IMC RK15 Installation guide

1 | P a g e

REEL KLEEN RK15

RK15

REEL KLEEN RK15

INSTALLATION, OPERATING AND MAINTENANCE MANUAL

PLEASE LEAVE WITH OPERATOR

A34/074 R1 ECN 8662 SEPTEMBER 2017

2 | P a g e

REEL KLEEN RK15

INDEX

EC DECLARATION OF CONFORMITY.................................................................................3

GUARANTEE.....................................................................................................................4

WATER SUPPLY................................................................................................................4

COMMISSIONING ............................................................................................................4

MAINTENANCE ................................................................................................................4

MATERIAL CONTENT........................................................................................................4

SAFETY.............................................................................................................................5

GENERAL INSTRUCTIONS.................................................................................................6

INSTALLATION .................................................................................................................7

ASSEMBLY INSTRUCTIONS...............................................................................................8

PARTS LIST.....................................................................................................................16

SERVICE .........................................................................................................................19

ADJUSTMENTS...............................................................................................................21

CONTACT DETAILS .........................................................................................................22

3 | P a g e

REEL KLEEN RK15

EC DECLARATION OF CONFORMITY

EC DECLARATION OF CONFORMITY

(Guarantee of Production Quality)

We, Imperial Machine Company Limited of:

Unit 1, Abbey Road, Wrexham Industrial Estate, Wrexham, LL13

9RF

Declare under our sole responsibility that the machine

REEL KLEEN RK15

As described in the attached technical documentation is in conformity with the Machine

Safety Directive 89/392/EEC as amended by 91/368/EEC and 93/44/EEC and is

manufactured under a quality system BS EN ISO 9001. It is also in conformity with the

protection requirements of the Electro Magnetic Compatibility Directive 89/336/EEC

and is manufactured in accordance with harmonised standards EN 55014-1 Emission

and EN 55014-2 Immunity (plus product specific standards).

Approved by E Plumb, Engineering Manager

Signed at Wrexham, Date September 2017

4 | P a g e

REEL KLEEN RK15

GUARANTEE

This equipment is guaranteed by IMC for 1 year from the date of its purchase from IMC, or

from one of its stockists, dealers or distributors. The guarantee is limited to the replacement

of faulty parts or products and excludes any consequential loss or expense incurred by

purchasers. Defects that arise from faulty installation, inadequate maintenance, incorrect

use or fair wear and tear are not covered by the guarantee.

The guarantee applies in this form to installations within the United Kingdom.

WATER SUPPLY

NOTE:These units are designed to be fitted to a mains water supply in accordance to local

water board regulations. This applies to UK installations; overseas customers should install

the machine in accordance with local regulations.

IF IN DOUBT, CHECK WITH YOUR LOCAL AUTHORITY

COMMISSIONING

These instructions are designed to aid you in the installation of the REEL KLEEN.

1. All REEL KLEEN’s come with hose, they are set at the proper tension and are ready

for wall mounting.

2. The REEL KLEEN can also be mounted from the floor or ceiling.

3. When floor or ceiling mounted, the hose guide should be adjusted to allow the hose

to be pulled from the REEL KLEEN in a straight line for maximum hose life.

4. A 3/4”BSP flexible connection is supplied for connection to the water inlet.

5. Connect water supply line and tighten with a spanner.

6. Turn on water supply and check for leaks.

MAINTENANCE

Other than regular cleaning the REEL KLEEN’s require no maintenance by the end user.

MATERIAL CONTENT

The REEL KLEEN contains the following materials:

Metals Stainless steel, Mild steel (inc plated).

Plastics and rubber Neoprene rubber.

5 | P a g e

REEL KLEEN RK15

SAFETY

Please read this manual carefully and follow the instruction. This manual contains important

information concerning the operating features of the REEL KLEEN RK15, as well as safety

precautions to be taken before, during and after installation. The following safety

precautions call attention to potentially dangerous conditions.

Warning: Indicates a situation in which personal injury may occur.

Caution: Indicates a situation in which damage to equipment or material

may occur.

Note: Provides helpful information for proper installation and operation of the hose reel.

6 | P a g e

REEL KLEEN RK15

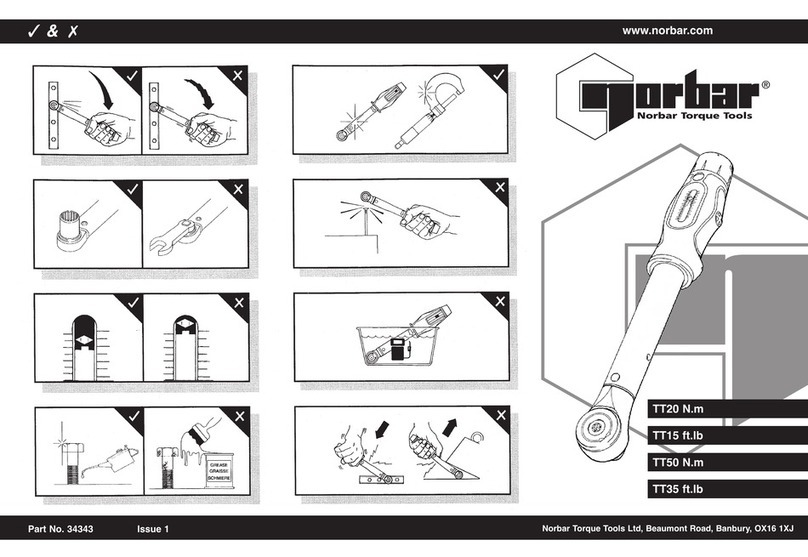

GENERAL INSTRUCTIONS

These suggestions are designed to aid you in the installation. Please read them carefully for

proper installation, which will ensure that the products will give long and dependable

service, with a minimum of maintenance.

1. Shut off water supply at main source and open faucets to drain lines.

2. Do not wipe grease off parts.

3. Hand-tighten first before using wrench.

4. Handle plated surfaces with care, being careful not to scratch with tools.

5. Do not force parts together. Tighten according to directions.

6. Rest fixtures on pads whenever necessary, and use wooden blocks and boards to

brace them in position.

Use this manual for installation and ordering parts from your dealer (please see final page

of this manual for details).

7 | P a g e

REEL KLEEN RK15

INSTALLATION

Caution: Instruct operators in the safe, proper use and maintenance of the

hose reel. Keep this manual for future reference.

Warning: Failure to read, understand and follow these instructions may

result in personal injury or even fatality.

A. Mounting:

Reels shipped with hose are ready for installation.

1. Mount hose reel with the main shaft (item 25 –see parts list on page 16) in the

horizontal position.

2. Mount reel with centre line of drum (8) in line with hose pay-out.

B. Supply hose:

Assemble input hose into main shaft (25). Do not use rigid pipe at input connection.

C. Secondary support cable:

Warning: The secondary chain must be used to protect personnel in case

of failure of mounting components or support structure.

1. Attach one end of secondary support cable to the hole in the stand cover (20).

2. Attach the other end of secondary support cable to a separate support. Do not

attach the secondary support cable to the same structure that supports the

hose reel.

Note: Make the cable as short as possible so that the hose reel will drop no more

than six inches if the main support fails.

8 | P a g e

REEL KLEEN RK15

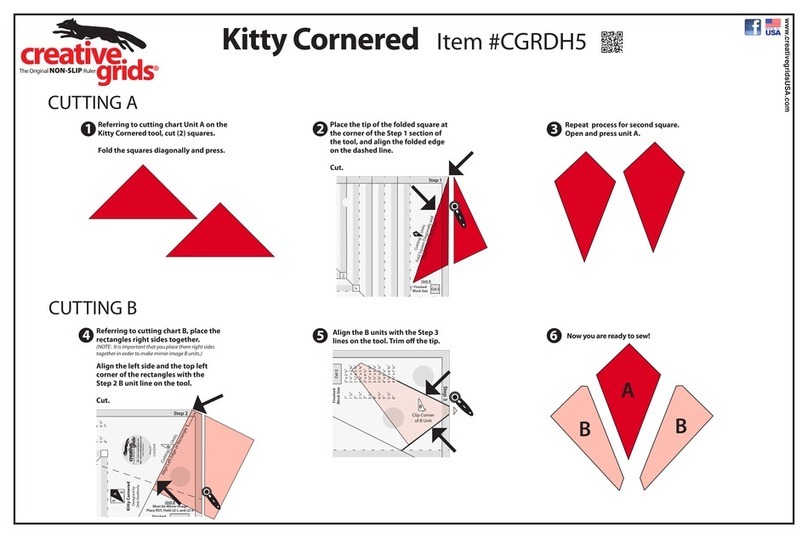

ASSEMBLY INSTRUCTIONS

9 | P a g e

REEL KLEEN RK15

10 | P a g e

REEL KLEEN RK15

11 | P a g e

REEL KLEEN RK15

12 | P a g e

REEL KLEEN RK15

13 | P a g e

REEL KLEEN RK15

14 | P a g e

REEL KLEEN RK15

15 | P a g e

REEL KLEEN RK15

16 | P a g e

REEL KLEEN RK15

PARTS LIST

Item

Number

Part

Number Qty.

Description

1 30-P-115 1 SCREW (1/4-20 x 1/2")

2 101-P-30 1 LOCK WASHER (1/4")

3 126-P-50 1 WASHER (1/4")

4 580-P-45 1 RETAINING RING

5 57844 1 COVER ASSEMBLY

6 106-P-77 6 LOCK NUT (10-24)

7 57846-2 1 RATCHET & SPRING ASSMBLY D513, D522, DB504

57846-3 RATCHET & SPRING ASSMBLY DB508

8 57827 1 DRUM ASSEMBLY

9 57812 1 GUIDE, CANOPY

10 57814 1 NOSE, GUIDE

11 ST-1 1 HOSE STOP (53732)

12 1137-P-62 4 SCREW (#6-32 x 5/16, SELF TAP)

13 160-P-77 2 LOCK NUT (10-24)

14 57855 2 CLAMP ASSEMBLY

15 576-P-46 1 RETAINING RING

16 43010 1 WASHER

17 C47040142 2 O-RING

18 M72420031

1 SWIVEL

19 576-P-46 1 RETAINING RING

20 57803 1 COVER, STAND

21 53821-27 1 HOSE ASSEMBLY (D513)

57883-1 1 HOSE ASSEMBLY (D522)

53821-26 1 HOSE ASSEMBLY (DB504, DB508)

22 671-P-10 1 HOSE CLAMP

23 658-P-49 BARB FITTING D522A, D522SA, D522GCA, D522HEA

658-P-35 BARB FITTING D513A, D504A, DB508A, D513-SA, DB504-SA, DB508-SA

24 160-P-50 4 LOCK NUT (10-24)

25 M37700002

1 MAIN SHAFT

26 160-P-77 2 LOCK NUT (10-24)

27 230-P-103 1 SELF-LOCK PIN

28 57823 1 GUIDE

29 2006 1 PIN, MOUNTING BRACKET

17 | P a g e

REEL KLEEN RK15

30 62388 1 CABLE, SAFETY (OPTIONAL)

31 2009 1 MOUNTING BRACKET

32 57877 1 PLATE, SWIVEL

33 228-P-10 1 COTTER PIN

34 30365 1 WASHER

35 57808 1 SWIVEL

36 30-P-115 4 SCREW (1/4-20 x 1/2")

37 101-P-30 4 LOCK WASHER (1/4")

38 57807 1 BASE PLATE

39 14058-2 1 HUB, SPRING RELEASE

40 57843 1 SHAFT LEVER

41 57727 1 SPRING, RATCHET

42 57850 1 PIN, SPRING

43 151-P-20 4 NUT (1/4-20 HEX HEAD)

44 57841 1 LEVER, RATCHET

45 47378 1 WASHER

46 103-P-20 1 LOCK WASHER (#6)

47 151-P-15 1 NUT (#6-32)

OPT. 57972 1 SWING MOUNT

18 | P a g e

REEL KLEEN RK15

19 | P a g e

REEL KLEEN RK15

SERVICE

Caution: Before attempting any service, always cut off supply input and

remove all mainspring tension.

A. Hose replacement:

1. Remove screws (item 36 –see parts list on page 17), washers (37) and nuts (43)

from base or swivel plate (38 or 32).

2. Remove retaining ring (19) and canopy guide (9).

3. Remove stand cover (20) exposing swivel (18).

4. Loosen clamp (22).

5. Remove old hose (21) from barb fitting (23).

6. Install new hose.

7. Reassemble by reversing above procedure.

Note: When replacing hose, be sure all hose fittings are secure.

B. O-Ring replacement:

1. Remove screws (36), washers (37) and nuts (43) from base or swivel plate (38 or

32).

2. Remove retaining ring (19) and canopy guide (9).

3. Remove stand cover (20).

4. Remove swivel (18).

5. Remove four nuts (24).

6. Remove swivel (18).

Note: Take care not to damage or scratch the main shaft (25) or swivel (18) during

swivel removal.

7. Remove old O-rings (17) and discard.

8. Clean all contamination from main shaft (25) and swivel (18).

9. Install new O-rings and apply a light coat of commercial grease to main shaft (25)

and swivel (18).

10. Remove all excess grease.

11. Reassemble by reversing above procedure.

C. Ratchet and spring assembly replacement:

If reel will not develop tension or retract hose, ratchet and spring assembly (7) will

need to be replaced.

To replace ratchet and spring assembly (7):

1. Remove screws (36), washers (37) and nuts (43) from base or swivel plate (38 or

32).

2. Remove retaining ring (4) and canopy guide (9).

3. Remove cover assembly (5).

4. Remove six nuts (6) and ratchet spring assembly (7) from drum assembly (8) and

replace.

20 | P a g e

REEL KLEEN RK15

5. To reassemble, reverse above procedure.

Note: Spring is completely self-contained and safe to handle.

Caution: When reassembling ratchet and spring assembly (7), be sure

arrow on ratchet plate aligns with alignment hole in drum (8).

Table of contents

Popular Tools manuals by other brands

Tohnichi

Tohnichi CPT-G quick start

FEDERAL PACIFIC

FEDERAL PACIFIC PSE Supplement to Inspection and Maintenance Recommendations

Nederman

Nederman 888 Series instruction manual

Probuilder

Probuilder 43609 instruction manual

Bosch

Bosch GST 160 CE Professional Original instructions

MountzPro

MountzPro MountzProDT135 owner's manual