Page1of20

Contents

ContentsandSpecifications.................................1

SafetyPrecautions...........................................2‐3

Assembly.............................................................4

Operation........................................................5‐6

Technique............................................................7

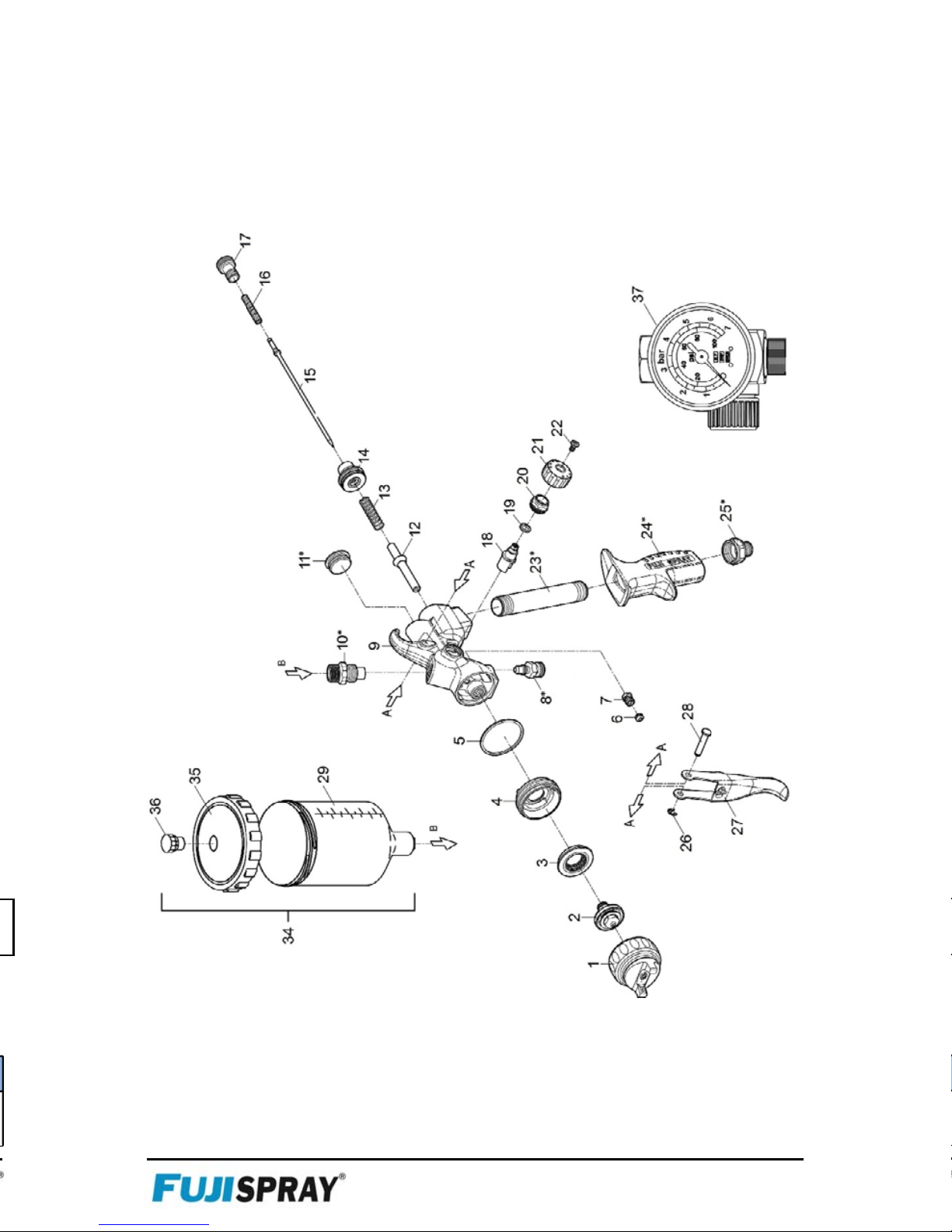

PartsDiagram..................................................8‐9

ViscosityGuide...................................................10

FinishProblems..................................................11

Troubleshooting..........................................12‐13

NeedlePackingNut............................................1 4

GeneralCleaning.........................................15‐16

ThoroughCleaning.............................................1 6

Reassembly........................................................17

WarrantyInformation........................................18

ServiceInformation............................................19

Notes..................................................................20

SPECIFICATIONS

AirSupplyPressure 26PSIatguninlet(1.8bar)

AirInletSize 1/4“BSPandNPS

AirSupplyHoseWidth 5/16”ID

FluidPassages StainlessSteel

FluidCoupler(PressureFeed) 3/8”x19P

FluidCoupler(Gravity) M16x1.5P

Airconsumption 15.2cfm

StandardAirCapSet 1.4mm

GunWeight(WithoutCup) 502g

Page2of20

Pleasereadtheseinstructionsbeforeusingtheequipment

FIREANDEXPLOSIONHAZARD

Equipmentmustnotbeusedinanareacontaminatedbyvolatileor

flammablematerials.Thiscouldignitethecontaminantscausinga

dangerousexplosion.

∙Donotsprayflammableorcombustiblematerialsnearanopenflame

orsourcesofignitionsuchascigarettes,motors,andelectrical

equipment.

∙Neveruse1,1,1‐trichloroethane,methylenechloride,other

halogenatedhydrocarbonsolventsorfluidscontainingsuchsolventsin

equipmentwithaluminumwettedparts.Suchusecouldresultina

seriouschemicalreaction,withthepossibilityofexplosion.Consultyour

fluidsupplierstoensurethatthefluidsbeingusedarecompatiblewith

aluminumparts.

∙Keepsprayareawell‐ventilated.Keepagoodsupplyoffreshair

movingthroughthearea.

∙Donotsmokeinthesprayarea.

∙Donotoperatelightswitches,engines,orsimilarsparkproducing

productsinthesprayarea.

∙Keepareacleanandfreeofpaintorsolventcontainers,rags,andother

flammablematerials.

∙Fireextinguisherequipmentshallbepresentandworking.

TOXICFLUIDORFUMESHAZARD

Toxicfluidsorfumescancauseseriousinjuryordeathifsplashedin

theeyesoronskin,inhaled,orswallowed.

∙ReadMSDS(MaterialSafetyDataSheet)toknowthespecifichazards

ofthefluidsyouareusing.

∙Alwayswearappropriateglovesandeyeprotection.

∙Alwaysweararespirator.Readallinstructionsoftherespiratorto

ensurethatitwillprovidethenecessaryprotectionagainstthe

inhalationofharmfulvapors.Alsocheckwiththelocaljurisdiction.

∙Paint,solvents,insecticidesandothermaterialsmaybeharmfulif

inhaled.

∙Storehazardousfluidinapprovedcontainers,anddisposeofit

accordingtoapplicableguideline.

∙Donotstopordeflectfluidleakswithyourhandorbody.