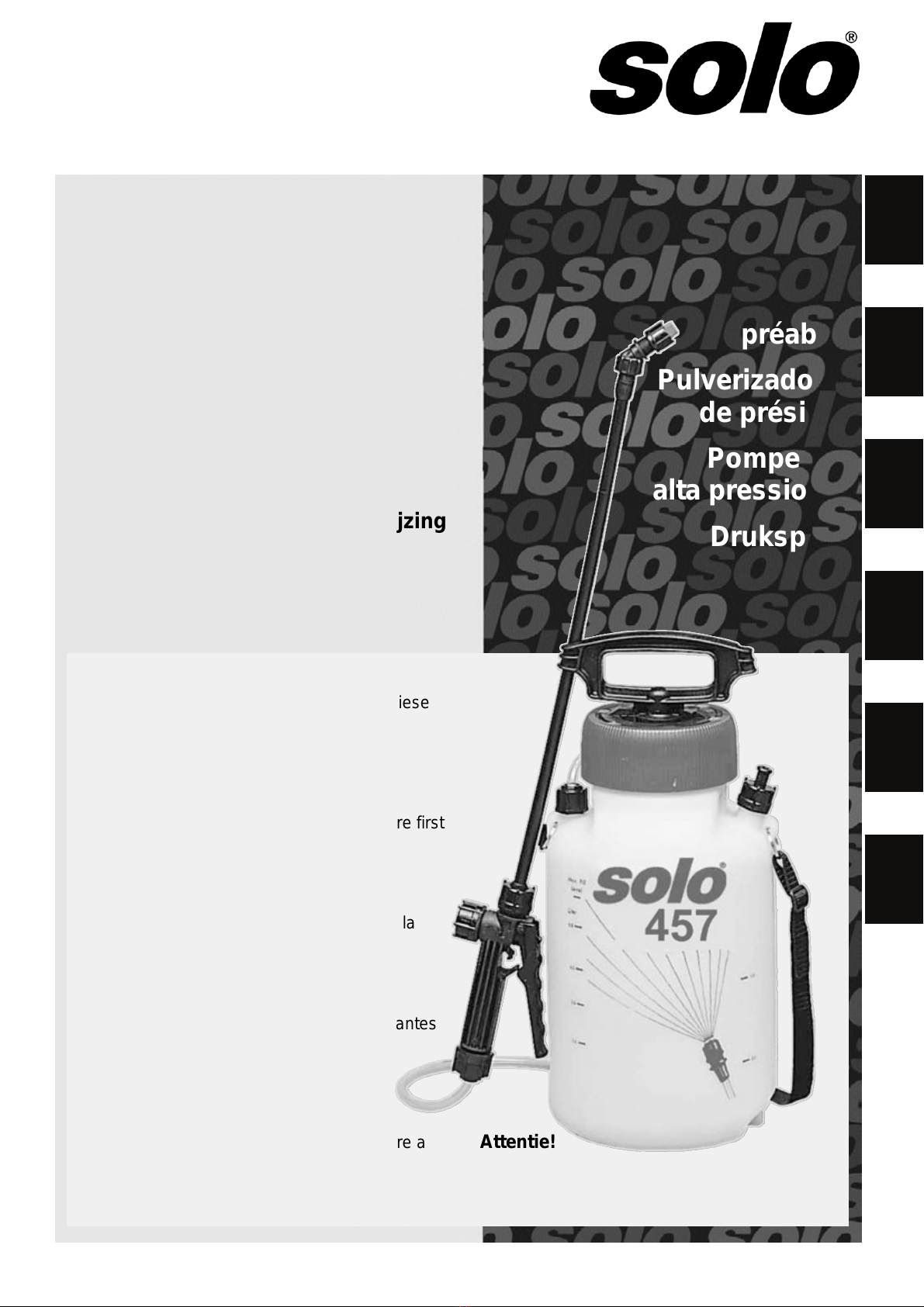

- ENGLISH - Pressure Sprayer 456 / 457

ENGLISH 2

Instruction manual

Original instructions

1. Safety directives and general

instructions

Compliance with this safety manual is a

prerequisite for proper operation of the sprayer.

The pressure sprayer must be checked before

each use.

Prior to every use, ensure the proper functioning

of the safety valve (4).

This pressure sprayer is suitable for applying

approved liquid plant protection, insecticides,

and weed killing substances, as well as liquid

fertilizers that are available from authorized

dealers. We recommend using only plant

protection substances that are approved by the

German BBA (German Federal Biological

Institute).

Solvent-free window cleaners, car wax, and

conservation substances are also suitable for

cleaning and care in private households.

The sprayer must be cleaned when changing the

spray substance. This avoids possible chemical

reactions.

Do not use liquids over 40°C.

Due to bodily hazard, only the abovementioned

liquid substances may be applied with this

sprayer. Disinfectants and impregnation

substances may not be used.

Never leave the filled and /or pressurized

pressure sprayer unattended for longer periods.

For safety reasons, children, young people

under the age of 16, and persons that are not

familiar with these operating instructions, may

not use this pressure sprayer.

The pressure sprayer must be kept out of the

reach of children.

The user is responsible relative to third persons.

The pressure sprayer must be de-pressurized

before disassembly of any component, and

before opening the pump, by pulling on the

pressure valve (Fig 3)! Before pulling on the

pressure valve, the sprayer must always be in an

upright position. Attention: keep the sprayer

away from your face!

Do not expose the pressure sprayer to high

temperatures.

Malfunctions of any kind, such as, for example

leaks at the tank, spray pipe and tubing,

signs of damage, cracks, etc.,

other irregularities,

is the syringe immediately make pressure on the

safety valve. The sprayer must not be reused, but

must be checked by a qualified person.

The manufacturer was not aware of any harmful

effects on the product materials caused by plant

protection substances at the time the product was

manufactured.

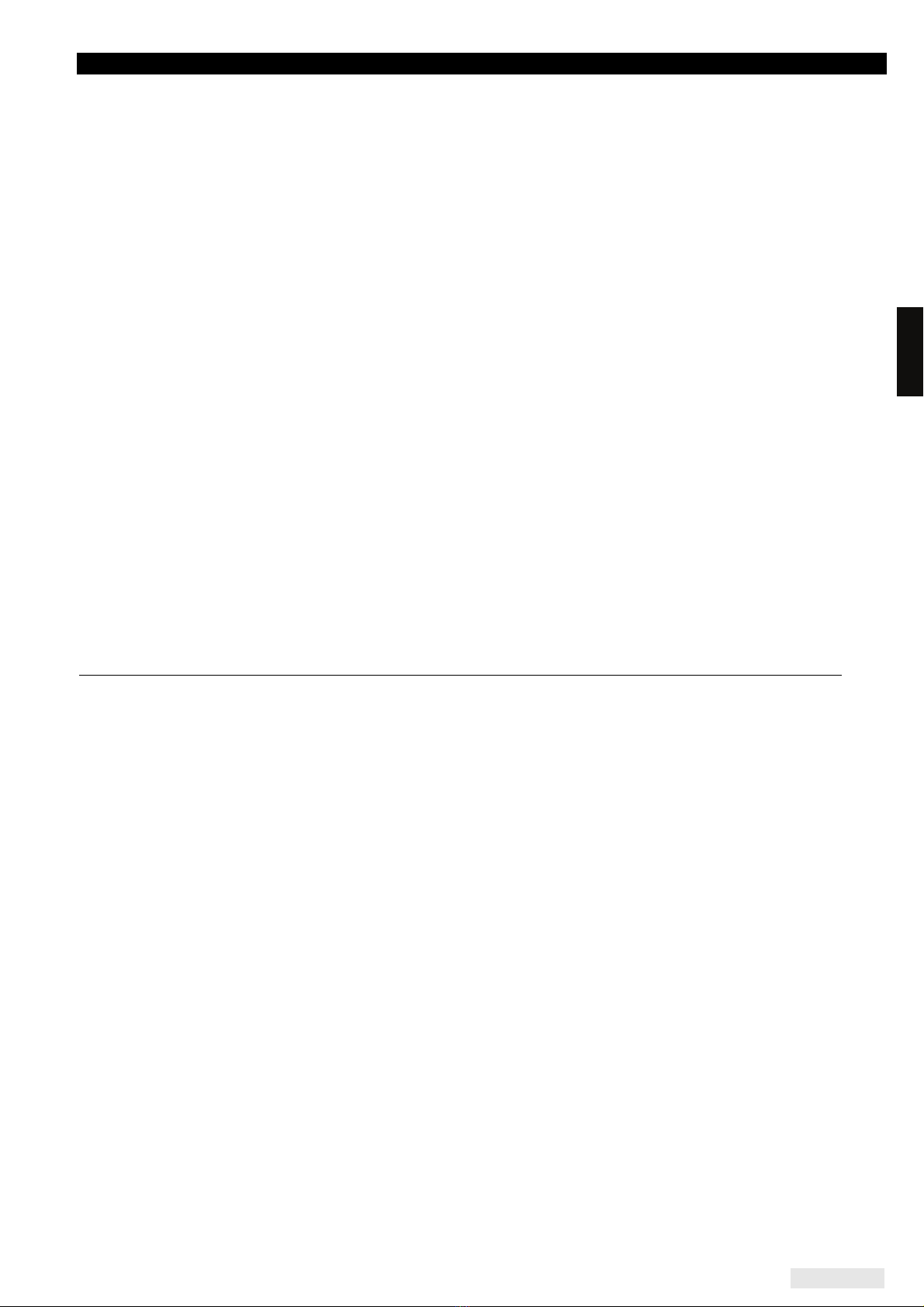

2. Assembly

You will find the following parts in the packaging

Spray tube

Alternative nozzle set with associated gasket

1 pc. each symbolic label for

container content: herbicide,

fungicide and insecticide.

NOTE: Affix the appropriate label to

identify the container content.

PLEASE NOTE:

Never pour different agents at the

same time into the container.

Before using a different agent,

thoroughly clean out the container

and all parts in contact with the

spray agent, then flush with plenty

of water. We recommend the

SOLO horticultural equipment

cleaner in 500 ml bottles; part no.

49 00 600.

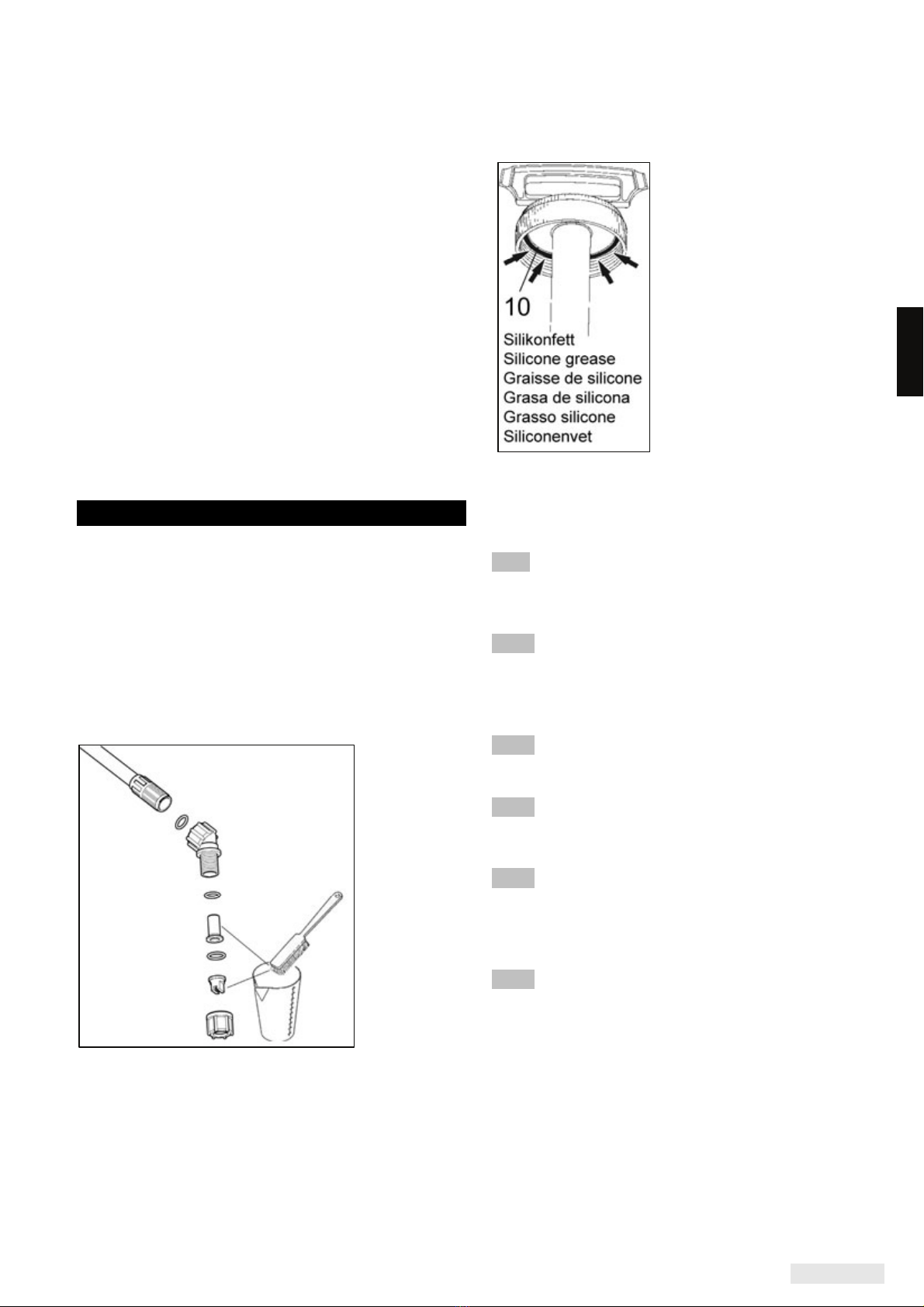

Firmly screw the spray tube with O-Ring (16x3

mm) onto the shut-off valve. In the process, -fasten

the threaded collar (Fig.2 pos 9) on straight and

firmly tighten it by hand – do not use force and do

not use any tools to firmly fasten the collar!

When your work is completed, the spray tube

should be fitted into the holding clamp. Please put

the nozzle completely up (Fig 1).

3. Placing in service

The pressure sprayer must be de-pressurized

before disassembling any component, and before

opening the pump, by pulling on the pressure valve

(Fig 3)! Before pulling on the pressure valve the

sprayer must always be in an upright position.

The pump must be removed to fill the spray liquid.

To do this, push the pump handle down and turn it

to the left (counterclockwise) until the handle clicks

into position. Unscrew pump by turning it counter

clockwise. Do not use any tools!

Fill the spray liquid to the fill mark maximum.

Model 456: 5,0 liters

Model 457: 7,0 liters

In this regard, follow the safety directives and

insure the correct dosing according to the

instructions provided by the manufacturer of the

spray substance!

Thoroughly mix the liquid, insert pump and refasten

firmly by turning clockwise. Firmly tighten by

turning pump handle clockwise until it clicks into

position.