IMC SPARTAN User manual

imc Meßsysteme GmbH • Voltastraße 5 • 13355 Berlin • Germany

© 2015 imc Meßsysteme GmbH

imc SPARTAN

Instruction book

Version 5 R 2 - 7/21/2015

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

Foreword

First, allow us to express our thanks that you have decided on this product. We wish you total success in

accomplishing your measurement assignments with the help of the imc hardware and software.

Disclaimer of liability

The contents of this documentation have been carefully checked for consistency with the hardware and

software systems described. Nevertheless, it is impossible to completely rule out inconsistencies, so that

we decline to offer any guarantee of total conformity.

We gratefully accept any suggestions for improvements, please contact our Hotline (hotline@imc-

berlin.de).

We reserve the right to make technical modifications of the systems.

Copyright

© 2015 imc Meßsysteme GmbH, Berlin, Germany

This documentation is the intellectual property of imc Meßsysteme GmbH. imc Meßsysteme GmbH

reserves all rights to this documentation. The applicable provisions are stipulated in the "imc Software

License Agreement".

The software described in this document may only be used in accordance with the provisions of the "imc

Software License Agreement".

imc Software and Microsoft® Windows

imc software runs on the Microsoft® Windows operating system. Microsoft Windows provides a

standardized user interface for imc software and all other Windows-applications.

A license for the respective version of Microsoft Windows is required.

Microsoft, MS and MS-DOS are registered trademarks and Windows is a trademark of Microsoft

Corporation.

Intel and Pentium are registered trademarks of Intel Corporation, USA.

All other trademarks are the property of their respective companies.

GPL Sources

Some components of our hardware use software, that is licensed under GNU General Public License

(GPL). If you would like a copy of the GPL source code contained in this product please contact the imc

Hotline.

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

Table of Contents 3

.................................................................................................................................................... 6

1 General ............................................................................................................................................. 6

1.1 Guide to Using the Manual

............................................................................................................................................. 7

1.2 Notes / Quality Management / Customer Support

.................................................................................................................................. 71.2.1 Quality Management

.................................................................................................................................. 71.2.2 imc Warranty

.................................................................................................................................. 71.2.3 ElektroG, RoHS, WEEE

.................................................................................................................................. 71.2.4 imc Customer Support / Hotline

.................................................................................................................................. 81.2.5 Product Improvement / Change Requests

.................................................................................................................................. 81.2.6 Other Notes

............................................................................................................................................. 10

1.3 Instruction manual

............................................................................................................................................. 10

1.4 Liability limitations

............................................................................................................................................. 10

1.5 Guarantee

............................................................................................................................................. 11

1.6 Before starting

............................................................................................................................................. 11

1.7 Notes on maintenance and servicing

............................................................................................................................................. 11

1.8 Safety .................................................................................................................................. 121.8.1 Responsibility of the user

.................................................................................................................................. 121.8.2 Operating personnel

.................................................................................................................................. 121.8.3 Special dangers

............................................................................................................................................. 13

1.9 After unpacking...

............................................................................................................................................. 13

1.10 Transport

............................................................................................................................................. 14

1.11 Storage

............................................................................................................................................. 14

1.12 Cleaning

.................................................................................................................................................... 15

2 Start of operation with the Hardware

............................................................................................................................................. 15

2.1 Precautions for operation

............................................................................................................................................. 16

2.2 Power supply

............................................................................................................................................. 17

2.3 Grounding, shielding of the devices

............................................................................................................................................. 17

2.4 Grounding with the use of the included power adapter

............................................................................................................................................. 18

2.5 Grounding with power supplied by a car battery

............................................................................................................................................. 18

2.6 Shielding

............................................................................................................................................. 19

2.7 Potential difference with synchronized devices

............................................................................................................................................. 19

2.8 Main switch

............................................................................................................................................. 19

2.9 REMOTE control

............................................................................................................................................. 21

2.10 Fuses (polarity-inversion protection)

............................................................................................................................................. 22

2.11 UPS .................................................................................................................................. 222.11.1 Buffering time constant and maximum buffer duration

.................................................................................................................................. 222.11.2 Charging power

.................................................................................................................................. 232.11.3 Take-over threshold

............................................................................................................................................. 23

2.12 Rechargeable accumulators and batteries

.................................................................................................................................. 232.12.1 Lead-gel batteries

.................................................................................................................................................... 24

3 Properties of the imc SPARTAN

............................................................................................................................................. 26

3.1 SPARTAN device properties

.................................................................................................................................. 263.1.1 Specific parameters

.................................................................................................................................. 263.1.2 Operating software imc DEVICES and imc STUDIO

.................................................................................................................................. 273.1.3 Sampling interval

............................................................................................................................................. 27

3.2 Measurement types

.................................................................................................................................. 273.2.1 Temperature measurement

.................................................................................................................................. 303.2.2 Bridge measurements

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

Table of Contents4

.................................................................................................................................. 383.2.3 Incremental Encoders

.................................................................................................................................. 473.2.4 Measurement with current-fed sensors

.................................................................................................................................. 483.2.5 Measure with ICP-Expansion connector

.................................................................................................................................................... 58

4 Hardware configuration of all devices

............................................................................................................................................. 58

4.1 SPAR/DI16-DO8-ENC4 digital multiboard

.................................................................................................................................. 594.1.1 Digital Inputs

.................................................................................................................................. 604.1.2 Digital outputs

.................................................................................................................................. 624.1.3 Incremental encoder channels

............................................................................................................................................. 67

4.2 Analog modules

.................................................................................................................................. 684.2.1 SPAR/T16 voltage and temperature

.................................................................................................................................. 754.2.2 SPAR/U16 voltage and temperature

.................................................................................................................................. 794.2.3 SPAR/B(C)16 bridge and voltage

.................................................................................................................................. 874.2.4 SPAR/BCF16 bridge, LVDT and voltage

............................................................................................................................................. 97

4.3 Other inputs and outputs

.................................................................................................................................. 974.3.1 SPAR/DI8-DO8-ENC4-DAC4 digital multiboard

.................................................................................................................................. 984.3.2 SPAR/DI16 digital inputs

.................................................................................................................................. 994.3.3 SPAR/DO16 digital outputs

.................................................................................................................................. 1024.3.4 SPAR/DAC8 analog outputs

.................................................................................................................................. 1034.3.5 Field bus cabling

............................................................................................................................................. 106

4.4 Miscellaneous

.................................................................................................................................. 1064.4.1 TEDS .................................................................................................................................. 1074.4.2 SYNC .................................................................................................................................. 1084.4.3 GPS .................................................................................................................................. 1094.4.4 Operation without PC

.................................................................................................................................. 1114.4.5 Filter settings

.................................................................................................................................. 1134.4.6 External sensor supply

.................................................................................................................................................... 114

5 Technical Specs

............................................................................................................................................. 114

5.1 General technical specification

.................................................................................................................................. 1145.1.1 Technical Specs for all devices

.................................................................................................................................. 1175.1.2 Analog modules

.................................................................................................................................. 1325.1.3 SPAR/DI16-DO8-ENC4

.................................................................................................................................. 1355.1.4 SPAR/DI8-DO8-ENC4-DAC4

.................................................................................................................................. 1365.1.5 SPAR/DI16 digital inputs

.................................................................................................................................. 1375.1.6 SPAR/DO16 digital outputs

.................................................................................................................................. 1385.1.7 SPAR/DAC8 analog outputs

.................................................................................................................................. 1395.1.8 Fieldbus: Technical Details

.................................................................................................................................. 1455.1.9 Synchronisation and time base

.................................................................................................................................. 1465.1.10 UPS .................................................................................................................................. 1475.1.11 Miscellaneous

.................................................................................................................................................... 155

6 Pin configuration

............................................................................................................................................. 155

6.1 Connecting DSUB-15 adapter plug

.................................................................................................................................. 1566.1.1 Overview of the modules and connectors

............................................................................................................................................. 157

6.2 Metal connector

............................................................................................................................................. 158

6.3 DSUB-15 pin configuration

.................................................................................................................................. 1586.3.1 Standard and Universal connector

.................................................................................................................................. 1596.3.2 Special connector

.................................................................................................................................. 1606.3.3 TEDS connector

............................................................................................................................................. 161

6.4 DSUB-9 pin configuration

.................................................................................................................................. 1616.4.1 DSUB-9 pin configuration

.................................................................................................................................. 1636.4.2 Pin configuration of the field busses

............................................................................................................................................. 167

6.5 DSUB-26 Pin configuration (High Density)

............................................................................................................................................. 168

6.6 REMOTE plug

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

Table of Contents 5

.................................................................................................................................................... 169

7 Last changes

.................................................................................................................................................... 172

8 Symbols and legend

.................................................................................................................................................... 173

Index

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

6General

1 General

1.1 Guide to Using the Manual

To look for WHAT?

Contents

You should really read the following chapters!

General

Guidlines and general notes

Properties of imc SPARTAN

Overview of imc SPARTAN

Device description

Overview of the device family, general technical description

Technical Specs

Data Sheets

Connectors

Pin configuration

Regularly updated information and up-to-date user's manuals can be accessed on www.imc-berlin.com.

7

24

58

114

158

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

7Guide to Using the Manual

1.2 Notes / Quality Management / Customer Support

1.2.1 Quality Management

imc Meßsysteme GmbH holds DIN-EN-ISO-9001 certification since May 1995.

You can download the CE Certification, current certificates and information about the imc quality system

on our Webpage: www.imc-berlin.com/about-imc/quality-assurance. For further information, please

contact our Hotline .

1.2.2 imc Warranty

Subject to the general terms and conditions of imc Meßsysteme GmbH.

1.2.3 ElektroG, RoHS, WEEE

The company imc Meßsysteme GmbH is registered under the following number:

·WEEE Reg.- # DE 43368136

·Brand: imcDevices

·Category 9: Monitoring and control instruments exclusively for commercial use

·Valid as of 24.11.2005

Our products fall under Category 9, "Monitoring and control instruments exclusively for commercial use"

and are thus at this time exempted from the RoHS guidelines 2002/95/EG.

_______________________________________________________

The law (ElektroG) governing electrical and electronic equipment was announced on March 23, 2005 in the German Federal Law

Gazette. This law implements two European guidelines in German jurisdiction. The guideline 2002/95/EG serves "to impose

restrictions on the use of hazardous materials in electrical and electronic devices". In English-speaking countries, it is abbreviated

as "RoHS" ("Restriction of Hazardous Substances").

The second guideline, 2002/96/EG "on waste electrical and electronics equipment" institutes mandatory acceptance of returned

used equipment and for its recycling; it is commonly referred to as WEEE guidelines ("Waste on Electric and Electronic

Equipment").

The foundation "Elektro-Altgeräte Register" in Germany is the "Manufacturers’ clearing house" in terms of the law on electric and

electronic equipment ("ElektroG"). This foundation has been appointed to execute the mandatory regulations.

1.2.4 imc Customer Support / Hotline

If you have problems or questions, please contact our Customer Support/Hotline:

Germany:

imc Meßsysteme GmbH

Phone:

+49 (0) 30 / 467 090 - 26

Fax:

+49 (0) 30 / 463 15 76

WWW:

www.imc-berlin.com

E-Mail:

For our international partners see www.imc-berlin.com/our-partners/distributor.

If you contact us you would help us, if you know the serial number of your devices and the version info of

the software. This documentation should also be on hand. Thank you!

7

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

8General

1.2.5 Product Improvement / Change Requests

You can help us to improve our documentation by giving us feedback on the following questions:

·What terms or descriptions are incomprehensible?

·What additions and enhancements you suggest?

·Where have material mistakes slipped in?

·Which spelling or typing errors have you found?

Responses and other feedback should be directed to the Hotline (phone / e-mail)

or by writing to:

imc Meßsysteme GmbH

Voltastrasse 5

D - 13355 Berlin

Germany

1.2.6 Other Notes

Remarks Concerning EMC

imc SPARTAN satisfies the EMC requirements for unrestricted use in industrial settings.

Any additional devices connected to imc SPARTAN must satisfy the EMC requirements as specified by

the responsible authority (within Europe1) in Germany the BNetzA - "Bundesnetzagentur" (formerly

BMPT-Vfg. No. 1046/84 or No. 243/91) or EC Guidelines 2004/108/EEC. All products which satisfy

these requirements must be appropriately marked by the manufacturer or display the CE certification

marking.

Products not satisfying these requirements may only be used with special approval of the regulating

body in the country where operated.

All signal lines connected to imc SPARTAN must be shielded and the shielding must be grounded.

Note

The EMC tests were carried out using shielded and grounded input and output cables with the

exception of the power cord. Observe this condition when designing your experiment to ensure high

interference immunity and low jamming.

Reference

See also General Notes > Precautions for operation > Grounding, shielding> Shielding

1If you are located outside Europe, please refer the appropriate EMC standards used in the country of operation.

7

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

9Notes / Quality Management / Customer Support

FCC-Note

This equipment has been tested and found to comply with the limits for a Class B digital device,

pursuant to Part 15 of the FCC Rules (CFR 15.105)2. These limits are designed to provide reasonable

protection against harmful interference in a residential installation. This equipment generates, uses,

and can radiate radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications. However, there is no

guarantee that interference will not occur in aparticular installation. If this equipment does cause

harmful interference to radio or television reception, which can be determined by turning the

equipment on and off, the user is encouraged to try to correct the interference by one or more of the

following measures:

·Reorient or relocate the receiving antenna.

·Increase the separation between the equipment and the receiver.

·Connect the equipment into an outlet on a circuit different from that to which the receiver is

connected.

·Consult our imc hotline or an experienced radio or television technician for help.

Modifications

The FCC requires the user to be notified that any changes or modifications made to this device that

are not expressly approved by imc may void the user's authority to operate this equipment.

2FCC - United States Federal Communications Commission

Cables

Connections to this device must be made with shielded cables with metallic RFI/EMI connector hoods

to maintain compliance with FCC Rules and Regulations.

Industrial Safety

We certify that imc SPARTAN in all product configuration options corresponding to this

documentation conforms to the directives in the accident prevention regulations in "Electric

Installations and Industrial Equipment" (BGV-A3 of the Index of Accident Prevention Regulations of

the Professional Guilds in Germany)3.

This certification has the sole purpose of releasing imc from the obligation to have the electrical

equipment tested prior to first use (§ 5 Sec. 1, 4 of BGV-A3). This does not affect guarantee and

liability regulations of the civil code.

3Formely VBG-4, refer http://www.bgfe.de

This device has been conceived and designed to comply with the current safety regulations for data

processing equipment (which includes business equipment). If you have any questions concerning

whether or not you can use this device in its intended environment, please contact imc or your local

distributor.

The measurement system has been carefully designed, assembled and routinely tested in accordance

with the safety regulations specified in the included certificate of conformity and has left imc in perfect

operating condition. To maintain this condition and to ensure continued danger-free operation, the user

should pay particular attention to the remarks and warnings made in this chapter. In this way, you

protect yourself and prevent the device from being damaged.

7

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

10 General

Read this manual before turning the device on for the first time! Pay attention to any additional

information pages pertaining to the pin configuration etc. which may have been included with this

manual.

Warning

Before touching the device sockets and the lines connected to them, make sure static electricity is

drained. Damage arisingfrom electrostatic discharge is not covered by the warrantee.

1.3 Instruction manual

This instruction manual provides important notes on using the device. The safe working is conditional on

compliance with all safety measures and instruction specified.

Additionally, all accident prevention and general safety regulations pertinent to the location at which the

device is used must be adhered to.

This instruction manual exclusively describes the device (hardware), not how to operate the imc

software! The instructions for the imc measurement software are provided in their own manual. Read

carefully the manual before beginning any work!

1.4 Liability limitations

All specifications and notes in the operating instruction manual are subject to applicable standards and

regulations, and reflect the state of the art well as accumulated years of knowledge andexperience.

The manufacturer declines any liability for damage arising from:

·failure to comply with the instructions provided,

·inappropriate use of the equipment,

·additionally, the general terms and conditions of the company imc Mess-Systeme GmbH apply.

1.5 Guarantee

Each device is subjected to a 24-hour "burn-in" before leaving imc. This procedure is capable of

recognizing almost all cases of early failure. This does not, however, guarantee that a component will not

fail after longer operation. Therefore, all imc devices are guaranteed to function properly for two years.

The condition for this guarantee is that no alterations or modifications have been made to the device by

the customer.

Unauthorized intervention in the device renders the guarantee null and void.

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

11Before starting

1.6 Before starting

Condensation may form on the circuit boards when the device is moved from a cold environment to a

warm one. In these situations, always wait until the device warms up to room temperature and is

completely dry before turning it on. The acclimatization period should take about 2 hours. This is

especially recommended for devices without ET (extended environmental temperature range).

We recommend a warm-up phase of at least 30 min prior to measure.

Existing ventilation slits must be kept unimpeded to avoid heat buildup in the device interior.

The devices have been designed for use in clean and dry environments. It is not to be operated in 1)

exceedingly dusty and/ or wet environments, 2) in environments where danger of explosion exists nor 3)

in environments containing aggressive chemical agents.

1.7 Notes on maintenance and servicing

No particular maintenance is necessary.

Note

The specified maximum errors are valid for 1 year following delivery of the device under normal

operating conditions (note ambient temperature!).

There are a number of important device characteristics which should be subjected to precise checking at

regular intervals. We recommend annual calibration. Our calibration procedure includes calibration of

inputs (checking of actual values of parameters; deviations beyond tolerance levels will be reported), a

complete system-checkup, newly performed balancing and subsequent calibration (the complete

protocol set with measurement values is available at an extra charge). Consult our Hotline for the price

for system calibration according to DIN EN ISO 9001.

For devices with UPS functions, we recommend maintenance every 2-3 years. Please read the notes in

the chapter rechargeable accumulators and batteries . When returning the device in connection with

complaints, please include a written, outlining description of the problem, including the name and

telephone number of the sender. This will help expedite the process of problem elimination.

For questions by telephone please be preparedto provide your device's serial number and have your imc

installation software, as well as this manual at hand, thanks! The serial number, necessary power supply,

interface type and software version included can be determined from the plaque on the side of the

device.

1.8 Safety

This section provides an overview of all important aspects of protection of personnel for reliable and

trouble-free operation. Failure to comply with the instructions and protection notes provided here can

result in serious danger.

23

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

12 General

1.8.1 Responsibility of the user

The device is for use in commercial applications. The user is therefore obligated to comply with legal

regulations for work safety.

Along with the work safety procedures described in this instruction manual, the user must also conform

to regulations for safety, accident prevention and environmental protection which apply to the work site.

The user must also ensure that any personnel assistingin the use of the device have also read and

understood the instruction manual.

1.8.2 Operating personnel

Warning

·Danger of injury due to inadequate qualifications!

·Improper handling may lead to serious damage to personnel and property. When in doubt, consult

qualified personnel.

·Work which may only be performed by trained imc personnel may not be performed by the user. Any

exceptions are subject to prior consultation with the manufacturer and are conditional on having

obtained corresponding training.

The instruction manual distinguishes the following degrees of qualification for performing various

actions:

·Users of the measurement equipment. Fundamentals of measurement engineering. Recommended:

knowledge of foundations of electrical engineering. Familiarity with the Microsoft Windows

operating system. Users may not open or modify the device.

·Qualified personnel is able, due to training in the field and to possession of skills, experience and

familiarity with the relevant regulations, to perform work assigned while independently recognizing

any hazards.

1.8.3 Special dangers

This segment states what residual dangershave been identified by the hazard analysis.Observe the safety

notes listed here and the warnings appearing in subsequent chapters of this manual in order to reduce

health risks and to avoid dangerous situations.

Warning

DANGER!

·Lethal danger from electric current!

·Contact with conducting parts is associated with immediate lethal danger. Damage

to the insulation or to individual components can be lethally dangerous.

Therefore:

·In case of damage to the insulation, immediately cut off the power supply and have

repair performed.

·Work on the electrical equipment must be performed exclusively by expert

electricians.

·During all work performed on the electrical equipment, it must be deactivated and

tested for static potential.

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

13Safety

Warning

DANGER!

·Injuries from hot surfaces!

·Devices from imc are designed so that their surface temperatures do not exceed

limits stipulated in EN 61010-1 under normal conditions.

Therefore:

·Handles are provided in order to ensure safe operation (for imc CRONOSflex

systems the handles must be "clicked" the devices).

·Surfaces whose temperature can exceed the limits under circumstances are

denoted by the symbol shown at left.

1.9 After unpacking...

Check the delivered system immediately upon receiving it for completeness and for possible transport

damage.

In case of damage visible from outside, proceed as follows:

·Do not accept the delivery or only accept it with reservations

·Note the extent of the damage on the packing documents or on the delivery service's packing list.

·Begin the claims process.

Please check the device for mechanical damage and/ or loose parts after unpacking it. The supplier must

be notified immediately of any transportation damage! Do not operate a damaged device!

Check that the list of accessories is complete:

·AC/DC-power adapter (not for racks)

with cable and pre-assembled LEMO connector

·DC-power LEMO connector

·Getting started with your imc measurement device (printed)

·Manufacturer's Calibration Certificate

Note

File a claim about every fault as soon as it is detected. Claims for damages can only be honored within

the stated claims period.

1.10 Transport

When transporting imc SPARTAN, always use the original packaging or a

appropriate packagingwhich protects the device against knocks and

impacts. If transport damages occur, please be sure to contact the imc

Customer Support. Damage arising from transporting is not covered in the

manufacturer's guarantee. Possible damage due to condensation can be

limited by wrapping the device in plastic sheeting.

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

14 General

The represented handling label for lithium ion batteries can be attached also

independently printed on the package (e.g. by gluing on the package or in a

transparent unlabeleddocument bag). Note however that the form and the

format are accurately given by IATA and the expression hasto take place in

color. Format: 120 x 110 mm

1.11 Storage

As a rule, the measurement device can be stored at temperatures rangingfrom -20°C to +85°C. The

following limitations apply in consequence of the manufacturer’s specifications.

1.12 Cleaning

·Always unplug the power supply before cleaning the device. Only qualified service technicians are

permitted to clean the housing interior.

·Do not use abrasive materials or solutions which are harmful to plastics. Use a dry cloth to clean the

housing. If the housing is particularly dirty, use a cloth which has been slightly moistened in a

cleaning solution and then carefully wrung out. To clean the corners, slits etc. of the housing, use a

small soft dry brush.

·Do not allow liquids to enter thehousing interior.

·Be certain that the ventilation slits remain unobstructed.

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

15Precautions for operation

2 Start of operation with the Hardware

2.1 Precautions for operation

Certain ground rules for operating the system, aside from reasonable safety measures, must be observed

to prevent danger to the user, third parties, the device itself and the measurement object. These are the

use of the system in conformity to its design, and the refraining from altering the system, since possible

later users may not be properly informed and may ill-advisedly rely on the precision andsafety promised

by the manufacturer.

Note

If you determine that the device cannot be operated in a non-dangerous manner, then the device is to

be immediately taken out of operation and protected from unintentional use. Taking this action is

justified under any of the following conditions:

I. the device is visibly damaged,

II. loose parts can be heard within the device,

III.the device does not work

IV.the device has been stored for a long period of time under unfavorable conditions (e.g. outdoors

or in high-humidity environments).

1. Observe the data in the chapter "Technical Specifications", to prevent damage to the unit through

inappropriate signal connection.

2. Note when designing your experiments that all input and output leadsmust be provided with

shielding which is connected to the protection ground ("CHASSIS") at one end in order to ensure

high resistance to interference and noisy transmission.

3. Unused, open channels (having no defined signal) should not be configured with sensitive input

ranges since otherwise the measurement data could be affected. Configure unused channels witha

broad input range or short them out. The same applies to channels not configured as active.

4. For measurement of voltages >60 V, only use banana jacks (4 mm) with contact protection.

5. If you are using a internaldevice drive, observe the notes in the imc DEVICES / imc STUDIO manual.

Particular care should be taken to comply with the storage device’s max. ambient temperature

limitation.

6. Avoid prolonged exposure of the device to sunlight.

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

16 Start of operation with the Hardware

2.2 Power supply

The device is powered by a DC-supply voltage which is supplied via a 2-pole LEMO-plug.

Device

LEMO plug type designation

Size

imc SPARTAN-1 to 8

FGG.1B.302 CLAD.52ZN

(middle)

imc SPARTAN-R

FGG.2B.302.CLAD.82ZN

(big)

The permissible supply voltage range is 10 to 32 V (DC) at 130 W max. consumption. The product package

includes either a corresponding desktop supply unit with 24 V , DC and a max. power consumption of 150

W or a desktop supply unit with 15 V , DC and a max. power consumption of 60 W. The mains voltage is

110 V to 240 V 50/60 Hz. The DC-supply inputs or our imc measurement devices are not designed for a

connection to a DC-grid.

Note

Please note, that the operation temperature of the desktop supply is prepared for 0°C to 40°C, even

if your measurement devices is designed for extended temperature range!

If the LEMO-plug is assembled with anappropriate cable it can be connected to a DC-voltage source such

as a car battery. When usingthis, note the following:

·Grounding of the device must be provided. If the supply voltage source has a ground reference

(ground connected to the (–) terminal), then the device is automatically grounded via the (–)

terminal. The table-top power supply unit is configured in this manner.

·The feed line must have low resistance, the cable must have an adequate cross-section. Any

interference-suppressing filters which may be inserted into the line must not have any series

inductor greater than 1 mH. Otherwise an additional parallel-capacitor is needed.

Pin configuration:

The +pin is marked with a red dot.

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

17Grounding, shielding of the devices

2.3 Grounding, shielding of the devices

In order to comply with Part 15 of the FCC-regulations applicable to devices of Class B, the system must

be grounded. Grounding is also the condition for the validity of the technical specifications stated.

imc SPARTAN devices can be equipped with two different supply units (please consider the following

two pictures variant A and B). For example a SPARTAN-R is equipped with the variant B. You can

distinguish the variants at the different positions of the plugs.

A

Variant A:

The DC-supply input on the

device itself (LEMO-plug,

female) is not galvanically

isolated from the housing

(CHASSIS):

-SUPPLY input is galvanically

connected to CHASSIS internally.

That means the device's internal

power supply circuitry

comprises non-isolating DC/DC

converter.

B

Variant B:

The DC-supply input on the

device itself (LEMO-plug,

female) is galvanically isolated

from the housing (CHASSIS):

-SUPPLY input is not connected

to CHASSIS internally. That

means the device's internal

power supply circuitry comprises

isolating DC/DC converter.

Hardware change: the SYNC plug is situated below the

CHASSIS plug on devices delivered before 2014.

Hardware change: the SYNC plug is situated between

REMOTE and supply plug devices delivered before 2014.

2.4 Grounding with the use of the included power adapter

imc SPARTAN system with a supply unit variant B (DC-supply input on the device itself (LEMO-plug, female) is galvanically

isolated from the housing (CHASSIS)) with AC/DC power adapter

Use of the included table-top power adapter is protected by the power plug's protection ground

connection: at the adapter's LEMO terminal, both the (-) pole of the supply voltage as well as the

shielding and connector pod are connected with the power cable's protection ground.

17

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

18 Start of operation with the Hardware

2.5 Grounding with power supplied by a car battery

imc SPARTAN system with a supply unit variant B (DC-supply input on the device itself (LEMO-plug, female) is galvanically

isolated from the housing (CHASSIS)) input with isolated DC-supply (e.g. battery)

If the power supply (e.g. car battery) and the measurement device are at different voltage levels, then if

they were connected by the supply line, it would cause a ground loop. For such cases, the isolated

internal device power supply ensures separation of the two voltage levels. The ground reference for the

measurement device must then be established in a separate step.

Isolated power inputs avoids ground loops in distributed topologies

With stationary installations and the use of (already isolated) AC/DC adapters, any system ground

differentials between the device and the central or local power supplies may not be relevant. The big

issue in such a case, in contrast to mobile, in-vehicle applications, is from where to obtain a reliable

ground voltage. Since it is convenient to use the AC power supply’s protection ground line as the ground

voltage, the LEMO-terminated AC/DC adapters for imc measurement devices are designed so that the

protection ground line is connected all the way through to the LEMO connector’s housing, thus securing

the device’s voltage level to protection ground. Additionally, in the AC/DC-adapter’s LEMO-terminal (not

the device’s LEMO-socket!), the reference ground of the power adapter is connected with the housing’s

(CHASSIS) protection ground: Since the AC/DC power adapter is already isolating, as is the power input,

this supply voltage’s reference would not initially be defined and can be set arbitrarily. In particular for

reasons of suppressing HF (high-frequency) interference signals stemming from the AC/DC switching

power adapter, direct grounding is normally advisable.

2.6 Shielding

Also, all signal leads to the device must be shielded and the shielding grounded (electric contact between

the shielding and the plug housing "CHASSIS").

To avoid compensation currents, always connect the shielding to one side (potential) only.If the imc

DSUB block screw terminal plug is used, the shielding should be connected to the pull-relief clamp on the

cable bushing. This part of the conductor-coated plastic plughousing has electrical contact to the device's

housing, just as Terminals 15 and 16 (labeled: "CHASSIS", to the left and right of the imc-plug cable

bushing) do; but is preferable to the "CHASSIS" terminals for optimum shielding.

17

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

19Potential difference with synchronized devices

2.7 Potential difference with synchronized devices

Note

When using multiple devices connected via the SYNC plug for synchronization purposes, ensure that all

devices are at the same voltage level. Any potential differences among devices may have to be evened

out using an additional line having adequate cross section.

If the synchronized devices are at different voltage levels, they should be compensated by means of a

lead having the appropriate cross-section. If the SYNC plug at your device is equipped with a yellow ring

it is already isolated and it is protected against potential differences (concerning devices as of

summer 2012).

Alternatively it is possible to isolate the devices by using the module ISOSYNC, see also chapter

Synchronization in the imc STUDIO / imc DEVICES manual.

2.8 Main switch

Switch ON:

The device's main switch is a power-on button with a built-in "POWER"-LED. In order to

activate the device the button must be pressed down for approx. 1 sec. The activation is

indicated by the "POWER"-LED flashing. If the device boots correctly, three short beep-

tones are emitted.

Switch OFF

In order to shut down the device the button must be pressed down again for approx. 1

sec. During the deactivation the "POWER"-LED is blinking constantly. The measured files

on the internal hard drive involved are closed before the device switches off by itself.

This process takes up to 10 seconds. Holding the power-on button down is not

necessary!

If no measurement is currently running, it takes only approx. one second for the device

to be deactivated.

2.9 REMOTE control

imc SPARTAN measurement devices can be switched on and off remotely, by control signals that are

accessible at the "REMOTE" connector of the device. These can be operated by externally installed

manual switches, relay contacts or electronic switching elements.

Depending on the different supply unit variants, used by the various imc SPARTAN types, several distinct

switching functions and operatingmodes are available as described in the tables below. The main

operating mode, available for all types, is the basic ON/OFF push button action performed with one

single temporarily closing contact: Connecting the signals "ON/OFF" (Pin13) and "SWITCH" (Pin2) for at

least a short time, activates the device as with the green main switch .Once powered up, the device

can be switched off by connecting the two signals once again, that means at least releasing the

connection and connecting again.

19

© 2015 imc Meßsysteme GmbH imc SPARTAN - Instruction book, Version 5 R 2 - 7/21/2015

20 Start of operation with the Hardware

REMOTE functions concerning only the imc SPARTAN devices with a supply unit variant A :

Signal

Function

Connection

Remarks

DSUB

ON

static activation /

deactivation

connect pin 10

with SWITCH

Starting only when external power supply is available.

Power up from internal battery is not supported

(blocked)

1. permanently jumpered with SWITCH:

automatic start with external power supply

2. with a static contact (ON), no push-button!

closed: on / opened: off

10

ON/OFF

push-button for

start / shutdown

connect pin 13

with SWITCH

Start up from internal battery is supported.

Brief connection will initiate start and shutdown

13

SWITCH

switch signal /

reference

connect pin 2, 3

with ON/OFF, ON

2, 3

REMOTE functions concerning only the imc SPARTAN devices with a supply unit variant B :

Signal

Function

Connection

Remarks

DSUB

ON

activation

connect pin 10

with SWITCH or

SWITCH1

permanently jumpered to SWITCH1:

automatic start with external power supply

e.g. in vehicle

10

OFF

deactivation

connect pin 9

with SWITCH

brief connection will deactivate the device

9

ON/OFF

push button for

start / shutdown

connect pin 13

with SWITCH

brief connection will initiate activation/deactivation as

with the green main switch

13

SWITCH

switch signal /

reference

connect pin 2

with ON/OFF, ON

or OFF

Brief connection via a push button will initiate

activation/deactivation. Note: power up from internal

battery is supported!

2

SWITCH1

activation only

from external

power supply

connect pin 3

with ON

static, permanently jumpered: for automatic activation

upon application of an external supply

3

K15-mode

controlling

activation with

an external low

power control

signal

jumper pin 12 to

SWITCH

K15-mode=SWITCH provides K15 control mode:

control voltage to be applied to "ON":

· startup: >9 V

· shutdown: <2 V (do not leave floating!)

(no significant current drawn)

12

MUTE

muting the

UPS buzzer

connect pin 5

with CHASSIS

e.g. for acoustic applications

5

RESET

immediate

shutdown

without saving

connect pin 1

with CHASSIS

Will cause a lost of measurement data!

in case of malfunction, only

1

RESET_

GND

reference for MUTE and RESET

CHASSIS

17

17

Table of contents

Other IMC Measuring Instrument manuals

Popular Measuring Instrument manuals by other brands

Mid Ocean Brands

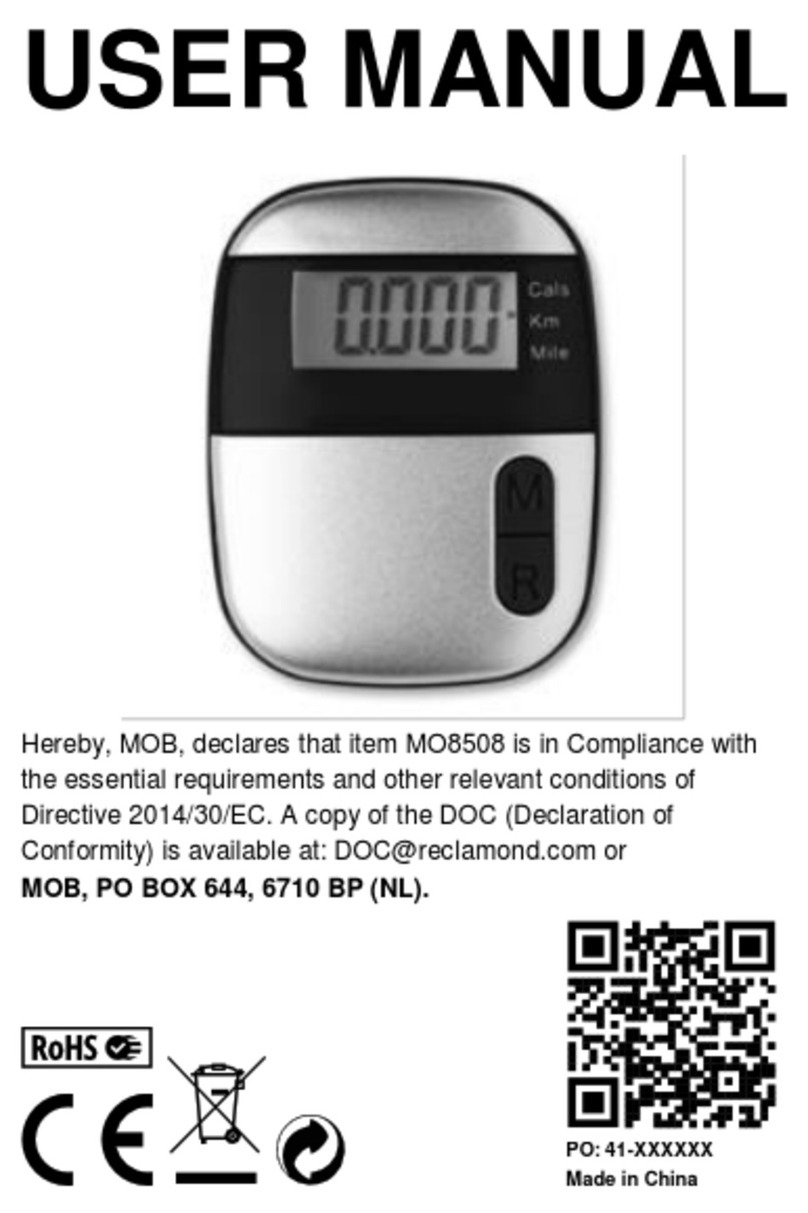

Mid Ocean Brands MO8508 user manual

FRONIUS

FRONIUS Smart Meter 50kA-3 operating instructions

Spot-on

Spot-on 39240 product manual

Next Century

Next Century RR4-TR Operation and installation guide

PerkinElmer

PerkinElmer Lambda 20 Installation and maintenance guide

PerkinElmer

PerkinElmer Lambda 11 Operation and Parameter Description