IMC IMCHX-007 Series User manual

!

1!

!!

!

IMCHX'007!Series!of!Ultrasonic!Soft!

Tube!Sealing!Machinery!

!

INTERNATIONAL)MACHINE)CONCEPTS)WELCOMES)YOU)TO)YOUR)NEW)

MACHINE)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

)

Operation!Manual:!Date!2016.!!

!

!

2!

!

CONTENTS'

Chapter'1'

Machine!Description!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!1.1!

Uncrating!Instructions!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!1.2!

Installation!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!1.3!

Electrical!and!Pneumatic!connections!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!1.4!

Chapter'2'

Technical!Parameters!and!Description!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!2.1!

Chapter'3'

Operation!Instruction!

Machine!layout!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!3.1!!!

HMI!Touch!Screen! 3.2!!!!!!!!!!

Operation!process!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!3.3!!!

Chapter'4'

Malfunctions!(Faults)!and!their!rectification!

Table!of!possible!faults!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!4.1!

Chapter'5'

Electrical!diagram!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!5.1'

Chapter'6'

List!of!Spare!Parts!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!6.1!

'

'

'

'

'

!

3!

Chapter'1'

1.1 Machine'Description'

'

This!machine!was!used!high'quality!imported!and!domestic!parts,!Designed!and!made!by!

professional!engineers!and!technicians!with!advanced!technology.!This!machine!has!simple!

operation,!low!failure!rate,!etc.!

Use!ultrasonic!to!weld!plastic!soft!tube!tail.!Do!not!need!any!adhesive!or!filler!or!solvent!when!

welding,!do!not!consume!large!amounts!of!heat,!and!easy!to!operate,!high!welding!speed,!

high!efficiency.!

This!machine!is!widely!used!in!toothpaste,!cosmetic,!medical!product,!food!and!industrial!

tubes!etc!

!

1.2 Un=crating'Instructions'

'

During!un'crating!make!sure!that!no!physical!damage!to!the!outside!of!the!crate!has!taken!

place.!Carefully!break!open!the!exterior!panels!to!reveal!the!machine!and!its!working!parts.!

The!machine!will!be!covered!in!a!plastic!protective!cover.!This!is!to!be!removed.!Make!sure!

that!no!parts!have!been!damaged!during!transport,!or!fallen!off!the!machine.!The!machine!will!

arrive!with!certain!parts!dis'assembled.!These!need!to!be!fitted!to!the!machine!!to!resemble!

the!photos!above!the!machine.!The!machine!is!fixed!to!the!wooden!pallet!by!four!metal!

brackets.!Remove!these!brackets!and!discard!or!keep!for!future!use.!The!doors!and!covers!

have!been!taped!closed!for!safety!reasons,!these!taped!parts!can!now!be!opened.!Surface!rust!

can!take!place!due!to!the!excessive!sea!sir!during!shipping.!This!will!only!be!surface!rust!and!a!

dry!cloth!should!be!used!to!remove!this!rust!residue.!The!entire!machine!has!bee!shipped!with!

an!oil!coating!on!the!surface!to!safeguard!the!machine!from!corrosion.!This!can!now!be!

removed!with!a!very!light!detergent.!The!non'stainless!steel!parts!should!be!re'oiled!to!

prevent!rusting!taking!place!after!cleaning.!Do!not!leave!the!machine!wet.!

!

The!machine!is!top'heavy!and!as!such,!care!should!be!taken!when!handling!the!!machine!and!

removing!it!from!its!wooden!pallet.!

!

NOTE:!DO!NOT!HANDLE!THE!MACHINE!ON!THE!FILM!BRACKETS!OR!ROLLERS.!These!parts!are!

critically!aligned!and!should!they!be!bent!out!of!position!the!film!may!run!off.!

!

!

1.3 Installation'

'

!Only'a'qualified'technician'should'perform'the'machine'installation'or'a'suitably'trained'

person.'

!

4!

Note:'it!is!dangerous!to!work!on!a!moving!machine!and!the!machine!should!be!off!and!

isolated!before!any!form!of!work!is!performed.!

!

•Machine!should!be!placed!in!a!well'ventilated!room,!free!from!dust!and!excessively!

corrosive!materials.!

•There!should!be!at!least!1,5m!space!around!each!side!of!the!machine!for!convenient!

operation!and!maintenance.!

•Prepare!the!power!supply!380V!or!220V/50HZ.!Three/Single!Phase!and!neutral,!and!

connect!to!an!appropriate!earth!wire.!

!

•Pneumatic!connections!should!take!place!as!the!designated!connection.!The!air!should!

not!be!less!than!6Bar!while!the!machine!is!operational.!Air!should!be!free!of!water!and!

contaminants.!

•The!machine!should!be!placed!on!level!ground.!After!installing!the!machine,!check!if!the!

machine!is!level!by!Level!Instrument.!If!not,!please!adjust!the!four!legs.!

•Check!every!part!of!the!machine!carefully!for!damage!during!shipping.!Tighten!any!loose!

parts,!screws!and!moving!parts.!

•All!gearboxes!should!be!checked!for!sufficient!oil.!

•Check!all!electrical!connections!for!loose!wires.!

•Make!a!test!of!the!machines!electrical!power!and!confirm!the!voltage!and!earth!

continuity.!All!safety!connections!relative!to!your!own!country!should!be!adhered!to.!

•Before!operating!the!machine,!please!lubricate!the!following!parts:!across!sealing!bearing!

and!its!bearing!holes,!longitudinal!where!sealing!the!parts!needs!oil.!

!

1.4'''''''Electrical'and'Pneumatic'connections'

This!machine!requires!only!a!single!phase!connection!and!earth!wire!

!

!DISCLAIMER!

IMC!will!not!be!held!responsible!for!incorrect!installation!and!subsequent!failure!of!the!

machine!due!to!any!installation!procedure!not!being!followed.!

!

!

!

'

'

'

'

'

'

!

5!

Chapter'2'

2.1'Technical'Parameters'and'Description'

'

Rated!Voltage!

AC220V!50/60HZ!singe!phase!

Sealing!Diameter!!

5'50mm!

Max!tube!height!

5'250mm!

Machine!Power!!

1.5KW!

Production!Speed!

8'16!tubes/min!

Outline!Dimension!

850x600x640mm!

!

!

!

!

!

6!

Chapter'3'

3.1'Machine'layout''

'

'

'

'

'

'

'

'

'

'

'

'

'

'

'

'

'

'

!

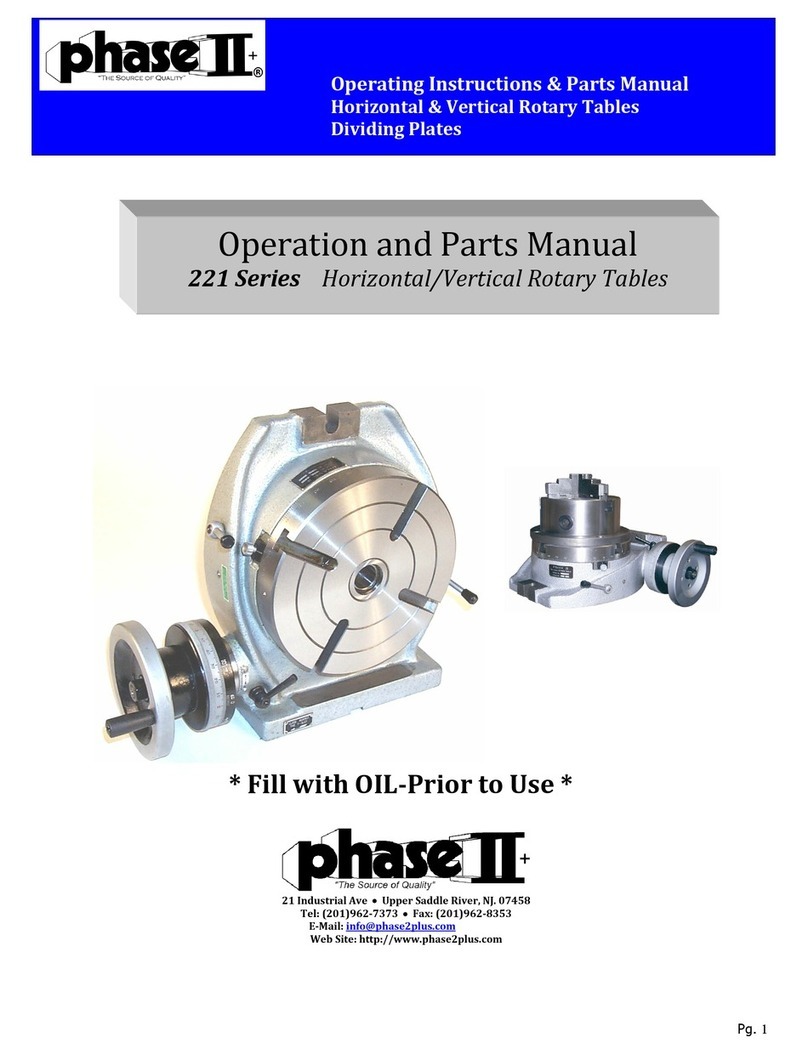

1.!Main!body!! 11.!PLC!

2.!Sensor!!!!12.!Holder!

3.!Tube!Height!adjustment!!!13.!Mould’s!gap!adjustment!!!

4.!Front!mould!! 14.!Power!lamp!

5.!Back!mould!! 15.!Power!switch!!!!!!!!!!!!!!!!

6.!Cutter!! 16.!Operational!plate!!!

7.!Gas'pressure!meter!!!17.!Tune!

8.!Gas'pressure!adjustment!! 18.!OSC!check!

9.!Emergency!button!! 19.!Over!load!lamp!

10.!Start!button!! 20.!Loading!meter!

!

'

Remark:!Please!check!the!front!mould!screw,!if!it!is!tightly!locked,!during!the!!

transportation!the!screw!can!become!loose!

!

!

7!

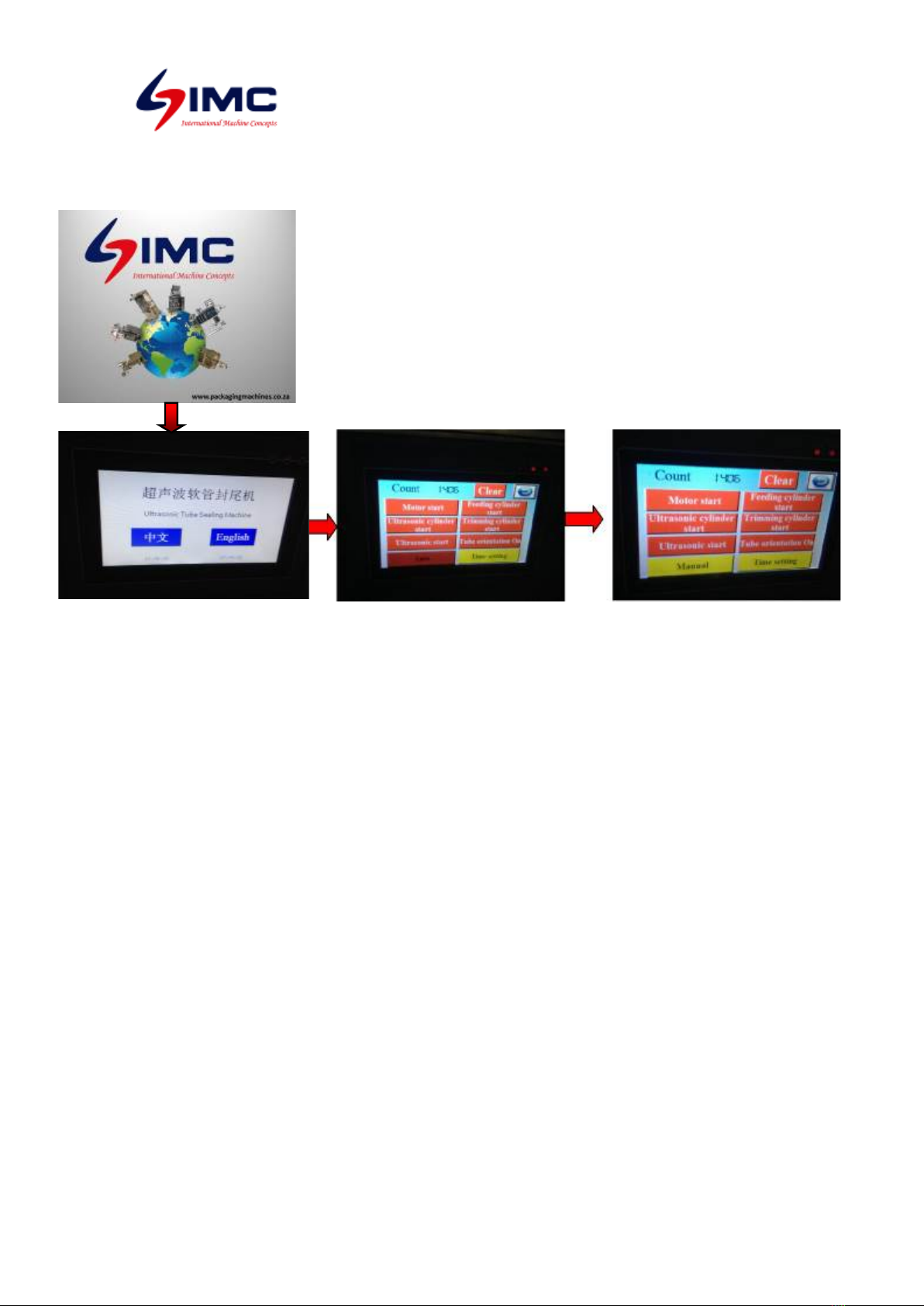

3.2'HMI'Touch'Screen''

'

'

!

!

!

Press!to!English!to!next!page,!and!press!Auto!to!switch!to!the!Manual!mode!

! On!the!Manual!mode!screen!

!

! Motor!start:!! This!is!to!control!the!Tube!holder!running!

! Feeding!cylinder!start:!! This!is!to!control!the!Tube!holder!feeding!

! Ultrasonic!cylinder!start:!This!is!to!control!the!up!mould!and!down!mould!working.!

! Trimming!cylinder!start:!!This!is!to!control!the!cutter!

! Ultrasonic!start:!! This!is!to!control!the!frequency,!this!is!same!as!the!“18.!OSC!!!!

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!check”!!

! Tube!Orientation!on!:!! This!is!to!control!the!Sense!off/on!!

! Time!setting:!! This!is!to!Adjust!the!Delay!time/!Welding!time/Holding!!

!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!!time!

! Delay!time:!!0.80!

! Welding!time:!! Tube!Diameter!20,!the!time!will!about:!0.20,!

! ! Tube!Diameter!30,!the!time!will!about!0.40!

! ! Tube!Diameter!40,!the!time!will!about!0.50!

! ! Tube!Diameter!50,!the!time!will!about!0.7!

! Holding!time:!! 0.35!

!

!

!

8!

3.3'Operation'process'

1. Connect!power!and!compressed!air!correctly!(suggest!0.5MPa).!

!

2. Press!the!Power!switch!

!

3. Press!‘OSC!check’!button!and!set!‘Tune!button’!at!the!same!time,!Please!use!the!screw!on!

the! Tune! button,! you! can! turn! to! Left! or! Right,! while! find! the! minimum! of! ‘Signal! light’!!!!!

(it' will' be'lower' than' 1A)' fixed! ‘Frequency! adjustment’.! (do' not' press!‘OSC' check’!

continuously,'press'it'intermittently)!

!

4. Put!tube!in!the!holder.!

!

5. Press!‘Ultrasonic!cylinder!start’,!front!mould!and!back!mould! will! close.! Set! ‘Moulds! gap!

adjustment’,! let! the! two! moulds! just! touch! with! no! gap.! Press! ‘Cutter! controller’! and!

confirm!the!cutter!works!smoothly.!(You!need'to'put'the'plastic'tube'in'the'tube'holder'

when'you'are'adjusting'it)!

!

6. Set!front!mould!and!back!mould!and!cutter!at!original!position.!

!

7. Put!the!tube!in!the!‘Holder’!and!press!‘Feeding!cylinder!start’,!the!tube!will!run!between!

two! moulds.! Adjust! the! height! of! holder! if! necessary.! (Our! suggesting! is! that! the! tube!

should!be!higher!than!the!back!mould!by!2!to!3!mm)!

8. Make!tube!back!to!original!position.!

!

9. Set!to!auto!status,!turn!on!sensor!if!tube!has!color!code!otherwise!turn!off!it.!

!

10. Press!‘Auto’!the!machine!will!work!automatically.!

!

'

'

!

9!

Chapter'4!

4.1.1''Malfunctions'(Faults)'and'their'rectification'

'

Failure'

Cause'

Remedy'

Machine!doesn’t!

work!or!work!

abnormal'

No!power!or!compressed!air'

Connect!power!and!compressed!air'

Low!compressed!air!pressure'

Increase!air!pressure'

Plastic!overflow!or!

not!good!after!

welding'

Two!moulds!too!closed!or!too!

parted'

Adjust!the!gap!between!two!

moulds'

Rough!edge!after!

cutting'

Cutter!blunt'

Sharpen!cutter!or!replace!sharp!

one'

Cutter!!has!!large!!gap!!between!!

back!mould'

Make!cutter!touch!back!mould!

'

!

10!

Chapter'5'

Electrical'diagram'

'

'

!

11!

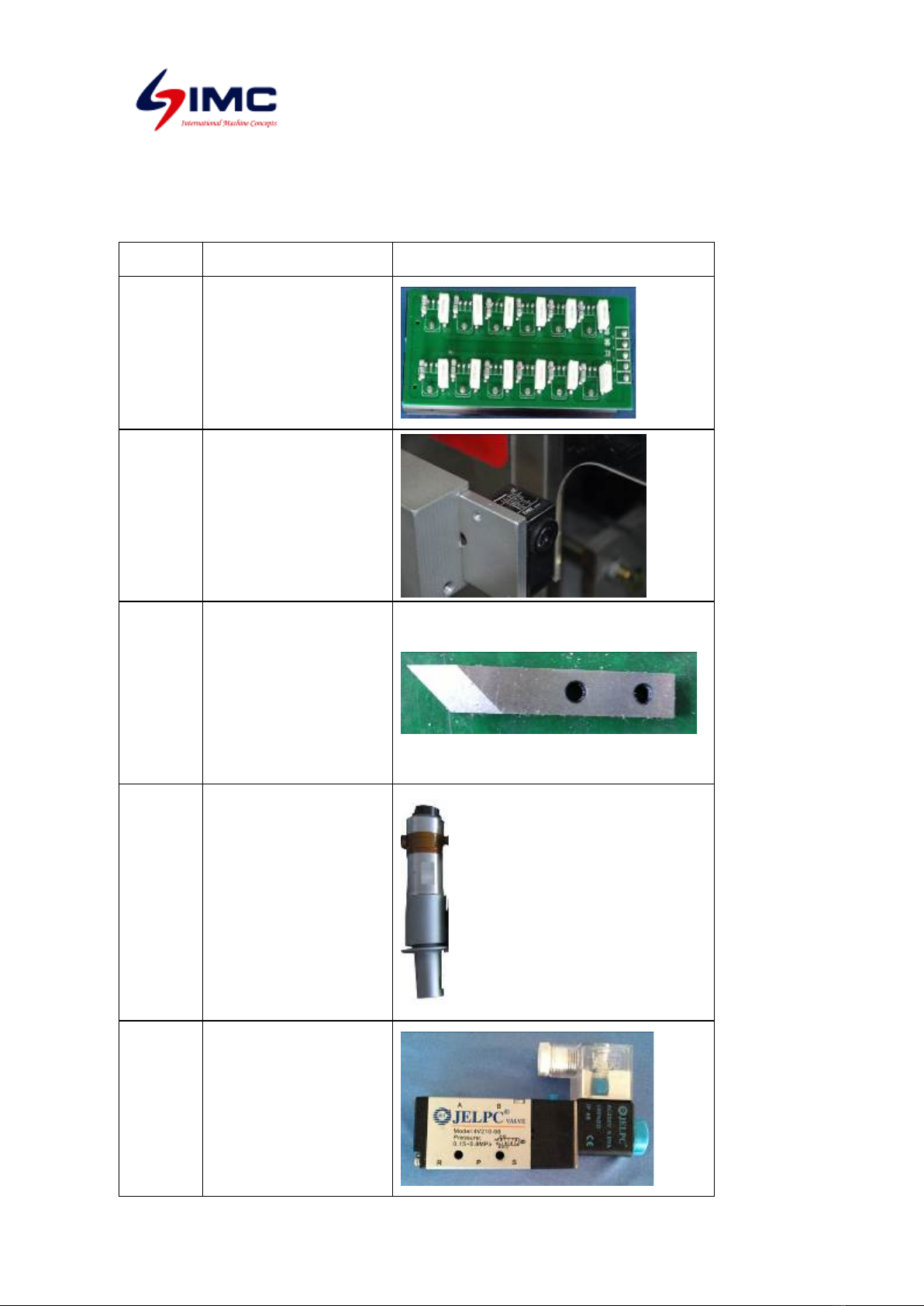

Chapter'6'

6.1'list'of'Spare'parts'

'

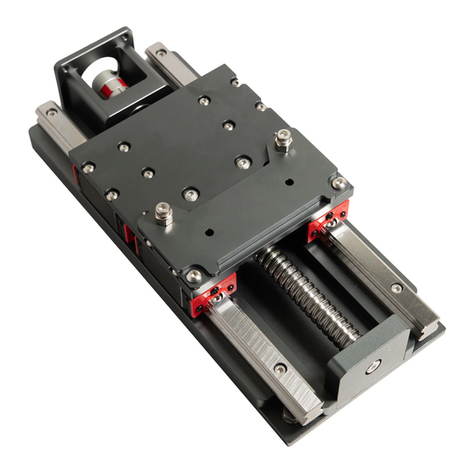

Num.

Spare parts name

Picture

1

Power board

2

Electric eyes

3

Cutter

4

Transducer

5

Electromagnetic valve

!

12!

6

Upper mould

7

Lower mould

8

Main board

9

PLC

10

Tube holder

!

!

Table of contents

Other IMC Industrial Equipment manuals