Operation Manual EPM-XPplus

Software Release 1.2.4.0 25.03.2020

Page 6 of 66

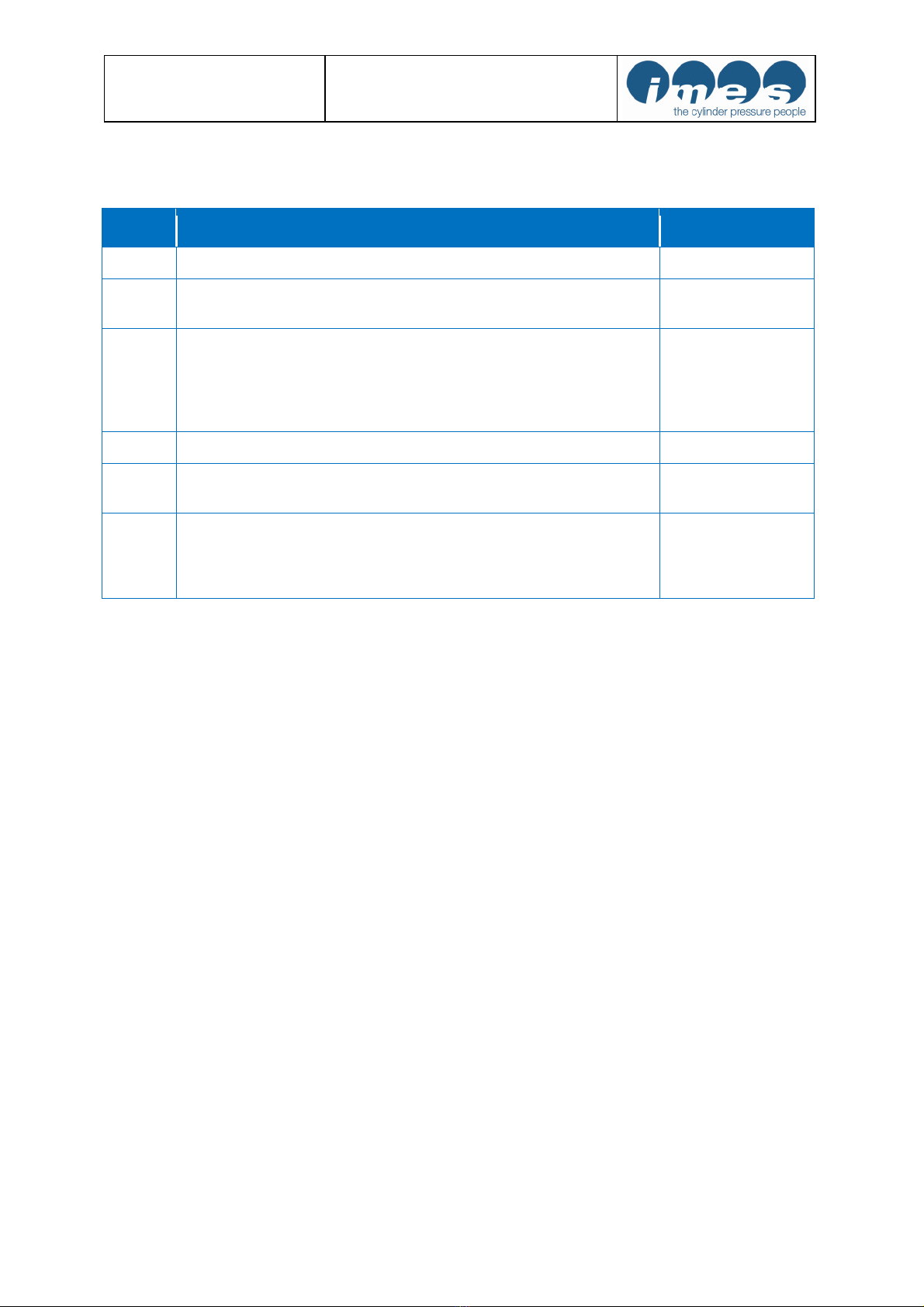

Figure 6: Battery holder........................................................................................................18

Figure 7: 4 x NiMh AAA 930 mAh installed on battery holder...............................................18

Figure 8: Selection of installed battery type ..........................................................................18

Figure 9: Indication during charging process .......................................................................19

Figure 10: Indication charging process completed................................................................19

Figure 11: Indicator cock Figure 12: Adaptor installed on indicator cock .................19

Figure 13: Indication of 2-stroke mode Figure 14: Indication of 4-stroke mode...............19

Figure 15: Warming up sensor Figure 16: Indication during measurement.....................20

Figure 17: Indication of measurement results on display for 3s ............................................20

Figure 18: Indication over temperature on measuring cell of sensor.....................................20

Figure 19: Dialog of installation ............................................................................................21

Figure 20: Select Destination Location .................................................................................21

Figure 21: Start Menu Folder................................................................................................22

Figure 22: Select additional tasks.........................................................................................22

Figure 23: Ready to install....................................................................................................22

Figure 24: Ready to install....................................................................................................23

Figure 25: Installation completed..........................................................................................23

Figure 26: EPM- XPplus connected via USB cable to PC .......................................................24

Figure 27: Start up window of EPM-XPplus ............................................................................24

Figure 28: EPM-XPplus unit connected to visualisation software ............................................25

Figure 29: Selection of engine configuration.........................................................................25

Figure 30: Entering of specific engine data...........................................................................25

Figure 31: Selection of directory on hard disc of PC for saving data.....................................26

Figure 32: Downloading and optimization process of measured data ...................................26

Figure 33: p/alpha diagram...................................................................................................27

Figure 34: Functions of p/alpha diagram ..............................................................................27

Figure 35: Cursor line functions of p/alpha diagram..............................................................28

Figure 36: p/volume diagram................................................................................................28

Figure 37: p/volume (log) diagram........................................................................................29

Figure 38: Button “Open”......................................................................................................29

Figure 39: Stored measurement file......................................................................................29

Figure 40: Information about cylinder during uploading process...........................................30

Figure 41: Balance diagram .................................................................................................30

Figure 42: Engine report diagram .........................................................................................31

Figure 43: Overview of bush puttons ....................................................................................31

Figure 44: Selection criteria for measurement files ...............................................................31

Figure 45: Selection of measurement files............................................................................32

Figure 46: Selection criteria for values and cylinder..............................................................32

Figure 47: Display of trending function .................................................................................33

Figure 48: Tools ...................................................................................................................33

Figure 49: CSV.....................................................................................................................33

Figure 50: CSV file selection ................................................................................................33

Figure 51: Selection field ......................................................................................................34

Figure 52: “Engine settings” .................................................................................................34

Figure 53: “Motor data”.........................................................................................................34

Figure 54: “Options” .............................................................................................................34

Figure 55: “Options” .............................................................................................................34

Figure 56: Cylinder pressure curve incl. motored curve........................................................35

Figure 57: Shifted Cylinder pressure curve incl. motored curve............................................35

Figure 58: Button “Save REF” ..............................................................................................36

Figure 59: Save the reference on hard disc of PC ................................................................36

Figure 60: Button “Open REF”..............................................................................................36

Figure 61: Selection of reference curve on hard disc of PC ..................................................36

Figure 62: Display of selected reference curve in comparison to a cylinder curve ................37