IMER MASONRY 350 F Guide

R02-12/2002

- Cod. 3210359 -

IMER INTERNATIONAL S.p.A.

Loc.SALCETO-53036POGGIBONSI(SIENA)

(ITALY)

tel. 0577 97341 - fax 0577 983304

MASONRY350 F

SEGATRICE

SCIE

SAWINGMACHINE

MASCHINENSÄGE

TRONZADORA

(1188793 - 1188797) EL

Manuale d'uso, manutenzione e ricambi

Manuel utilisation entretien pieces de rechange

Operating,maintenance, spare parts manual

Handbuch für Bedienung, Wartung und Ersatzteile

Manual de uso, mantenimiento y recambios

2

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

Particolare attenzione deve essere fatta alle avvertenze contrassegnate con questo simbolo :

Il faut prêter une attention toute particulière aux notes précédées de ce symbole:

Special attention must be given to warnings with this symbol:

Lesen Sie die mit diesem Symbol bezeichneten Abschnitte mit besonderer Aufmerksamkeit:

Se tiene que prestar una atención especial a las indicaciones marcadas con el signo:

14

15

1

2

3

4

5

6

7

8

9

10

11

12

13

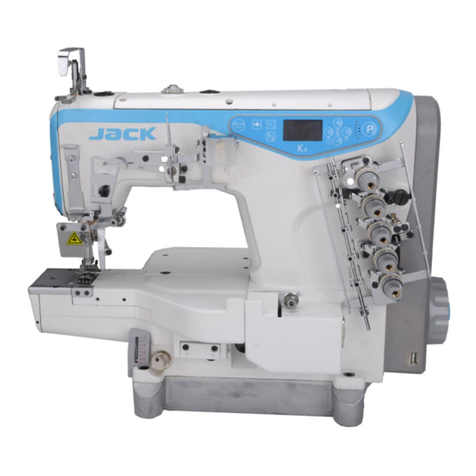

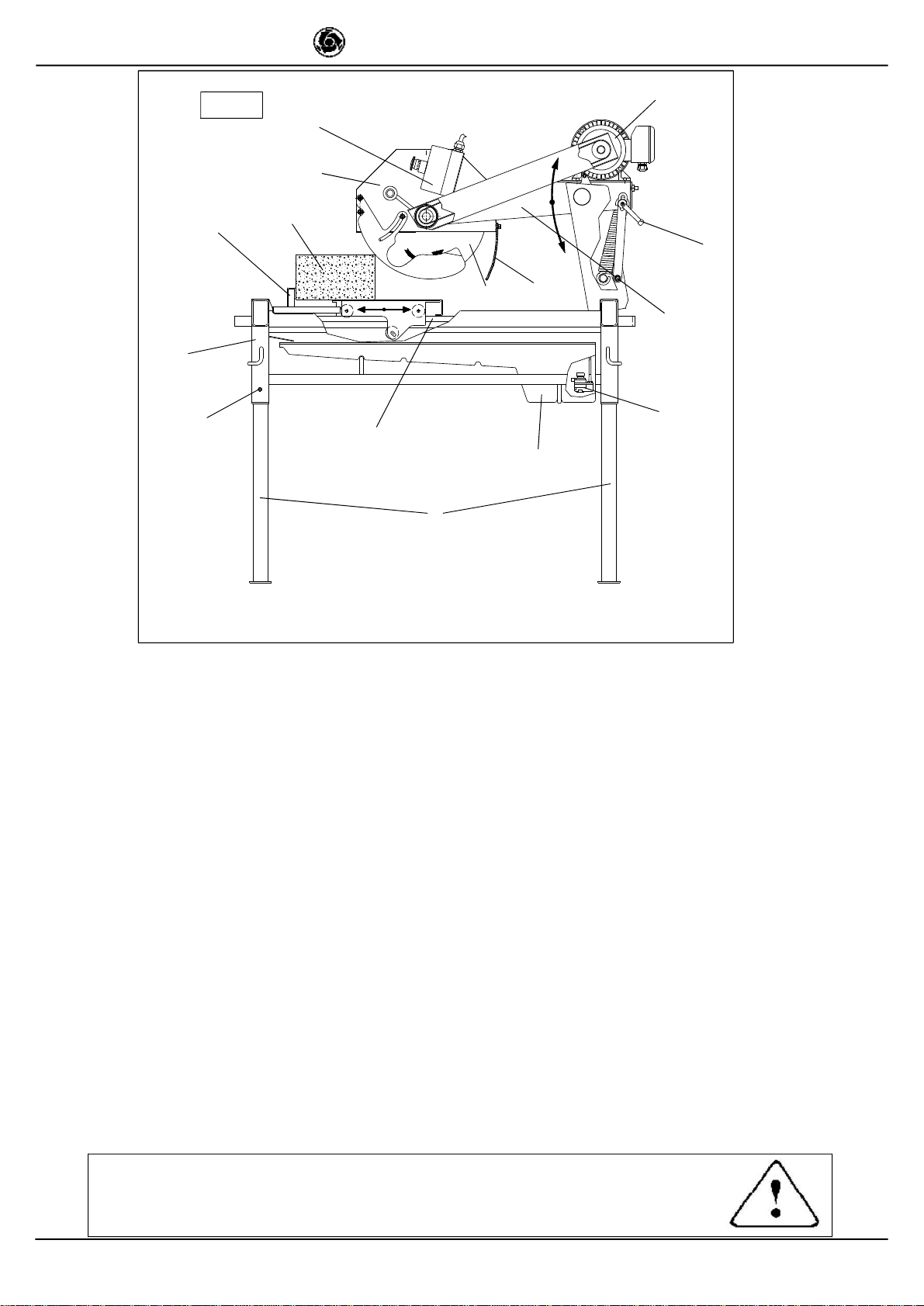

Fig. 1

D

1. Teleskoppfuss

2. Spritzschutz

3. Motor

4. Trennscheibenhalterung

5. Wasserpumpe

6. Gleitführung

7.Kontakglied

8. Werkstückschlitten

9. Wasserbecken

10. Sägeblattverkleidung

11. Halterungssperrgriff

12. Zu schneidendes Werkstück

13. Trennscheibe

14. Gestell

15. Erdungsschraube

F

1. Colonne télescopique

2. Bavolet

3. Moteur

4. Bras porte-lame

5. Pompe a eau

6. Coulisse

7. Contacteur

8. Chariot porte-pièce

9. Cuve a eau

10. Protection de la lame

11. Poignée de blocage du bras

12. Pièce à couper

13. Lame

14. Châssis

15. Vis de terre

GB

1. Telescopic leg

2. Spray guard

3. Motor

4. Blade support

5. Water pump

6. Guide

7. Contactor

8. Worktable

9. Water tank

10. Blade guard

11. Support locking handle

12. Work piece

13. Blade

14. Frame

15. Earth screw

I

1. Gamba telescopica

2. Grembialina paraschizzi

3. Motore elettrico

4. Braccio portadisco

5. Pompa acqua

6. Guida scorrimento

7. Magnetotermico

8. Carrello portapezzo

9. Vasca acqua

10. Protezione lama

11. Maniglia bloccaggio braccio

12. Pezzo da tagliare

13. Disco

14.Telaio

15. Vite di terra

E

1. Pie telescopico

2. Placa delantal salpicaduras

3. Motor

4. Brazo portahoja

5. Bomba del agua

6. Guia de deslizamiento

7. Contactor

8. Carro portapieza

9. Deposito de agua

10. Proteccion cuchilla

11. Manilla de bloqueo brazo

12. Pieza a cortar

13.Hoja

14. Bastidor

15. Tornillo de contacto de tierra

9

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

Table2indicatesthenoiselevelproducedbythe sawing machine,

measured at the operator’s ear (LpA at 1 m - 98/37CE) and the

environmental noise emission level (power LWA) measured in

accordance with EN ISO 3744; UNI EN 12418.

GB GB

Dear Customer,

Congratulations on your choice of purchase: this IMER saw, the

result of years of experience, is a fully reliable machine and is

equipped with the latest technical innovations.

- WORKING IN SAFETY

To work in complete safety, read the following

instructions carefully.

-ThisOPERATIONANDMAINTENANCEmanualmustbekepton

site by the person in charge, e.g. the SITE FOREMAN, and must

always be available for consultation.

Thismanualistobe considered anintegralpartofthemachine,andit

must be preserved for future reference (EN292/2) throughout the

machine’s normal working life. If the manual is damaged or lost, a

replacement may be requested from the saw manufacturer.

- The manual contains important information regarding site

preparation, installation, machine use, maintenance procedures

and requests for spare parts. Nevertheless, the installer and the

operator must both have adequate experience and knowledge

of the machine prior to use.

- To guarantee complete safety of the operator, safe operation

and long life of equipment, follow the instructions in this manual

carefully, and observe all safety standards currently in force for

the prevention of accidents at work. Use personal protection

(safety footwear, suitable clothing, gloves, goggles, etc.).

- Safety glasses or a protective visor must be worn at all

times.

- Ear protection must be worn at all times.

- MAKE SURE THAT WARNING SIGNS ARE ALWAYS

LEGIBLE.

- It is strictly forbidden to carry out any form of

modification to the steel structure or working parts of the

machine.

- IMER INTERNATIONAL declines all responsibility for non-

compliance with laws and standards governing the use of this

equipment, in particular; improper use, defective power supply,

lack of maintenance, unauthorised modifications, and partial or

total failure to observe the instructions contained in this manual.

IMER INTERNATIONALis entitled to modifythe characteristics of

the sawing machine and/or the contents of this manual without

necessarily updating previous machines and/or manuals.

1. TECHNICAL DATA

Table 1 shows the saw’s technical data, referring to figure 1.

2. DESIGN STANDARDS

MASONRY350Fsawsaredesignedandmanufacturedaccordingto

the following standards: EN 292-1-2; EN 12418; EN 60204-1.

3. NOISE EMISSION LEVEL

TABLE 1

TECHNICAL DATA 1188793 1188797

Blade rpm rpm 1.980 1.910

Blade diameter mm 350

Blade mounting hole mm 25,4

Motor rating Kw 2,2 1,7

Voltage V 230 110

Current A 12 21

Frequency Hz 50

Motor rpm rpm 2.800 2.700

Cutting table dimension cm 50 x 43

Overall dimensions

(widthxlengthxheight) cm 86 x 118 x 136

Overall dimensions for

transport

(widthxlengthxheight) cm 83 x 125 x 98

Weight Kg 112

Weight for transport Kg 132

Blade rotation direction(seen

from blade clamping flange) CLOCKWISE

TABLE 2

SAWINGMACHINE TYPEOFMOTOR LpA

(dB) LWA

(dB)

Masonry350F EL ELECTRIC 86 98

4. CUTTING SPECIFICATIONS

This saw model has been specially designed for cutting stone,

ceramics, marble, granite, concrete and similar materials. Only

water-cooled diamond blades with continuous or segmented

edges (see paragraph 13) must be used. Under no

circumstances must dry cutting blades be used or materials

other than those specified above. IMER INTERNATIONAL

declines all responsibility for damage caused by improper use

of the above machine.

5. CUTTING CAPACITY

- max. cutting capacity with vertical blade = 120mm in one

single pass.

- max. height of workpiece: 230 mm (in two passes).

- min. width of workpiece: 50mm.

- max. cutting length: 470 mm (with blade lowered), 550 mm

(with blade fully raised).

-Blade at 45°: with support at 45° on the work surface.

6. WARNING

- Do not load the saw with workpieces that exceed the specified

weight (max. 40 kg)

- Ensure stability of machine: it must be installed on a solid

base with a maximum slope of 5° (fig. 2).

- Ensure the workpiece is stable before, during and after cutting:

in any case, workpieces must not overhang the worktable.

- Respect the environment; use suitable receptacles for

collection of cooling water contaminated with cutting dust.

7. SAFETY PRECAUTIONS

- IMER saws are designed for work on construction sites and

under conditions of natural light, hence the workplace must be

adequately lit.

- The machine must never be used in environments

subject to risks of explosion and/or underground sites

- IMER saws may only be used when fitted with all required

safety devices, which must be in perfect condition.

- Never use makeshift and/or faulty power cables.

- Make electrical connections on the construction site where

they will not be subject to damage. Never stand the saw on

power supply cables.

- Lay power cables in such a way as to prevent water

penetration. Only use connectors fitted with water-spray

protection (IP57, EEC).

- Repairs to electrical installations must only be carried out by

qualified technicians. Always ensure that the machine is

disconnected from the power supply and is completely immo-

bile during repairs and maintenance operations.

- Connect the machine to a suitable

equipotential earthing plant on the construction

site with wire braid of minimum 16 mm² section.

The connection point is identified by a screw

welded to the frame (Ref. 15, fig.1), and on the

rating plate by the earthing symbol.

- Stop the saw only by means of the main switch

(Ref. 7, fig. 1).

- The symbol shown on the label (see left)

indicates the warning “ENSURE ALL

PROTECTIONDEVICESAREINSTALLEDANDIN

PERFECTCONDITIONBEFORESWITCHINGON

THEMACHINE”(fig.3).

8. ELECTRICAL SAFETY

IMER saws comply with EN 60204-1; and are fitted with:

- Protection device against automatic re-start after power failure.

- Short-circuit cutout device

- Motor overload cutout switch

Fig. 3

10

MASONRY 350 F

IMER INTERNATIONAL S.p.A. GB

GB

9. TRANSPORTATION (fig. 4)

- WARNING! Before moving the saw, lock head

support carriage movement by means of the relative knob

(Ref. 11, fig. 1). Remove the plug from the power socket.

To transport the machine use slinging equipment with 4

rope legs, fixing the hooks to the relative attachments.

10. INSTALLATION (Fig. 4)

Lift the machine out of its package and fix the hooks to the

relative attachments on the machine.

- Unlock the legs by sliding out pins (ref.1).

-Lock thelegsat workingheight.Refitthe pinsinthe legsupports.

- Install the machine on a completely even and stable surface.

- Release the carriage from the lever that secures it to the frame.

11. ELECTRICAL CONNECTION

- Ensure that there is an overload cutout device

fitted up-line on the power line.

- Ensure that the mains voltage corresponds to that specified

for the machine: 230V/50Hz - 110V/50Hz. The electrical power

cable must be suitably sized to avoid voltage drops. Cable

drums must not be used.

Connect the machine to an efficient earthing system.

The size of the power cable wires must be based on operating

current and length of the power line to prevent excessive

voltage drops (ref.Table 3).

Cables used on construction sites must be fitted with suitable

external sheathing that is resistant to wear, crushing and

extreme weather conditions (for example H07RN-F).

- All power supply installations must comply with

CEI 64-8 standards (harmonised document CENELEC

HD384).

12. MACHINE START-UP

Before connecting the machine to the power supply:

1 - Ensure that the metal structure is connected to an earthing

plant as indicated in Section 7 “Safety Precautions”.

2 - Ensure that the tank contains sufficient cooling water.

3 - Ensure that the power circuit corresponds to the requirements

as indicated in Section 11 “Electrical connections”.

- RESIDUAL CURRENT CIRCUIT PROTECTION

(KIT 230V-P/N.1169245 ; KIT 110V-P/N.1169249):

It’s obligatory to fit the saw with the differential switch

kit P/N 1169249 on the feeding cable(ref.3, fig.7).

To start up the saw, press the green ON key on the RCCB

switch and an orange led illuminates (RCCB protection on).

RESIDUAL CURRENT CIRCUIT BREAKER TEST:

Press the black key TEST on the RCCB; the switch

disconnects and the orange led turns off.

After performing the TEST, press the ON key again to activate

theRCCB.

- Carry out the RCCB TEST before each machine

start-up.

4 - Connect the machine to the power supply

5 – Press the black switch (Ref.7, fig.1) after ensuring that

cooling water reaches the blade: adjust the flow of cooling water

by turning the cock next to the blade guard (do not perform

cutting without water).

6 - Check that the direction of blade rotation corresponds to that

indicated by the arrow on the blade guard.

7 - If all is in order, proceed with cutting.

13. EMERGENCY STOP

- In an emergency, stop the machine by pressing the

stop control switch.

- The motor is fitted with an overload cutout device.

If the motor overheats, it will automatically shut down.

Allow the motor to cool and press the black switch on the

overload cutout device to restart (Ref. 7, fig. 1).

- The motor is protected against automatic re-start

after interruptions due to power failure. To resume

operation, when power is re-connected, press the black

switch on the overload cutout device (Ref. 7, fig. 1).

14. BLADE INSTALLATION (Fig.5)

By means of a hex wrench no.10, loosen the 3 screws that secure

the blade guard (Ref. 3). Using a hex wrench no. 13, loosen the

screw that secures the flanges on the blade: this screw has a

left-hand thread (rif.1). Remove the mobile flange (rif.2) and check

that the flanges, disc shaft and blade are not damaged.

- Never use worn blades.

- Only use blades that are designed for the number

of revolutions indicated on the machine rating plate.

- Check that blade rotation corresponds to that

indicated on the blade guard.

Centre the blade against the fixed flange, position the mobile

flange and tighten the securing screw by means of a hex

wrench no. 13 (turn clockwise). Return the guard to its original

position, locking the 3 screws (Ref. 3).

- Ensure that the blade guard (Ref.3) is locked

securely into position.

- WARNING! An incorrectly installed blade or a

screw insufficiently tightened can provoke damage to

the machine or injury to persons.

- Note that the blade must have an

external diameter of 350 mm., a central

hole diameter of 25.4 mm and max.

thickness of 3 mm.

- Check that the blade to be used is

suitable for the material to be cut.

- Do not use blades for wood! (fig. 6).

15. USE

- Leave a space of 150 cm around the machine to ope-

rate in full safety.

-Donotallowotherpersonstoapproachthemachineduringcutting.

- Never use the machine in fire-risk areas. Sparks can cause fire or

explosions.

- Make sure that the machine is switched off before positioning or

handling.

- Always ensure that the blade is free of any contact before start-

up. - Ensure correct installation of all protective devices.

Before starting work, fill the water tank. Top up during operation

whenever necessary: N.B. the pump suction hose must

always remain immersed in water.

- Insert the plug in the power socket.

- WARNING! For safety purposes the removal of

protective guards from the machine is strictly prohibited

The machine is protected against overload: this protection

triggers stopping the machine, after which the time necessary

for the overload to cool must pass before it is possible to

restart the machine.

- WARNING! Always switch off the machine before

carrying out blade adjustment.

15.1 VERTICAL BLADE MOVEMENT

To raise or lower the blade, slacken the support locking handle

turning it anti-clockwise (Ref. 11, fig. 1). The blade support (Ref. 4,

fig.1) remains free to rotate, so it can be secured in the desired

position, fully tightening the handle (ref. 11, fig. 1).

- Ensure that the locking handle is tightened fully before

starting work.

15.2 BLADE POSITIONING FOR 45° CUTS

To makea cut at 45°, the 45° support on the carriage is necessary.

Oncetheworkpieceiscorrectlypositioned,cuttingcanbegin,starting

the electric motor.

15.3 CUTTING

For safe use of the machine when cutting, push the carriage

forwards as the cut advances, placing your hands to the two

sides of the carriage. Never push directly on the piece to be cut.

Fig. 6

11

MASONRY 350 F

IMER INTERNATIONAL S.p.A. GB

GB

- Check that the blade is aligned with the cutting line.

- Place the workpiece on the worktable (ref. 8, fig. 1), resting firmly

against the stop. Start the motor.

Wait until the water reaches the blade. Begin cutting.

- Horizontal cutting movement is carried out by pulling the carriage

towards the blade.

-As cutting thickness increases, the blade is subjected

to greater stress. To avoid overloading the motor, the

operator should continually check blade feed speed. The

speed will also depend on the characteristics of the

material being cut (hardness, toughness etc.).

15.3.1 CUTS WITH BLADE LOWERED FROM ABOVE

Bring the blade support to its highest position and lock. Position the

workpiece.Start themachine, unlock the bladesupportand begin

vertical cutting until the blade reaches its lowest point. Lock the

support once more and proceed with horizontal cutting

15.3.2 BLADE CHANGE

To change the blade refer to section 13.

16. MAINTENANCE

- WARNING! Servicing must always be carried out by

qualified technicians and only after the motor has been

switched off.

- Always keep the guards in proper working order

and free from damage. Take particular care to ensure

that the blade guards are kept efficient and clean,

replacing them if they are damaged.

- As there is the continuous risk of inadvertent

damage to the electric cables, these must be checked

regularly each time before the machine is used.

Never leave the machine out in the open. Make sure that it is

stored in a sheltered area away from extreme weather

conditions.

Below is a list of the cleaning operations that must be carried out

at the end of every shift.

16.1 TANK CLEANING ON WORK COMPLETION

- Empty the tank by removing the plug. Remove cutting residue

using a jet of water.

16.2 TANK REMOVAL (Fig.7).

- Lift the tank (ref.1) to detach from its supports (ref.2) and

remove from the side indicated by the arrow.

16.3 WORK SURFACE CLEANING

Alwayskeep work surfaces clean. Residual dirt can impair cutting

precision.

16.4 GUIDE RAIL CLEANING

It is good practice to remove all traces of dirt from the guides.

16.5 CLEANING AND MAINTENANCE OF COOLING

CIRCUIT

- If water does not reach the blade stop the machine immediately

to avoid blade damage.

-Afterswitchingoffthemachineensurethatthewaterlevelissufficient.

- If necessary, after disconnecting the machine from the power

supply check that the tap, hose and pump filter are not blocked

- If necessary, check that the impeller rotates freely (after

extended periods of disuse)

16.6 TENSIONING THE DRIVE BELT (fig. 8)

- Switch off the electric motor and remove the plug from the

power supply.

- Unscrew the 4 screws that secure the movable belt guard (ref. 1).

- Loosen the 4 (ref. 2) screws that clamp the electric motor to

the blade support.

- Tension the belt using the nut (ref. 3): apply a force of about

F=6 Kg to the centre of the free section of the belt, the arrow

should be about f=6 mm (fig. 9).

-Tightenthe screws on the electric motor,checking the alignment

of the motor pulley and the blade pulley

- Refit the guard and lock it using the 4 screws.

- To avoid shortening the life of the belt, the bearings

and the blade shaft, do not overtension the belt. Finally,

check the two pulleys are aligned.

16.7 DRIVE BELT REPLACEMENT

Repeat the operations described in section 16.6, replacing the

belt before tensioning it

17. REPAIRS

- Do not start the saw during repair work.

Onlyuse genuine IMER spare parts and do notmodify them.

- If the guards are removed to carry out repairs, they

must be refitted properly when the repair work is finished.

18. TROUBLESHOOTING

- WARNING! Before carrying out any maintenance

operations, switch off the machine, and remove the plug

from the power socket.

FAULT CAUSE REMEDY

Motor does not start

when switch is

turned

- Defective power

cable

- Plug not inserted in

socket correctly

- Power cable from

plug to control panel

detached

- Loose wire inside

motor circuit board

- A wire has become

disconnected inside

the panel

- Faulty main switch

-The overload safety

device has been

activated.

- Check power cables

- Ensure correct

connection

- Connect cable- re

-Connect wire

- Remake the

connection

- Replace switch

-Wait for a fewminutes

and then try restarting

the machine.

Vertical blade

movement not

smooth

- locking knob too tight - Slacken knob

Horizontal carriage

movement not

smooth

- Guide rails dirty - Clean the guide rails

Lack of cooling water

supply to blade Refer to section 16.5: "cleaning and

maintenance of cooling circuit" (Chapter 16.5)

Blade does not cut

- Blade is worn

- Drive belt not

tensioned

- Fit newblade

-Tension the belt

Motor starts but

blade does not rotate Belt is broken Replace drive belt

18

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

Fig. 4

11

Fig. 8

Fig. 9

1

1

2

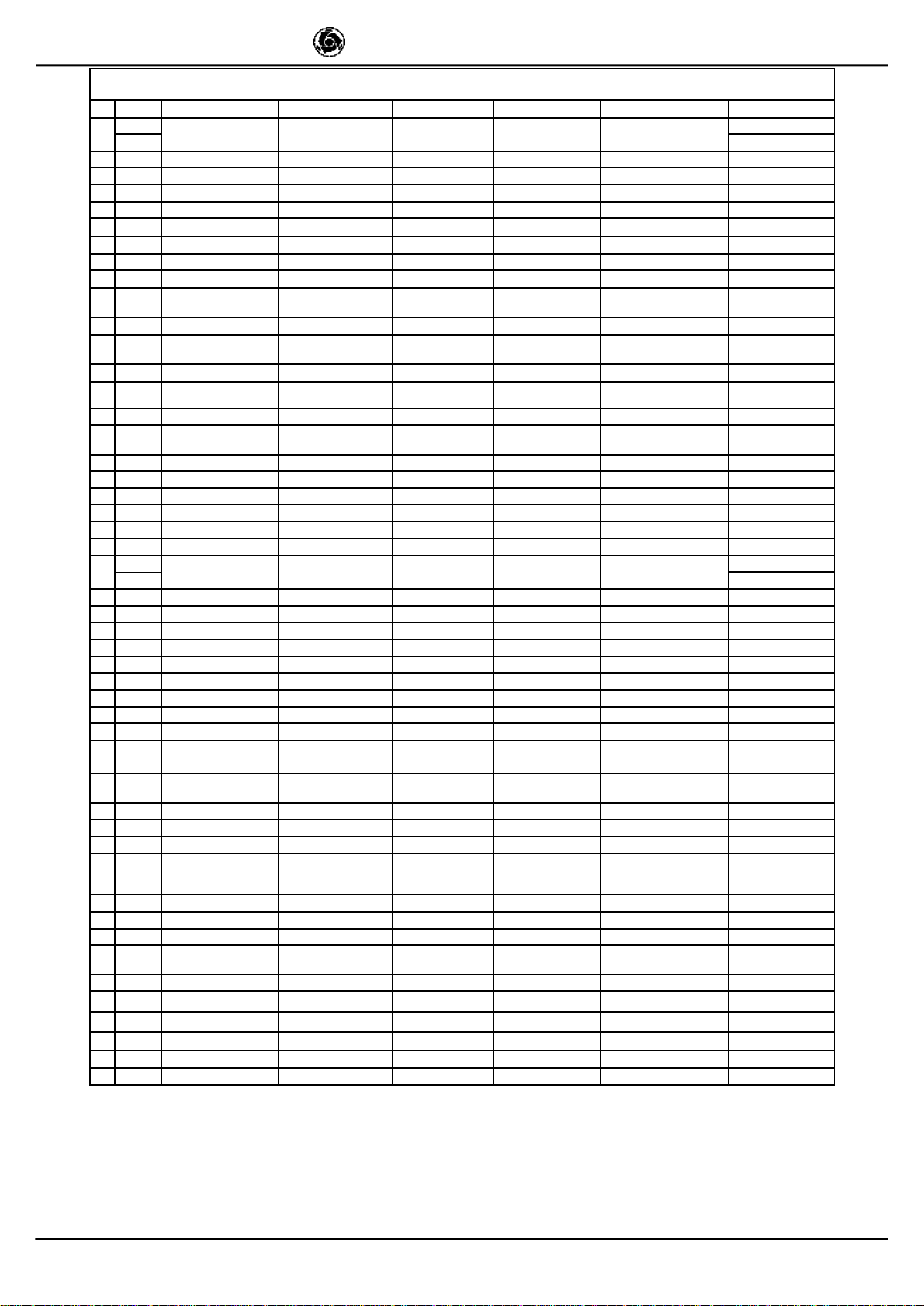

3Masonry 350 F - Tab. 3

Lunghezza cavo (m)

Longueur câble (m)

Cable length (m)

Kabel Länge (m)

Longitud cable (m)

V 230

I= 12 A 0 ÷ 14 15 ÷ 23 24 ÷ 37

V110

I= 21 A 0 ÷ 8 9 ÷ 14 15 ÷ 22

sezione cavo (mm²)

section câble (mm²)

cable (mm²)

kabel (mm²)

cable (mm²)

1.5 2.5 4

Fig.2

5° MAX

Fig.5

2

1

Fig. 7

2

19

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

RICAMBI:Pertuttigliordinideipezzidiricambiovogliateindicare:1- Tipodimacchina.2 - Numerodicodicee diriferimentocollocatoincorrispondenzadiognidefinizione.3-Numerodiserie

eannodicostruzioneriportatosullatarghettadellamacchina.SIMBOLOGIA:Intercambiabilità(esempio):Finoallamacchina matricolaN°5240èstatoinstallatoilrif.1cod.3204530,dallamcchina

matricolaN° 5241è statoinstallatoilrif.1.1cod.3204520.Ilrif.1.1è intercambiabile( )conil rif.1.Nonsonointercambiabiliirif.1e rif.1.1seintabellaèpresenteilsimbolo( ).

PIECESDERECHANGE:Pourtouteslescommandesdepiècesderechange,veuillezindiquer:1-LeTypedemachine2-LeNumérodecodeetderéférencesetrouvantenfacedechaquedéfinition

3- LeNumérodesérieetl'annéedeconstructionsetrouvantsurlaplaquetted'identificationdelamachine

SYMBOLOGIE:Intercambiabilità(exemple):Jusqu'àlamachinematriculeN°5240,nousavonsinstallélaréf.1code3204530;àpartirdelamachinematriculeN°5241,nousavonsinstallélaréf.

1.1code3204520.Laréf.1.1estinterchangeable( )aveclaréf.1.Lesréf.1etréf.1.1nesontpasinterchangeblessilesymbole( )n'estpassurletableau.

SPARE PARTS:Allordersforsparepartsmustindicatethefollowing:1 -Typeofmachine.2-Partnumberandpositionnumberofeachpart.3-Serialnumberandyearofmanufacturereported

onthemachine'sidentificationplate.

SYMBOL:Interchangeability(example):Pos..1P.n.3204530wasinstalledonmachincsuptoN°5240andPos.1.1P.n.3204520installedonmachineN°5241onwards.Pos.1.1isinterchangeable

( ) with Pos. 1.Pos. 1 and Pos. 1.1are not interchangeable if the ( )symbol appears in the table.

ERSATZTEILE:FürErsatzteilbestellungenbittediefolgendenAngabenmachen:1)Maschinentyp2)JeweilszugeordneteArt.-Nr.undPositionsnummer3)SeriennummerundBaujahr(Angabeaufdem

Maschinenschild)

SYMBOLE:Austauschbarkeit(Beispiel):BiszurMaschinenummer5240istRef.1Cod.3204530undabMaschinennummer5241istRef.1.1Cod.3204520installiertworden.Ref.1.1undRef.1sindaustaschbar

( ).Ref.1undRef.1.1sindnichtaustauschbar,wenndasSymbol( )angegebenist.

PIEZASDERECAMBIO:Parapedirunapiezaderecambiohayqueindicarsiempre:1-Eltipodemáquina.2-Losnúmerosdegódigoydereferenciaindicadosencorrespondenciadecadadefinición.3-Elnúmero

deserieyelañodeconstrucciónindicadosenlaplacadelamáquina.

SIMBOLOGIA:Intercambiabilidad(ejemplo):HastaelequipoconmatrìculaN°5240,sehainstaladolapiezaconref.1ycòd.3204530;apartirdelamàquinaconmatrìculaN°5241,sehainstaladolapiezacon

ref.1.1ycòd.3204520.Lapiezaconref.1.1sepuedeintercambiar( )conlapiezaconref.1.Sientablasehallapresenteelsìmbolo( ),laspiezascoreferencia1y1.1nosonintercabiables.

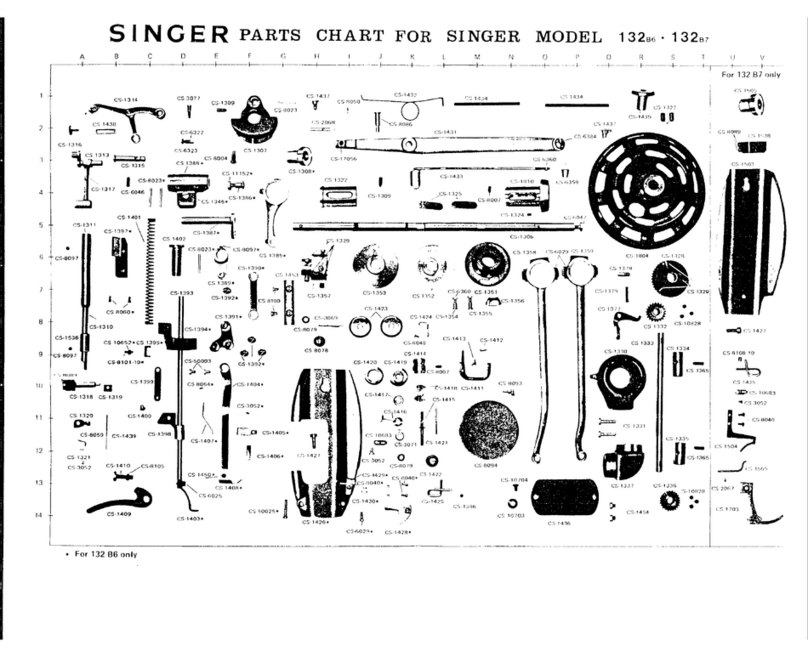

Rif. Cod. I F GB D E Note

1 3204530 Riduttore Réducteur Reducer Untersetzungsgetriebe Reductor 5240

2 3204520 Riduttore Réducteur Reducer Untersetzungsgetriebe Reductor 5241

OPTIONAL

TAV.1

TAV. 1 KIT RUOTE - KIT DE ROUES - WHEEL KIT - RÄDER - SATZ - KIT DE RUEDAS

Rif. Cod. I F GB D E Note

1 2226700 COPIGLIA GOUPILLE SPLIT PIN KLAPPSPLINT CHAVETA

2 2211150 RUOTA ROUE WHEEL RÄDER RUEDA

3 3206261 GUIDA SCORRIMENTO

TUBO SX COULISSE DU TUYAU

G.CHE LEFT TUBE GUIDE GLEITFÜHRUNG ROHR

LINKS

GUÍA

DESPLAZAMIENTO

TUBO IZQUIERDO

4 3206262 GUIDA SCORRIMENTO

TUBO DX COULISSE DU TUYAU

DROIT RIGHT TUBE GUIDE GEITFÜHRUNG ROHR

RECHTS

GUÍA

DESPLAZAMIENTO

TUBO DERECHO

5 2222082 VITE VIS SCREW SCHRAUBE TORNILLO 5739 M 10X60 Z

6 2223650 DADO ECROU DISK MUTTER TUERCA 5588 M10 Z

7 3206641 ROSETTA RONDELLE WASHER UNTERLEGSCHEIBE ARANDELA 6592 28X50X2 Z

8 3206260 TUBO RUOTE TUYAU ROUES WHEEL TUBE RÄDERROH TUBO RUEDAS

20

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

TAV.2

TAV.2TAV.2

RIF. COD. I F GB D E NOTE

1 3208421 CARRELLO CHARIOT CARRIAGE WAGEN CARRO

2 2222061 VITE VIS BOLT SCHRAUBE TORNILLO 5739 M 8X20 Z

3 2222515 VITE VIS BOLT SCHRAUBE TORNILLO 5931 M 8X16 Z

4 3204945 CUSCINETTO ROULEMENT BEARING LAGER COJINETE 608-2RS1

5 2223923 DADO AUTOBLOCCANTE ECROU DE SÛRET! SELF LOCKING

NUT SELBSTSICHERNDE

MUTTER TUERCA

AUTOBLOQUEANTE M 8

6 3207397 RUOTA ROUE WHEEL RAD RUEDA

7 2222090 VITE VIS BOLT SCHRAUBE TORNILLO 5737 M 8x75 Z

8 3210193 GUIDA GLISSIERE GUIDE BAR FÜHRUNG GUÍA

9 3208442 ADESIVO BATTUTA

SINISTRA ADHESIF BUTÉE

GAUCHE LEFT FENCE

ADHESIVE LABEL SCHILD LINKER

ANSCHLAG ADHESIVO TOPE

IZQUERDO

10 3208441 ADESIVO BATTUTA

DESTRA ADHESIF BUTÉE

DROITE RIGHT FENCE

ADHESIVE LABEL SCHILD RECHTER

ANSCHLAG ADHESIVO TOPE

DERECHO

11 3205581 RIVESTIMENTO GOMMA REVETEMENT IN

CAOUTCHOUC RUBBER

COAITING GUMMI BEKLEIDUNG GOMA REVESTIMIENTO

12 2224612 ROSETTA RONDELLE WASHER UNTERLEGSHEIBE ARANDELA D.21X43 Z

13 3206086 PERNO PIVOT PIN ZAPFEN PERNO

14 3201517 GAMBA PIED LEG FUB PATA

15 3210350 GRUPPO TESTA DI

TAGLIO GROUPE TêTE DE

COUPE CUTTING HEAD

GROUP SCHNEIDKOPF-GRUP-

PE GRUPO CABEZA DE

CORTE

16 3206096 SUPPORTO SUPPORT SUPPORT UNTERLAGE SOPORTE

17 2223920 DADO

AUTOBLOCCANTE ECROU DE SURETE SELF LOCKING

NUT SELBSTSICHERNDE

MUTTER TUERCA

AUTOBLOCANTE M 10

18 3201015 TAPPO BOUCHON PLUG STOFFEN TAPON

19 2222587 VITE VIS SCREW SCHRAUBE TORNILLO 5933 M8X20 Z

20 3210171 PARASCHIZZI PROTECTION

ÉCLABOUSSURES SPRAY GUARD GUMMISPRITZSCHUTZ PROTECCIÓN CONTRA

SALPICADURAS

21 3210169 TELAIO CHASSIS FRAME RAHMEN BASTIDOR

22 3205526 CONVOGLIATORE TOBOGGAN WATER RUN-OFF

TRAY FÖRDERER TRANSPORTADOR

23 2222425 VITE VIS SCREW SCHRAUBE TORNILLO AUTOFOR.TE 4,2X13

24 3204818 VASCA CUVE DRUM MISCHWANNE RECIPIENTE

25 2235428 TAPPO BOUCHON PLUG STOFFEN TAPÓN

21

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

TAV.2TAV.2

RIF. COD. I F GB D E NOTE

26 3210360 POMPAACQUA POMPE EAU WATERPUMP WASSERPUMPE BOMBADELAGUA 230V-50Hz

3210378 110V-50Hz

27 2292365 TUBO TUBE TUBE ROHR TUBO L=1.3 m.

28 2224320 ROSETTA RONDELLE WASHER UNTERLEGSCHEIBE ARANDELA D.10X21X2

29 3210161 ALBEROTRASMISSIONE ARBRE SHAFT WELLE EJE

30 2209450 BOCCOLANYLON DOUILLENYLON NYLONBUSHING NYLON-BUCHSE MANGUITONYLON

31 2222002 VITE VIS SCREW SCHRAUBE TORNILLO 5739M6x16Z

32 2222059 VITE VIS SCREW SCHRAUBE TORNILLO 5739M8X25ZSX.

33 3208414 LEVAASCATTO LEVIER LEVER HEBEL PALANCA

34 3208422 GONIOMETRO GONIOMÈTRE GONIOMETER WINKELMESSER GONIÓMETRO

35 3207213 SUPPORTOFISSAGGIO

GUIDE SUPPORTGLISSIERE GUIDEBAR

SUPPORT FUHRUNGINTERLAGE GUIASUPORTE

36 3208428 SLITTACARRELLO CHARIOTGLISSIÈRE TROLLEYSLIDE KARRESCHLITTEN CARROCORREDERA

37 3210236 SUPPORTOFISSAGGIO

GUIDESX SUPPORT GLISSIERE

SX GUIDEBAR

SUPPORTSX FUHRUNGINTERLAGE

SX GUIASUPORTE SX

38 2222580 VITE VIS SCREW SCHRAUBE TORNILLO M4X20Z

39 3210153 ASTAROTAZIONE

CARTERDISCO TIGERéGLAGE

ROTATION ROTATION

ADJUSTINGROD DREH-REGULIERSTA-

NGE ASTAREGLAJEROTACIóN

40 3209333 POMELLO POIGNÉE KNOB KNOPF POMO M8Z

41 3210644 BLOCCAGGIO

CARRELLO CHARIOTCALAGE TROLLEYCLAMPING KARREEINSPANNUNG CARROBLOQUEO

42 2222016 VITE VIS SCREW SCHRAUBE TORNILLO 5739M6x20Z

43 2223924 DADO ECROU NUT MUTTER TUERCA M6 Z

44 3209332 ECCENTRICO EXCENTRIQUE CAM EXZENTERBUCHSE EXCÉNTRICO

45 2222018 VITE VIS SCREW SCHRAUBE TORNILLO 5931M8X35Z

46 2224534 ROSETTA RONDELLE WASHER UNTERLEGSCHEIBE ARANDELA 6X12.5Z

47 3210163 PULEGGIA POULIE PULLEY RIEMENSCHEIBE POLEA

48 3210354 QUADROELETTRICO BOITERELECTRIQUE JUNCTIONBOX GEHAUSE CAJAELECTRA 230V/50HZ

3210376 110V/50HZ

49 2288885 MANOPOLA POIGNÉE HANDGRIP GRIFF EMPUÑADURA

50 3206513 CUSCINETTO PALIER BEARING LAGER COJINETE 62052RS

51 3210179 CARTERDISCO CARTERDISC DISCCOVER SCHEIBENGEHäUSE CÁRTER

52 3232759 ANELLOPARAOLIO BAGUED'ÉTANCHÉITÉ OILSEALRING ÖLABSTREIFRING ANILODERÉTEN 35X52X7

53 3204777 FLANGIAINTERNA FLASQUEINTÉRIEURE INNERFLANGE FLANSCHINN. BRIDAINTERIOR

54 3204776 FLANGIAESTERNA FLASQUEEXTÉRIEURE OUTERFLANGE FLANSCHAUSS. BRIDAEXTERIOR

55 3210156 UGELLOACQUA TUYAUEAU WATERHOSE WASSERDüSE TUBOAGUA

56 3210629 CUSCINETTO PALIER BEARING LAGER COJINETE 60062RS

57 3205635 RUBINETTO ROBINET VALVE HAHN GRIFO

58 3210140 CARTERLAMA CARTERLAME BLADE COVER SCHEIBENGEHÄUSE CÁRTERHOJA

59 2222006 VITE VIS SCREW SCHRAUBE TORNILLO M8X30Z

60 3210189 DADO

AUTOBLOCCANTE ECROUDESURETE SELFLOCKING NUT SELBSTSICHERNDE

MUTTER TUERCA

AUTOBLOCANTE M20Z

62 3204889 LEVAASCATTO LEVIER LEVER HEBEL PALANCA

63 2229300 LINGUETTA LANGUETTE KEY KEIL LENGUETA 6X6X20

64 2224910 ROSETTA RONDELLE WASHER UNTERLEGSCHEIBE ARANDELA DEV.D.10Z

65 3210142 ASTAREGOLAZIONE

ROTAZIONE TIGEROTATION

CARTERDISQUE BLADEGUARD

ROTATIONROD

DREHSTANGEDER

SCHUTZHAUBE-TREN-

NSCHEIBE

ASTAREGLAJEROTACIóN

GUARDADISCO

66 3210152 MOLLA RESSORT SPRING FEDER MUELLE

67 2227320 ANELLOARRESTO BAGUE D'ARRÊT STOPRING ARRETIERRING ANILLODEPARADA E/20

68 3210181 PERNOMOLLA PIVOTRESSORT SPRINGPIN FEDER PERNOMUELLE

69 3210206 PARASCHIZZIDISCO PROTECTION

ÉCLABOUSSURES SPRAYGUARD GUMMISPRITZSCHUTZ PROTECCIÓNCONTRA

SALPICADURAS

70 3210353 VITETIRANTE VIS TIRANT TIE RODSCREW TRÄGER TORNILLOTIRANTES

71 3210542 PROTEZIONEDXDISCO PROTECTION DISQUE DX DISK PROTECTION DX SCHUTZSCHEIBE PROTECCIÓN DISCO DX

72 3210543 PROTEZIONESXDISCO PROTECTION DISQUE SX DISK PROTECTION SX SCHUTZSCHEIBE PROTECCIÓN DISCO SX

73 3210576 ROSETTA NYLON RONDELLENYLON NYLONWASHER UNTERLEGSCHEIBE ARANDELANYLON 8.4XX17X1.5

74 2224140 ROSETTA RONDELLE WASHER UNTERLEGSCHEIBE ARANDELA 8X18Z.

75 2222110 VITE VIS SCREW SCHRAUBE TORNILLO 8X80 Z

22

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

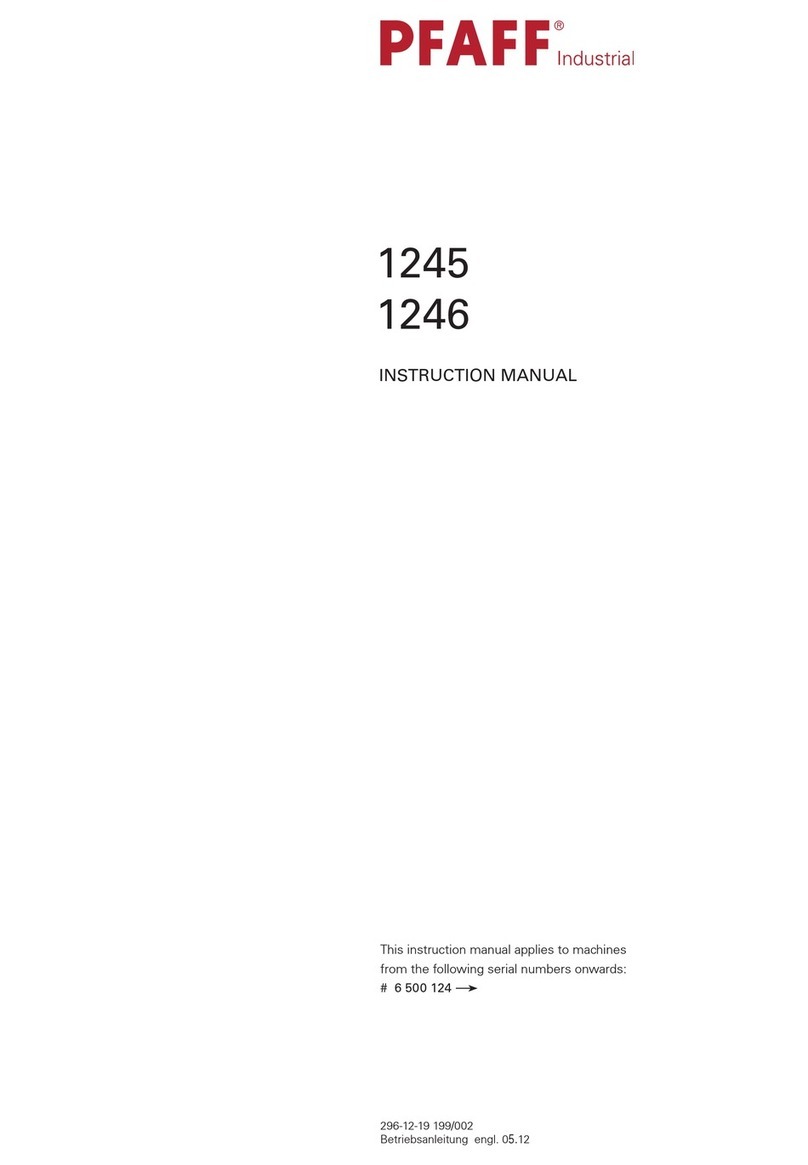

TAV.3TAV.3

RIF. COD. I F GB D E N OTE

13210355 MOTORE MOTEUR MOTOR MOTOR MOTOR 230V/50Hz

3210377 110V/50Hz

2 3210162 CARTER CINGHIE

INTERNO CARTER EXTÉRIEUR

COURROIS BELTS EXTERNAL

COVER RIMEN

AUSSENSCHUTZHAUBE CÁRTER EXTERIOR

CORRERAS

3 3210185 CINGHIA COURROIE BELT RIEMEN CORREA 470 J 12

4 3210164 CARTER CINGHIE

ESTERNO CARTER INTÉRIEUR

COURROIS BELTS INTERNAL

COVER RIMEN

INNENSCHUTZHAUBE CÁRTER INTERIOR

CORRERAS

5 3210165 STAFFA SUPPORTO

CARTER CINGHIE ÉTRIER SUPPORT

CARTER COURROIS

SUPPORT

BRACKET FOR

BELTS COVER

BUGELHALTERUNG

DER

RIEMENSCHUTZHAUBE

ESTRIBO SOPORTE

CÁRTER CORREAS

6 3210460 CASSETTA ELETTRICA BOITER ELECTRIQUE JUNCTION BOX GEHAUSE CAJA ELECTRCA

72285601 CONDENSATORE CONDENSATEUR CAPACITOR KONDENSATOR CONDENSADOR 230V/50Hz (µF 35)

3213013 110V/50Hz (µF 120)

8 2222002 VITE VIS BOLT SCHRAUBE TORNILLO M 6X16 Z

9 2224530 ROSETTA RONDELLE WASHER UNTERLEGSCHEIBE ARANDELA 6X12.5 Z

10 2223924 DADO

AUTOBLOCCANTE ECROU DE SURETE SELF LOCKING

NUT SELBSTSICHERNDE

MUTTER TUERCA

AUTOBLOCANTE M 6 Z

11 3203921 VITE VIS BOLT SCHRAUBE TORNILLO M 5X10 Z

12 2224140 ROSETTA RONDELLE WASHER UNTERLEGSCHEIBE ARANDELA 8X18 Z

13 2223923 DADO

AUTOBLOCCANTE ECROU DE SURETE SELF LOCKING

NUT SELBSTSICHERNDE

MUTTER TUERCA

AUTOBLOCANTE M 8 Z

14 2222176 VITE VIS BOLT SCHRAUBE TORNILLO M 8X50 Z

15 2222004 VITE VIS BOLT SCHRAUBE TORNILLO M 8X35 Z

16 2227320 ANELLO ARRESTO BAGUE D'ARR T STOP RING ARRETIERRING ANILLO DE PARADA E 20

17 3210157 PULEGGIA POULIE PULLEY RIEMENSCHEIBE POLEA

TAV .3

TAV.4TAV.4

RIF. COD. I F GB D E NOTE

1 3210462 CASSETTA ELETTRICA BOITER ELECTRIQUE JUNCTION BOX GEHAUSE CAJA ELECTRA

23207920 MAGNETOTERMICO CONTACTEUR CONTACTOR KONTAKGLIED CONCTACTOR 230V/50 Hz

3207922 110V/50 Hz

3 3207928 PULSANTE BOUTON PUSH DRUCKKNOPF PULSANDOR

4 3210356 PIASTRA QUADRO

ELETTRICO PLAQUE PANNEAU

ÉLECTRIQUE ELECTRIC PANEL

PLATE

PLATTE DER

ELEKTRISCHEN

SCHALTTAFEL

CHAPA QUADRO

ELÉCTRICO

53207923 BOBINA DI MINIMA BOBINE COIL SPULE BOBINA 230V/50 Hz

3207926 110V/50 Hz

TAV. 4

23

MASONRY 350 F

IMER INTERNATIONAL S.p.A.

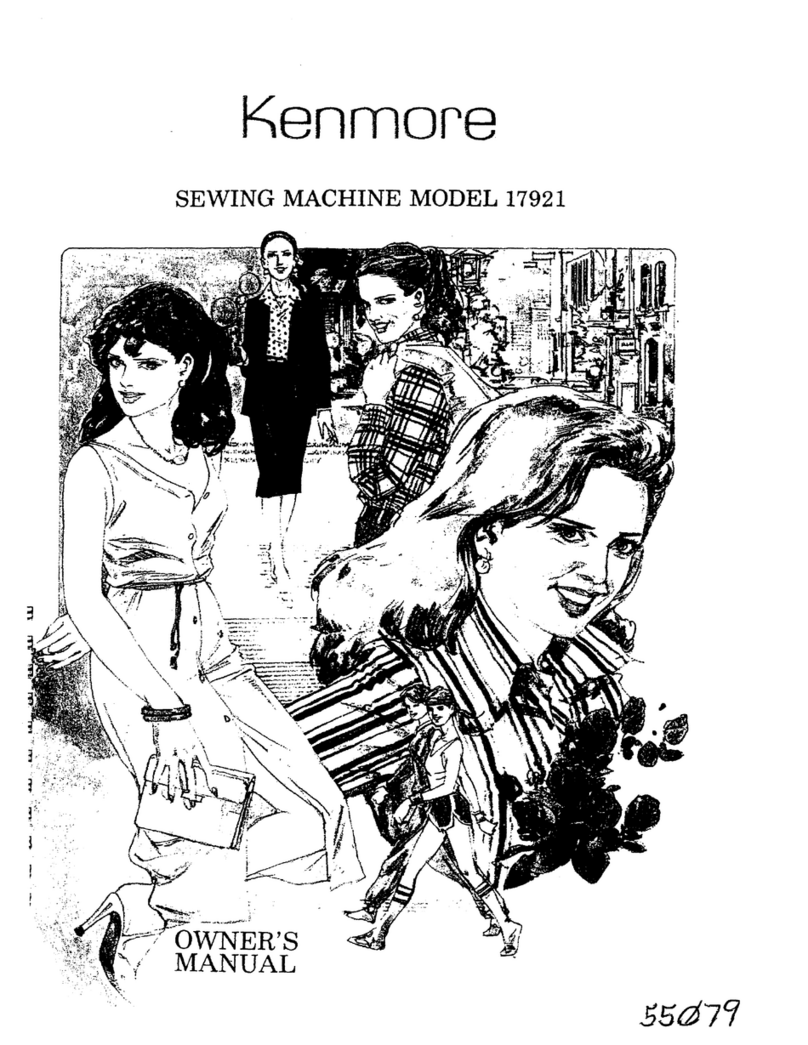

SCHEMA ELETTRICO / SCHEMA ELECTRIQUE / WIRING DIAGRAM / SCHALTPLAN / ESQUEMA ELECTRICO

I F GB D E

L1 CONDUTTORE DI LINEA

FASE CONDUCTEUR DE LIGNE

PHASE PHASE LINE

CONDUCTOR PHASENLEITER CONDUCTOR DE LINEA

FASE

NCONDUTTORE DI LINEA

NEUTRO CONDUCTEUR DE LIGNE

NEUTRE NEUTRAL LINE

CONDUCTOR MITTELLEITER CONDUCTOR DE LINEA

NEUTRO

PE CONDUTTORE DI

PROTEZIONE CONDUCTEUR DE

PROTECTION TERRE PROTECTION

CONDUCTOR SCHUTZLEITER CONDUCTOR DE

PROTECCION

I1 INTERRUTTORE

MAGNETOTERMICO INTERRUPTEUR

MAGNÉTOT THERMO-MAGNETIC

CUTOUT SWITCH SCHUTZSCHALTER INTERRUPTOR

MAGNETOTÉRMICO

C1 CONDENSATORE MARCIA CONDENSATEUR MOTOR CAPACITOR KONDENSATOR GANG CONDENSADOR DE

MARCHA

K1 BOBINA BOBINE COIL SPULE BOBINA

M1 MOTORE LAMA MOTEUR LAME BLADE MOTOR SÄGEBLATTMOTOR MOTOR DE LA

CUCHILLA

M2 MOTORE POMPA MOTEUR POMPE PUMP MOTOR PUMPENMOTOR MOTOR DE LA BOMBA

TAV.5 SUPPORTO 45° - SUPPORT 45° - 45° SUPPORT - SOPORTE 45°- UNTERLAGE45°

Rif. Cod. I F GB D E Note

1 2284859 POMELLO POIGNEE KNOB KNOPS POMO

TAV. 5

PROTEZIONE DIFFERENZIALE

KIT 230V - Cod.1169245

KIT 110V - Cod.1169249

OPTIONAL

Table of contents

Other IMER Sewing Machine manuals