IMER MASONRY 300 Guide

R01 -2004/06

-Cod.3210848 -

IMERINTERNATIONALS.p.A.

Loc.SALCETO-53036POGGIBONSI(SIENA)

(ITALY)

tel.0577 97341 -fax0577 983304

MASONRY300

SEGATRICE

SCIE

SAWINGMACHINE

MASCHINENSÄGE

TRONZADORA

(1188618-1188620)

Manualed'uso,manutenzione ericambi

Manuelutilisation entretien pieces de rechange

Operating,maintenance,sparepartsmanual

Handbuch fürBedienung,Wartung und Ersatzteile

Manualde uso,mantenimientoyrecambios

2

MASONRY300

IMERINTERNATIONALS.p.A.

Particolareattenzionedeve esserefatta alleavvertenzecontrassegnate con questosimbolo:

Ilfautprêteruneattentiontouteparticulièreauxnotesprécédéesdecesymbole:

Specialattentionmustbegiventowarningswiththissymbol:

LesenSiediemitdiesemSymbolbezeichnetenAbschnitte mitbesondererAufmerksamkeit:

Setienequeprestarunaatenciónespecialalasindicaciones marcadasconelsigno:

14

1

2

3

45

6

7

8

9

10

11

12

13

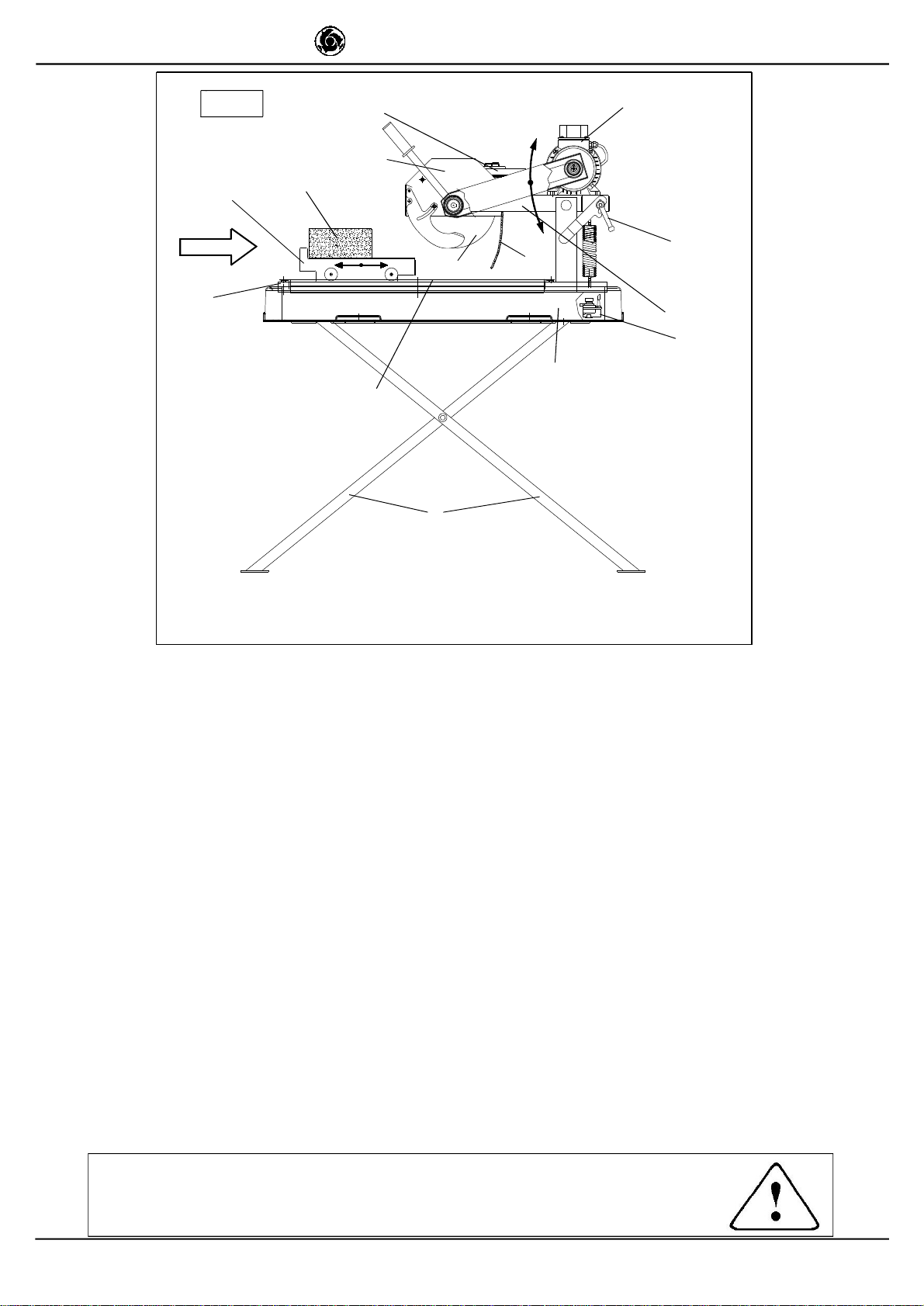

Fig.1

D

1.Gestel

2.Spritzschutz

3.Motor

4.Trennscheibenhalterung

5.Wasserpumpe

6.Gleitführung

7.Gehause

8.Werkstückschlitten

9.Wasserbecken

10.Sägeblattverkleidung

11.Halterungssperrgriff

12.ZuschneidendesWerkstück

13.Trennscheibe

14.Gestell

15.Scheibengehäuse

F

1.Chevalet

2.Bavolet

3.Moteur

4.Brasporte-lame

5.Pompe aeau

6.Coulisse

7. Boiter elettrique

8.Chariotporte-pièce

9.Cuve aeau

10.Protection de lalame

11.Poignée de blocage du bras

12.Pièceàcouper

13.Lame

14.Châssis

15.Carter disc

GB

1.Trestleelement

2.Sprayguard

3.Motor

4.Blade support

5.Water pump

6.Guide

7.Unction box

8.Worktable

9.Water tank

10.Blade guard

11. Support locking handle

12. Work piece

13.Blade

14.Frame

15.Disc cover

I

1.Cavalletto

2.Grembialina paraschizzi

3.Motore elettrico

4.Braccioportadisco

5.Pompa acqua

6.Guida scorrimento

7.Quadroelettrico

8.Carrelloportapezzo

9.Vascaacqua

10.Protezione lama

11.Manigliabloccaggiobraccio

12.Pezzoda tagliare

13.Disco

14.Telaio

15.Carter disco

E

1.Cabalette

2.Placadelantalsalpicaduras

3.Motor

4.Brazoportahoja

5.Bomba delagua

6.Guiade deslizamiento

7. Cajaelectra

8.Carro portapieza

9. Depositode agua

10.Proteccion cuchilla

11.Manillade bloqueo brazo

12.Piezaacortar

13.Hoja

14.Bastidor

15.Cárter

X

11

MASONRY300

IMERINTERNATIONALS.p.A.

GB GB

Dear Customer,

Congratulations on your choiceof purchase: thisIMERsaw, the

resultofyearsofexperience,isafullyreliablemachine and is

equipped withthe latest technicalinnovations.

-WORKINGINSAFETY

To workincompletesafety,readthefollowing

instructionscarefully.

-ThisOPERATIONANDMAINTENANCEmanualmustbekepton

sitebythe person incharge,e.g.the SITEFOREMAN,and must

alwaysbe availablefor consultation.

-Themanualistobeconsidered partofthemachineandmustbe

keptfor futurereference(EN292/2) untilthemachine isdisposed

of.Ifthe manualisdamagedorlost,areplacementmaybe

requestedfromthe sawmanufacturer.

-Themanualcontainsimportantinformationregardingsite

preparation,installation,machine use,maintenanceprocedures

and requests for spare parts. Nevertheless, the installer and the

operator must bothhaveadequateexperienceand knowledge

ofthe machine prior touse.

-Toguarantee completesafetyofthe operator,safeoperation

and long lifeofequipment, followthe instructionsinthismanual

carefully,and observeall safetystandardscurrentlyinforcefor

thepreventionofaccidents atwork.Use personalprotection

(safetyfootwear,suitableclothing,gloves, goggles, etc.).

-Safetyglassesoraprotective visor mustbewornatall

times.

-Earprotectionmust bewornatalltimes.

-MAKESURETHATWARNINGSIGNSAREALWAYS

LEGIBLE.

-Itisstrictlyforbiddentocarryoutanyformof

modificationtothesteelstructureor workingpartsofthe

machine.

-IMERINTERNATIONALdeclinesall responsibilityfornon-

compliancewithlawsand standardsgoverning the useofthis

equipment, inparticular;improper use,defectivepower supply,

lack ofmaintenance,unauthorised modifications, and partialor

totalfailure toobservethe instructions contained inthis manual.

IMERINTERNATIONALisentitledtomodifythecharacteristicsof

the sawing machine and/or the contents ofthismanualwithout

necessarilyupdating previousmachinesand/or manuals.

1.TECHNICALDATA

Table1showsthe saw’stechnicaldata,referring tofigure 1.

2.DESIGNSTANDARDS

MASONRY300sawsaredesignedandmanufacturedaccording to

thefollowingstandards: EN292-1-2;EN12418; EN60204-1.

TABLE1

TECHNICALDATA 1188618 1188620

Blade rpm rpm 2960

Blade diameter mm 300

Blade mountinghole mm 25,4

Motorrating Kw 2

Voltage V 230 110

Current A 13.5 30

Frequency Hz 50

Motorrpm rpm 2800 2780

Cuttingtabledimension cm 315x365

Overalldimensions

(widthxlengthxheight) cm 60x108x68

Overalldimensionsfor

transport

(widthxlengthxheight) cm 61x109x69

Waterpumpflowrate L/min 10

Watertankcapacity L 42

Weight Kg 60

Weightfortransport Kg 72

Blade rotationdirection(seen

fromblade clampingflange) CLOCKWISE

3.NOISE EMISSIONLEVEL

Table2indicatesthenoiselevelproducedbythe sawingmachine,

measured atthe operator’sear(LpA at1m-98/37CE)and the

environmentalnoiseemission level(power LWA)measured in

accordancewithENISO3744;UNIEN12418.

4.CUTTINGSPECIFICATIONS

Thissawmodelhasbeenspecially designedfor cuttingstone,

ceramics,marble,granite,concreteandsimilar materials.Only

water-cooleddiamondbladeswithcontinuousorsegmented

edges(seeparagraph13) mustbeused.Underno

circumstancesmustdrycuttingbladesbe usedormaterials

other thanthosespecifiedabove.IMERINTERNATIONAL

declinesallresponsibility for damagecausedbyimproperuse

oftheabovemachine.

5.CUTTINGCAPACITY

-max.cutting capacitywithverticalblade =108mm inone

singlepass.

-max.heightofworkpiece:190mm(intwopasses).

-max.heightofworkpiece:50mm.

-max.cuttinglength:365mm(withbladelowered),515 mm

(withbladefullyraisedh=108).

-Bladeat45°:withsupportat45°on theworksurface.

6.WARNING

-Do notloadthe sawwithworkpiecesthatexceedthespecified

weight(max.25kg)

-Ensurestability ofmachine:itmust be installedonasolid

basewithamaximumslopeof5°(fig.2).

-Ensure theworkpieceisstablebefore,during andaftercutting:

inanycase,workpiecesmust notoverhang theworktable.

-Respect the environment; usesuitablereceptaclesfor

collection ofcoolingwatercontaminatedwithcutting dust.

7.SAFETYPRECAUTIONS

-IMERsawsaredesignedfor workonconstructionsitesand

underconditionsofnaturallight,hencethe workplacemust be

adequatelylit.

-Themachinemust neverbeusedinenvironments

subject torisks ofexplosion and/or underground sites

-IMERsawsmayonlybeused whenfitted withall required

safety devices,whichmust be inperfectcondition.

-Never usemakeshiftand/or faultypowercables.

-Makeelectricalconnectionson theconstructionsitewhere

theywillnotbe subjecttodamage.Neverstandthesawon

powersupplycables.

-Laypowercablesinsuchawayastopreventwater

penetration.Onlyuseconnectorsfitted withwater-spray

protection(IP67,EEC).

-Repairs toelectricalinstallationsmustonly be carriedout by

qualified technicians.Alwaysensurethatthe machine is

disconnectedfromthepowersupplyandiscompletelyimmo-

bileduringrepairsandmaintenanceoperations.

-Thesymbolshownonthelabel(seeleft)indicates

thewarning“ENSUREALLPROTECTIONDEVICES

ARE INSTALLEDAND INPERFECTCONDITION

BEFORESWITCHINGONTHEMACHINE”(fig.3).

8.ELECTRICALSAFETY

IMERsawscomplywithEN60204-1;and are fitted with:

-Protection deviceagainst automaticre-startafter power failure.

-Short-circuitcutoutdevice

-Motor overload cutoutswitch

Fig.3

TABLE2

SAWING MACHINE TYPEOFMOTOR Lp A(dB) LWA(dB)

Masonry300 ELECTRIC 85 96

12

MASONRY300

IMERINTERNATIONALS.p.A. GB

GB

9.TRANSPORTATION

-WARNING! Beforemovingthesaw,lock head

supportcarriagemovementbymeansoftherelative knob

(Ref.11,fig.1).

Thesawweights 53 Kgand canbemovedbymeansofthe

sidehandlesonthetank.

Alwaysemptythetankbeforemovingthemachine.

10.INSTALLATION

The machine must be placed on asmoothsurfacethatisatleast

as large as the tank, withthe sawon the relativestand (Ref. 11,

fig.1).ThecorrectsidefortheoperatorisasshowninFig.1

position X.

- Ensurethatthestand ispositionedontherelative

inserts on thetankbase and thussecured.

Always remove theplug fromthemainspowerbefore

movingthemachine.

11.ELECTRICALCONNECTION

Connect the mainspower cabletothe plug on the electrical

panel.

RESIDUALCURRENTCIRCUITPROTECTION

(KIT230V-P/N.1169245 -KIT110V-P/N.1169249):

It’sobligatorytofitthesawwiththedifferential

switchkitP/N1169249 on thefeeding cable.

Tostartup the saw,press the green ONkeyon the RCCB

switchand an orange led illuminates(RCCBprotection on).

RESIDUALCURRENTCIRCUITBREAKERTEST:

Press the black key TESTon the RCCB; the switch

disconnects and the orange led turnsoff.

After performing the TEST,press the ONkeyagaintoactivate

theRCCB.

-CarryouttheRCCB TESTbeforeeachmachinestart-

up.

Then startthe sawbysupportofthe switchon the handle,

comprising twobuttons: green for start, red for stop.

The RCCBisdeactivated eachtimethe power supplyis

disconnected

THERMALCUTOUTPROTECTION:

-Theelectricmotor isprotectedagainst overloadby

athermalcutout;intheeventofoverheatingthisdevice

shuts down themotor.

CoolthemotorandrestartbymeansoftheRCCB

switchand themainswitchon thehandle.

Themachineisprotectedagainstshortcircuits bya

magneticprotection insidetheRCCB.

-Ensure thatthe mainsvoltagecorrespondstothatspecified

forthe machine: 230V/50Hz. The electricalpowercablemust

besuitablysizedtoavoidvoltagedrops. Cabledrumsmustnot

beused.

Cablesusedonconstructionsitesmust be fittedwithsuitable

externalsheathingthatisresistanttowear,crushingand

extremeweatherconditions(for exampleH07RN-F).

-All powersupplyinstallationsmust complywith

CEI64-8standards(harmoniseddocumentCENELEC

HD384).

12.MACHINESTART-UP

Before connecting the machine tothe power supply:

1-Ensure thatthe tankcontainssufficientcooling water.

2-Connect the power supplycabletothe electricpanelplug.

3-Turn on the concretemixer using the switchlocated on the

electriccontrolpanel(ref. 7,fig.1) comprising twobuttons: the

green one switcheson the machine,whilethe red one switches

itoff. The switchhasminimumvoltage protection:after apower

failure or accidentalpower loss, pushthe green startbutton to

startthe machine up again.

4-Check thatthe direction of blade rotation correspondstothat

indicated bythe arrowon the blade guard.

Open the valveand ensure sufficientflowofcooling water to

the diamond blade.

5-Never drycutmaterialor cutwhen cooling water levels

arelow.

6-If all isinorder,proceed withcutting.

13.EMERGENCYSTOP

-Incase ofanemergency,stop themachineby

pressing theredstop button (extended),thendisconnect

theplug fromthepowersupplysocket.

-Themotorisprotectedagainstautomaticre-start

afterinterruptionsduetopowerfailure.Toresume

operation,whenpowerisre-connected,press thegreen

switchontheoverloadcutoutdevice.

14.BLADEINSTALLATION

Alwaysremovetheplug fromthemainspower.

The diamond blade ismade ofmaterialthatmaybe damaged

when subject tohigh temperatures, and therefore must be

cooled during the workphases.

Toreplacethe blade,proceed asfollows:

1.Block axialmovementofthe cutting head bymeansofthe

handwheels(ref.11fig.1).

2.Stop the blade rotation fitting the shaftblocking pin(ref. 1fig.

5) inthe holeofthe beltcover (ref. 2fig.5) rotating the blade

till the pinhasentered the holeinthe shaft.

Verifythattheblade doesn’tturn,otherwiserepeatthe

operation again.

3.Disassemblethe frontguard.

4.Loosen the locknutbyrotating clockwise(left thread),

using a19 mm wrench.

5.Movethe cutting head forward slightlyand incline to

removethe blade fromits seat.

6.Ensure thatthere are no foreign objects between the

fixing flange and diamond blade.During disassembly,avoid

useoftoolsthatcoulddentor deformthe flange.

7.Insertthe newblade proceeding inreverseorder ofthe

operation described atpoint4.Takespecialcare toensure

correct direction ofrotation ofthe diamond blade.

8.Tighten the blade locknutfullydownbyrotating

anticlockwise(left thread),toatorque of40 Nm.

9.Takethe shaftblocking pinoffthe beltcover.

10.Verifythe blade turn freely.

11.Connect the plug again.

-Note that theblademust have anexternaldiameter

of300 mm, acentralholediameterof25.4mm and max.

thickness of3mm.

-Check that thebladetobeusedissuitablefor the

materialtobecut.

-Neverdrycutmaterialorcutwhencooling

waterlevelsarelow.

-Donotuse blades for wood!(fig.6).

15. USE

-Leave aspace of150cmaroundthe

machinetooperateinfull safety.

-Donotallowother personstoapproachthe

machineduringcutting.

-Never usethe machineinfire-risk areas.Sparks

cancausefireorexplosions.

-Makesurethatthemachine isswitchedoffbefore positioning or

handling.

-Always ensure thatthe blade isfree ofanycontact beforestart-

up. -Ensurecorrectinstallationofallprotectivedevices.

Before starting work,fill the water tank. Topup during operation

whenever necessary:N.B. thepumpsuction hosemust

alwaysremainimmersedinwater.

-Insertthe pluginthe powersocket.

-WARNING! For safety purposes theremovalof

protectiveguardsfromthemachineisstrictlyprohibited

-WARNING! Alwaysswitchoff themachinebefore

Fig.6

13

MASONRY300

IMERINTERNATIONALS.p.A. GB

GB

carryingoutbladeadjustment.

15.1VERTICALBLADEMOVEMENT

Toraiseorlowertheblade,slackenthesupportlockinghandleturning

itanti-clockwise(Ref. 11,fig.1).The bladesupport(Ref.4,fig.1)

remainsfreetorotate,soitcanbesecuredinthedesiredposition,fully

tightening thehandle(ref.11,fig.1).

-Ensurethatthelockinghandleistightenedfullybefore

startingwork.

15.2BLADEPOSITIONINGFOR45°CUTS

Tomakeacutat45°,the45°supportonthe carriage isnecessary.

Oncetheworkpieceiscorrectlypositioned, cutting canbegin,starting

theelectric motor.

15.3CUTTING

-Check that thebladeisalignedwiththecutting line.

-Placetheworkpieceon theworktable(ref.8,fig.1),restingfirmly

against thestop. Startthemotor.

Waituntil thewaterreachestheblade.Begincutting.

-Horizontalcuttingmovementiscarriedoutbypullingthe carriage

towardstheblade.

-As cutting thickness increases,thebladeissubjected

togreaterstress.Toavoidoverloading themotor,the

operator shouldcontinuallycheck bladefeedspeed.The

speedwillalsodependonthecharacteristicsofthe

materialbeing cut(hardness,toughnessetc.).

15.3.1CUTSWITHBLADELOWEREDFROMABOVE

Bringthebladesupporttoits highestpositionandlock.Positionthe

workpiece.Startthe machine,unlocktheblade supportandbegin

verticalcutting until the blade reachesits lowest point. Lock the

supportoncemore and proceed withhorizontalcutting

15.3.2BLADECHANGE

Tochange the blade refer tosection 13.

16.MAINTENANCE

-WARNING! Servicing must always becarriedoutby

qualifiedtechniciansand onlyafterthemotor has been

switchedoff.

-Alwayskeeptheguardsinproperworkingorder

andfreefromdamage.

-Asthereisthecontinuousriskofinadvertent

damagetotheelectriccables,these must bechecked

regularlyeachtimebeforethemachineisused.

Never leavethe machine outinthe open.Makesure thatitis

stored inasheltered areaawayfromextremeweather

conditions.

Belowisalist ofthe cleaning operationsthatmust be carried out

atthe end ofeveryshift.

16.1TANKCLEANINGONWORKCOMPLETION

-Emptythe tankbyremoving the plug.Removecutting residue

using ajetofwater.

16.2WORKSURFACECLEANING

Alwayskeepworksurfacesclean.Residualdirtcanimpaircutting

precision.

16.3GUIDERAILCLEANING

It isgood practicetoremoveall tracesofdirtfromthe guides.

16.4CLEANINGAND MAINTENANCEOF COOLING

CIRCUIT

-If water doesnotreachthe blade stop the machine immediately

toavoidblade damage.

-After switching offthe machine ensure thatthe water levelis

sufficient.

At regular intervals(or when the flowrateofthe blade cooling

water isreduced) clean the cooling water supplycircuit. Todo

this, disassemblethe deliverynozzlelocated inside the blade

guard and clean inwater.

Periodicallyclean the cooling water deliveryline between the

pumpand valve,and blade guard using water.

16.5TENSIONINGTHEDRIVE BELT(fig.8)

-Switchoff theelectricmotor andremovetheplug fromthe

power supply.

-Unscrewthe4screwsthatsecurethemovablebeltguard

(ref.1).

-Loosen the 4(ref. 2) screwsthatclampthe electricmotor to

the blade support.

-Tension the beltusing the nut(ref. 3):applyaforceofabout

F=6Kgtothe centre ofthe free section ofthe belt, the arrow

shouldbe about f=6mm (fig.9).

-Tightenthescrewsonthe electricmotor,checkingthe

alignmentof the motor pulley and the blade pulley

-Refitthe guard and lock itusing the 4screws.

-To avoidshortening thelife ofthebelt,thebearings

andthebladeshaft,do notovertensionthebelt.Finally,

checkthetwopulleysarealigned

16.6DRIVE BELTREPLACEMENT

Repeatthe operationsdescribed insection 16.5,replacing the

beltbefore tensioning it

17.REPAIRS

-Donotstartthesaw during repairwork.

Onlyusegenuine IMERspareparts anddonotmodifythem.

-Iftheguardsareremovedtocarryoutrepairs,they

must berefittedproperlywhentherepairworkisfinished.

Table of contents

Other IMER Sewing Machine manuals