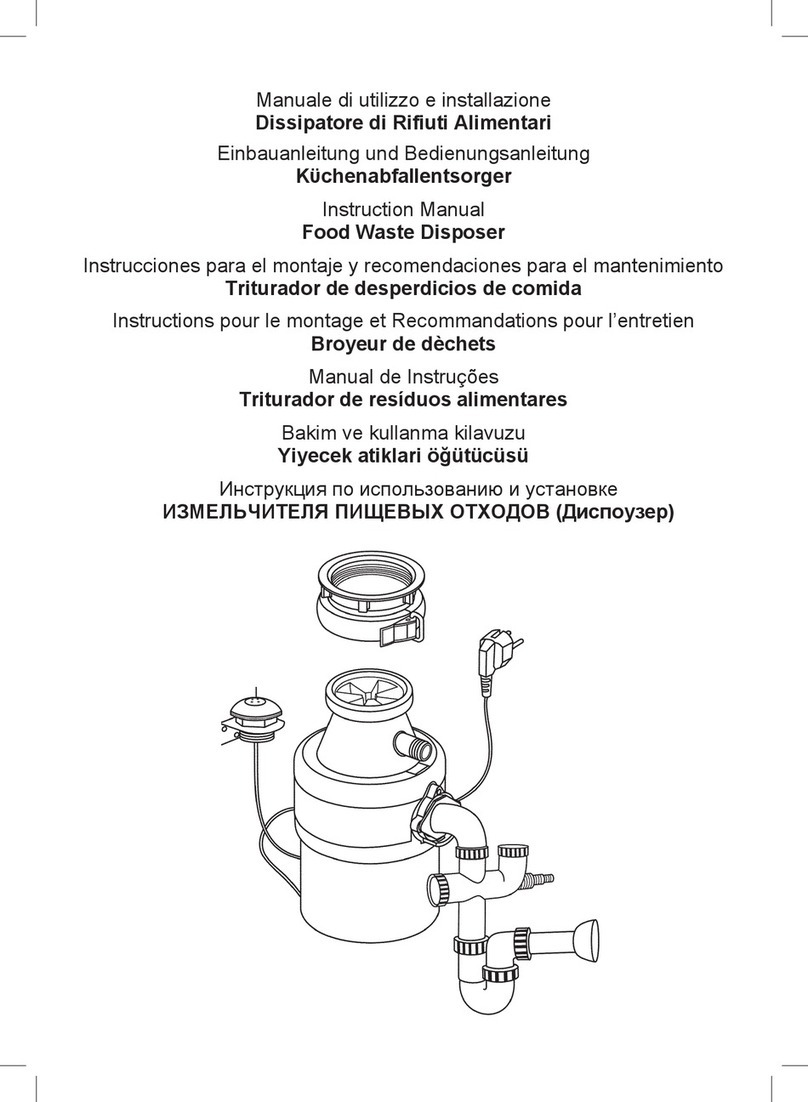

WASTE OUTLET CONNECTION

All 500 Series Disposers are fitted with a neoprene housing which is designed

to couple to a 42mm copper or plastic fitting, lead piping should not be used.

The size of the waste outlet must not be reduced. A running trap should be

fitted although ‘P’ or ‘S’ type traps can be used. Do not fit a bottle trap. The

length of run between the machine and the main junction must be kept to a

minimum and the pipe must have a positive fall of at least 1 in 7. Changes of

direction should be made with swept bends rather than elbows, and cleaning

eyes should be fitted where possible, in accordance with standard plumbing

practice.

The waste outlet position can be changed by loosening the hose clip at the

top of the neoprene housing. The motor and housing can then be rotated until

the outlet is in the required position. Tighten the hose clip once the outlet is in

the required position.

All Waste Disposers must have an independent drain pipe that does not also

serve sinks, dishwashers or similar equipment. The end of the waste pipe

must be beyond any grease traps and if the outlet feeds into an outside gully,

the pipe should enter the gully below the covering grid. Use a back entry yard

gully.

When fitting the trap make certain that the top invert of the trap lies below the

rubber outlet spout of the waste disposer. Failure to do this will prevent the

machine from draining completely. Also ensure that on all models the outlet

tail does not enter the outlet spout beyond the register, if this tail is fitted to

deeply into the spout it will obstruct the outlet flow

The 523 Disposer is sink mounted and the neoprene housing contains an inlet

boss for the sink overflow near the top of the housing. If this is required the

center of boss needs to be cutout before the overflow is connected.