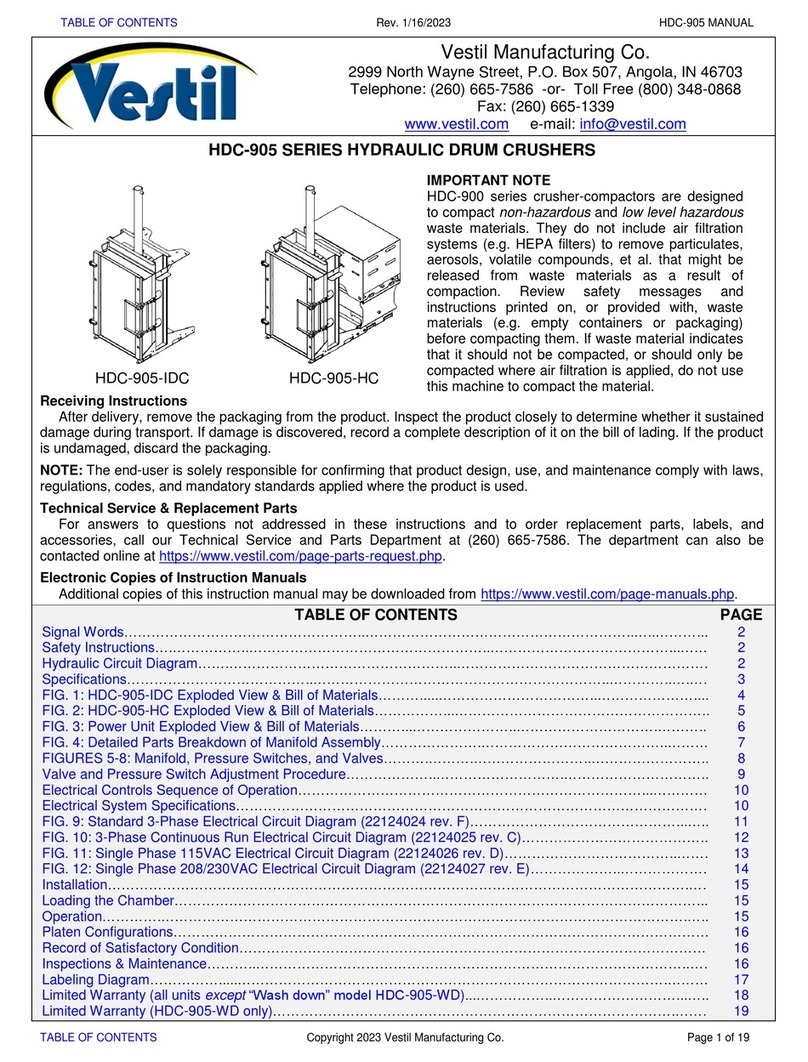

IMC F79/703 Service manual

Installation, Operating and Servicing

Instructions

A34/103 R2 ECN 4839 MAY 2021

WASTESTATION COMPACT

THREE PHASE MODEL (415V-50HZ) F79/703

Please make a note of your product details for

future use:

Date Purchased:_________________________

Model Number:__________________________

Serial Number:__________________________

Dealer:_________________________________

________________________________

_______

2 | P a g e

CONTENTS

MACHINE DIMENSIONS......................................................................................3

INTRODUCTION...................................................................................................5

MODEL INFORMATION .......................................................................................5

ON DELIVERY.................................................................................................................. 5

GUARANTEE........................................................................................................5

INSTALLATION OPTIONS....................................................................................6

FOR THE INSTALLER .................................................................................................... 6

SELECTION OF SITE ..................................................................................................... 6

ORDER OF CONNECTION FOR ALL INSTALLATION OPTIONS.......................7

SUPPLY CONNECTIONS –HOT AND COLD WATER INLET SUPPLIES..........7

WASTE OUTLET CONNECTION .........................................................................8

ELECTRICAL CONNECTION...............................................................................9

MACHINE RATINGS ..................................................................................................... 10

TESTING ......................................................................................................................... 10

OPERATION OF MACHINE................................................................................11

MACHINE RUNNING MODES & INDICATOR LIGHTS.......................................... 11

INITIAL OPERATION..........................................................................................12

NORMAL OPERATION.......................................................................................14

RELEASING A JAM............................................................................................14

Note.....................................................................................................................15

WATER FLOW CONTROL........................................................................................... 15

MAINTENANCE..................................................................................................15

USAGE................................................................................................................16

CIRCUIT DIAGRAM: WASTESTATION COMPACT 415V-3 PHASE-50Hz........17

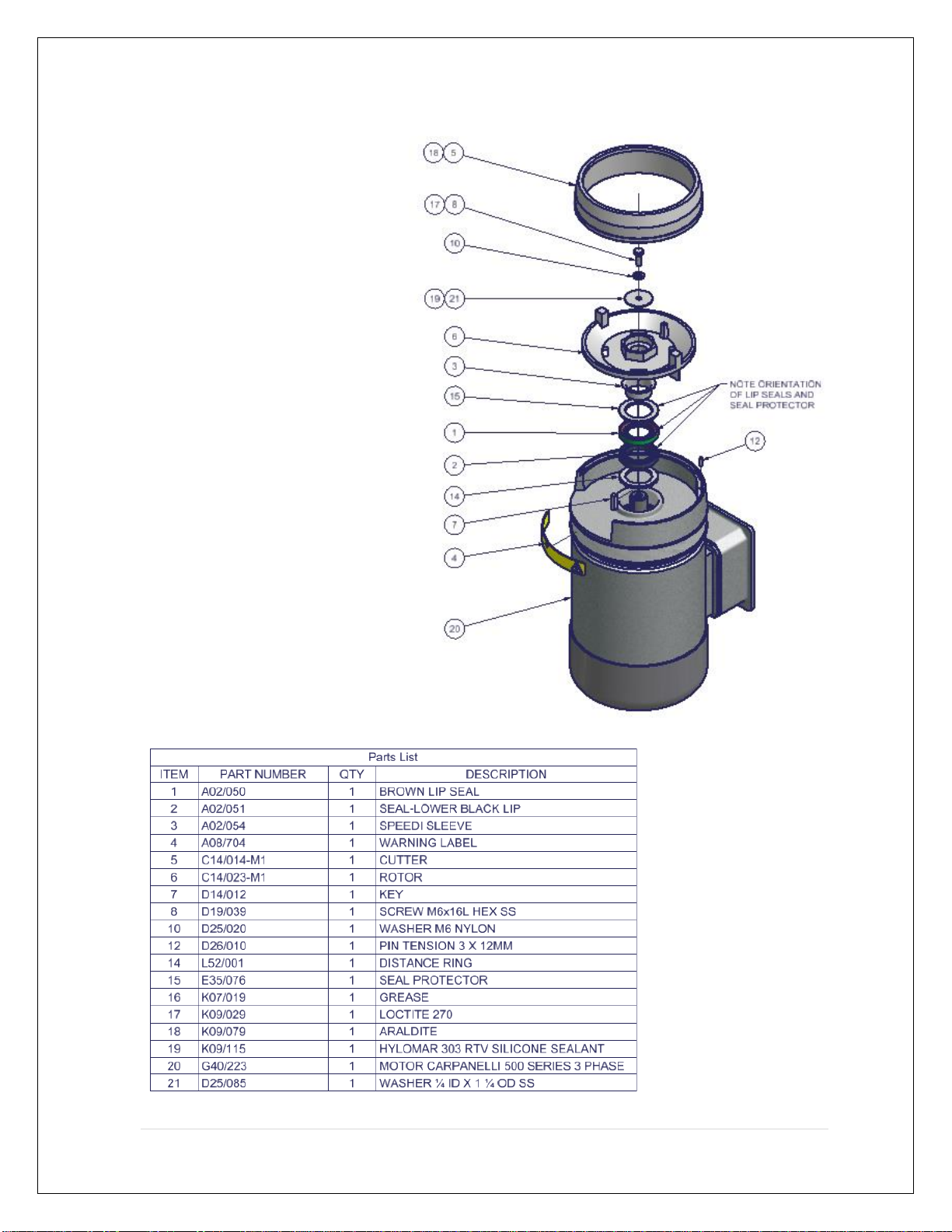

PARTS LIST –MACERATOR.............................................................................18

PARTS LIST F79/703 WasteStation Compact....................................................19

SPARES..............................................................................................................19

FAULT DIAGNOSIS............................................................................................20

ORDERING SPARE PARTS...............................................................................21

FURTHER INFORMATION.................................................................................21

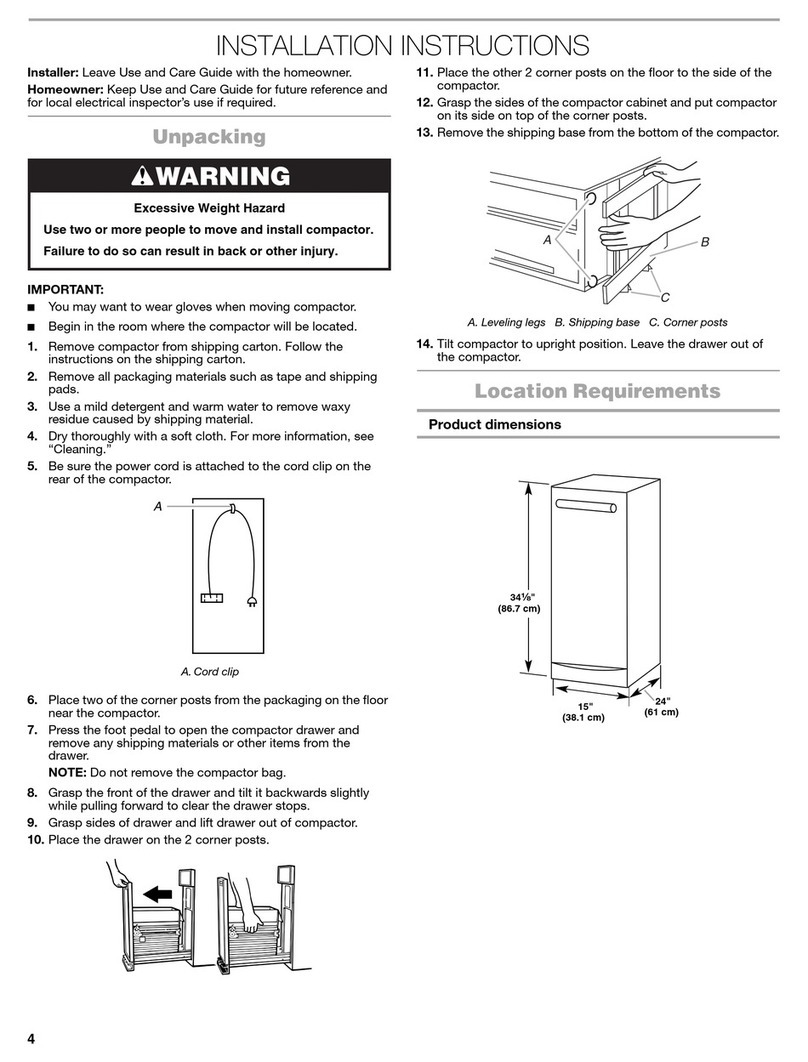

MACHINE DIMENSIONS

ALL DIMENSIONS IN mm

UNLESS OTHERWISE

STATED

STEEL CODE

DRAWN

ECN

DATE

X dimension Y dimension DWG

REVISION No

F79/240

OVERALL DIMENSIONS

Ian Marshall

1

TBA

12/02/21

TITLE F79/240 WASTESTATION COMPACT

GENERAL TOLERANCE ± BURR SIDE DOWN UNLESS OTHERWISE STATED SHEET

BEND RAD MAT THICKNESS Saved as \\master1\Solid Edge\Product Assemblies\IMC Products\WASTESTATION\F79-240 New Hopper.dft

DO NOT SCALE

WHISBY ROAD, LINCOLN, LN6 3QZ

0.4

©2021 LINCAT LTD

GENERAL ANGULAR TOLERANCE ± 1°

600 700

895 ADJUSTABLE

160

APPROX.

150 MAX

FOR

SERVICES

4 | P a g e

COLD WATER

CONNECTION

HOT WATER

CONNECTION

SERIAL No. LABEL

ELECTRICAL

SUPPLY

CONDUIT

WASTE

OUTLET

300 210

400

CONTROL BOX DIMENSIONS

View on Rear of Machine Showing

Connections for Services

INTRODUCTION

This machine is intended for the processing of food waste matter by maceration under an

automatic water flow, dewatering of the macerated food waste and discharge of the

dewatered food waste into a receptacle. The ‘grey’ water will be discharged into the

drainage system.

This machine is to be operated by trained personnel only.

MODEL INFORMATION

There is currently one 3 Phase version: -

F79/703 with motor (size combined) 4.1kW

Please read these instructions carefully for trouble-free installation and operation.

Please observe these instructions carefully.

The guarantee applies in this form to installations within the United Kingdom. Contact your

WasteStation supplier first.

ON DELIVERY

Please check the contents against the following list and notify both the Carrier and Supplier

within 24 hours if anything is missing or damaged.

Fully assembled WasteStation with following items loose: -

Release key = 1 off

Feeding Pusher = 1 off

Waste bin = 3 off

Instruction Manual = 1 off

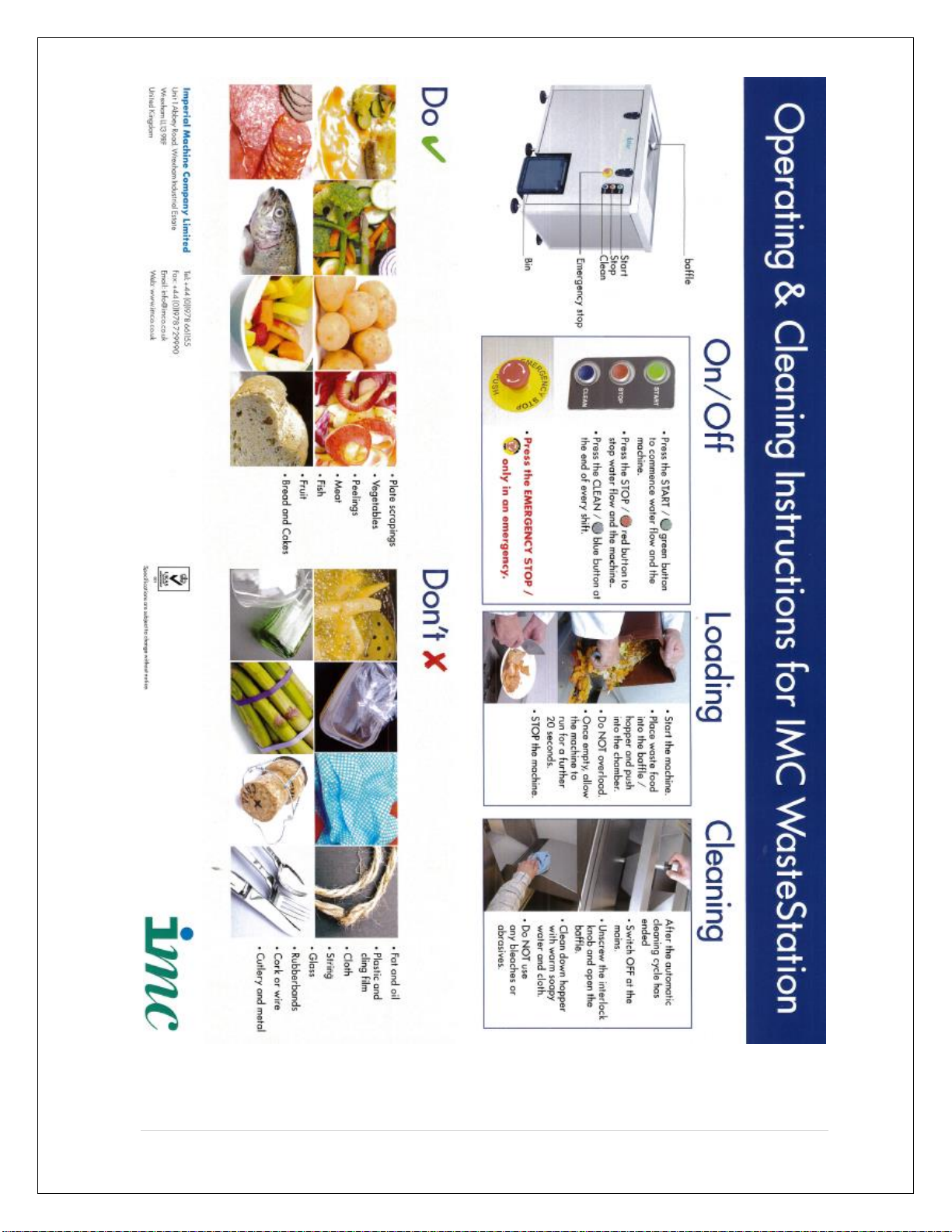

Operating Plaque = 1 off (wall mounted self-adhesive)

GUARANTEE

This machine is guaranteed by Lincat for 2 Years (UK warranty only) from the date of its

purchase from Lincat, or from one of its stockists, dealers or distributors. The guarantee is

limited to the replacement of faulty parts or products and excludes any consequential loss

or expense incurred by purchasers. Defects, which arise from faulty installation, inadequate

maintenance, incorrect use, and connection to the wrong electricity supply or fair wear and

tear, are not covered by the guarantee.

The guarantee applies in this form to installations within the United Kingdom only.

6 | P a g e

Please observe the following instructions carefully.

INSTALLATION OPTIONS

FOR THE INSTALLER

These Instructions contain important information designed to help the user obtain the

maximum benefit from the investment in an IMC WasteStation Compact.

Please read them carefully before starting work, and consult with the supplier in the event

of any queries.

Be sure to leave this Instruction Manual with the user after the installation of the machine is

complete.

The machine is operated from the built-in control box.

SELECTION OF SITE

Select the site of the WasteStation Compact with care so that it is convenient both for the

major source of food waste and for access by machine operators. The machine should be

installed as close to the existing drains as is reasonably practicable.

Install so that the front of the machine with the controls on faces the operator.

ORDER OF CONNECTION FOR ALL INSTALLATION OPTIONS

Install in the following sequence:

1 Adjust height and level to leave a gap of 100mm between the floor and underside

of machine chassis.

2 Reconnect the locknut tothe large cable gland onthe rear panel, remove side panel

for access.

3 Connect waste outlet to the drains

4 Connect both water supply pipes ensuring correct orientation

5 Connect the electricity supply

6 Test and make any necessary adjustments.

7 Fix the self-adhesive instruction plaque in a prominent position adjacent to machine

WARNING –THE MOTOR ON THE DEWATERER MUSTROTATE IN DIRECTION OF

ARROW OR SERIOUS DAMAGE WILLOCCUR TO THE UNIT DURING FOOD PROCESSING

IF THE PIPE JOINTS ARE NOT CORRECTLY MADE, WATER LEAKAGE MAY OCCUR

1. Move the unit into position and adjust the levelling feet, it is advised that the height of

the machine should be set to give a gap of 100mm underneath the machine to the

floor for cleaning access.

2. Using a spirit level, check that the top of the unit is level in both planes and that it is

at the required height. When correct, tighten all nuts and re-check levels.

3. Continue with SUPPLY CONNECTION INSTRUCTIONS.

SUPPLY CONNECTIONS –HOT AND COLD WATER INLET SUPPLIES

THE FOLLOWING ARE IMPORTANT INSTALLATION REQUIREMENTS

The plumbing system is to be installed and used in accordance with the requirements of the

Water Supply (Water Fittings) Regulations and Byelaws. The purpose of these regulations

is to protect your drinking water supply from contamination.

TheWasteStation Compact is supplied with a cold-water air break, customers are to ensure

that the HOT water supply is compliant and has an approved air break or back flow

prevention.

By-laws and Regulations vary by region so it is important to check with the authority having

jurisdiction in your area.

A 15mm HOT and a 15mm COLD water supply are required on WasteStations, and the

connections should be made to the ¾” ‘Washing Machine’ style connections on the rear of

the machine. The head of water should not be less than 0.18 bar (1.8m). Use the ‘NEW

Supplied Hoses’, Do Not Use ‘Old Hoses’.

When fitted with the class A air break hopper and baffle, these machines meet UK water

regulations. The water supply connection is achieved via a storage cistern or mains supply,

to which no other fittings are to be coupled.

The rate of water flow required for normal food waste is 8 -10 litres per minute.

8 | P a g e

WASTE OUTLET CONNECTION

The machines are fitted with a standard 2” waste pipe stub outlet. The size of these outlets

must not be reduced, and the drainpipe should run into 54mm outside diameter pipe work

as far as its junction with the main pipe or outside manhole connection.

The length of run between the machine and the main junction must be kept to a minimum

and the pipe run must have a fall of at least 1 in 7.

It is recommended that a running trap should be fitted, although “P” or “S” type traps can be

used. Do not use bottle traps. Changes of direction should be made by bends rather than

elbows and cleaning eyes should be fitted where possible, in accordance with standard

plumbing practice. Copper pipe and compression fittings should be used, but plastic tubing

is acceptable to most drainage authorities.

IMCWasteStations must have an independent waste pipe, which does not also serve sinks,

dishwashers and similar equipment. It is imperative that the waste pipe from the

WasteStation bypasses any existing in-line grease trap or grease separator that may be

present unless said trap or separator has been specified to suit the output of the

WasteStation along with the existing equipment. Should a grease trap or separator be used

solely for the WasteStation, it must be specified by the supplier to suit the output of the

WasteStation. If this outlet is positioned below a control box, it is important to use fittings,

which give at least the minimum 220 mm clearance, required for service access. Ensure

the installation complies with local water regulations.

Every machine is run and tested by Lincat before dispatch. The water flow adjustments will

require resetting when installed in the final location. A ‘full bore’service valve should be

installed in the pipe work to each of the water inlets and these should be set fully open to

start with, adjusting to suit during installation. Ensure that water supply demands made by

other equipment served by the same supply pipe do not starve the WasteStation. To avoid

this, run the piping in a size larger than recommended above and reduce at connection

point to the machine.

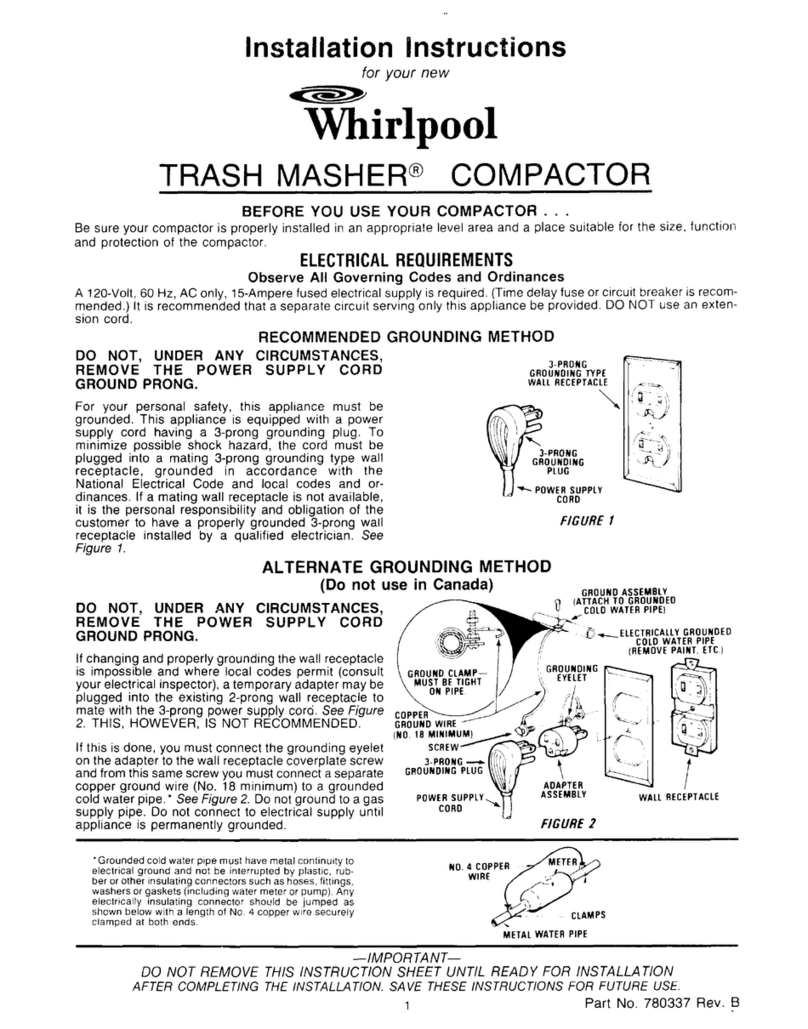

ELECTRICAL CONNECTION

All electrical work must be carried out by a qualified electrician and in accordance with the

IET Codes of Practice. Examine the rating plate located on the rear panel (next to the mains

inlet) to ensure that the characteristics shown are correct for the supply available. The

supply cable fitted is the minimum required for connection to the mains supply. Site

conditions may vary with additional length of cable run, encapsulation in trunking, bunched

with other cables etc. Should this apply, the electrician must alter the cable accordingly.

The WasteStation must be connected to a suitable 16 AMP three-phase isolator providing

at least 3mm separation in all poles.

The mains supply cord - cable colours and cable markings are shown in the table below:

Warning: This appliance must be earthed.

If the supply cord becomes damaged it must be replaced by qualified electrician in order to

avoid a hazard.

Examine the rating plate attached to the machine to ensure that the characteristics shown

are correct for the supply available. The rating plate is located on the rear of the machine.

Connection

Cable Colour

Cable Marking

Live 1

Brown

L1

Live 2

Black

L2

Live 3

Grey

L3

Earth

Yellow/Green

None

10 | P a g e

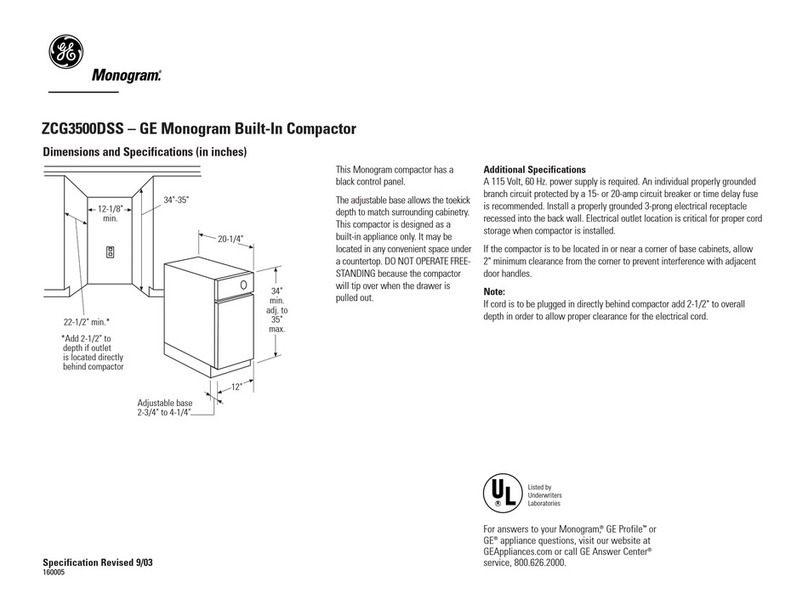

MACHINE RATINGS

The table below illustrates typical fuse ratings for an ambient temperature of 25-35

centigrade. Should the environment temperature be greater than this, de-rate accordingly.

Model

Electricity

Supply

Volts-

Phase-Hz

Input kW

Amps/phase

WasteStation

Compact

415-3-50

2.95

Note: Start-up current will be higher

The supply to the machine must also be protected by a 30mA RCD (type A,

curve B) such as IMC part number G76/043, which may be purchased separately from

the Lincat Spares Department (contact details shown on final page of this document)

WARNING: This machine must be earthed

WARNING: This machine must not be PAT tested under any circumstances.

It contains an inverter (motor drive) which can be damaged by the test and the test results

will be invalid anyway. This advice is in accordance with standard practice within the

industry and is due to the inductive/capacitive components used within the inverter. If in

doubt, please contact Lincat Service Department.

TESTING

Check finally that all supply connections are correctly made and soundly fixed, that nothing

has been left in the grinding chamber, that the rotor is free to rotate (use the release key if

necessary) and that the interlock knob is screwed down (FINGER TIGHT ONLY).

The machine is now ready to operate.

OPERATION OF MACHINE

During the operation of the machine certain indicator lights will be illuminated on the front

control box these give an indication of what operation the machine is carrying out.

MACHINE RUNNING MODES & INDICATOR LIGHTS

When the machine is running the button lights on the front of the machine will be constantly

lit or flash, the meaning of this is explained below.

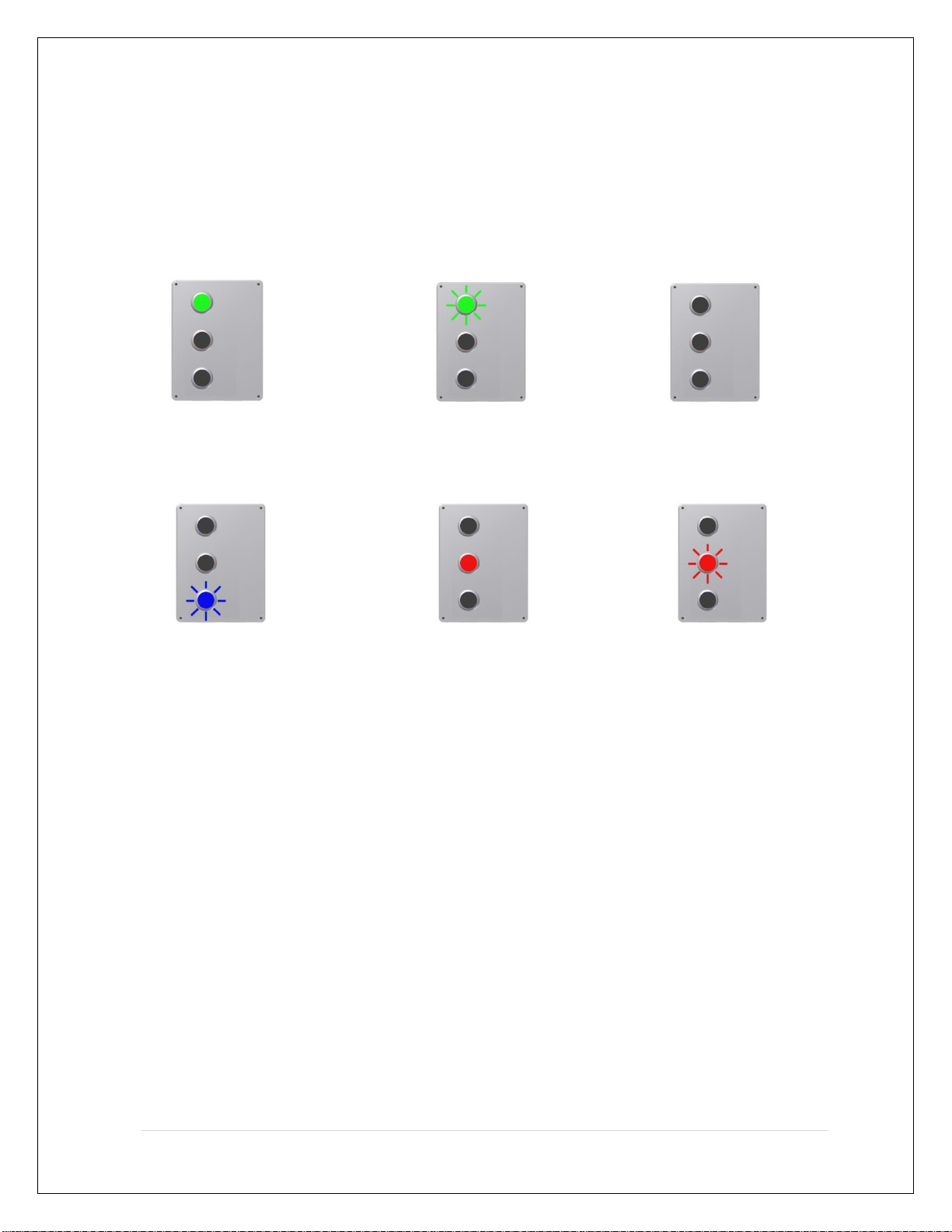

Solid Green Flashing Green No Lights

Machine Running Machine Stopping Machine Stopped

No Warnings

Flashing Blue Solid Red Flashing Red

Machine in Cleaning Mode WARNING! –Bin Not Present WARNING! –Bin Full

Machine Stopped Machine Stopped

12 | P a g e

INITIAL OPERATION

1. Switch on the electricity and water supplies.

2. Ensure that a waste bin is in place in the machine outlet area (a red light will

illuminate if the bin is not in place).

3. Press the green ‘START’ button, water should flow immediately, if no water flows

within 2 > 3 seconds, press the emergency stop button to stop the machine and check

the water supply connections and ensure that the water supplies are turned on.

4. With the machine running, inspect the waste and water supply piping for leaks. Use a

flow meter to check that the volume of water flowing is correct –refer to WATER

SUPPLY CONNECTION. If adjustments are needed, use a screwdriver to adjust the

position of the slot on the control screw of the service valve. Maximum flow is with the

slot in line with the pipe.

5. Undo the front panel of the machine by releasing the black catch on the front panel.

Ensure that the auger within the dewaterer (WastePro II) is rotating in a clockwise

direction (viewed from top and same direction as the arrow on the motor). Replace

the front panel ensuring the catch is secured.

6. Try a small amount of food waste (see poster on next page) to check disposal and

dewatering are working successfully and that there is no internal obstruction in the

waste pipe causing a blockage. Also check that a small amount of waste goes into

the waste bin.

7. With the machine running unscrew the baffle interlock knob .The machine will switch

itself off almost immediately. By the time the knob is fully unscrewed and the safety

baffle open, the rotor in the grinding chamber will have completely stopped.

When these checks, tests and adjustments are completed, the IMC WasteStation

Compact is ready for use.

On completion of installation, Commissioning, the appliance is now operational. The

person in charge of this equipment must keep this manual in a safe place and accessible

to all operators and servicing providers. It is the site’s responsibility to ensure adequate

training and instruction has been provided to all associated personnel involved in the

operation of the appliance.

875520

14 | P a g e

NORMAL OPERATION

1. Ensure that safety baffle is closed and the interlock knob is screwed down fully but

lightly. (Do not overtighten).

2. Press green button to start. This activates the start-up sequence. Allow 20 seconds

to fully complete the start up.

3. Feed waste into the hopper at a slow uniform rate (not too fast), using the feeding

pusher if necessary, briefly allowing each load to clear the macerator before feeding

in the next batch.

4. If the macerator stalls or is severely overloaded, it may cause the automatic cut out

on the motor to operate. Once the motor has cooled it can be re-started. Note that

stopping the motor and restarting it reverses the direction of the rotor and can help

to relieve an overload. If the machine remains stalled, see RELEASING A JAM

below.

5. If overly wet food goes into the waste bin then the rate of feeding the hopper should

be decreased, and the unit allowed to run with no food for a short while to allow it to

flush.

RELEASING A JAM

Food Waste Disposers can jam under overload or if unsuitable materials are placed

inside. IMC machines are designed to withstand this and no damage will normally

result, as the machine will switch itself off. It is necessary to clear the jam as follows:

1. Switch off at the mains isolating switch.

2. Remove the baffle by unscrewing the interlock knob and lifting off.

3. Take out any bulk waste in the disposal chamber. Rubber gloves are

recommended

4. If the item, which blocked the disposer, is apparent, remove it.

5. A release wrench is provided with which to turn the rotor if it is jammed. Place

the hexagon socket of the wrench over the hexagonal boss on the centre of

the rotor, or the tines into the rotor and against the cutting edges (depending

on the type of key supplied) lever backwards and forwards until the jammed

material releases. Remove the release wrench and remove the material.

6. Replace the wrench, and ensure that the rotor is totally free throughout its full

rotation.

7. Remove the release wrench

8. Replace the baffle, screwing the interlock knob fully home.

9. Switch on at the mains isolating switch.

10. Press the START button and continue disposal.

In the event of difficulty, call your supplier or the manufacturer for a qualified service

engineer.

NOTE

The macerator and dewaterer motors, are each protected by a thermal overload relay. If

either motor experiences a problem (e.g. due to a component jam) then the machine will

automaticallyshut down for ashort period (typically 10-15 minutes). At the endof this period

the thermal overload relay will reset itself and the machine will return to normal standby

mode ready for operation.

The pump motor is protected by an inverter. If the pump motor experiences a problem, the

inverter will register a fault and the machine will automatically shut down and will remain

inoperable until the problem is rectified and the fault condition on the inverter is cleared.

Should this occur, please contact service personnel for advice.

WATER FLOW CONTROL

When operating theWasteStation, the water flow control should initially be set at its highest

position before turning it down whilst the waste is being processed. The rate of water flow

can be adjusted up or down for each installation to take account of unique factors such as

the length of, and number of bends in, the drainage piping, and the fall of the pipe.

A bucket of warm (NOT HOT), soapy water poured into the FWD’s hopper at the end of

each day will both clean the equipment and help disperse any residual solids in the piping.

MAINTENANCE

Daily: Clean down thoroughly after use especially inside the hopper. Unscrew the safety

interlock knob and open the baffle to gain access internally

Cleaning is assisted by the use of a low-pressure spray, an IMC Pre-Rinse Spray or

a Reel-Kleen retractable hose reel.

Place a washing bowl with some warm soapy water in it into the waste bucket area,

unclip the waste chute and with a ‘dishwashing brush’ or similar, clean out the inside

of the outfeed chute and also the outfeed area of the dewaterer.

Wipe over the exterior of the machine, including the back areas not normally visible.

Proprietary cleaners may safely be used but avoid particularly aggressive cleaners

and neat bleach solutions.

End each day by pressing the blue ‘Clean’ button and allowing the machine to

perform its own dewaterer internal automated cleaning cycle (a bin must be in place

to do this)

12 monthly: Check for motor bearing wear by:

-Sound of motor

-Side movement of rotor

-Maintenance Guide MG-016 refers to the Maintenance of the macerator

unit.

16 | P a g e

WARNING –BEFORE ATTEMPTING SERVICE WORK ENSURE THAT

ELECTRICITY SUPPLY AND WATER SUPPLY ARE TURNED OFF AT THE MAIN SUPPLY AND

WATER STOPCOCK.

USAGE

1 THE IMC WASTESTATION COMPACT IS DESIGNED FOR THE DISPOSAL

AND DEWATERING OF FOOD WASTE.

2 DO NOT PUT CLING FILM, LIQUID FAT, STRING, CLOTH, PLASTIC, WIRE,

GLASS, CORK, STYROFOAM, BOILING WATER, HOT SOUP, HOT LIQUID,

BONES OR METAL OBJECTS INTO THE MACHINE.

3 ALWAYS START THE MACHINE BEFORE PUTTING WASTE INTO IT.

INTRODUCING MIXED WASTE INTO THE MACHINE WILL ENSURE MORE

EFFICIENT DISPOSAL THAN ACCUMULATING AND INTRODUCING

WASTE OF A SIMILAR NATURE.

4 DO NOT FEED LARGE AMOUNTS ALL AT ONCE, THIS WILL CAUSE

BLOCKAGES.

5 IF FEEDING LARGE QUANTITIES OF THE SAME FOOD ITEM, i.e. RICE,

PASTA, POTATOES ETC. IT MUST BE FED SLOWLY ALLOWING EACH

SMALL BATCH TO PASS THROUGH THE DEWATERER INTO THE BIN OR

BLOCKAGES MAY OCCUR.

6 IN NORMAL OPERATION, THE MACHINE SHOULD ALWAYS BE STOPPED

BY PRESSING THE RED BUTTON. THE EMERGENCY STOP BUTTON

SHOULD BE RESERVED FOR GENUINE EMERGENCIES. STOPPING THE

MACHINE ROUTINELY USING THE RED BUTTON WILL CAUSE

BLOCKAGES AND DAMAGE WITHIN THE DEWATERER MODULE, PUMP

OR CONNECTING PIPES.

7 UNDER NO CIRCUMSTANCES SHOULD THIS MACHINE BE PAT-TESTED,

AS DOING SO MAY CAUSE DAMAGE TO THE INVERTER CONTAINED

WITHIN THE CONTROL BOX. REFER TO PAGE 11 FOR FURTHER

INFORMATION.

CIRCUIT DIAGRAM: WASTESTATION COMPACT 415V-3 PHASE-50HZ

Note that this schematic diagram, plus the full wiring diagram, are both available

on request from the Lincat Service Desk (see page 25 for contact information)

18 | P a g e

PARTS LIST –MACERATOR

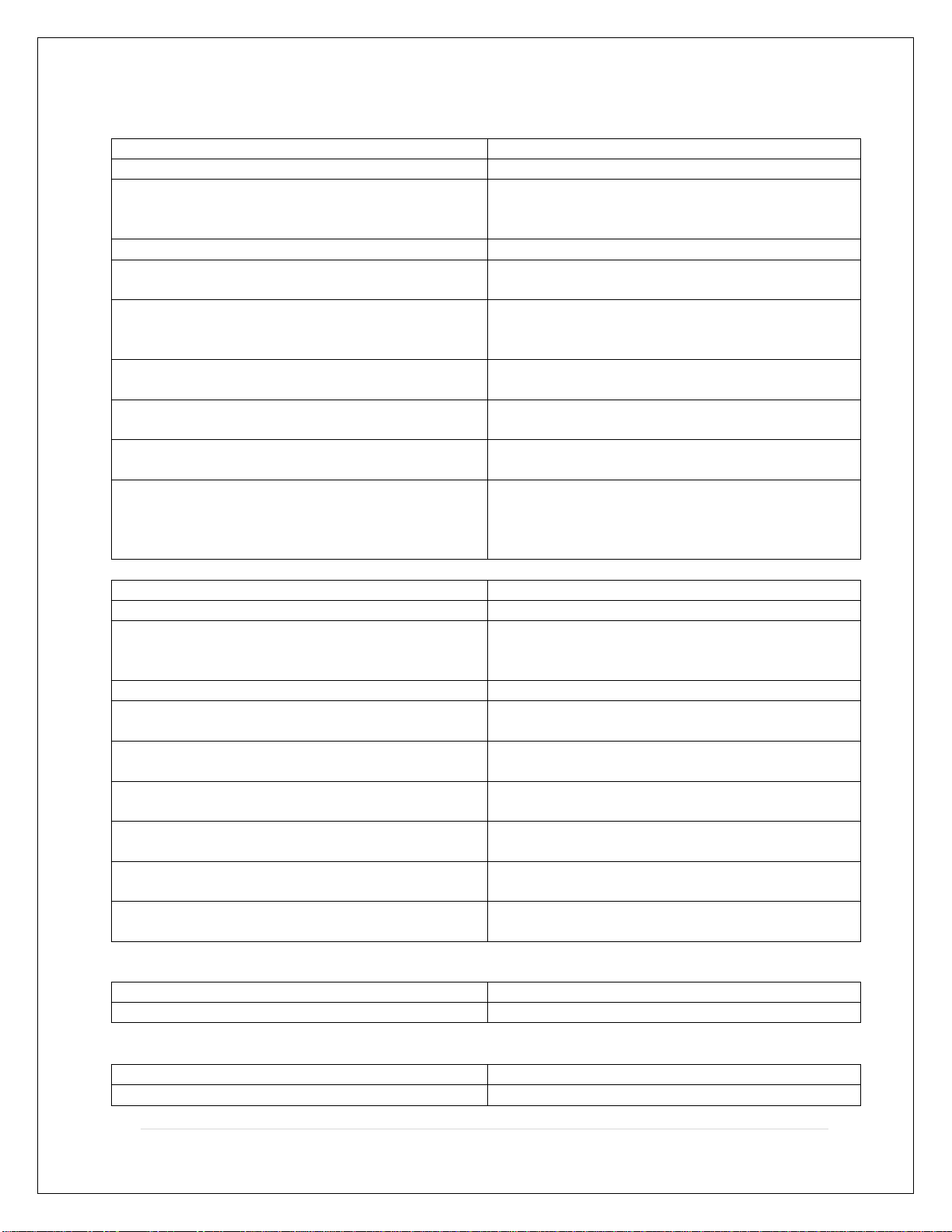

PARTS LIST F79/7030 WASTESTATION COMPACT

REF

PART No.

DESCRIPTION

1

S79/043

Hopper Interlock Switch Assembly

2

S79/273

Baffle Assembly Full

3

A21/052

Single Aerocatch

4

G45/121

Emergency Stop ‘Switch Only’

5

J03/165

Solenoid Valve (X1)

6

S78/106

Dewaterer Complete Assembly 3PH

7

S60/002

Macerator Assembly 3PH

8

A19/034

Adjustable Foot

9

A09/034

Pump Full Assembly

10

879269

Outlet Chute, Clip On

11

G45/140

Ultrasonic Bin Level Sensor

SPARES

PART NO

DESCRIPTION

A13/125

Scraper

E19/024

Release Key

J06/072

Inlet Hose

K12/469

Waste Bin

G76/043

RCD, 30mA, type A, curve B (for installing the machine) see page 10

20 | P a g e

FAULT DIAGNOSIS

Machine does not start

Cause

Action

Electrical supply is not turned on.

Switch on supply.

The mains isolator is switched off or RCD has

tripped

Call site electrician to switch on the isolator or

reset the RCD. If problem persists contact

service personnel

Waste bin is full (flashing red light)

Empty and then replace the bin

Waste bin is out of position (solid red light)

Replace the bin in its correct position

inside the bin enclosure on the machine

Baffle is not correctly fitted

Check baffle is in position and secured. If

problem persists contact service personnel

(see safety circuit also)

1 of the motor overload relays has tripped

Rectify the problem then reset the overload

relay.

The inverter is in a fault condition causing

machine to trip

Contact Service personnel

Emergency stop button has been pressed.

Deal with the emergency then reset the button

by turning it clockwise as shown on the button

Safety Circuit In Error

Check baffle is in position and secured; Check

Emergency stop is released; check magnet is

still present within the baffle knob assy. If

problem persists contact service personnel

Unexpected system stop

Cause

Action

Electrical supply turned off

Switch on supply.

The mains isolator has been switched off or the

RCD has tripped

Call site electrician to switch on the isolator or

reset RCD. If problem persists contact service

personnel.

Waste bin is full (flashing red light)

Empty and then replace the bin

Waste bin is out of position (solid red light)

Replace the bin in its correct position

inside the bin enclosure on the machine.

Baffle is not correctly fitted

Check baffle is in position and secured. If

problem persists contact service personnel.

1 of the motor overload relays has tripped

Allow motor to cool for 10 minutes and restart.

If problem persists contact service personnel.

The inverter is in a fault condition causing

machine to trip

Contact Service personnel

Emergency stop button has been pressed

Deal with the emergency then reset the button

by turning it clockwise as shown on the button.

Waste jammed in disposer grinding unit

Remove blockage from grinding unit.

See instructions on page 14.

Waste not processed

Cause

Action

A blockage has occurred in the waste pipe.

Clear blockage from waste pipe.

Slurry in Bin

Cause

Action

Feeding too quickly.

Allow to clear and feed more slowly.

Table of contents

Other IMC Trash Compactor manuals