IMER COMBI 350/600 Guide

IMER INTERNATIONAL S.p.A.

53036 POGGIBONSI (SIENA) loc. SALCETO

(ITALY)

tel. (0577) 983300 - fax (0577) 983304

COMBI 350/600 - 350/1000

Imanuale uso manutenzione ricambi

Fmanuel utilisation entretien pieces de rechange

GB Operating,maintenance, spare parts manual

DHandbuch für Bedienung, Wartung und Esatzteile

Emanual de uso, mantenimiento y recambios

INTERNATIONAL S.p.A

IMER

06/2001 - R5

- Cod. 3201536 -

(FAM. AK012 - AK013)

SEGATRICE

SCIE

SAWING MACHINE

MASCHINENSÄGE

TRONZADORA

(1188720 - 1188750 -1188724 -1188754)

8

(R5)

COMBI 350/600 - 350/1000

IMER INTERNATIONAL S.p.A.

GBDear Customer,

Congratulations on your choice of purchase: IMER saws are the

result of years of experience and is equipped with all the latest

technical innovations.

WORKING IN SAFETY

To work in complete safety, read the following instructions

carefully.

- This OPERATION AND MAINTENANCE manual must be kept on

site by the person in charge, e.g. the SITE FOREMAN, and must

always be available for consultation.

- The manual is to be considered integral part of the machine and

must be kept for future reference (EN 292/2) until the machine is

disposed of. If the manual is damaged or lost, a replacement may

be requested from the saw manufacturer.

- The manual contains important information regarding site

preparation, machine use, maintenance procedures, and requests

for spare parts. Nevertheless, the installer and the operator must

both have adequate experience and knowledge of the machine prior

to use.

- To guarantee complete safety of the operator, safe operation and

long life of equipment, follow the instructions in this manual carefully,

and observe all safety standards currently in force for the prevention

of accidents at work (use of safety footwear and gloves in accordance

with S.I. N°3073 of 30/11/92).

Safety glasses or a protective visor must be worn at

all times.

MAKE SURE THAT SIGNS ARE LEGIBLE.

It is strictly forbidden to carry out any form of

modification to the steel structure or working parts of the

machine.

- IMER INTERNATIONAL declines all responsibility for non-

compliance with laws and standards governing the use of this

equipment, in particular; improper use, defective power supply, lack

of maintenance, unauthorised modifications, and partial or total failure

to observe the instructions contained in this manual.

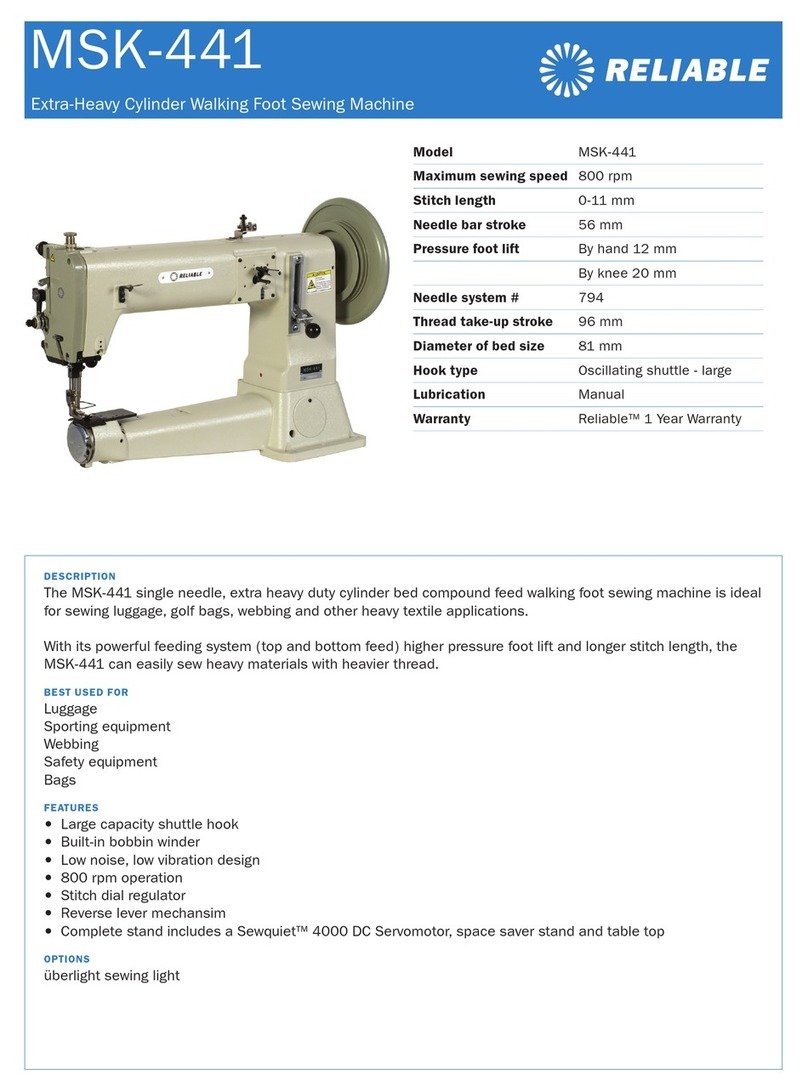

1. TECHNICAL DATA

2. DESIGN STANDARDS

COMBI 350 saws are designed and manufactured according to the

following standards: I.E.C. 34.4;

CEI EN60204; EN 292/2.

3. NOISE EMISSION LEVEL

Operator exposure to sound emission levels (continuous sound

pressure levels equal to A weighting); the COMBI 350 saw noise

emission level during cutting is 93 dB(A) with continuous rim blade.

4. CUTTING SPECIFICATIONS

This saw model has been specially designed by IMER for cutting

stone, ceramics, marble, granite, concrete and similar materials.

Only water-cooled diamond blades with continuous or segmented

edges must be used. Under no circumstances must dry cutting

blades be used or materials other than those specified above. IMER

INTERNATIONAL declines all responsibility for damage caused by

improper use of the above machine.

5. CUTTING CAPACITY

- Max. thickness (mm): 120 (90°); 70 (45°)

- Workpiece width (mm): max. 520; min 50

- Length: COMBI 350/600 COMBI 350/1000

thk. x l (mm) 25 x 600 25 x 1000

60 x 560 60 x 960

(*) 90° cut from above

120 x 530 120 x 930

120 x 700 (*) 120 x 1100 (*)

(**) 45° 45 x 530 (**) 70 x 930 (**)

6. WARNING

- Do not load the saw with workpieces that exceed the specified

weight (max. 40 kg)

- Ensure stability of machine and workpiece before, during or after

cutting. Install supplementary support surfaces at the same height

as the worktable.

- Respect the environment; use suitable receptacles for collection

of cooling water contaminated with cutting dust.

7. SAFETY PRECAUTIONS

IMER saws are designed for work on construction sites and under

conditions of natural light and in workshops under conditions of

natural or artificial lighting of minimum 500 LUX.

The machine must never be used in environments

subject to risks of explosion and/or underground sites.

- IMER saws may only be used when fitted with all required safety

devices which must be in perfect condition.

- Never use makeshift and/or faulty power cables.

- Make electrical connections on the construction site where they

will not be subject to damage. Never stand the saw on power supply

cables.

- Lay power cables where they are not subject to risk of damage or

contact of connectors with water. Only use connectors fitted with

water-spray protection (IP55).

- Repairs to electrical installations must only be carried out by

qualified technicians. Always ensure that the machine is

disconnected from the power supply and is completely immobile

during repairs and maintenance operations.

Connect the machine to a suitable equipotential

earthing plant on the construction site with wire braid

of minimum 16 mm² section. The connection point is

identified by a screw welded to the frame (see Fig.1),

&RPEL &RPEL

%ODGHUSP USP

%ODGHGLDPHWHU PP

%ODGHPRXQWLQJKROH PP

0RWRUUDWLQJ .Z

0RWRUUSP USP

&XWWLQJWDEOH

GLPHQVLRQV PP [ [

2YHUDOOGLPHQVLRQV PP [[ [[

2YHUDOOGLPHQVLRQV

IRUWUDQVSRUW PP [[ [[

:HLJKW .J

:HLJKWIRUWUDQVSRUW .J

%ODGHURWDWLRQ

GLUHFWLRQVHHQIURP

EODGHFODPSLQJ

IODQJH

$17,&/2&.:,6(

&XUUHQW $

9ROWDJH 9

)UHTXHQF\ +]

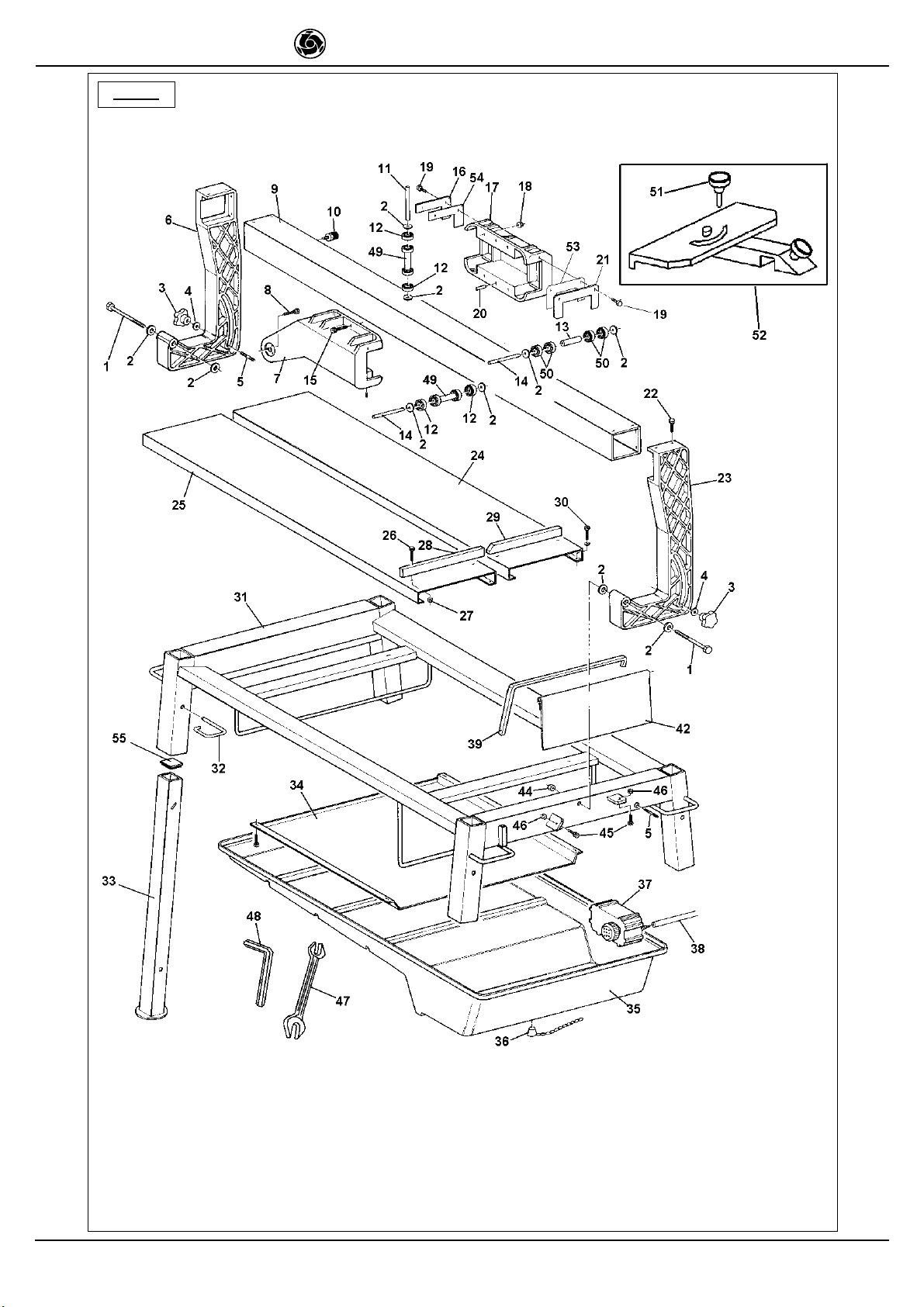

1 TELESCOPIC LEG

2 SPRAY GUARD

3 MOTOR

4 BLADE SUPPORT ARM

5 WATER PUMP

6 GUIDE

7 MAIN SWITCH

8 WORKTABLE

9 WATER TANK

10 BLADE GUARD

11 EARTHING SCREW

Fig.1

Pay special attention to warnings bearing the

following symbol.

9

(R5)

COMBI 350/600 - 350/1000

IMER INTERNATIONAL S.p.A.

and on the rating plate by the

earthing symbol.

- Stop the saw only by means of the main switch.

- The symbol shown on the label (see left) indicates

the warning ENSURE ALL PROTECTION DEVICES

ARE INSTALLED AND IN PERFECT CONDITION

BEFORE SWITCHING ON THE MACHINE

8. ELECTRICAL SAFETY

IMER saws comply with EN 60204-1; and are fitted with:

- protection device against automatic re-start after power failure.

- Short-circuit cutout device

- Motor overload cutout switch

9. TRANSPORTATION (Ref. Fig.2)

WARNING! Always remove the plug from the power

socket before moving the saw, and lock head support carriage

movement by means of the relative knob (ref. 3). To transport

the machine use slinging equipment with 4 rope legs, fixing

the hooks to the relative attachments.

10. INSTALLATION (Ref. Fig.2)

Fix the hooks to the relative attachments on the machine and lift

the machine out of its package.

- Unlock the legs by sliding out split pins (ref.2) and pins (ref.1).

- Lock the legs at working height. Refit the pins in the leg supports

and insert the split pins.

- Install the machine on a completely even and stable surface.

11. ELECTRICAL CONNECTION

Ensure that there is an overload cutout device fitted

up-line on the power line. If necessary, install an IMER quick

connect residual current circuit breaker (RCCB) (code no.

1169245 available in kit form).

Ensure that the mains voltage corresponds to that specified for the

machine: 380 V/50 Hz (for three-phase motors) or 230 V/50 Hz

(for single-phase motors).

All power supply installations must comply with CEI 64-8

standards (harmonised document CENELEC HD384).

The electrical power cable must be suitably sized to avoid voltage

drops. Cable drums (with collector rings) must not be used.

Cable dimensions will vary according to the start-up current and

length of cable. In general cable sizes of 4 x 4 mm² are sufficient for

lengths up to 50 metres. After installation always carry out voltage

testing under load conditions, both at start-up and during operation.

During operation, voltage drops must never exceed 5%. In the case

of longer cables or a power supply network subject to variations,

use cables with a section of at least 6 mm². Cables used on

construction sites must be fitted with suitable external sheathing

that is resistant to wear, crushing and extreme weather conditions.

12. MACHINE START-UP

Before connecting the machine to the power supply:

1 - Ensure that the metal structure is connected to an earthing

plant as indicated in Section 7 Safety Precautions.

2 - Ensure that the tank contains sufficient cooling water.

3 - Ensure that the power circuit corresponds to the requirements

as indicated in Section 11 Electrical connections

4 - Connect the machine to the power supply

5 - Set the switch to 1 and when the motor is started return to

position 0 after ensuring that cooling water reaches the blade.

6 - Check that the direction of blade rotation corresponds to that

indicated by the arrow on the blade guard.

7 - ON THREE-PHASE MOTOR MODELS (380 V/50 Hz): if blade

rotation is incorrect, invert the two wires inside the power plug.

Repeat operation indicated in point 5.

8 - If all is in order, proceed with cutting.

13. EMERGENCY STOP

In the event of emergency, stop the machine by

pressing the stop control switch.

- The motor is fitted with an overload cutout device. If the motor

overheats, it will automatically shut down. Allow motor to cool

before re-starting.

- The motor is protected against automatic re-start after

interruptions due to power failure. To resume operation, when

power is re-connected, repeat machine start-up procedure.

14. BLADE INSTALLATION (Ref.Fig.3)

By means of a hex wrench no.10, remove front screws (ref.1) and

loosen the other two screws (ref.2) which secure the blade guard.

Turn the guard clockwise to gain access to the securing screw

(ref.4). Use a hex wrench no. 13 to remove the screw (turn anti-

clockwise). Remove the mobile flange and check that the flanges,

disc shaft and blade are not damaged.

Never use worn blades.

Only use blades that are designed for the number of

revolutions indicated on the machine rating plate.

Check that blade rotation corresponds to that

indicated on the blade guard.

Centre the blade against the fixed flange, position the mobile flange

and tighten the securing screw by means of a hex wrench no. 13

(turn clockwise). Return the guard to its original position and lock

by means of screws (ref.1 and 2).

- Ensure that the blade guard is locked securely into position.

WARNING! An incorrectly installed blade, or a screw

insufficiently tightened can provoke damage to the machine

or injury to persons.

- Note that the blade must have an external diameter of 350

mm., a central hole diameter of 25.4 mm and max. thickness

of 3 mm.

- Check that the blade to be used is suitable for the material to

be cut.

15. USE

Leave a space of 150 cm around the machine to ope-

rate in full safety.

- Do not allow other persons to approach the machine during cutting.

- Never use the machine in fire-risk areas. Sparks can cause fire or

explosions.

- Make sure that the machine is switched off before positioning or

handling.

- Always ensure that the blade is free of any contact before start-

up.

- Ensure correct installation of all protective devices.

Ensure that blade rotation corresponds to the

indications on the blade guard.

Before starting work, fill the water tank. Top up during operation

whenever necessary: N.B. the pump suction hose must always

remain immersed in water.

Insert the plug in the power socket.

WARNING! For safety purposes the removal of

protective guards from the machine is strictly prohibited

The machine is protected against overload.

WARNING! Always switch off the machine before

carrying out blade adjustment.

15.1 VERTICAL BLADE MOVEMENT (Ref. Fig. 4)

To raise or lower the blade, slacken knob (ref.2) by turning it anti-

clockwise. Set blade support (ref.1) to the required position and

lock by tightening the knob fully (ref.2).

Ensure that the locking knob is tightened fully before starting

work.

15.2 BLADE POSITIONING FOR CUTS AT 45° (Ref.Fig.5)

- Slacken knobs (ref.1) on both sides of the machine. The blade

support arm (ref.2) is unlocked and so can be set to its stroke limit,

i.e. inclined at 45° with respect to the worktable. Tighten the two

knobs fully to lock into position.

- To bring the blade back to the vertical position (pos.0) carry out

the above operations in reverse order.

- Ensure that the locking knobs (ref.1) are tightened fully before

starting work.

15.3 CUTTING

- Before cutting, check that the blade is aligned with the cutting

line.

- Place the workpiece on the worktable snugly against the fence.

- Start the motor and wait until the water reaches the blade to

begin cutting.

- Start cutting movement by pulling the carriage towards you

by means of the relative handle (ref.1 fig.6).

- Cutting feed speed must be varied to suit workpiece thickness

and material. Cutting too fast may overload the motor.

15.3.1 CUTS WITH BLADE LOWERED FROM ABOVE

(Ref. Fig.8)

Bring the blade support to its highest position and lock. Position

the workpiece on the worktable. Start the machine, unlock the blade

support and begin vertical cutting until the blade reaches its lowest

point. Lock the support once more and proceed with horizontal

cutting.

15.3.2. GROOVE CUTS (Ref. Fig.8)

To make shallow groove cuts, the opposite procedure to through-

GB

10

(R5)

COMBI 350/600 - 350/1000

IMER INTERNATIONAL S.p.A.

GBcutting must be used, i.e. by pushing the head unit instead of pulling

it. Move the blade support (ref.1) to its limit position (closest to the

operator) and lock, after having positioned the blade at the required

cutting height. Place the workpiece against the fence (ref.2). Start

the machine and begin cutting by pushing the blade support in the

direction of the arrow.

15.3.3 BLADE CHANGE

To change the blade refer to section 14. BLADE INSTALLATION.

16. MAINTENANCE

WARNING! Always switch the machine off and remove

the plug from the power socket before carrying out any

maintenance operations .

Always check that the protective guards are in the

correct position and in perfect condition.

As there is the continuous risk of inadvertent damage

to the electric cables, these must be checked regularly each

time before the machine is used.

Never leave the machine out in the open. Make sure that it is stored

in a sheltered area away from extreme weather conditions.

Replace worn or faulty components with original spare parts.

16.1 TANK CLEANING ON WORK COMPLETION

On completion of work, empty the tank and remove. Clean

thoroughly to remove cutting residue.

16.2 TANK REMOVAL (Ref.Fig.7)

Lift the tank (ref.1) to detach from its supports (ref.2) and remove

from the side indicated by the arrow.

16.3 WORK SURFACE CLEANING

Always keep work surfaces clean. Residual dirt can impair cutting

precision.

16.4 GUIDE RAIL CLEANING

The horizontal guide elements on the carriage are protected against

dirt build-up by scrapers. However we advise thorough cleaning of

the guide rails to ensure correct operation.

WARNING! Do not use any type of lubricant on the guide rail.

16.5 CARRIAGE CLEARANCE ADJUSTMENT (Ref. fig.9)

LATERAL ADJUSTMENT: turn adjustment screw 1 gradually

clockwise using a hex wrench no.3, so that the internal roller comes

into contact with the bar. Take care not to exert too much pressure.

Repeat the same operation with the other adjustment screws

according to the order indicated in the figure. Adjust vertical

clearance by means of the screws located on the lower part of

carriage (A). On completion, if carriage travel is not smooth, slacken

the adjustment screws by turning the wrench anti-clockwise; if

clearance has not been eliminated repeat the above operation.

16.6 CLEANING AND MAINTENANCE OF COOLING CIRCUIT

- If water does not reach the blade stop the machine immediately to

avoid blade damage.

- After switching off the machine ensure that the water level is

sufficient.

- If necessary, after disconnecting the machine from the power

supply check that the tap, hose and pump filter are not blocked

- If necessary, check that the impeller rotates freely (after extended

periods of disuse)

- If necessary, remove the pump and check that the pump/motor

coupling is in perfect condition.

16.7 DRIVE BELT REPLACEMENT

- Disconnect the machine from the power supply

- Remove the water hose connection by loosening the hose clamp

on the blade guard.

- Remove the blade, the two flanges, the blade half-guard securing

screws, the locking knob (ref.1, chart 02) and remove the blade

external half-guard (motor side).

- Remove the blade shaft with pulley from the bearing (ref.27, drawing

02) and fit into the bearing of the half-guard previously removed

(ref.14, chart 02).

- Fit the new belt onto the two pulleys and refit the belt tensioner.

- Refit the seal on the edge of the guard and ensure that it is in good

condition and that the two locating pins are in the correct position.

- Refit the guard inserting the blade shaft into the bearing (ref.27,

chart 02) taking care to align the screw (ref.51, drawing 02) located

on the slot of the head fulcrum (ref.19, drawing 02) with the locking

handle hole (ref.1, drawing 02).

- Join the two blade half-guards using the two locating pins to align

correctly.

- Screw in the two blade half-guards by tightening diagonally opposite

screws alternately.

- Screw in and tighten the locking handle before installing the blade.

17. TROUBLESHOOTING

N.B.: Before carrying out any maintenance

operations, switch off the machine, set the switch to 0 and

remove the plug from the power socket.

)$8/7 &$86( 5(0('<

0RWRUGRHVQRWVWDUW

ZKHQVZLWFKLV

WXUQHG

'HIHFWLYHSRZHU

FDEOH

3OXJQRWLQVHUWHGLQ

VRFNHWFRUUHFWO\

3RZHUFDEOHIURP

SOXJWRFRQWUROSDQHO

GHWDFKHG

/RRVHZLUHLQVLGH

PRWRUFLUFXLWERDUG

$ZLUHKDVEHFRQH

GLVFRQQHFWHGLQVLGH

WKHSDQHO

)DXOW\PDLQVZLWFK

7KHRYHUORDGVDIHW\

GHYLFHKDVEHHQ

DFWLYDWHG

&KHFNSRZHUFDEOHV

(QVXUHFRUUHFW

FRQQHFWLRQ

&RQQHFWFDEOHUH

&RQQHFWZLUH

5HPDNHWKH

FRQQHFWLRQ

5HSODFHVZLWFK

:DLWIRUDIHZPLQXWHV

DQGWKHQWU\UHVWDUWLQJ

WKHPDFKLQH

9HUWLFDOEODGH

PRYHPHQWQRW

VPRRWK

ORFNLQJNQREWRR

WLJKW 6ODFNHQNQRE

/RFNLQJNQREVGR

QRWORFN

WKUHDGLVZRUQ 5HSODFHNQREV

%ODGHLQFOLQDWLRQ

QRWVPRRWK

ORFNLQJNQREWRR

WLJKW 6ODFNHQNQRE

+RUL]RQWDOEODGH

PRYHPHQWQRW

VPRRWK

ORFNLQJNQREWRR

WLJKW 6ODFNHQNQRE

/DFNRIFRROLQJ

ZDWHUVXSSO\WR

EODGH

5HIHUWRVHFWLRQFOHDQLQJDQG

PDLQWHQDQFHRIFRROLQJFLUFXLW

%ODGHGRHVQRWFXW

,QFRUUHFWEODGH

URWDWLRQ

%ODGHLVZRUQ

5HPRYHWKHEODGH

DQGUHILWLQWKHSRVLWLRQ

DVLQGLFDWHGRQWKH

EODGHODEHO

)LWQHZEODGH

0RWRUVWDUWVEXW

EODGHGRHVQRW

URWDWH

%HOWLVEURNHQ 5HSODFHGULYHEHOWVHH

&KDSWHU

17

(R5)

COMBI 350/600 - 350/1000

IMER INTERNATIONAL S.p.A.

Fig.2

Fig.4

Fig.6 Fig.7

Fig.8

Fig.5

Fig.3

Fig.9

18

(R5)

COMBI 350/600 - 350/1000

IMER INTERNATIONAL S.p.A.

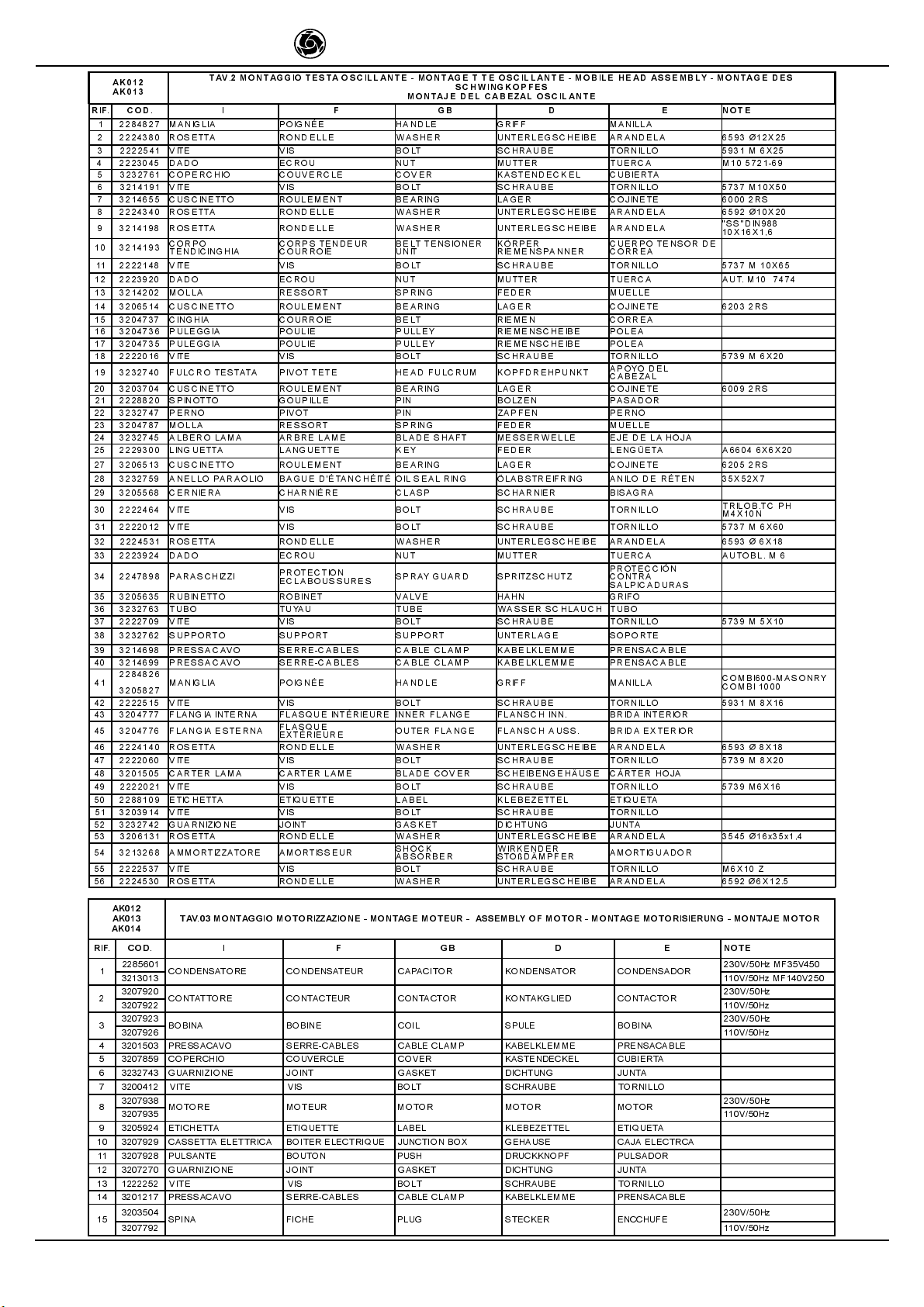

$.$. 7$90217$**,27(/$,20217$*(&+Æ66,6)5$0($66(0%/<5$+0(10217$*(0217$-('(/%$67,'25

&20%,&20%,

5,) &2' , ) *% ' ( 127(

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 ;

526(77$ 521'(//( :$6+(5 817(5/(*6&+(,%( $5$1'(/$ ;

92/$17,12 92/$17 +$1':+((/ +$1'5$' 92/$17(

526(77$ 521'(//( :$6+(5 817(5/(*6&+(,%( $5$1'(/$ ;

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0[

%5$&&,2 %5$6 527$5<%/$'($50 $50'5(+6&+$8)(/ %5$=2 ';

&$55(//2 &+$5,27 &$55,$*( :$*(1 &$552 ';

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0[

*8,'$ */,66,(5( *8,'(%$5 )h+581* *8Ë$ &20%,

&20%,

$00257,==$725( %87(((1

&$287&+28& '$03(5 672'b03)(5 $0257,*8$'25

3(5129(57,&$/( 3,927 3,1 =$3)(1 3(5129(57,&$/

&86&,1(772 528/(0(17 %($5,1* /$*(5 &2-,1(7( 56

',67$1=,$/( (175(72,6( 63$&(5 ',67$1=67h&. ',67$1&,$/

3(512 3,927 3,1 =$3)(1 3(512

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

5$6&+,$725(

$17(5,25( 5$&/(85$9$17 )52176&5$3(5 925'(5(5

$%675(,)(5 5$63$'25'(/$17(52

&$55(//2 &+$5,27 &$55,$*( :$*(1 &$552 6;

'$'2 (&528 187 0877(5 78(5&$ 0

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

3(512 3,927 3,1 =$3)(1 3(512

5$6&+,$725(

3267(5,25( 5$&/(85$55,(5( 5($56&5$3(5 +,17(5(5$%675(,)(5 5$63$'2575$6(52

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

%5$&&,2 %5$6 527$5<%/$'($50 $50'5(+6&+$8)(/ %5$=2

3,$12',7$*/,2 3/$1'(&283( &877,1*7$%/( 6&+1(,')/b&+( 0(6$'(&257( &20%,';

&20%,';

3,$12',7$*/,2 3/$1'(&283( &877,1*7$%/( 6&+1(,')/b&+( 0(6$'(&257( &20%,6;

&20%,6;

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

'$'2 (&528 187 0877(5 78(5&$ $872%/',$0

%$7787$ %87(( (1'6723 $16&+/$* 723( 6;

%$7787$ %87(( (1'6723 $16&+/$* 723( ';

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

7(/$,2 &+Æ66,6 )5$0( 5$+0(1 %$67,'25 &20%,

&20%,

3(512 3,927 3,1 =$3)(1 3(512

*$0%$ 3,('02%,/( &2//$36,%/(/(* )8 3$7$0Ï9,/

&2192*/,$725( 72%2**$1 :$7(55812))75$< )g5'(5(5 75$163257$'25 &20%,

&20%,

9$6&$ &89( '580 0,6&+:$11( 5(&,3,(17(

7$332 %28&+21 3/8* 672))(1 7$3Ï1

3203$ 3203( 3803 3803( %20%$ 9+]

9+]

78%2 78%( 78%( 52+5 78%2

68332572 6833257 6833257 817(5/$*( 623257(

3$5$6&+,==, 3527(&7,21

e&/$%286685(6 635$<*8$5' *800,635,7=6&+87= 3527(&&,Ï1&2175$

6$/3,&$'85$6

'$'2 (&528 187 0877(5 78(5&$ $872%/0

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

'$'2 (&528 187 0877(5 78(5&$ 0

&+,$9( &/e 63$11(5 *$%(/6&+/8(66(/ //$9(

&+,$9( &/e 63$11(5 *$%(/6&+/8(66(/ //$9(

5827$ 528( :+((/ 5$' 58('$

&86&,1(772 528/(0(17 %($5,1* /$*(5 &2-,1(7( 56

92/$17,12 92/$17 +$1':+((/ +$1'5$' 92/$17(

*21,20(752 *21,20Ê75( *21,20(7(5 :,1.(/0(66(5 *21,Ï0(752

)(/752 )(875( ),/= )(/7 ),(/752

)(/752 )(875( ),/= )(/7 ),(/752

7$332 %28&+21 3/8* 672))(1 7$321

18. RICAMBI :Per tutti gli ordini dei pezzi di ricambio vogliate indicare: 1 - Tipo di macchina. 2 - Numero di codice e di riferimento collocato in corrispondenza

di ogni definizione. 3 - Numero di serie e anno di costruzione riportato sulla targhetta della macchina. SIMBOLOGIA: Intercambiabilità (esempio): Fino alla macchina

matricola N° 5240 è stato installato il rif.1 cod.3204530,dalla mcchina matricola N° 5241 è stato installato il rif.1.1 cod.3204520. Il rif.1.1 è intercambiabile ( ) con il rif.1.

Non sono intercambiabili i rif.1 e rif.1.1 se in tabella è presente il simbolo ( ).

18. PIECES DE RECHANGE :Pour toutes les commandes de pièces de rechange, veuillez indiquer: 1 - Le Type de machine 2 - Le Numéro de code et de référence

se trouvant en face de chaque définition 3 - Le Numéro de série et l'année de construction se trouvant sur la plaquette d'identification de la machine

SYMBOLOGIE: Intercambiabilità (exemple):Jusqu'à la machine matricule N° 5240, nous avons installé la réf. 1 code 3204530; à partir de la machine matricule N° 5241, nous

avons installé la réf. 1.1 code 3204520. La réf. 1.1 est interchangeable ( ) avec la réf.1. Les réf. 1 et réf. 1.1 ne sont pas interchangebles si le symbole ( ) n'est pas sur le

tableau.

18. SPARE PARTS :All orders for spare parts must indicate the following: 1 - Type of machine.2 - Part number and position number of each part.3 - Serial number

and year of manufacture reported on the machine's identification plate.

SYMBOL: Interchangeability (example):Pos..1 P.n. 3204530 was installed on machincs up to N° 5240 and Pos.1.1 P.n. 3204520 installed on machine N° 5241 onwards. Pos.

1.1 is interchangeable ( ) with Pos. 1.Pos. 1 and Pos. 1.1 are not interchangeable if the ( ) symbol appears in the table.

18. ERSATZTEILE: Für Ersatzteilbestellungen bitte die folgenden Angaben machen: 1) Maschinentyp 2) Jeweils zugeordnete Art.-Nr. und Positionsnummer 3)

Seriennummer und Baujahr (Angabe auf dem Maschinenschild)

SYMBOLE: Austauschbarkeit (Beispiel):Bis zur Maschinenummer 5240 ist Ref. 1 Cod. 3204530 und ab Maschinennummer 5241 ist Ref. 1.1 Cod. 3204520 installiert worden.

Ref. 1.1 und Ref. 1 sind austaschbar ( ). Ref. 1 und Ref.1.1 sind nicht austauschbar, wenn das Symbol ( ) angegeben ist.

18. PIEZAS DE RECAMBIO :Para pedir una pieza de recambio hay que indicar siempre: 1 -El tipo de máquina. 2 -Los números de gódigo y de referencia

indicados en correspondencia de cada definición. 3 -El número de serie y el año de construcción indicados en la placa de la máquina.

SIMBOLOGIA : Intercambiabilidad (ejemplo): Hasta el equipo con matrìcula N° 5240, se ha instalado la pieza con ref. 1 y còd. 3204530; a partir de la màquina con matrìcula

N° 5241, se ha instalado la pieza con ref. 1.1 y còd. 3204520. La pieza con ref. 1.1 se puede intercambiar ( ) con la pieza con ref. 1. Si en tabla se halla presente el sìmbolo

( ), las piezas co referencia 1 y 1.1 no son intercabiables.

5LI &RG , ) *% ' ( 1RWH

5LGXWWRUH 5pGXFWHXU 5HGXFHU 8QWHUVHW]XQJVJHWULHEH 5HGXFWRU

5LGXWWRUH 5pGXFWHXU 5HGXFHU 8QWHUVHW]XQJVJHWULHEH 5HGXFWRU

19

(R5)

COMBI 350/600 - 350/1000

IMER INTERNATIONAL S.p.A.

TAV. 1.1

20

(R5)

COMBI 350/600 - 350/1000

IMER INTERNATIONAL S.p.A.

$.

$.

$. 7$90217$**,202725,==$=,21(0217$*(027(85$66(0%/<2)027250217$*(02725,6,(581*0217$-(02725

5,) &2' , ) *% ' ( 127(

&21'(16$725( &21'(16$7(85 &$3$&,725 .21'(16$725 &21'(16$'25 9+]0)9

9+]0)9

&217$7725( &217$&7(85 &217$&725 .217$.*/,(' &217$&725 9+]

9+]

%2%,1$ %2%,1( &2,/ 638/( %2%,1$ 9+]

9+]

35(66$&$92 6(55(&$%/(6 &$%/(&/$03 .$%(/./(00( 35(16$&$%/(

&23(5&+,2 &289(5&/( &29(5 .$67(1'(&.(/ &8%,(57$

*8$51,=,21( -2,17 *$6.(7 ',&+781* -817$

9,7( 9,6 %2/7 6&+5$8%( 7251,//2

02725( 027(85 02725 02725 02725 9+]

9+]

(7,&+(77$ (7,48(77( /$%(/ ./(%(=(77(/ (7,48(7$

&$66(77$(/(775,&$ %2,7(5(/(&75,48( -81&7,21%2; *(+$86( &$-$(/(&75&$

38/6$17( %28721 386+ '58&..123) 38/6$'25

*8$51,=,21( -2,17 *$6.(7 ',&+781* -817$

9,7( 9,6 %2/7 6&+5$8%( 7251,//2

35(66$&$92 6(55(&$%/(6 &$%/(&/$03 .$%(/./(00( 35(16$&$%/(

63,1$ ),&+( 3/8* 67(&.(5 (1&&+8)( 9+]

9+]

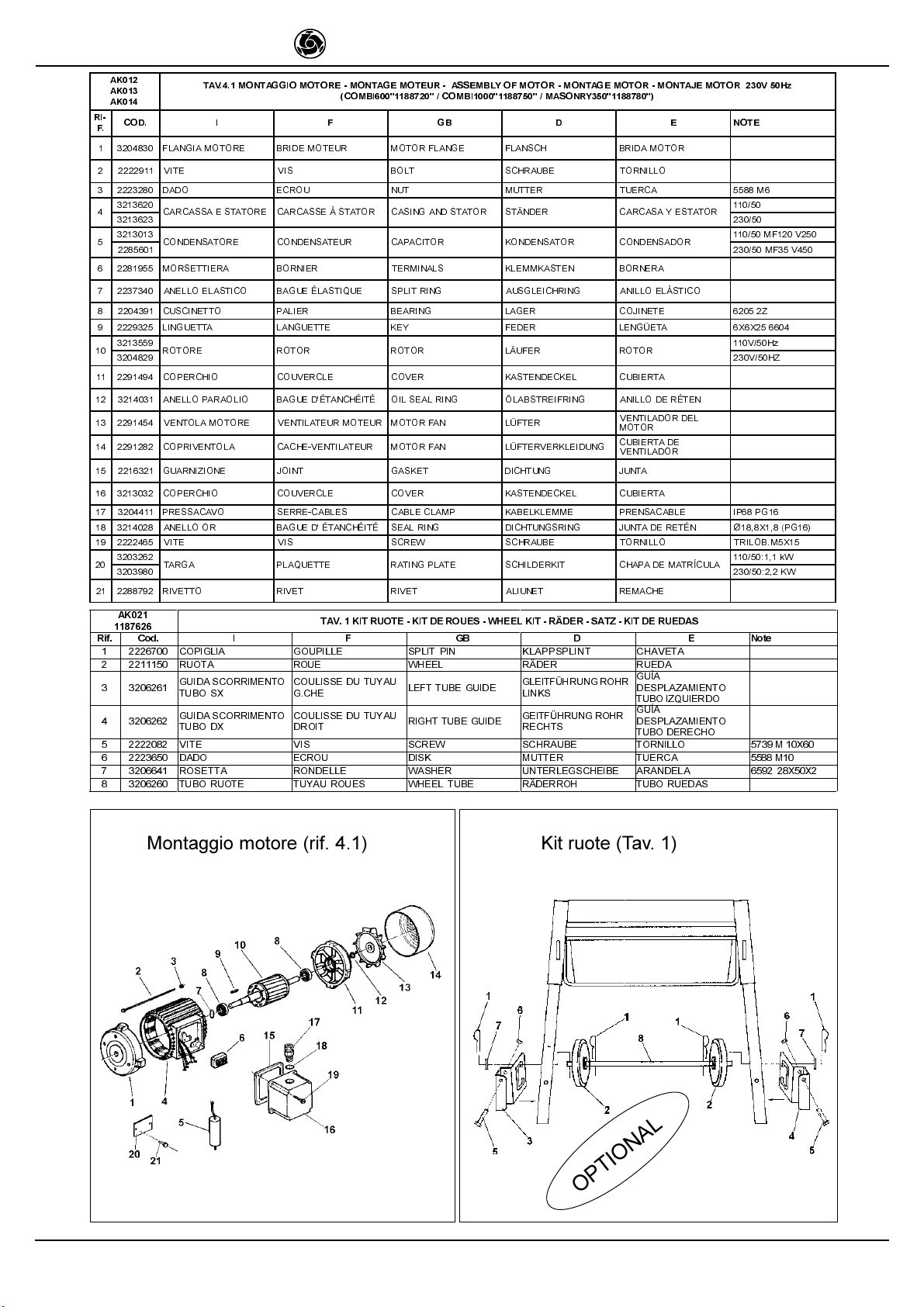

$.

$.

7$90217$**,27(67$26&,//$17(0217$*(77(26&,//$17(02%,/(+($'$66(0%/<0217$*('(6

6&+:,1*.23)(6

0217$-('(/&$%(=$/26&,/$17(

5,) &2' , ) *% ' ( 127(

0$1,*/,$ 32,*1e( +$1'/( *5,)) 0$1,//$

526(77$ 521'(//( :$6+(5 817(5/(*6&+(,%( $5$1'(/$ ;

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

'$'2 (&528 187 0877(5 78(5&$ 0

&23(5&+,2 &289(5&/( &29(5 .$67(1'(&.(/ &8%,(57$

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

&86&,1(772 528/(0(17 %($5,1* /$*(5 &2-,1(7( 56

526(77$ 521'(//( :$6+(5 817(5/(*6&+(,%( $5$1'(/$ ;

526(77$ 521'(//( :$6+(5 817(5/(*6&+(,%( $5$1'(/$ 66',1

;;

&2532

7 ( 1 ' ,& ,1 * + ,$ &25367(1'(85

&28552,( %(/77(16,21(5

81,7 .g53(5

5,(0(163$11(5 &8(5327(1625'(

&255($

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

'$'2 (&528 187 0877(5 78(5&$ $870

02//$ 5(66257 635,1* )('(5 08(//(

&86&,1(772 528/(0(17 %($5,1* /$*(5 &2-,1(7( 56

&,1*+,$ &28552,( %(/7 5,(0(1 &255($

38/(**,$ 328/,( 38//(< 5,(0(16&+(,%( 32/($

38/(**,$ 328/,( 38//(< 5,(0(16&+(,%( 32/($

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

)8/&527(67$7$ 3,9277(7( +($')8/&580 .23)'5(+381.7 $32<2'(/

&$%(=$/

&86&,1(772 528/(0(17 %($5,1* /$*(5 &2-,1(7( 56

63,12772 *283,//( 3,1 %2/=(1 3$6$'25

3(512 3,927 3,1 =$3)(1 3(512

02//$ 5(66257 635,1* )('(5 08(//(

$/%(52/$0$ $5%5(/$0( %/$'(6+$)7 0(66(5:(//( (-('(/$+2-$

/,1*8(77$ /$1*8(77( .(< )('(5 /(1*h(7$ $;;

&86&,1(772 528/(0(17 %($5,1* /$*(5 &2-,1(7( 56

$1(//23$5$2/,2 %$*8('e7$1&+e,7e 2,/6($/5,1* g/$%675(,)5,1* $1,/2'(5e7(1 ;;

&(51,(5$ &+$51,e5( &/$63 6&+$51,(5 %,6$*5$

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 75,/2%7&3+

0;1

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

526(77$ 521'(//( :$6+(5 817(5/(*6&+(,%( $5$1'(/$ ;

'$'2 (&528 187 0877(5 78(5&$ $872%/0

3$5$6&+,==, 3527(&7,21

(&/$%286685(6 635$<*8$5' 635,7=6&+87= 3527(&&,Ï1

&2175$

6$/3,&$'85$6

58%,1(772 52%,1(7 9$/9( +$+1 *5,)2

78%2 78<$8 78%( :$66(56&+/$8&+ 78%2

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

68332572 6833257 6833257 817(5/$*( 623257(

35(66$&$92 6(55(&$%/(6 &$%/(&/$03 .$%(/./(00( 35(16$&$%/(

35(66$&$92 6(55(&$%/(6 &$%/(&/$03 .$%(/./(00( 35(16$&$%/(

0$1,*/,$ 32,*1e( +$1'/( *5,)) 0$1,//$ &20%,0$6215<

&20%,

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

)/$1*,$,17(51$ )/$648(,17e5,(85( ,11(5)/$1*( )/$16&+,11 %5,'$,17(5,25

)/$1*,$(67(51$ )/$648(

(;7e5,(85( 287(5)/$1*( )/$16&+$866 %5,'$(;7(5,25

526(77$ 521'(//( :$6+(5 817(5/(*6&+(,%( $5$1'(/$ ;

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

&$57(5/$0$ &$57(5/$0( %/$'(&29(5 6&+(,%(1*(+b86( &È57(5+2-$

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;

(7,&+(77$ (7,48(77( /$%(/ ./(%(=(77(/ (7,48(7$

9,7( 9,6 %2/7 6&+5$8%( 7251,//2

*8$51,=,21( -2,17 *$6.(7 ',&+781* -817$

526(77$ 521'(//( :$6+(5 817(5/(*6&+(,%( $5$1'(/$ [[

$00257,==$725( $0257,66(85 6+2&.

$%625%(5 :,5.(1'(5

672'b03)(5 $0257,*8$'25

9,7( 9,6 %2/7 6&+5$8%( 7251,//2 0;=

526(77$ 521'(//( :$6+(5 817(5/(*6&+(,%( $5$1'(/$ ;

21

(R5)

COMBI 350/600 - 350/1000

IMER INTERNATIONAL S.p.A.

TAV. 03

TAV. 02

22

(R5)

COMBI 350/600 - 350/1000

IMER INTERNATIONAL S.p.A.

$.

7$9.,75827(.,7'(528(6:+((/.,75b'(56$7=.,7'(58('$6

5LI &RG , ) *% ' ( 1RWH

&23,*/,$ *283,//( 63/,7 3,1 ./$3363/,17 &+$9(7$

5827$ 528( :+((/ 5b'(5 58('$

*8,'$6&255,0(172

78%2 6; &28/,66('878<$8

*&+( /()778%(*8,'( */(,7)h+581*52+5

/,1.6

*8Ë$

'(63/$=$0,(172

78%2,=48,(5'2

*8,'$6&255,0(172

78%2'; &28/,66('878<$8

'52,7 5,*+778%(*8,'( *(,7)h+581*52+5

5(&+76

*8Ë$

'(63/$=$0,(172

78%2'(5(&+2

9,7( 9,6 6&5(: 6&+5$8%( 7251,//2 0;

'$'2 (&528 ',6. 0877(5 78(5&$ 0

526(77$ 521'(//( :$6+(5 817(5/(*6&+(,%( $5$1'(/$ ;;

78%2 5827( 78<$8528(6 :+((/ 78%( 5b'(552+ 78%258('$6

OPTIONAL

Montaggio motore (rif. 4.1) Kit ruote (Tav. 1)

$.

$.

$.

7$90217$**,202725(0217$*(027(85$66(0%/<2)027250217$*(027250217$-(027259+]

&20%,&20%,0$6215<

5,

) &2' , ) *% ' ( 127(

)/$1*,$02725( %5,'(027(85 02725)/$1*( )/$16&+ %5,'$02725

9,7( 9,6 %2/7 6&+5$8%( 7251,//2

'$'2 (&528 187 0877(5 78(5&$ 0

&$5&$66$(67$725( &$5&$66(¬67$725 &$6,1*$1'67$725 67b1'(5 &$5&$6$<(67$725

&21'(16$725( &21'(16$7(85 &$3$&,725 .21'(16$725 &21'(16$'25 0)9

0)9

0256(77,(5$ %251,(5 7(50,1$/6 ./(00.$67(1 %251(5$

$1(//2(/$67,&2 %$*8(e/$67,48( 63/,75,1* $86*/(,&+5,1* $1,//2(/¬67,&2

&86&,1(772 3$/,(5 %($5,1* /$*(5 &2-,1(7( =

/,1*8(77$ /$1*8(77( .(< )('(5 /(1*h(7$ ;;

52725( 52725 52725 /b8)(5 52725 9+]

9+=

&23(5&+,2 &289(5&/( &29(5 .$67(1'(&.(/ &8%,(57$

$1(//23$5$2/,2 %$*8('e7$1&+e,7e 2,/6($/5,1* g/$%675(,)5,1* $1,//2'(5e7(1

9(172/$02725( 9(17,/$7(85027(85 02725)$1 /h)7(5 9(17,/$'25'(/

02725

&235,9(172/$ &$&+(9(17,/$7(85 02725)$1 /h)7(59(5./(,'81* &8%,(57$'(

9(17,/$'25

*8$51,=,21( -2,17 *$6.(7 ',&+781* -817$

&23(5&+,2 &289(5&/( &29(5 .$67(1'(&.(/ &8%,(57$

35(66$&$92 6(55(&$%/(6 &$%/(&/$03 .$%(/./(00( 35(16$&$%/( ,33*

$1(//225 %$*8('e7$1&+e,7e 6($/5,1* ',&+781*65,1* -817$'(5(7e1 ;3*

9,7( 9,6 6&5(: 6&+5$8%( 7251,//2 75,/2%0;

7$5*$ 3/$48(77( 5$7,1*3/$7( 6&+,/'(5.,7 &+$3$'(0$75Ë&8/$ N:

.:

5,9(772 5,9(7 5,9(7 $/,81(7 5(0$&+(

23

(R5)

COMBI 350/600 - 350/1000

IMER INTERNATIONAL S.p.A.

19. SCHEMA ELETTRICO / SCHEMA ELECTRIQUE / WIRING DIAGRAM / SCHALTPLAN / ESQUEMA ELECTRICO

,)*%'(

/

&21'87725(',/,1($

)$6( &21'8&7(85'(/,*1(

3+$6( 3+$6(/,1(

&21'8&725 3+$6(1/(,7(5 &21'8&725'(/,1($

)$6(

1

&21'87725(',/,1($

1(8752 &21'8&7(85'(/,*1(

1(875( 1(875$//,1(

&21'8&725 0,77(//(,7(5 &21'8&725'(/,1($

1(8752

3(

&21'87725(',

3527(=,21( &21'8&7(85'(

3527(&7,217(55( 3527(&7,21

&21'8&725 6&+87=/(,7(5 &21'8&725'(

3527(&&,21

,

,17(5587725(

0$*1(727(50,&2 ,17(55837(85

0$*1e727 7+(5020$*1(7,&

&872876:,7&+ 6&+87=6&+$/7(5 ,17(5583725

0$*1(727e50,&2

&

&21'(16$725(0$5&,$ &21'(16$7(85 02725&$3$&,725 .21'(16$725*$1* &21'(16$'25'(

0$5&+$

.

%2%,1$ %2%,1( &2,/ 638/( %2%,1$

0

02725(/$0$ 027(85/$0( %/$'(02725 6b*(%/$7702725 02725'(/$

&8&+,//$

0

02725(3203$ 027(853203( 380302725 3803(102725 02725'(/$%20%$

This manual suits for next models

1

Other IMER Sewing Machine manuals