Operating Instructions & Parts Manual

Horizontal & Vertical Rotary Tables

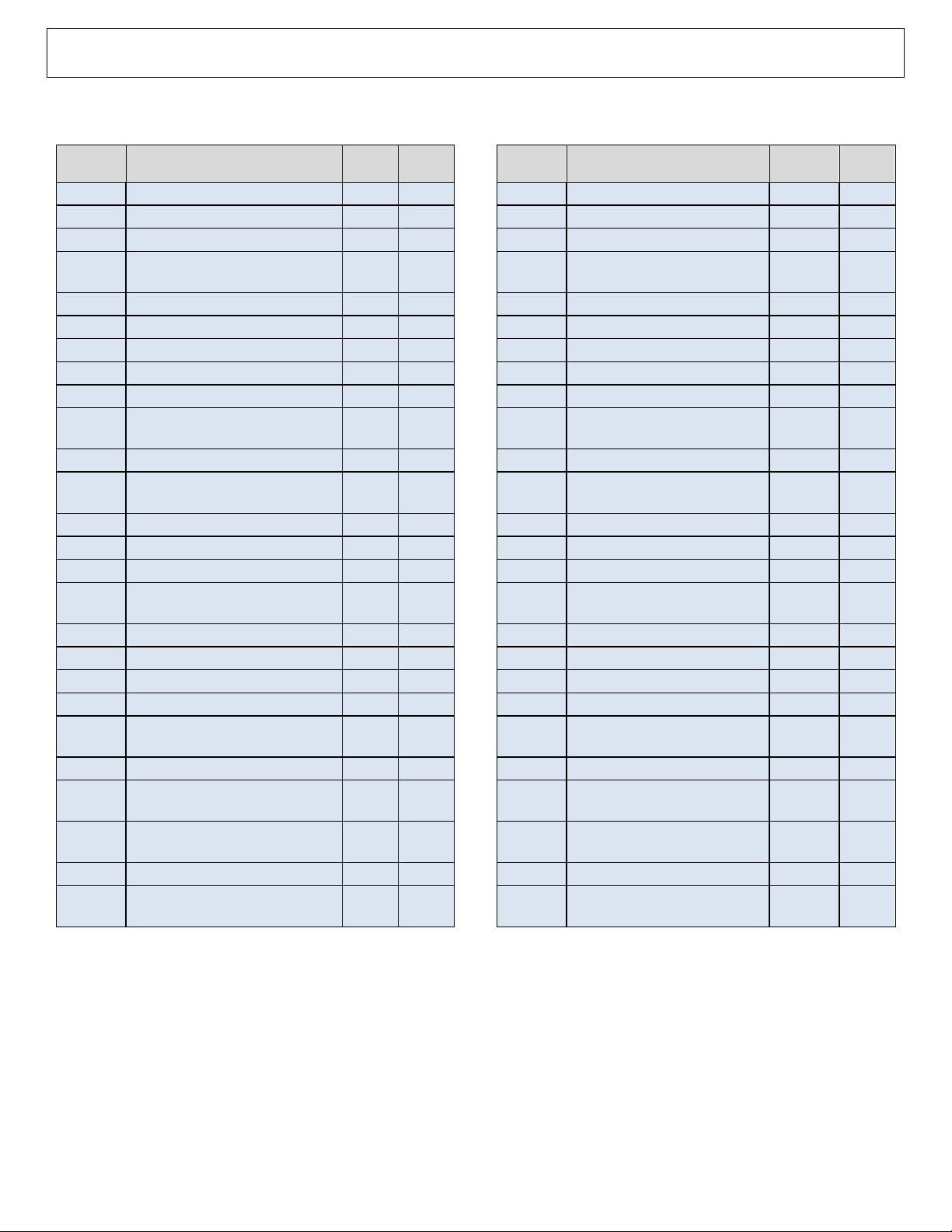

Dividing Plates

Pg. 2

Operating Instructions & Parts Manuals

Please read and save these instructions. Read carefully before attempting to assemble, install, operate or maintain the product described. Protect

yourself and others by observing all safety information. Failure to comply with instructions could result in personal injury and or property damage!

Retain instructions for future reference.

Description

The dual position rotary tables are for indexing,

circular cutting, angle setting, boring and spot

facing operations. The meehanite cast iron table is

precision machined and is provided with a Morse

Taper center hole. The table is graduated with a

360°scale. A micro collar graduated to one minute

with a ten second accuracy vernier scale is

provided. Rotary table features include lock-down

handles and crank disengagement mechanism.

Worm gear and center hole taper are hardened

and ground. The dividing plates accessory allows

the operator to accurately divide the 360°rotation

of the clamping surface into divisions of 2 through

66, and all divisibles of 2, 3 and 5 from 67-132.

Unpacking

Check for shipping damage. If damage has occurred, a

claim must be filed with carrier immediately. Check for

completeness. Immediately report missing parts to

dealer. Carefully remove table from crate.

Important: The tool has been coated with protective

coating. In order to ensure proper fit and operation the

coating must be removed, remove coating with mild

solvents such as mineral spirits and a soft cloth.

Nonflammable solvents are recommended. After

cleaning, cover all exposed surfaces with a light coating

of oil. Be sure to lubricate table as described in

"Maintenance"

Caution: Never use highly volatile solvents. Avoid

getting cleaning solution on paint, as it may tend to

deteriorate these finishes. Use soap and water on

painted components.

Specifications

Dividing Plates Accessory

Possible divisions of

One rotation: ...................2 thru 66, and all

...............................................divisibles of 2, 3, and 5

...............................................from 67-132

Rotary Tables

Accuracy Maximum T.I.P.

Flatness of clamping surface ....................0.0006”

Parallelism of clamping

Surface to base ...............................................0.0008”

Squarness of clamping surface

to angle face.....................................................0.0004"

Squareness of clamping surface

to center slot ...................................................0.0008"

Concentricity of center bore.....................0.0008"

Maximum spacing error:

6” & 8”................................ 1 minute, 20 seconds

10”, 12” & 16” ................ 45 seconds

General Safety Information

1. Read and follow all operating instruction before

operating rotary table.

2. Understand and obey all safety instructions

supplied with mill or other machines on which the

rotary table is used.

3. Always secure rotary table to work surface or other

machine.

4. Always secure workpiece to rotary table clamping

surface if used.

5. Always secure face plate to rotary table clamping

surface if used.

6. Always secure rotary table clamping surface with

lock-down handles when possible.

7. Maintain and lubricate tool properly.

Installation

1. Mount rotary table securely to machine work

surface.

2. Use slots provided on table and be sure that table is

rigidly and safely secured.

3. Table can be mounted horizontally or vertically

with slots provided.

4. Fill with any light duty oil up to bottom of sight

glass only. Table is not sealed and may leak from

handle if overfilled.