IMER USA MINUTEMAN User manual

INSTRUCTION MANUAL

IMER U.S.A. inc.

MINUTEMAN MIXER

(1126608)

R

Machine serial N°

Part. number 3210929_R01 - 12/2012

IMER U.S.A. Inc.

221WesthamptonPlace

CapitolHeights,MD

20743

Ph/800.275.5463

Thank you for purchasing a MINUTEMAN Mixer from an IMER U.S.A. dealer. Your decision is an

intelligent one. No other mixer in the world today offers the features and value of the MINUTEMAN

Mixer.

At IMER U.S.A. we continually searchforways tobetter serve our customers. Should you have an ideaor

thoughttosharewithusregardingthisProductwe wouldappreciatehearingfromyou.

Ourmottois"Tools and Services for the 21st Century".

We lookforward to deliveringthegoods.

Thank youagain foryour purchase,

*After the initialset-up the MINUTEMAN Mixer can be knocked down or reassembled in

1 minute.

* Direct drivedrum rotation, efficient and safe.

* Portable, the large12" wheelsmake moving the MINUTEMAN a breeze around the

home or job site.

* Compact, the clever design allows the MINUTEMAN to fit into the trunk or hatchback

area of almost all cars.

*Finish, the highqualityof paintandconstructioncomponentsensurea pieceof equipment

that you will be proud to own for years.

Mace T. Coleman, Jr.

President, IMER U.S.A. Inc.

221WesthamptonPlace

CapitolHeights,MD

20743

Ph/ 800.275.5463

S/N :

2

IMER U.S.A. Inc.

3

MINUTEMAN

TABLE OF CONTENTS

TECHNICALDATA.....................................................................................................page 4

NOISELEVEL ...........................................................................................................page 5

WIRINGDIAGRAM....................................................................................................page 5

SAFETY NOTES ........................................................................................................page 6

ASSEMBLY ...............................................................................................................page 7

MOVING THE MINUTEMAN................................................................................. page 9

SETTING UP THE MINUTEMAN .......................................................................... page 9

OPERATING THE MINUTEMAN .......................................................................... page10

MAINTENANCE AND CLEANING......................................................................... page10

ORDERINGSPAREPARTS....................................................................................... page10

SPAREPARTSDIAGRAM......................................................................................... page11

WARRANTY ....................................................................................................... page14

IMER U.S.A. Inc.

4

MINUTEMAN

Product development and improvement is an ongoing process, therefore, specifications may change

without notice.

*Capacitiesbasedon usablevolume.

TECHNICAL DATA

1 MIXINGDRUM 5 GEARBOXMOUNTINGFRAME

2 ON/OFFSWITCH 6 SWIVELBRACKET

3 DUMPHANDLE 7 MAINFRAME

4 MOTORANDGEARBOXDRIVE 8 T-BAR

Drum capacity 5 cubic feet

Batch Output 2.5 cubic feet, 225 lbs. *

Drum Diameter 24 inches

Discharge outlet height 23 inches

Wheels 12" x 2.5"

Single Phase electric motor 0.5 HP

Voltage 110 / 115 V

Hertz 60

Motor R.P.M. 3350

Nominal current 6.2 Amp

Operating dimensions 42" x 25" x 58"

Storage dimensions 25" x 25" x 25.5"

Weight 120 pounds

IMER U.S.A. Inc.

5

MINUTEMAN

The MINUTEMAN has a noiseemission level of 65 decibels. It's veryquiet, operateit anywhere.

NOISE LEVEL

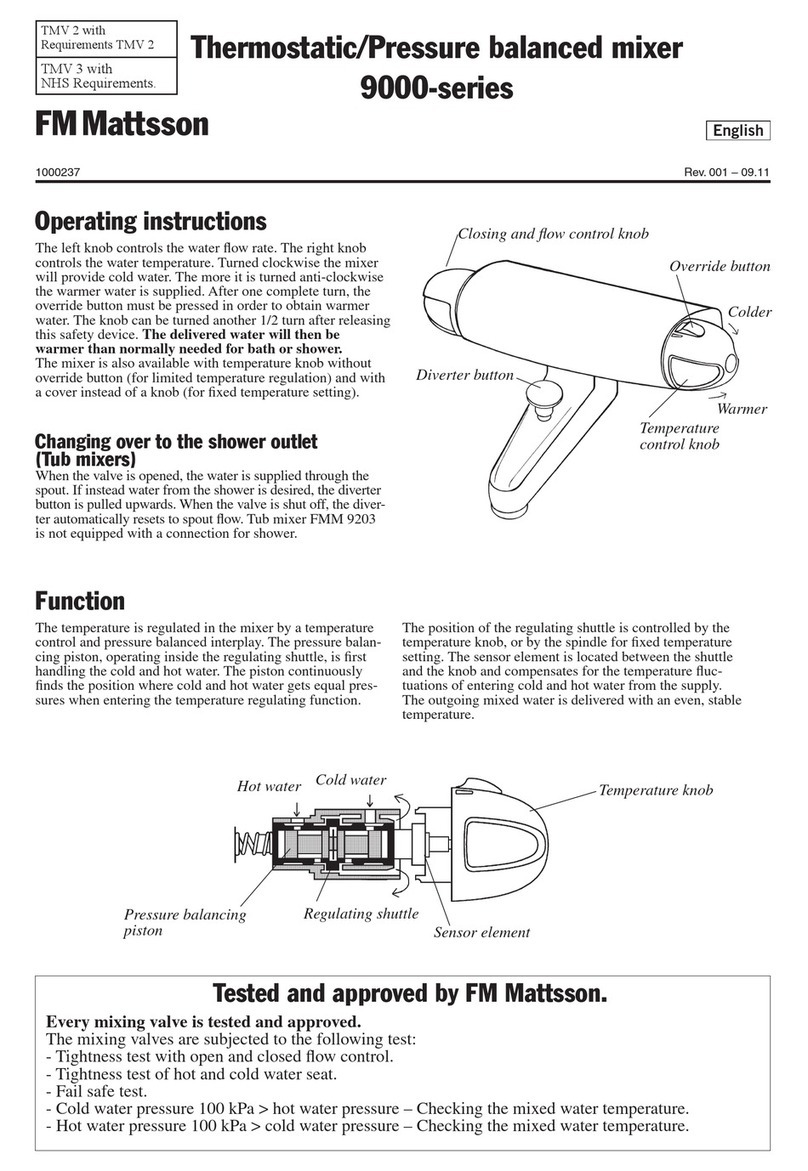

WIRING DIAGRAM

N

L1

S1

F2

C1

M1

AM

AA

Neutral wire

Phase wire

Stop and start button

Thermal protection for electric motor

Capacitor

Single phase motor

Motor winding

Motor winding

WARNING

Any type of electrical repair or trouble-shooting should only be performed

by an IMER dealer or a properly qualified electrical repair shop. For

assistance with any electrical difficulty, IMER U.S.A. is always directly

available @ 800.275.5463.

The MINUTEMAN motor is manufactured as a class II Double Insulation

type ( ), it does not require a ground wire.

CAUTION: when carrying out repairs, class II Double Insulation protection

willonlybemaintainediforiginalinsulatingmaterialsareusedand provided

the specifications and insulating materials remain unmodified.

IMER U.S.A. Inc.

6

MINUTEMAN

Your MINUTEMAN mixer has been designed with safety in mind. However, as with anytype of machinery,

some basic DO'S and DONT'S apply:

IMPORTANT !

READ THIS SECTION CAREFULLY !

Place your hand or hands in or around any part of

the drum while it is operating !

DO NOT

Place any tools or instruments in or around the drum

while it is operating !

DO NOT

DO NOT

Clean, assemble or work on the unit while it is plugged in !

Allow water to contact the motor or electrical connections at any time !

DO NOT

DO NOT

DO NOT

Operate the unit in or around water puddles.

DO NOT

Leave the machine unattended !

DO NOT

Operate the mixer on a surface that is not flat or is

uneven !

Always operate the MINUTEMAN on a level surface,

if placed on an incline the machine will fall over.

Allow other persons around the mixer while it is operating ! Keep children away

from your work area !

SAFETY NOTES

DO NOT

Operate the mixer while under the influence of alcohol or drugs !

IMER U.S.A. Inc.

7

MINUTEMAN

12

SAFETY NOTES

DO

Read all the instructions before operating the mixer.

DO

Usecaution whenassemblingandtransportingthemixer. Tieit downgoodinyourvehicle.

DO

Keep the mixer clean and free of debris and mix build-up. After using, fill the drum with

water and run the MINUTEMAN for 10 minutes or so, most of the cement will break

loose from the drum.

DO

Keepallthemovingpartslightlylubricated, WD-40maybe sprayedallaroundthemachine

(wheel axles, swivel bracket, etc.).

DO

Periodically inspect your mixer for abnormal wear or damage. If something does not

seem right call your dealer or IMER USA direct @ 800.275.5463.

ASSEMBLY - Follow drawings 1 thru 6 -

DO

Wear the appropiate safety gear; hard hat ,gloves, goggles, ear protection and wear

tight clothing around the mixer. Loose clothing can cause injury should it become

entangled with the mixer.

Do not start and stop the mixer with material in the drum, this will damage the motor and

is not the best way to mix.

Always have the drum rotating when filling or discharging the mixer, this produces the

highest quality concrete.

DO NOT

Place the main frame (# 18 Drawing 1) on a

level surface as illustrated in this diagram.

Insert and secure the T-bar (# 20 Drawing 1)

into the main frame with the 3" hex head bolt

andnut,usingtheopenwrenchprovidedinthe

assembly kit.

Slidethewheels(#8Drawing1)ontothemain

framebar(#18Drawing1)andanchorthemin

placewiththecotterpins(#13Drawing1)which

are included inthe assembly kit providedwith

eachMINUTEMANmixer.

IMER U.S.A. Inc.

8

MINUTEMAN

Fit the gear-box frame andmotor assembly (#

7 Drawing 1) into the swivel bracket (# 15

Drawing 1) with the anchor pin, (# 17 Drawing

1) slide the cotter pin through the anchor pin

hole (# 16 Drawing 1).

34

5 6

Mount the mixing drum (# 4 Drawing 1) onto

thegear-boxshaft(#29Drawing 2)byaligning

theguidenotchwiththelocatingpinonthegear

shaft.Securethedrumtothegear-boxshaftwith

theT-handlebolt(#5 Drawing1)andwasher(#

6Drawing1)providedintheassemblykit.Once

the T-bolt is tightened as much as possible by

hand,giveita whackor twowitha hammer:no

more, no less.

ASSEMBLY

Secure the mixing blades (# 2 Drawing 1) to

the innerdrum withthe screws (# 1Drawing 1)

andnuts(#3Drawing1)providedintheassembly

kit.Assembly with the screws heads on the

outerdrum.

Finally, insert tilting handle(# 10 Drawing 1) in

the handle mounting tube and lock using the

cotter pin provided in the assemblykit.

Slide theswivelbracket (# 15Drawing1) onto

themainframeupright.Thegear-boxandmotor

assembly (# 7Drawing 1) ismounted into this

swivelbracket.

5

6

29

DRUM

DRIVE

SHAFT

IMER U.S.A. Inc.

9

MINUTEMAN

Drawing 6

Drawing 4

WRONGASSEMBLY POSITION FOR

THE SWIVEL BRACKET CORRECTASSEMBLYPOSITION FOR

THE SWIVEL BRACKET

CORRECT

DIRECTION

CAUTION - SET-UP IMPORTANT

Positionthemachineonalevel surface

as illustrated in the drawing 6

(maximunallowableslopeis5degrees,

as shown in drawing 6).

To complete the mixer set-up, before

loadingthedrum,makesure themixer

can properly discharge into a wheel-

barrow.

MOVING THE MINUTEMAN

WARNING

Always disconnect the power cord before

moving the mixer.

To roll the machine, hold the support leg and dump

handleandmoveas showninDrawing4.

WARNING

Do not attempt to move the mixer when

there is material in the drum, it must be

empty.

YES

NO

WRONG

DIRECTION

IMER U.S.A. Inc.

10

MINUTEMAN

1)Usea2 prong,grounded,110/115volt,60Hz, powerconnectionforsafeoperation.Thelineshouldbeat

least 12 gauge.

2) To mix concrete, add water, concrete, and aggregate while the drum is rotating.

3)Dischargethe mixedconcretebyelevating the dumphandle(#10 Drawing1) whilethedrumis rotating.

NOTE: When tilting the drum to discharge the concrete, do so slowly. It is important to

perform the discharge smoothly, this keeps the machine balanced and upright.

4) The ON/OFF switch in the motor of the MINUTEMAN mixer provides thermal protection to the motor in

the event of overheating. Should your motor shut off automatically, turn off the unit and unplug it for 15

minutes.Thisallows themotorto cool.Afterthecoolingperiod, plugin themotorandpress thestart switch.

If the motor does notrestart and continue torun, contact your local IMERproductsdistributor, or callIMER

directat800.275.5463.

OPERATION

The MINUTEMAN Mixer requires very low maintenance. However, a few basic maintenance procedures

shouldbefollowed.

NOTE: Always unplug the mixer from its power source before any cleaning or

maintenance functions are performed.

1) Clean the mixer after each use and do not allow any concrete to buildup on any portionof the mixer.

2) Essentially the gearbox is sealed for life. The quality of the gears and the lubricant are such that

changing the oil is not necessary. Should you want to change the oil, see your dealer or call IMER

U.S.A direct for instruction @ 800.275.5463.

3) Keep all moving parts lightly greased.

4) Keep the electric motor cooling fins clean and free ofdebris build-up.

5)Before storing the MINUTEMAN after a project is completed, spray n' wipe the entire machine with

WD-40.

NOTE: When spraying the mixer with water, do not direct the water onto the motor or

the ON/OFF switch assembly.

MAINTENANCE AND CLEANING

All orders for spare parts must include the following:

1) Type of machine.

2) Part number and drawing references of each part, see the parts list.

3) Serial number and year of manufacture recorded on the machine's

identification plate.

SPARE PARTS

IMER U.S.A. Inc.

11

MINUTEMAN

DRAWING #1 - FRAME AND DRUM ASSEMBLY

Ref. P.n. Description NOTE

1 2222193 SCREW TB M12 x 25

2 2250155 MIXING PADDLE

3 2223700 NUT 5588 M12 Z

4 2250719 DRUM

5 2222982 T - BOLT

6 2224428 WASHER 14X36X6

7 3210935 GEAR BOX FRAME

8 3206390 WHEEL

9 2235450 PLASTIC PLUG

10 3206148 DUMP HANDLE

12 3210947 I.D. PLATE

13 2226700 COTTER PIN

15 3210893 SWIVEL BRACKET

16 2226702 SPLIT-PIN 1.8/35

17 3210936 PIVOT AXLE

18 3206365 MAIN FRAME

19 2222148 BOLT M10X65 5737

20 2255749 T-BAR

21 2289740 WRENCH 17X19

22 2223650 NUT M10 5588

23 3206800 CIRCLIP M1455 ZA ø14

IMER U.S.A. Inc.

12

MINUTEMAN

DRAWING #2 MOTOR AND GEARBOX ASSEMBLY(110/115 V - 60Hz)

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15 16

19

20

20

21

22

23

2425

26

27

29

30

3133

34

28

32

35

36

37

38

40

39

41

42

IMER U.S.A. Inc.

13

MINUTEMAN

DIAGRAM #2 MOTOR AND GEARBOX ASSEMBLY

COD. 3210492 (110 / 115 V - 60 Hz)

UP TO SERIAL

NUMBER: RIF. P.n. Description Note

1 2222010 BOLT M6x25

2 2207405 OIL SEAL 55x40x10

3 2222012 BOLT M6x60

4 3210485 GEARBOX CASE-HALF

5 3210482 GEARBOX GASKET

6 2228360 SHEAR PIN Ø8x16

7 2229500 KEY 8x7x15

8 2204420 BEARING 6201

9 3210487 GEAR Z 81

10 2229249 KEY 5x5x12

11 3210483 PINION GEAR Z 9

12 3210486 GEARBOX CASE-HALF

13 3210904 FAN

14 3210911 ELECTRIC BOX COMPLETE (ALL COMPONENTS)

1005797 15 3210233 SWITCH

16 3210955 ELECTRICAL PLUG

19 3210923 CAPACITOR 50µF 250 V

1005797 20 3233039 ELECTRIC BOX ASS'Y+ SCREW + GASKET ONLY

21 3209214 GASKET

22 2223260 NUT M6

23 2224530 WASHER Ø6x12.5

24 2204550 BEARING 6205

25 3210479 GEAR Z 104

26 2204504 BEARING 6008

27 2228819 LOCATING PIN Ø6x12

28 3210494 MOTOR ASS'YWITH CASE HALF

29 3210481 DRIVE SHAFT SPINDLE

30 3210496 RIGHT SIDE MOTOR COVER

31 3210495 LEFT SIDE MOTOR COVER

32 3210036 SCREW M5x16

33 3210587 RATING PLATE

35 3210906 STATOR

36 3210898 SPACER WASHER

37 3210486 ROTOR

38 3210901 SCREW M5x22

39 3208982 BEARING 6202

40 3210488 INSULATING FLANGE

41 2207350 OIL SEAL 12x32x7

42 3210902 BEARING 6002

IMER U.S.A. Inc.

14

MINUTEMAN

221WesthamptonPlace

CapitolHeights,MD

20743

Ph/ 800.275.5463

U.S.A. INC.

IMER

EQUIPMENT WARRANTY

R

U.S.A. INC.

We warrant to the original purchaser that the IMER equipment described herein (the "equipment") shall be

free from defects in material and workmanship under normal use and service for which it was intended for

period of one (1) year from the dateof purchase bythe original purchaser.

Our obligation under this warranty is expressly limited to replacing or repairing, free of charge, F. O.B. our

designated servicefacility, suchpart of the equipment asour inspection shall disclose to bedefective. Parts

such as engines, motors, pumps, valves, electric motors, etc. furnished by us, but not manufactured byus,

willcarryonlythewarrantyofthemanufacturer.Transportationchargesordutiesshallbebornebypurchaser.

This shall be the limit of our liability with respect to the quality of the equipment.

This warranty shall not apply to any equipment, or parts thereof, which has been damaged by reason of

accident, negligence, unreasonable use, faulty repairs, or which has not been maintained and operated in

accordancewithourprintedinstructionsfortheequipment.Further,thiswarrantyis voidif theequipment,or

any of its components, is altered or modified in any way.

THIS WARRANTY IS EXPRESSLY IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY OF

MERCHANTABILITY OR FITNESS FORAPARTICULAR PURPOSE.

We make no other warranty, representation or guarantee, nor is anyone authorized to make one on our

behalf. We shall not be liable for consequential damage of any kind, including loss or damage resulting,

directly or indirectly, from the use or loss of use of the machine. Without limiting the generality of the

foregoing, thisexclusionfromliabilityembracesthe purchaser'sexpensesfordowntime,damages forwhich

the purchaser may be liable to other person, damages to property, and injury or death of anypersons.

This warranty shall not be deemed to cover maintenance parts, including but not limited to blades, belts,

hoses, hydraulic oil, or filters, for which we shall have no responsability or liabilitywhatsoever.

HEADQUARTERS

Table of contents

Other IMER USA Mixer manuals