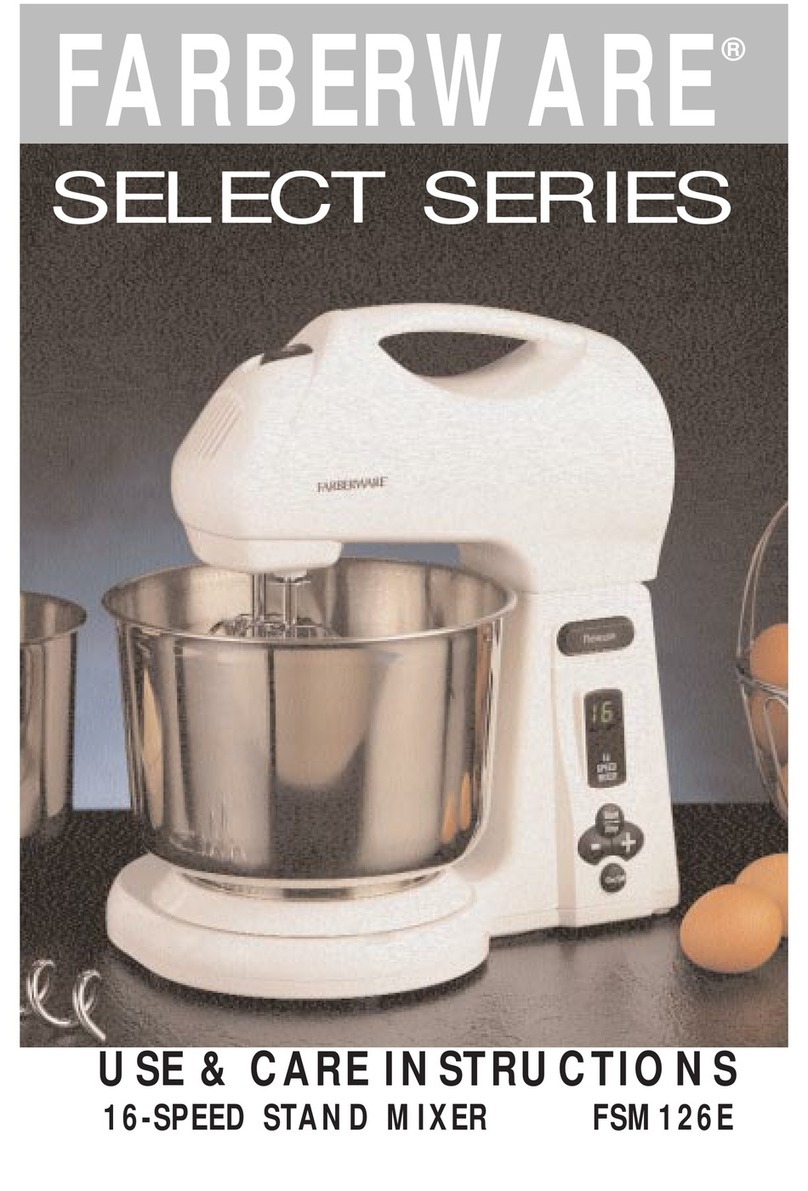

IMER USA MORTARMAN 360 A MortarMixer User manual

IMER INTERNATIONAL S.p.A.

MIX 360

1

MORTARMAN® 360"A" MortarMixer

INSTRUCTION MANUAL and PARTS LIST

MANUAL DE USO, MANTENIMIENTO y RECAMBIOS

Machine serial N°

Part. number 3211378 R02 - 2018/09

Thank you for purchasing a Mortarman® 360 from an IMERU.S.Adealer.

Your decision is an intelligent one. There is no other mortar mixer in the world which delivers the

benets

and features of the Mortarman® 360:

- Revolutionary horizonal mixing action.

- Oil bath gearbox, plenty of torque to mix materials wet or dry.

- Full width fenders and independent suspension ......standard gas or electric motors can be swapped

back and forth in under an hour.

- Advance drum and paddle design, excellent mixing and discharge action.

- Telescopic foot stands which provide additional stability during operation.

- Reduced Maintenance ....no zerks to grease or bearings to pack.

At IMER U.S.A we continually search for ways to better serve our customers.

Should you have an idea or thought to share with us regarding thisproduct we would apppreciate

hearing

from you. Our motto is "Tools and Services for the 21st Century". We look forward to deliveringthe

goods.

Thank you again for your purchase,

Mace T. Coleman Jr.

President, Imer U.S.A. Inc.

3654 EnterpriseAvenue

Hayward , 94545 California

Toll Free (800) 275-5463

Ofce: (510) 670-7970

Fax (510) 783-4255

IMER INTERNATIONAL S.p.A.

MIX 360

3

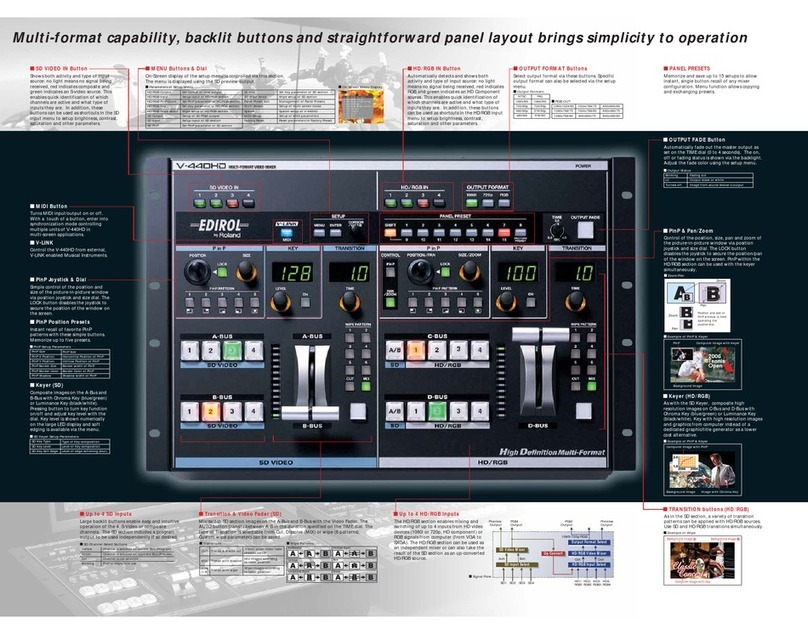

IMPORTANT

MIXING INSTRUCTIONS

AGGREGATE BIGGER THAN 1/8" WILL DAMAGE MIXER

SAND SILO

LIME

CEMENT

PRE - MIX 60 lb

SPEC - MIX 80 lb

SILO

Set up mixer

Start mixer

Do not add water

1. Add 1/2 sand

2. Add lime

3. Add cement

4. Mix materials dry

5. Add 3/4 of water

6. Add rest of sand

7. Add rest of water

8. Mix up thoroughly

Set up mixer

Start mixer

Do not add water

1. Check bag weight

2. Determinate max load

3. Add 1/2 of max load

4. Add 3/4 of water

5. Add rest of bags

6. Mix up thoroughly

Set up mixer

Start mixer

Do not add water

1. Add 1/2 of max load

2. Add 3/4 of water

3. Add rest of material

4. Add rest of water

5. Mix up thoroughly

MIXER DRUMCAPACITY

120:4.5 CUBIC FEET (250 lbs)*

240:9 CUBIC FEET (400 lbs)*

360:13 CUBIC FEET (700 lbs)*

750:27 CUBIC FEET (1700 lbs)*

* WEIGHT IS COMBINED SAND, LIME, AND CEMENT MIXTURE

IMER INTERNATIONAL S.p.A.

MIX 360

4

Dear customer,

congratulations on your choice of purchase: the IMER cement mixer, the

result of years of experience, is a very reliable machine equipped with all

the latest technical innovations.

The machine can mix both dry or wet ne grain materials (plaster, mor-

tar, cement, oor sub-bases, rendering, synthetic resins or pre-packed

mixes).

WORKING IN SAFETY

In order to be able to work in complete safety, the following instruc-

tions must be read carefully

- This OPERATING AND MAINTENANCE manual must be kept on site

by the person responsible for the site, e.g. the SITE FOREMAN, and

must always be available for consultation.

- The manual should be considered as being an integral part of the ma-

chine, and must be kept for future reference (EN 292/2) until the ma-

chine itself is disposed of. If the manual becomes damaged or lost, a

replacement can be obtained from the manufacturer.

- The manual contains important information regarding the preparation

of the site, installation and use of the machine, maintenance and spare

parts ordering. Nevertheless, the installer and operator must both have

adequate experience and knowledge of the machine.

- In order that the safety of the operator, safe working and long life of

the equipment can all be guaranteed, the instructions in this manual

must be followed together with safety standards and health and safety

at work laws currently in force (use of suitable footwear and clothing,

use of helmets, gloves and goggles, etc. in accordance with S.I N° 3073

of 30/11/92.

. ALWAYS MAKE SURE THAT SIGNS ARE LEGIBLE

. It is strictly forbidden to carry out any form of modication to

the structure or working parts of the machine.

IMER International decline any responsibility in the case of non-compli-

ance with laws and standards governing the use of this equipment. In

particular: improper use, defective power supply, lack of maintenance,

unauthorised modications, partial or total failure to observe instructions

contained in this manual.

1. DESIGN STANDARDS

The MIX360 mixer has been designed and constructed in accordance

with the following standards:

IEC 34.1; IEC 34.5; EN292-1,EN292-2,EN60204-1.

2. NOISE EMISSION LEVEL

Table 2 indicates the noise level produced by the mixer, measured at

the operator’s ear (LpA at 1 m - 98/37CE) and the environmental noise

emission level (power LWA) measured in accordance with EN ISO 3744

(2000/14/CE).

TABLE 2

TYPE OF MOTOR LpA(dB) LWA(dB)

ELECTRIC 70 81

ENGINE 88 103

3. MIXING CAPACITY

The mixing capacity of the machine per cycle is 200 litres (approximate-

ly half of the tank height).

4. SAFETY MEASURES

-The IMER cement mixer can only function if all the safety devices with

which it is equipped are in perfect condition.

-The machine will not operate if the mains connection is defective.

-On-site power connection lines must be installed so that they cannot

be damaged. Do not stand the machine on the mains connection line.

-The power lines must be installed so that water cannot penetrate con-

nections. Only use connectors tted with protection against water spray.

-Repairs to the electrical plant must only be carried out by specialised

personnel. Do not operate the mixer during maintenance or repair op-

erations.

-Accident prevention and health and safety at work regulations must be

complied with in the working area.

. The machine must only be stopped using the appropriate

switch.

. Do not open the tank protection cover to stop the machine.

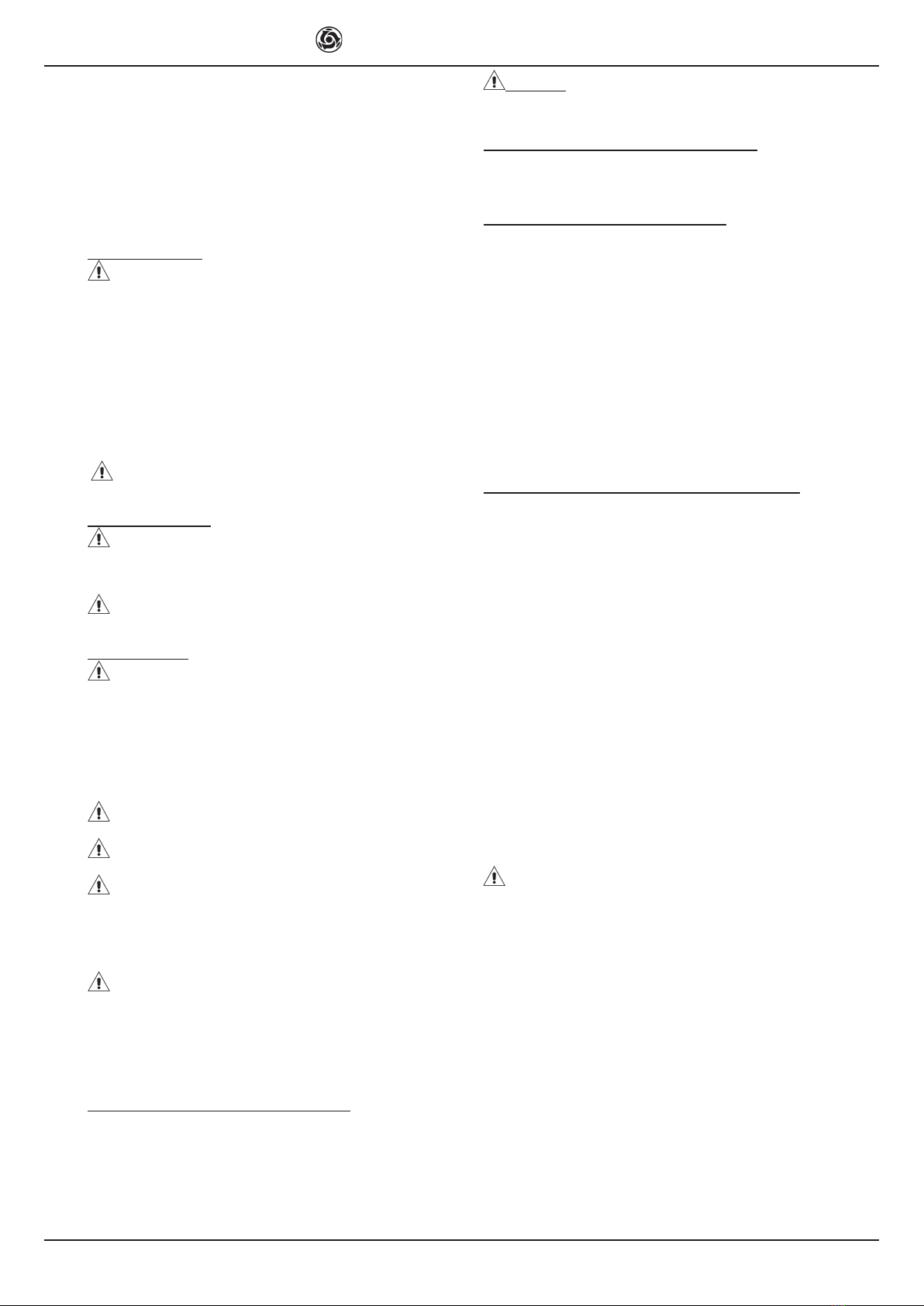

5. ELECTRICAL SAFETY

The IMER mixer complies with standards EN60204-1. In particular, it is

equipped with a system that prevents automatic restart after the power

supply line is interrupted.

-Residual current protection of electrical equipment

-Electrical safety device that prevents the machine from operating when

the tank protection cover is open.

When used on construction sites, the mixer can be connected to an

earthing system by attaching an earthing braid (or wire) of minimum

section 16 mm² (see Fig. 2).

6. MECHANICAL SAFETY

-A guard over the outlet prevents access to the mixing zone.

-The tank protection cover allows the mix components to be loaded with-

out access to the mixing zone.

The mixer will stop if the cover is opened.

7. TRANSPORT

. WARNING!! Always disconnect the machine from the mains

before moving it.

-When on-site, the mixer can be moved manually from one location to

another as shown in Fig. 3.

-For other types of handling, the mixer must be lifted using a four-cable

sling attached to the lifting lugs, as shown in Fig. 4.

8. INSTALLATION

Lift the mixer (the mixer is tted with a lifting jack - ref. 4, g. 7).

- Screw in the outlet opening handle (see Fig. 6).

If there are no lifting means available, lift the mixer using the jack sup-

plied (see Fig. 7).

1 - Raise the rear supporting legs (Ref. 2 Fig. 7) to their maximum height

and lock them in position using the locking pins.

2 - Use the handle (Ref. 1 Fig. 7) to raise the machine, resting it on the

rear legs (Ref. 2 Fig. 7).

3 - Position the front legs (Ref. 3 Fig. 7) (towing side) at the height re-

quired and lock them using the locking pins.

4 - If the machine is to be positioned at maximum height, insert the lower

lug (Ref. 5 Fig. 7) in the support (Ref. 7 Fig. 7), raise and lock the rear

legs (Ref. 2 Fig. 7) at the third hole from the bottom.

5 - Remove the lower fork connection Ref. 5 and lower the jack so that

the upper fork connection can be inserted (Ref. 6 Fig. 7), then complete

the lifting operation.

For intermediate working levels, the rear part of the machine should be

lifted in a single operation, as in points 1 and 2, by using the lower con-

nection point on the jack (Ref. 5 Fig. 7).

To return the machine to the towing position, follow this procedure in

reverse order.

Position the machine on level ground, adjusting the telescopic legs to

the required height.

Ensure that the machine is in a stable working position.

9. USE

-Do not allow other people to remain in the vicinity of the machine dur-

ing operation.

-Do not use the machine in a re-risk zone. Sparks may cause res or

explosions.

-Always switch off the machine before leaving it unattended.

-The machine must only be transported or positioned with the motor

switched off.

9.1 START-UP

9.1.1 ELECTRICAL CONNECTION

-Check that the supply voltage is the same as dataplate specications.

-Ensure that the power supply line is tted with a differential protection

device upstream.

-Connect the machine to the earthing plant and the mains power supply.

-Ensure that the blades rotate in a clockwise direction.

If the paddles rotate in an anti-clockwise direction, stop the machine,

disconnect the mains plug and invert one of the phases inside the plug,

by rotating the inverter slot between the pins using a screwdriver (Fig.

8).

- Start the motor by pressing the black on/off pushbutton on the control

panel.

9.1.2 ENDOTHERMIC MOTOR

-Check the motor (see motor manual).

-Check the motor oil level (see motor manual).

-Fill the fuel tank (see motor manual).

IMER INTERNATIONAL S.p.A.

MIX 360

5

-Start the motor, following the instructions contained in the motor man-

ual.

-Allow the motor to warm up at reduced rpm.

-Increase the rpm to maximum using the accelerator lever mounted on

the frame.

Machines with an endothermic motor are tted with a centrifugal ex-

panding clutch mounted on the motor.

The clutch enables the paddle rotation speed to be increased gradually,

which can be stopped when the motor is operating at minimum rpm.

Motor operating speed can be controlled by means of the accelerator

lever (rif. 5, tab. 9).

9.2 WORKING CYCLE

. WARNING! Check that the machine stops rotating when the

tank protection cover is lifted.

Start-up the machine with the tank empty.

-With the water supply connected to the mains, start feeding water by

opening the valve mounted on the tank, and add the cement and ag-

gregate.

-The tank protection grid is tted with a bag splitter to enable pre-packed

mixes to be used.

-When the mix has reached the required consistency, place a suitable

container under the outlet and, keeping the paddles moving, open the

outlet using lever Ref. 1 (see Fig. 9).

Lift the lever to position A and push it as far as possible to position B.

To close the outlet, return the lever to Pos. C.

. Avoid starting the machine with a full load.

Do not overll the tank (see 3. MIXING CAPACITY).

10. EMERGENCY STOP

. In the event an electric motor fault, press the OFF pushbutton

(Ref. 17 Fig. 1) and disconnect the mixer from the power supply.

In the case of endothermic motors, move the acceleration lever to

the minimun position.

. The motor is protected from thermal overloads. If it overheats

it will stop. It must be allowed to cool before restarting.

11. MAINTENANCE

. WARNING! Before carrying out any form of maintenance

work, always switch off the mixer.

-Replace worn or faulty components using original spare parts.

-Check the oil level through the transparent level indicator on the side of

the reduction gear casing.

-Change the oil in the reduction gear with SAE 90 oil after 2000 hours of

work (approximately 0.9 Kg).

-To top up or replace the oil, used the ller pipe (ref. 1, g. 10). Lift the

motor casing to gain access to the ller.

. Used oil is classied as special waste and must be treated as

such in accordance with laws in force.

. Always ensure that writing and other instructions on the ma-

chine are legible.

. Always ensure that the protection devices are undamaged

and efcient.

-At the end of the work session, remove dirt and/or any other deposits

formed during mixing by washing thoroughly (to wash the machine, use

the wash-water hose with pressure regulator, Ref. 51 Tav. 1, mounted

on the mixing tank valve).

. Check the condition of the power cable before using the ma-

chine; it may have become inadvertently or unknowingly damaged.

-Check the endothermic motor according to the instructions contained

in the motor manual.

If guards are removed due to maintenance requirements or other excep-

tional circumstances, proceed as described below, and always ret the

guards before resuming operation.

11.1 COVER PROTECTION ADJUSTMENT(FIG. 11)

The adjustment of the limit switch must be carried out with the tank

protection cover lowered.

Move the limit switch to the correct position using the slots and re-tight-

en the screws for disel engine.

The lling side cover grid opening is protected by a interlocked cut off

device that stops the engine as the protection cover is lifted, the adjust-

ment is carried out by correcting the lenght of the wire and re-tighten

the screw.

. WARNING

Check that the machine stops when the tank protection cover is

lifted

11.2 OUTELET PROTECTION REMOVAL (Réf.Fig.12)

- Slacken screws Ref. 2 and remove protection Ref. 1.

- To replace the protection, align the holes with those of brackets Ref. 3

and tighten with screws Ref. 2. Use spanner N°13.

11.3 MIXING PADDLE REPLACEMENT (Fig.13)

- Lift the tank protection grid Ref. 1.

- Remove head protection Ref. 2, rotating it in an anti-clockwise direc-

tion.

- Slacken screws Ref. 3 and nuts Ref. 4. Use open-ended spanner N°17

and Allen key N*6.

- Remove the paddle clamps Ref. 5, 6 and 7 and replace the worn rub-

bers Ref. 8, 9 and 10. Inserting the new rubbers between holders Ref.

11, 12 and 13 and clamps Ref. 5, 6 and 7. Utilize the slots to adjust as

necessary and lock in position with nuts and bolts Ref. 3 and 4.

- Push arm Ref. 14 to manually rotate the paddles in a clockwise direc-

tion, checking the mating of the rubbers with the tank.

- If there are zones where the rubber is not in contact with the tank,

repeat the adjustment. Re-adjust utilizing the slots in brackets Ref. 15

and 16 if necessary.

- Replace and lock in position protection Ref. 2, rotating it in a clockwise

direction. Lower the cover grid Ref. 1.

11.4 TENSIONING AND REPLACING TRANSMISSION BELTS

11.4.1 MIXERS FITTED WITH ELECTRIC MOTOR

(Fig. 14)

1. Unscrew the locking screws and lift the motor casing.

Use spanner N°6.

2. To tension the belts, slacken nut Ref. 1, tighten nut Ref. 2 and re-

tighten nut Ref.1. Use spanner N*19.

3. To replace the belts, slacken nut Ref. 23?? and nut Ref. 1, remove the

old belts. Replace them with new belts of same characteristics. Tension

as described in point 2.

4. Lower the casing and lock in position with the locking screws.

11.4.2 MIXERS FITTED WITH ENDOTHERMIC MOTORS

(Fig. 15)

1. Unscrew the locking screws and lift the motor casing. Use spanner

N°17.

2. To tension the belts, slacken nut Ref.1, tighten nut Ref.2 and re-tight-

en nut Ref.1.

3. To replace the belts, slacken nuts Ref.1 and Ref.2, remove the old

belts. Replace with new belts of same characteristics. Tension as de-

scribed in point 2.

4. Lower the casing and lock in position with the locking screws.

- Check the tension of the transmission belts after 4 hours from rst

start-up and after each belt change, otherwise check the tension every

18-20 hours.

. When replacing transmission belts, remember that a too tight

belt will cause damage to shafts and bearings, a too slack belt will

wear out rapidly.

11.4.3 REQUIREMENTS FOR CORRECT TRANSMISSION

BELT TENSIONING (Fig. 16)

To ensure correct tension of the transmission belts, apply a force “F”

(0.9 kg) on the centre of section “S”; distance “f” should be as specied

in the table in Fig. 16.

IMER INTERNATIONAL S.p.A.

MIX 360

6

12. TROUBLESHOOTING

. WARNING!

Switch the machine off by pressing the OFF pushbutton and dis-

connect from power supply before carring out any maintenance

operations.

PROBLEM CAUSE REMEDY

(MIXER WITH

ELECTRIC MOTOR)

The motor does not

start when switched

on.

- No power in the

supply line - Check the line

- The electric plug

and socket are not

connected properly

- Make a proper

connection

- The cable from the

plug to the electric

panel is broken

- Replace the cable

- A wire has become

disconnected inside

the panel

- Re-make the

connection

- A wire has become

disconnected on the

motor terminal board

- Re-make the

connection

- The pushbutton is

faulty.

- Replace the

pushbutton.

- The protective cover

is open - Close it

- The limit switch is

faulty - Replace it

- A wire has becone

disconnected inside

the limit switch

- Re-make the

connection

The endothermic

motor does not start - See motor manual

The discharge outlet

leaks water

- The sealing gasket

is worn - Replace the rubber

- The spring is broken

or ineffective - Replace the spring

Scraper rubbers do

not mate with the

tank

- Worn rubbers

- Replace the

rubbers and/

or adjust their

position (11.3

MIXING PADDLE

REPLACEMENT)

The outlet will not

open

- Depositin the outlet

protector

- Remove and clean

the outlet(11.2

REMOVAL OF TANK

PROTECTION

COVER)

During mixing,

the paddle rpm

decreases or

paddles stop

- Belts are slack and

are slipping

- Tension the

belts(11.4

TENSIONING

AND REPLACING

TRANSMISSION

BELTS)

Water does not

arrive at the tank

- There is no water in

the feed line

- Change the feed

line

- Water hose or valve

blocked

- Clean the hose or

valve

The blades do

not stop when the

protection cover is

raised

- Limit switch not

mounted correctly

- Adjust position of

limit switch (11.1)

- Cam not mounted

correctly

- Refer to limit

switch adjustment

instructions (11.1)

13. RESIDUAL RISKS AND SAFETY NOTICES

Although the machine is constructed in line with established legislation,

certain residual risks cannot be eliminated and require the use of indivi

dual safety equipment. The machine is equipped with notices to indicate

the residual risks and how to avoid them.

NOISE HAZARD

Wear ear defenders

HAND CRUSHING/SHEARING HAZARD

Wear gloves

EYE INJURY HAZARD

Wear safety glasses

INCORRECT USE HAZARD

Read the manual before operating the machine

TRAPPING/CRUSHING AND SHEARING HAZARD

Do not remove the guards

Do not touch drive components

ELECTROCUTION HAZARD

Danger - electrical power

Note that the employer is responsible for ensuring his workers use indi-

vidual safety equipment.

DANGER INHALATION POWDER

CAUTION !!!

Keep the hands away from the outlet.

ALWAYS avoid inhalation of and skin contact

with silica dust and/or mist. Provide proper

dust removal. Use dust-collection system when

applicable.

SILICA DUST WARNING

Grinding/cutting/drilling of masonry, concrete, metal and other materials

with silica in their composition my give off dut or mists cintainig crystalli-

ne silica. Silica is a basic component of sand, quartz, brick clay, granite

and numerous other minerals and rocks. Repeated and/or substantial

inhalation of airborne crystalline silica can cause serious or fatal respira-

tory diseases, including silicosis. In addition, California and some other

authorities have listed respirable crystallinesilica as a substance known

to cause cancer. Whwn cutting such materials, always follow respiratory

precautions.

Use appropriate NIOSH-approved respiratory protection where dust

hazard may occur. Paper masks or surgical masks without a NIOSH

approval number are not recommended because they do little to protect

the worker. For more information about respirator programs, including

what respirators have received NIOSH approval as safe and effective,

please visit the NIOSH website at:

http://www.cdc.gov/niosh/topics/respirators

IMER INTERNATIONAL S.p.A.

MIX 360

7

Observe OSHA regulations for respirator use (29 C:F.R. § 1910.134).

Visit http://www.osha.gov for more information.

California proposition 65 message

Some dust created by power sanding, sawing, grinding, drilling, and other

construction activities contain chemicals know (to the State of California)

to cause cancer, birth defects or other reproductive harm. Some exam-

ples of these chemicals are:

-Lead, from lead-based paints

-Crystalline silica, from bricks and cement and other masonry products

-Arsenic and chromium, from chemically treated lumber

For further information , consult the following sources:

http://www.osha.gov/dsg/topics/silicacrystalline/index.html

http://www.cdc.gov/niosh/docs/96-112/

http://oehha.ca.gov/prop65/law/P65law72003.html

http://www.dir.ca.gov/Title8/sub4.html

http://www.P65warnings.ca.gov

Your risk from these exposures varies depending on how often you do

this typer of work. To reduce your exposure to these chemicals, work in a

well-ventilated area, and work with approved safety equipment, such as

dust masks that are specially designed to lter out microscopic particles.

Where use of a dust extraction device is possible, it should be used. To

achieve a high level oof dust collection, use an industrial HEPA vacuum

cleaner. Observe OSHA 29 CFR part 1926.57 and 1926.103.

IMER INTERNATIONAL S.p.A.

MIX 360

8

DESCRIPTION

l1 4-6,3 (A) SWITCH + COIL

MMOTOR

S1 LIMIT SWITCH

PE EARTH LINE WIRE

RPHASE LINE

WIRE 1

SPHASE LINE

WIRE 2

TPHASE LINE

WIRE 3

400 V

400 V

PRESA

CEE 400V - 50/60HZ

16A h6

400V / 50-60Hz

IMER INTERNATIONAL S.p.A.

MIX 360

9

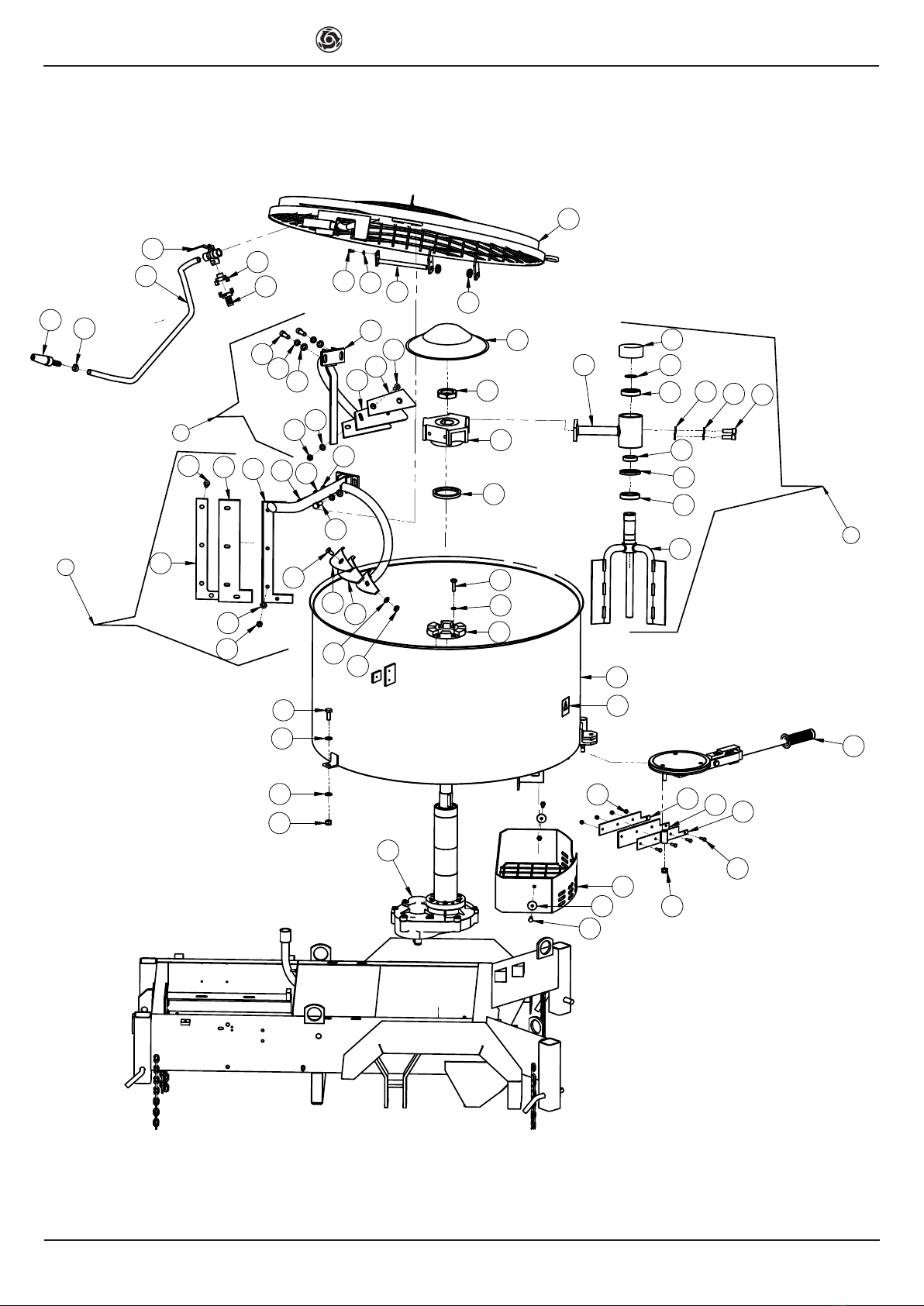

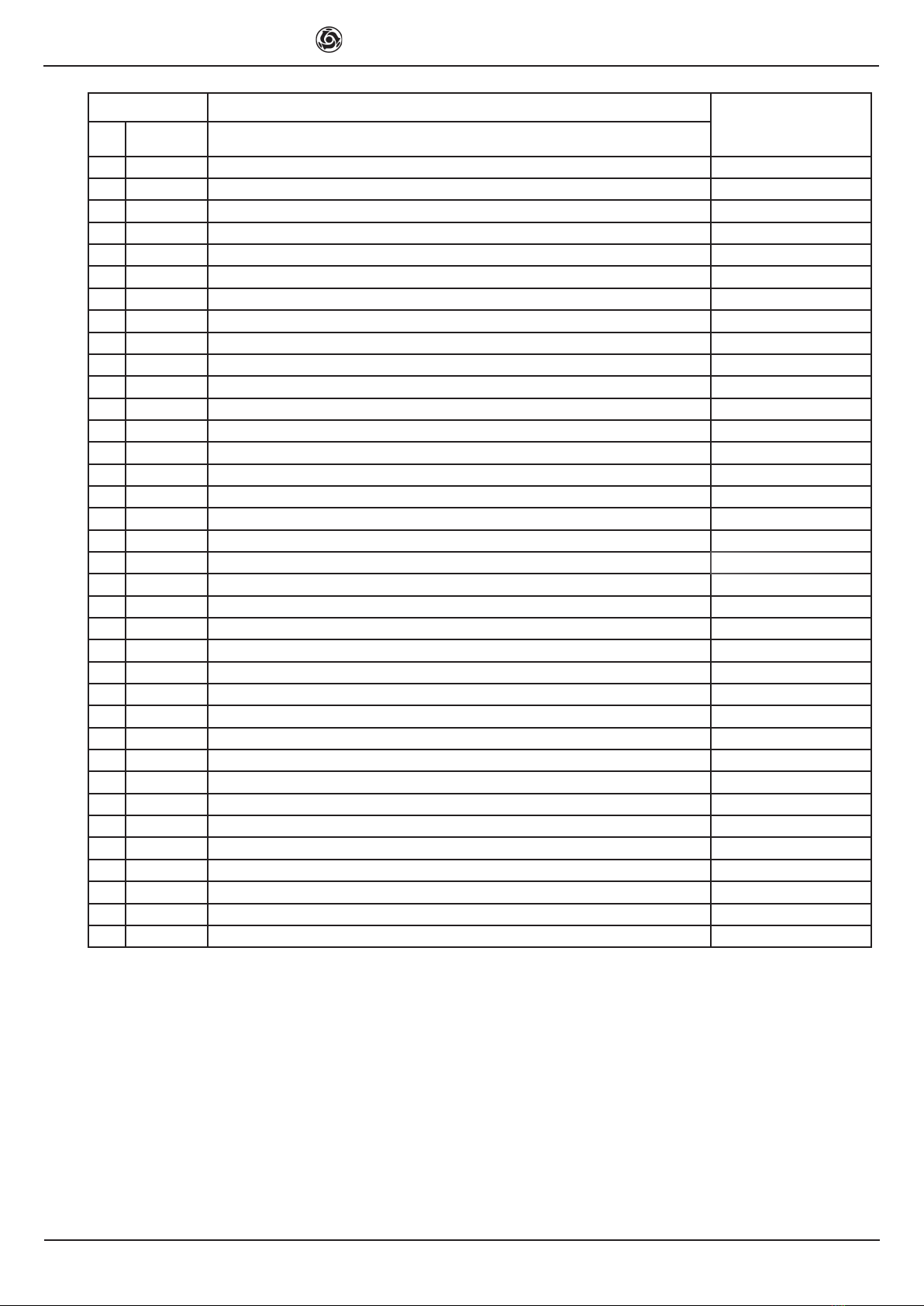

TAV. 1 DESCRIPTION NOTE

Rif. COD.TANK ASSEMBLY

12206763 REDUCTION GEAR

32218068 TAP

42222181 BOLT 5739 M12x30

52222073 BOLT 5739 10X35

62222076 BOLT 5739 M8x25

72223921 NUT Autobl.M12

82224910 WASHER Dev.C72 Ø10z

93224203 FITTING

10 2226800 FITTING

11 3210979 TANK

12 3211274 PROTECTION

13 3211022 ROUND NOZZLE

14 2236593 BOLT PROTECTOR

15 2223924 NUT AUTOBL. M 6

16 3228545 PROTECTION GRID

17 2207750 OIL SEAL RING

18 2222550 BOLT UNI5931 M12x35

19 2224380 WASHER 6593 Ø12X25

20 2224900 WASHER Dev. C72Ø12z

21 2250334 HEAD

22 3211025 ROTATING PADDLE

23 2257710 PROTECTION

24 2252604 PROTECTION

25 2250916 PADDLE ASSEMBLY

26 3211028 PADDLE ASSEMBLY

27 2222599 BOLT 5933 M10X15

28 2223655 NUT 5589 M10

29 3211607 PERIPHERAL S CRAPER

30 2294771 PADDLE

31 2250934 RUBBER

32 2250919 PADDLE HOLDER

33 2294770 PADDLE

34 2250935 RUBBER

35 2227220 STOP RING

36 2204505 BEARING

37 3211026 ARM

38 3206002 MIXER

39 2222016 BOLT 5739 M6X20

40 3211600 OUTLET SCRAPER

41 2247876 RUBBER

42 3211033 BACKING PLATE

43 3211036 RUBBER

44 2253853 BACKING PLATE

45 3211383 BOLT UNI 5739 M6X16

46 2201912 PIN

49 2209953 BUSH

50 2222601 BOLT 5933 M10x30

51 2218069 FIXED NOZZLE

52 2225741 CLIP

53 2226779 HOSE CONNECTOR

54 2292356 RUBBER HOSE

55 3205992 OIL SEAL RING

56 2288205 ADHESIVE LABEL

57 3206003 RING

58 2224920 WASHER M6 Z

59 2223840 NUT

60 2224190 WASHER 8X32 Z

61 2224340 WASHER M10X20 Z

IMER INTERNATIONAL S.p.A.

MIX 360

10

6

4

15

60

39

59

7

19

41

24

40

23

12

44

13

16

57

55

35

36

36

38

19 18

8

5

14

19

7

11

43

28

61

50

42

18 20

19

4

28

61

31

20

18

19

32

34

33

1

21

20

27

28 61

27

49

46

58

45

22

26

25

29

30

37

3

9

10

54

51

17

52

56

TAV. 1

IMER INTERNATIONAL S.p.A.

MIX 360

11

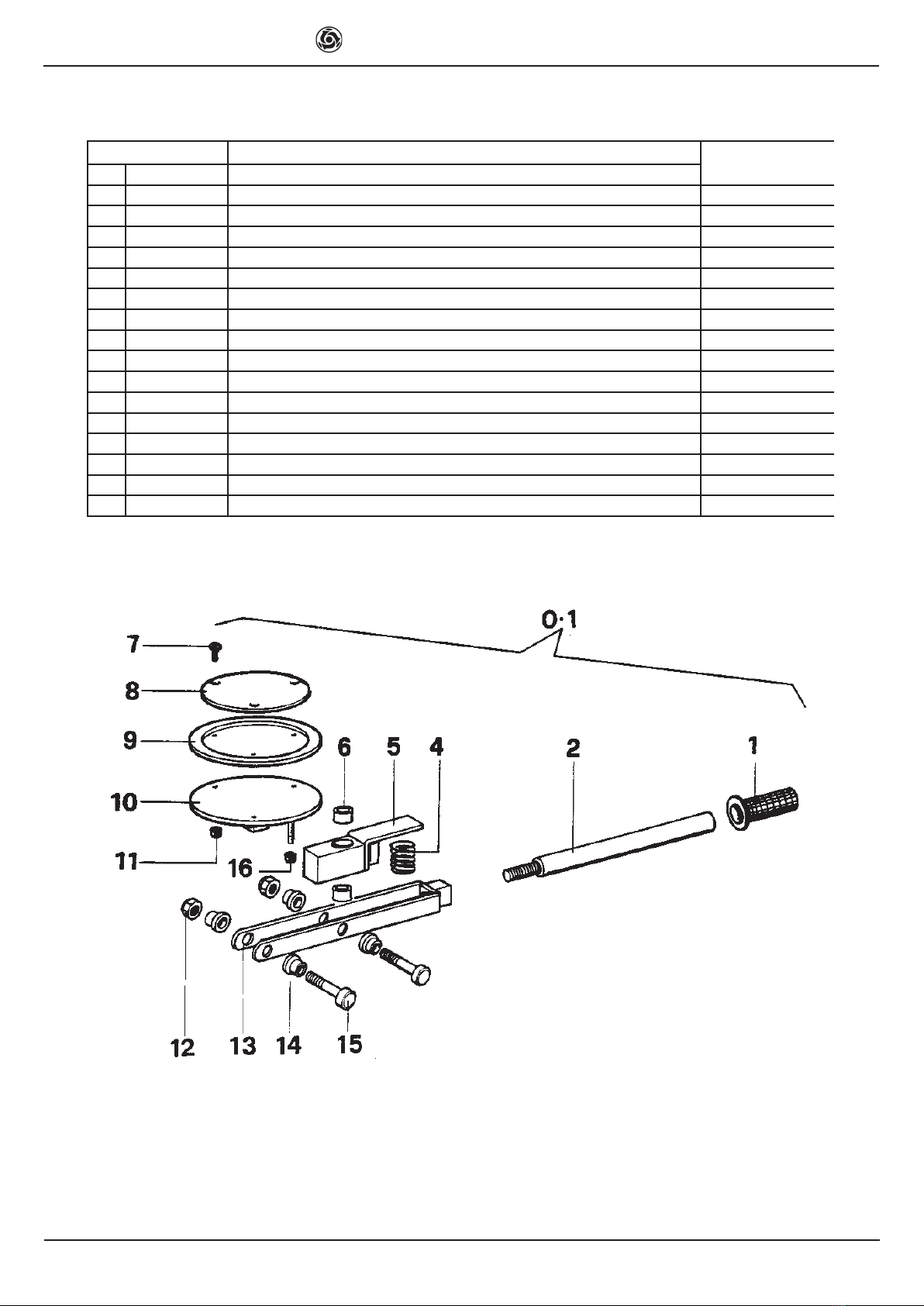

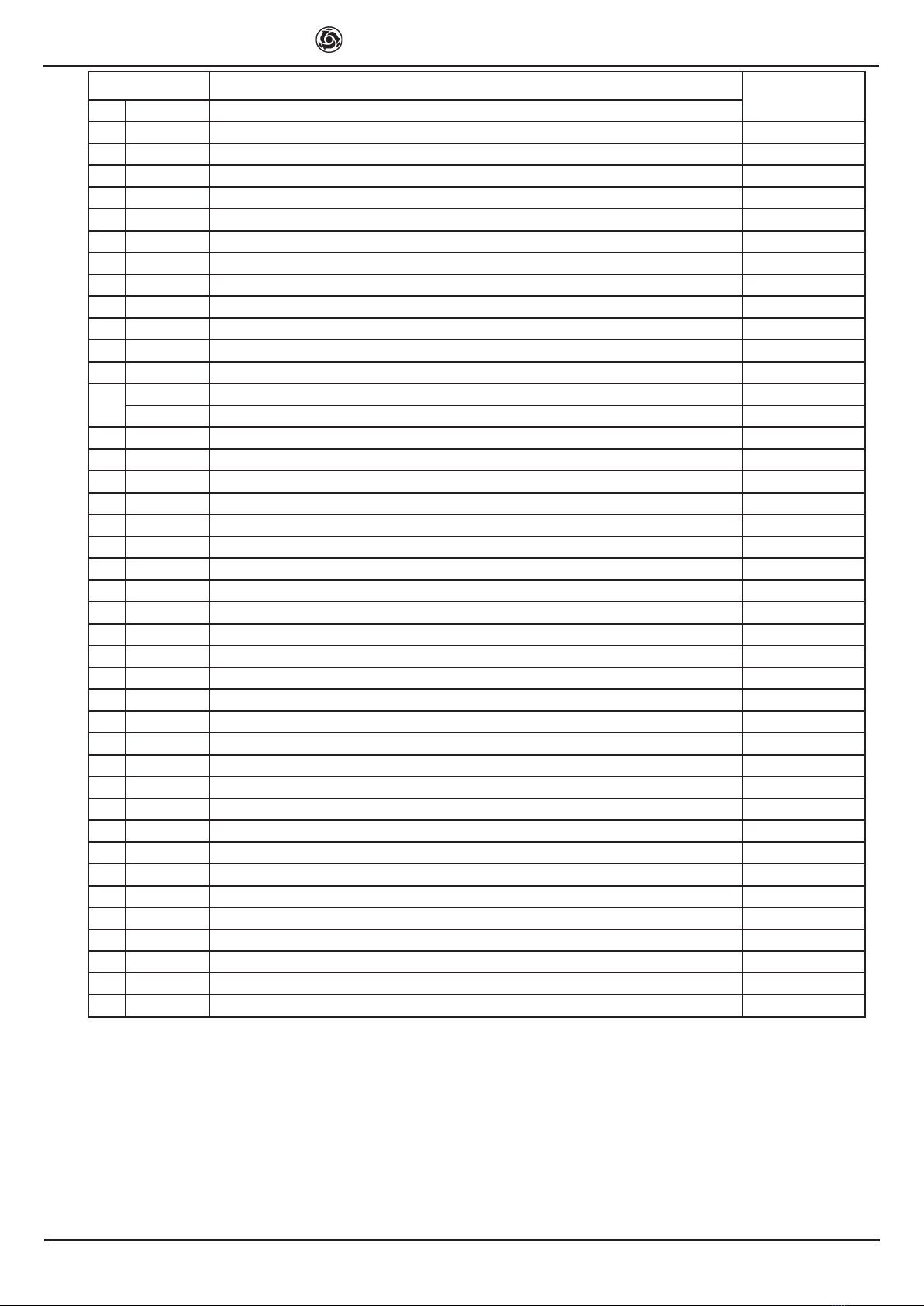

TAV. 2 DESCRIPTION NOTE

RIF. COD.OUTLET ASSEMBLY

0.1 3211022 OUTLET ASSEMBLY

1 2288885 HANDLE

22259894 OUTLET LEVER

4 2231301 SPRING

52237795 JOINT

62209822 BUSH

7 2222600 BOLT 963 M6x26

8 2225033 DISC

9 2292581 GASKET

10 2253863 DISC

11 2223924 NUT

12 2223920 SELF LOCKING NUT AUTOBL. M 6

13 2254015 FORK 7474 M10

14 2209821 BUSH

15 2223006 BOLT

16 2223921 SELF LOCKING NUT 7474 M12

IMER INTERNATIONAL S.p.A.

MIX 360

12

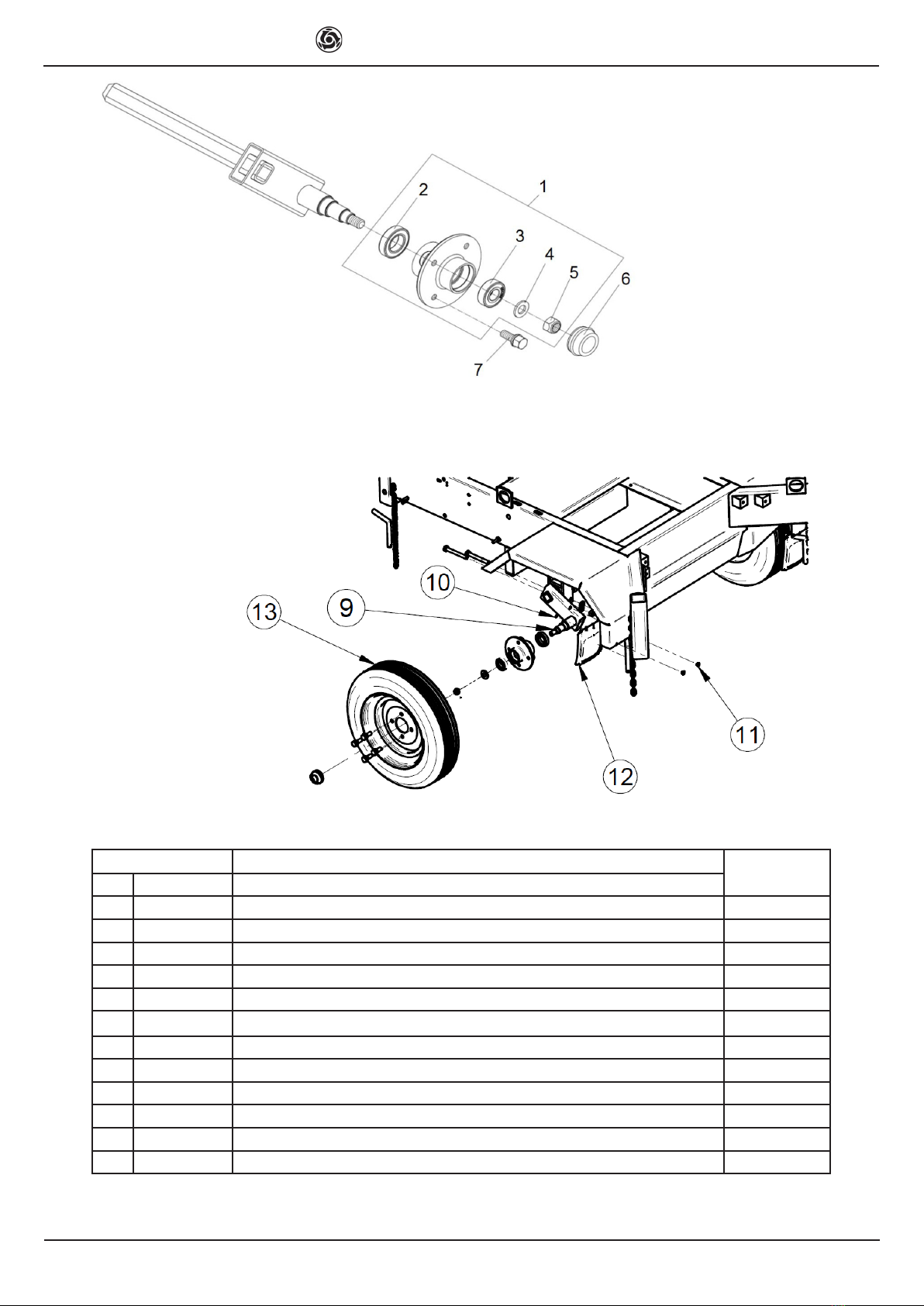

TAV. 3 DESCRIPTION NOTE

RIF. COD.TOWING ASSEMBLY

13236429 HUB

23210629 BEARING

3 2204560 BEARING

4 2224640 WASHER 16x33x3 Z

5 3236427 SELF LOCKING NUT

6 3236428 COVER

7 3234146 BOLT

93236410 AXLE

10 2224532 WASHER 4x8 Z

11 3236412 RIVET

12 3236412 SPLASH GUARD

13 2211407 WHEEL

IMER INTERNATIONAL S.p.A.

MIX 360

13

TAV. 4 DESCRIPTION NOTE

RIF. COD. FRAME ASSEMBLY

1 2222566 BOLT 5931 M12X80

2 2222016 BOLT 6950 M6X20

3 2216277 GASKET

4 2225745 CLIP

52223921 NUT AUTOBL.M10

6 2226700 SPLIT PIN

7 3211268 NIPPLES

8 3225284 SECURITY CABLE

9 3210977 FRAME

10 3201044 PROTECTION

11 3230525 HANDLE/TOW BAR

12 2256128 LEG

13 3210978 JACK

14 3211047 PROTECTION

15 2256600 PIN

16 2257705 TERMINAL

17 3211087 CASING 400v 50 Hz

3211052 CASING Honda - Hatz

18 2224530 WASHER

19 2292370 RUBBER HOSE

21

3211110 IDENTIFICATION PLATE 400v 50Hz

3211106 IDENTIFICATION PLATE Honda

3226905 IDENTIFICATION PLATE Hatz

24 2222530 BOLT

25 2235460 PLUG

26 2222056 SCREW 5739 M 10X25

27 2259537 COVER

28 2224340 WASHER 6592 Ø10X20

29 2223920 SELF LOCKING NUT 7474 M10

30 3230526 HANDLE/TOW BAR MS4-900004

31 3208565 HEAD TOWING

32 2222049 BOLT 5737 12X80 z

33 3209781 TIMONE PLATE

34 3236412 SPLASH GUARD

35 3230304 SUPPORT

36 3208587 PIN

1

32

29

5

6

25

27

10

31 33

13

14

17

30

34

16 24

26 35

36

12

28

8

2

18 2

18

5

3

7

11

15

9

4

19

12

21

IMER INTERNATIONAL S.p.A.

MIX 360

14

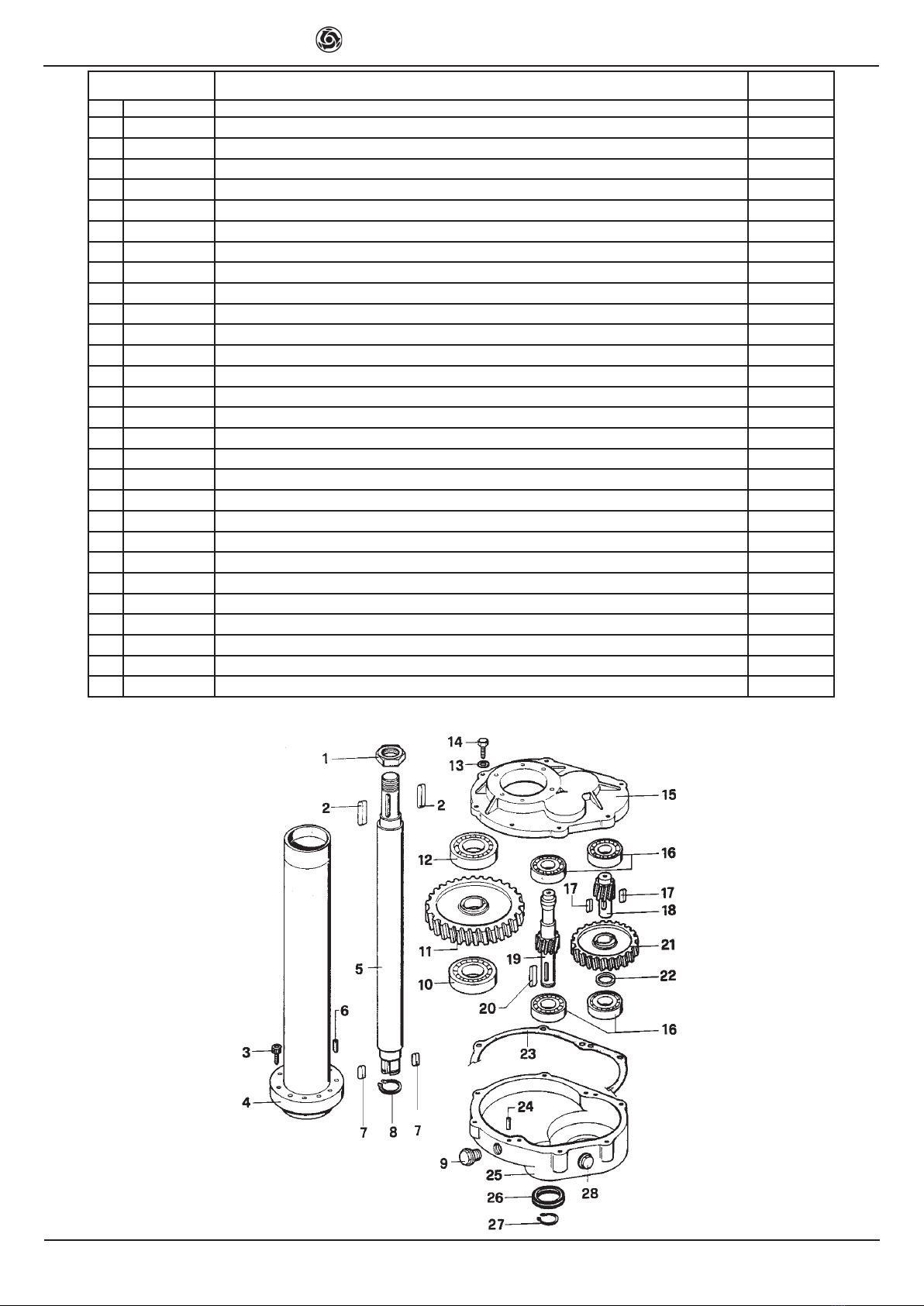

TAV. 5 DESCRIPTION MIX 360

RIF. COD. REDUCTEUR GEAR NOTE

1 2223840 NUT 5589 MB42

22229602 KEY 10X8X50

3 2222530 BOLT 5931 8X35 Z

42258007B ROD

5 2201161 CENTRAL SHAFT

6 2228740 GROUND PIN

72229549 KEY 10X8X30

8 2227260 STOP RING 3653 E34

92235420 OIL LEVEL PLUG

10 2204509 BEARING

11 2202517 GEAR

12 2204510 BEARING

13 2224140 WASHER Ø 8X18

14 2222006 BOLT 5739 M8X30

15 2236735 FLANGE M 21

16 2204550 BEARING 6205

17 2229450 KEY 8X7X20

18 2202858 PINION

19 2202871 PINION

20 2229400 KEY 6604 8X7X30

21 2202526 GEAR

22 2237256 SPACER

23 2216319 GASKET

24 2228820 GUDGEON PIN Ø 6X14

25 2215092 REDUCTION GEAR CASING

26 2207301 OIL SEAL RING 42X25X7

27 2227270 STOP RING 3653 E24

28 3211268 PLUG

IMER INTERNATIONAL S.p.A.

MIX 360

15

TAV. 7 DESCRIPTION NOTE

Rif. COD.ASSEMBLY OF MOTOR 400V 50Hz

2 2222016 BOLT 5739 6x20z

3 3228538 BELT AX 63

4 2205538 PULLEY DP 130 2A

5 2222581 BOLT

63201598 PLUG

8 2224531 WASHER 6593 6x18z

93236670 SWITCH

11 3211047 PROTECTION

12 2222146 SCREW 5739 M10X30

13 2224260 WASHER Ø10X30 z

15 1224113 WASHER 6593 Ø10X50

16 3228506 ELECTRIC MOTOR Kw 3 - 400V/50Hz

17 2205581 PULLEY DP 100 2A

18 2223920 NUT AUT. 7474 M10

19 2223650 NUT uni-5588 M10

20 3211076 BOLT M10x80z

21 3211057 MOTOR MOUNTING PLATE

24 3211073 LIMIT SWITCH

25 3211826 CABLE CLAMP 25X1.5

26 3211096 CABLE CLAMP PG 13.5

27 2222021 BOLT 5739 M6X16z

28 2223920 NUT AUT. 7474 M10

29 3211767 SUPPORT

30 3231562 SPANNER

31 3211067 PIN

32 3211064 SUPPORT

33 3211075 BOLT 7380 M6X40

34 3211091 SUPPORT

35 3211391 SHEATH

36 2222098 SCREW 5739 M10X40

37 3211360 SCREW M.6X10 ISO 7380

38 2222077 SCREW M 10X20 Z

39 2224530 WASHER 6X12.5Z

40 3201044 PROTECTION

41 3228572 CABLE CLAMP

42 3236412 SPLASH GUARD

IMER INTERNATIONAL S.p.A.

MIX 360

16

TAV. 7

12

19 20

4

2

5

40

21

32

31

37

29

16

3

30 24

42

33

39

35

8

27

26

13

13

18

13

34

11

18

13

15

6

25

41

9

25

38

17

36

IMER INTERNATIONAL S.p.A.

MIX 360

17

TAV. 8 DESCRIPTION NOTE

RIF. COD. ASSEMBLY OF MOTOR HONDA - HATZ

12224910 WASHER DEV.C72 Ø10Z

22223920 SELF LOCKING NUT 7474 M10

3 3211077 BOLT 5933 M8X30

5 2284805 HANDLE

62284398 SHEATH AND FERRULE

7 2212120 CABLE ACCELERATOR

8 2224140 WASHER Ø 8X18

92223650 NUT 5588 M10Z

10 3211076 BOLT 5739 M10X80Z

11 3211057 ENGINE MOUNTING PLATE

12 2222088 SCREW 5737 M 8X40

13 2223923 SELF LOCKING NUT M.8

14 3211406 MOTOR HONDA GXV340

3230277 MOTOR HATZ 1B40V 1"

15 2222098 BOLT 5739 M10X40

16 2224260 WASHER 6593 Ø10X30Z

17 2224940 WASHER DEV. Ø8Z C72

18 2221994 BOLT

19 3211428 PULLEY 3A DP=500 F24

20 3211710 BELT A 90

21 3211047 PROTECTION

22 2289357 CLUTCH

24 2221997 SCREW 7/16x70z

25 2222016 BOLT 5739 M6X20z

26 2224530 WASHER Ø6x12.5Z

27 2229327 KEY 4X6.5 UNI 6606

28 3231573 LIMIT SWITCH

29 3211767 SUPPORT

30 3211096 SHEATH GROMMET PG 13.5

31 3211067 PIN

32 2239400 SPRING CATCH

33 3236412 SPLASH GUARD

34 2224531 WASHER 6x18z

36 2237748 SPACER

37 2225796 CLAMP

38 3211075 BOLT 7380 M6X40

39 3211064 SUPPORT

40 2222021 BOLT M6X16z

41 3231562 SPANNER

42 2222581 BOLT

43 3211391 SHEATH

IMER INTERNATIONAL S.p.A.

MIX 360

18

18

12

15 13

8

16

3

24

25

42

2

1

27

36

5

21

11

39

31

38

30

43

14

19

20

41

28

33

40 34

29

26

22

13 37

32

6

7

8

17

10

9

TAV. 8

IMER INTERNATIONAL S.p.A.

MIX 360

19

TAV. 10 DESCRIPTION MIX 360

RIF. COD. LEG EXTENSION KIT (OPTIONAL) NOTE

1 3200457 Leg extension

2 2227048 Key ring

3 2226715 Split pin M 12

IMER INTERNATIONAL S.p.A.

MIX 360

20

221 Westhampton Place

Capitol Heights, MD 20743

Ph. 301.336.3700

Fax 301.336.6687

Toll Free: 800.275.5463

www.imerusa.com

We warrant to the original purchaser that the IMER equipment described herein (the "equipment")

shall be free from defects in material and workmanship under normal use and service for which it was

intended for period of one (1) year from the date of purchase by the original purchaser.

Our obligation under this warranty is expressly limited to replacing or repairing, free of charge, F.

O.B. our designated service facility, such part of the equipment as our inspection shall disclose to be

defective. Parts such as engines, motors, pumps, valves, electric motors, etc. furnished by us, but

not manufactured by us, will carry only the warranty of the manufacturer. Transportation charges or

duties shall be borne by purchaser. This shall be the limit of our liability with respect to the quality of

the equipment.

This warranty shall not apply to any equipment, or parts thereof, which has been damaged by rea-

son of accident, negligence, unreasonable use, faulty repairs, or which has not been maintained and

operated in accordance with our printed instructions for the equipment. Further, this warranty is void if

the equipment, or any of its components, is altered or modied in any way.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED OR

IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR A

PARTICULAR PURPOSE.

We make no other warranty, representation or guarantee, nor is anyone authorized to make one on

our behalf. We shall not be liable for consequential damage of any kind, including loss or damage

resulting, directly or indirectly, from the use or loss of use of the machine. Without limiting the gene-

rality of the foregoing, this exclusion from liability embraces the purchaser's expenses for downtime,

damages for which the purchaser may be liable to other person, damages to property, and injury or

death of any persons.

This warranty shall not be deemed to cover ma ntenance parts, including but not limited to blades,

belts, hoses, hydraulic oil, or lters, for which we shall have no responsability or liability whatsoever.

ONE YEAR WARRANTY

Table of contents

Other IMER USA Mixer manuals