Imesa IM10 Product guide

E170203X 17/02/2017

IM10 SERVICE BOOK

FOR TUMBLE DRYERS SERIES “T” FROM SERIAL

NUMBER E201603001

FOR TANDEM SERIES: TDM FROM SERIAL

NUMBER T201603001

FOR FLATWORK IRONERS FI SERIES FROM

SERIAL NUMBER E201604011

IMESA S.p.A.

Via degli Olmi 22

31040 Cessalto (TV), Italia

tel. +39.0421.468011

fax +39.0421.468000

www.imesa.it

E170203X 17/02/2017

INDEX

SECTION “A” – INTRODUCTION........................................................................................5

1) CONTENT OF MANUAL ........................................................................................5

2) SAFETY RULES.....................................................................................................5

3) MANUFACTURER LIABILITY ................................................................................6

4) IM10 MICROPROCESSOR FEATURES................................................................7

SECTION “B” – WARNINGS AND TROUBLESHOOTING..................................................7

SECTION “C” – USER MENU PARAMETERS....................................................................7

1) ACCESS TO USER MENU .............................................................................................7

2) SETTING.........................................................................................................................8

1. CHOOSE LANGUAGE...........................................................................................8

2. DATA SETTING......................................................................................................8

3. TIME SETTING.......................................................................................................8

4. TEMPERATURE °C/°F...........................................................................................8

5. WRINKLE SYSTEM ON / OFF...............................................................................8

6. FAST FORWARD...................................................................................................9

7. TOUCH SCREEN DISABLING...............................................................................9

8. USER PASSWORD................................................................................................9

9. PROGRAMS UPLOAD / DOWNLOAD...................................................................9

10. KEYPAD BEEP.......................................................................................................9

11. SCREEN LAYOUT HANDLING............................................................................10

12. ICONS UPLOADING FROM USB ........................................................................10

13. MACHINE NUMBER (Only for central cash setting).............................................11

14. AVAILABLE TIME TO RESET CREDIT (Only with payment system on)..............12

15. AUTOMATIC START (only with payment system on)...........................................12

3) RECORDINGS ..............................................................................................................12

1. WORKING TIME...................................................................................................12

2. PROGRAMS STATS............................................................................................12

3. RECORDINGS DOWNLOAD ...............................................................................12

4. ENERGY STATS..................................................................................................13

5. PARTIAL CREDIT (only with payment system on)...............................................13

6. RESET PARTIAL CREDIT (only with payment system on) ..................................13

7. TOTAL CREDIT (only with payment system on)...................................................13

8. RESET TOTAL CREDIT (only with payment system on)......................................13

4) PROGRAMS..................................................................................................................14

1. SINGLE CYCLE....................................................................................................14

E170203X 17/02/2017

SOMMARIO

3

2. DEFAULT PROGRAMS .......................................................................................14

3. NEW PROGRAM..................................................................................................15

SECTION “D” – EXPERT MENU PARAMETERS .............................................................17

1) ACCESS TO TECH MENU............................................................................................17

2) SETTINGS.....................................................................................................................18

1. MOTORS..............................................................................................................18

2. ENERGY ..............................................................................................................18

3. PAYMENT SYSTEMS..........................................................................................20

4. RESIDUAL HUMIDITY .........................................................................................21

5. MODEM................................................................................................................22

6. TILTING................................................................................................................22

7. NUMBERS OF PROGRAMS TO SHOW..............................................................23

8. SCREEN SAVER..................................................................................................23

9. SLIDE SHOW DELAY TIME.................................................................................23

10. SCREEN SAVER REFRESH TIME......................................................................23

3) MAINTENANCE ............................................................................................................23

1. OUTPUTS TEST ..................................................................................................23

2. INPUTS TEST ......................................................................................................25

3. ALARM HYSTORY...............................................................................................25

4. MODEM (only on machines equipped with remote service) .................................25

5. WORKING HOURS..............................................................................................25

6. MAX TEMPERATURE REACHED .......................................................................25

7. RECORDS DOWNLOAD......................................................................................25

4) PASSWORDS / INITIALIZATIONS................................................................................26

1. TECHNICIAN PASSWORD..................................................................................26

2. USER PASSWORD..............................................................................................26

3. SMS PASSWORD................................................................................................26

4. DEFAULT PROGRAM RESET.............................................................................26

5. MACHINE CONFIGURATION RESET.................................................................26

6. LOAD DRIVER FILE.............................................................................................27

7. DRUM DRIVER INITIALIZATION (only with drum inverter PRESENT)................27

8. FAN DRIVER PROGRAMMING (only with fan inverter PRESENT).....................28

9. ASK FOR DATE/TIME/LANGUAGE.....................................................................28

10. LOAD LANGUAGE FROM USB...........................................................................28

11. SCREEN SAVER FILE UPLOADING FROM USB...............................................29

12. FIRMWARE VERSION.........................................................................................31

E170203X 17/02/2017

SOMMARIO

4

13. FIRMWARE UPDATING.......................................................................................31

14. DO CALIBRATION TOUCH..................................................................................32

15. SAVE ALL ON USB..............................................................................................32

16. LOAD ALL FROM USB.........................................................................................33

17. REBOOT ..............................................................................................................33

18. REFLASH BOOT!.................................................................................................33

19. LOAD SYSTEM ICONS FROM USB....................................................................33

20. RESET THE APP PANNEL..................................................................................34

21. DEBUG MESSAGES............................................................................................34

4) MESSAGES ..................................................................................................................34

1. SERVICE REQUEST MESSAGE.........................................................................34

E170203X 17/02/2017

SOMMARIO

5

SECTION “A” – INTRODUCTION

1) CONTENT OF MANUAL

Present manual contains all useful information for a correct using of controls available

on IMESA tumble dryers “T” series.

It is written in compliance with the European Community rules in force. The information

here written is addressed to the service provider who must be sure to fully understand

them before use of the machine. This manual must always be available for

consultancy. In case it should be lost or damaged, ask for a new copy from the

manufacturer. The producer is not responsible for any consequences coming from

incorrect dryer use due to incomplete or misreading of this manual. The manufacturer

reserves itself the right to modify the specifications written in this manual or the

characteristics of each machine. Some pictures in this manual may differ from what

assembled on the machine. Diagrams and technical data may be changed without

previous notice.

This manual and its attachments are part of the replacement kit, so they must be kept

together and follow the machine even in the case of sale to another user or service

provider

2) SAFETY RULES

Not respecting the following instruction may cause damages to people, things and

animals.

Installations and maintenance of the item here described must be done by authorized

personnel, which knows the product and respect the European Rules in the matter of

installation and maintenance of industrial machines.

These flatwork ironers must be used only for professional iron of garments and linen:

any other use is forbidden unless manufacturer authorization in writing.

It is forbidden to put anything in the machine other than items to be ironed; do not use

the machine with fabrics contaminated by dangerous substances such as explosives,

inflammable etc. make sure they are rinsed or aired before ironing.

It is forbidden to iron garments soaked in substances known to be harmful to persons

such as lead, poison or cancer-producing products.

To avoid risks of fire or explosion, do not approach the machine with combustible or

inflammable substances.

Always refer to ironing instructions reported on the linen label.

The use of this machine is forbidden to people under 16 years of age.

External supplementary connection to the machine releases the manufacturer from any

responsibility if they are not properly done.

E170203X 17/02/2017

SOMMARIO

6

ELECTROCUTION DANGER

Any intervention on the ironer electric parts must be taken over only by a qualified

technician and only after the electric supply has been cut off.

Only manufacturer's technicians can modify power and control circuits, otherwise,

the warranty would be no more valid.

ATTENTION!

Even when the main switch is positioned on “0”, the cables upstream have tension!

OPERATOR PSYCHOPHYSICAL CONDITIONS

The user must be in perfect psycho-physical condition; during the running cycle, the user

must always assume a vertical posture in front of the machine. A sudden or not controlled

movement must be avoided, for example, evade doing sudden or not controlled

movements in order to avoid dangerous impact with the ironer chassis, i.e. when the linen

is collected or introduced.

The other people present in the laundry room must not distract the operator who is working

on the machine.

While working, the operator must not be distracted by TV, radio or any other source of

distraction.

ATTENTION!

These instructions do not cover all possible risks. The user must always pay high attention

and respect carefully the rules..

3) MANUFACTURER LIABILITY

The instructions written in this manual are not replacing, but completing the duties deriving

from the safety and accident prevention laws. With reference to what is written in this

manual, the manufacturer is not responsible when:

The machine user does not respect safety and accident prevention laws in force;

The machine was not correctly installed;

Periodical and/or programmed maintenance is missing;

Manual instructions were not respected;

Defects occur in the power supply;

Non authorized modifications made on the machine;

Non-authorized personnel use the machine;

Wrong connection to IM10 control board

E170203X 17/02/2017

SOMMARIO

7

4) IM10 MICROPROCESSOR FEATURES

Available from: MARCH 2016.

Installed on: TUMBLE DRYER “T” SERIES

–FLATWORK IRONERS “FI” – TANDEM

Data transfer interface: USB

SW updatable: YES

Programmable: YES

Inverter communication: MODBUS

Keypad: TOUCHSCREEN

Locking door: NO

Usable on self-service: YES

Power board: ASAC31IM10ESIC00

SECTION “B” – WARNINGS AND TROUBLESHOOTING

Consult alarm section and troubleshooting on our website www.imesa.it. Use the link here

below to access the page related IM8 programmer. This troubleshooting is valid also for

previous controls as the IM6 microprocessor and the IM9 mechanical timer.

SECTION “C” – USER MENU PARAMETERS

1) ACCESS TO USER MENU

The user menu contains all functions and monitoring of the IM10 logic board. The menu

access is available as follow:

Standard setting (not self-service): touch the symbol “⋮”on top right and digit

password “123456”.

Self-service setting: when the machine is on, as soon as the display shows

programs icons, on the top right corner symbol “⋮”is shown for 30 sec. This symbol

allows entering the password input screen. Digit “123456”as the password.

The number of figures available is not fixed, so to enter the menu use the correct

password, only. Cancel wrong figures using “⌫”.

E170203X 17/02/2017

SOMMARIO

8

To leave the page use “X”.

When a password is recognized, the rectangle view becomes green, the blue confirmation

and entry command on the desired menu “Ѵ” lights up.

2) SETTING

1. CHOOSE LANGUAGE

Select a language. Dictionary of different languages must be present on the IM10 board.

2. DATA SETTING

Set the date of the system. This function is available on the following path

:\USER\SETTING\DATA SETTING.

NOTE: If the date, month and year are settled, the day of the week will be defined

automatically (perpetual calendar).

3. TIME SETTING

Set the time of the system. This function is available on the following path

:\USER\SETTING\TIEM SETTING.

NOTE: the time can be set in 24h format or AM/PM.

4. TEMPERATURE °C/°F

This function is available on the following path: \USER\SETTING\TEMPERATURE °C/°F.

there are two scales available:

- °C (Celsius)

- °F (Fahrenheit)

Here below, comparative schedule between those two scales:

5. WRINKLE SYSTEM ON / OFF

This function is available on the following path

:\USER\SETTING\ANTI WRINKLE ON/OFF.

When activated, the anti-wrinkle system performs as follow:

- The anti-wrinkle system activates at the end of the washing cycle. The display

shows “ANTI WRINKLE” during the whole cycle.

- Before the starting of the anti-wrinkle cycle and door left locked, there is the

possibility to set the “ANTI-WRINGLE CYCLE START DELAY”. Once the time of

delay is expired, the motor activates the anti-wrinkle cycle.

- During that cycle the motor runs as per parameters set on directory ANTI-WRINKLE

(note: this directory is available only when the ANTI-WRINKLE function has been

activated):

ANTI-WRINKLE FORWARD

ANTI-WRINKLE BACKWARD

ANTI-WRINKLE PAUSE

- Anti-wrinkle duration cycle lasts exactly as per ANTI-WRINKLE CYCLE

DURATION.

- Phases “ANTI-WRINGLE CYCLE START DELAY” and “ANTI-WRINKLE CYCLE

DURATION” alternate.

- That sequence will stop only when “ANTI-WRINKLE MAXIMUM

(MINUTES/SECONDS)” expired.

- The anti-wrinkle function is OFF by default.

- The anti-wrinkle cycle is definitively interrupted when the door opens.

E170203X 17/02/2017

SOMMARIO

9

- When reversing drum is present, the drum speed keeps the same as during the

cycle just ended.

- When the anti-wrinkle function is activated, this is valid for all programs stored.

- The anti-wrinkle function is available also on a coin-op version.

- When tumble dryer with no reversing drum, the anti-wrinkle function runs in the

same direction respecting pauses.

6. FAST FORWARD

This function can be activated/deactivated using command

:\USER\SETTING\FAST FORWARD.

When it is on (PRESENT), during the cycle on the top right of the display there is the

symbol “▶" green coloured.

When it is off (ABSENT), there is no symbol “▶”.

Pressing symbol “▶" allows the proceeding to the next cycle stage.

Then skip function can be executed for the following phases, in sequence:

-Initial cooling down phase (if available)

-Heating phase

-Heating phase step 2 (if available)

-Heating phase step 3 (if available)

-… ….

-Final cooling time.

7. TOUCH SCREEN DISABLING

This function can be activated/deactivated using command

:\USER\SETTING\DISABLE TOUCH.

When it is on (PRESENT), the touch screen is enabled.

When it is off (ABSENT), during the cycle execution only STOP command is active on the

touch screen.

8. USER PASSWORD

This function can be activated/deactivated using command

:\USER\SETTING\USER PASSWORD.

It allows the modifying password to access USER area.

The new password input takes two stages on two pages sequentially.

Password must be entered and reconfirmed.

IM10 requires a different password on each ambient (technical area, the user area, factory

default settings, etc.). In the case of a duplicate, IM10 intervenes and block it obliging to

insert a different password.

9. PROGRAMS UPLOAD / DOWNLOAD

Not active function.

10. KEYPAD BEEP

This function can be activated/deactivated using command

:\USER\SETTING\KEYPAD BEEP.

When it is on (PRESENT), there will be a beep when the screen is tough.

When it is off (ABSENT), the beep sound is absent.

E170203X 17/02/2017

SOMMARIO

10

11. SCREEN LAYOUT HANDLING

This function is available on the following path:

\USER\SETTING\SCREEN LAYOUT HANDLING.

Operations available are handling, cancelling and changing programs icons.

When active, it shows icons on the screen. The display is composed by:

-First line: the number of the page on which you are working on.

For example, if there are 18 icons, total pages to handle are 6 because there are 3

icons per page.

The function of the first line is to show on which page the user is working. The

following example is when the user is working on the second page and total pages

are 6:

“SCREEN LAYOUT HANDLING 2/6”

-On the central line, there are icons complete of description;

-On the down line there are 4 commands:

- “< ” and “> ”: to browse pages until the one to set icons

- “←] ”: that is equal to exit

- “X ”: to cancel an icon

- “+ ”: to add an icon (the command is available only if there is an empty

position and the icon is missing)

1) To cancel an icon:

- use “< ” and “> ”to reach the page where there is the icon to cancel

- push “X ”

- red “X ”light on every icon: select the icon to cancel.

NOTE: that command just cancels the icon, not the program.

2) To reset an icon:

ousing “< ” and “> ” to reach the page of the icon to reset

opush “+ ”

oit shows the program list stored: select the program for which the icon has to

be restored

3) To modify an icon:

ousing “< ” and “> ” to reach the page of the icon to modify

oclick on the icon that has to be modified

oonce commands appear:

i. “↓” and “↑”: to browse available icons

ii. “Ѵ” to confirm the icon selected

12. ICONS UPLOADING FROM USB

Programs icons are images appearing on the screen when selecting the program.

IMESA uploads by default around twenty and the customer can assign them to the

program using procedure SCREEN LAYOUT HANDLING.

Original dimension:

-Dimension 96x96 pixel. ATTENTION: images of different format will NOT be

converted!

-Format: .jpeg

-NOTE: files names can have any name

E170203X 17/02/2017

SOMMARIO

11

-Original icons folder is stored on the following path and name (for ex. capitulate

IMESA):

:\UFFTEC2\SOFTWARE AND LISTS\IM10\ICONS_IM10\IMESA_ICONS_IM10

Original icons files must be converted into files accepted by IM10.

This conversion is executed by macro on xlsm file: link.

Click on the rose button “CONVERT ICONS ON IM10 FORMAT”.

The display shows: . Click on OK.

Select the folder with original icons (read above).

ATTENTION: folder will appear as empty!

Click on OK.

The display shows: . Click on OK.

Icons for IM10 are now present on folder “usericons” with “.IM10ico” extension inside the

original folder.

Create a folder named “IM10_DATA” in the USB key.

NOTE: this key must be formatted “FAT32”.

Copy & paste folder “usericons” inside path IM10_DATA:

TO LOAD ICONS FOLDER

IM10 must be already on, insert USB key.

Upload icons using command: \USER\SETTING\UPLOAD ICONS FROM USB

It shows EXECUTE? UPLOAD ICONS FROM USB

Touch “Ѵ”

It shows “UPLOAD ICONS FROM USB OK”.

Push OK.

ATTENTION: during the uploading there are no instructions. The uploading lasts in 40”.

At the end of the uploading, it shows “UPLOADING OK”.

Push OK: IM10 turns off and on by itself.

NOTE: icons can be added anytime: that is there is the possibility to upload an icon at the

time, without cancelling the ones already stored.

Attention: if an icon is uploaded with the same name of an icon already present on IM10, it

will be overwritten.

NOTE: in case the key is not inserted, after 10" of attempting the communication, a WDT

expires and the display shows "INSERT USB KEY".

13. MACHINE NUMBER (Only for central cash setting)

THE NUMBER IS PRESENT ON THE SETTING BUT THE NUMBER IS NEVER SHOWN.

When the machine is set on CENTRAL CASH, an identification number >1 must be

assigned.

This parameter is available on :\USER\SETTING\MACHINE NR.

The user sets the machine so that when it is on the waiting for a selection (turned on, on

standby, without credit) screen savers alternates to a page saying (on the biggest

E170203X 17/02/2017

SOMMARIO

12

available font) “MACHINE NR. Xx” where “xx” corresponds to a number on the central

cash.

This parameter must be available in the only event the machine is set on “CENTRAL

CASH”.

THE NUMBER IS PRESENT ON THE SETTING BUT THE NUMBER IS NEVER SHOWN.

14. AVAILABLE TIME TO RESET CREDIT (Only with payment system on)

When the machine is set on coin op, on the user area it is shown

:\USER\SETTING\TIME TO RESET CREDIT.

This parameter (1-60, default 5’) is the time between eventual cycle interruption and reset

of the residual credit.

In the case of a standby or a cycle interruption due to the opening of the door exceeds 5’

without restart of the cycle, it is supposed the customer wants to stop the cycle. To make

the machine available for another customer, credit/time are reset and the cycle definitively

aborted.

NOTE: eventual residual credit available on standby phase is NOT reset in case of power

failure.

15. AUTOMATIC START (only with payment system on)

When the machine is set on “payment system present”, the user area shows parameter:

:\USER\SETTING\ AUTOMATIC START.

This parameter defines to start the cycle (only after having checked all safeties are OK)

pressing the START button (=ABSENT) or automatically at minimum credit reached

(=PRESENT).

3) RECORDINGS

16 WORKING TIME

This function is available on the following path

:\USER\RECORDINGS\WORKING TIME.

It allows reading effective working hours of the machine from its putting into service.

17 PROGRAMS STATS

This function is available on the following path

:\USER\RECORDINGS\PROGRAMS STATS.

It shows a total number of cycles done from the putting into service of the machine. It

allows the user to view how many times a certain program has been done in relation to

total cycles.

All data can also be downloaded through menu RECORDINGS DOWNLOAD.

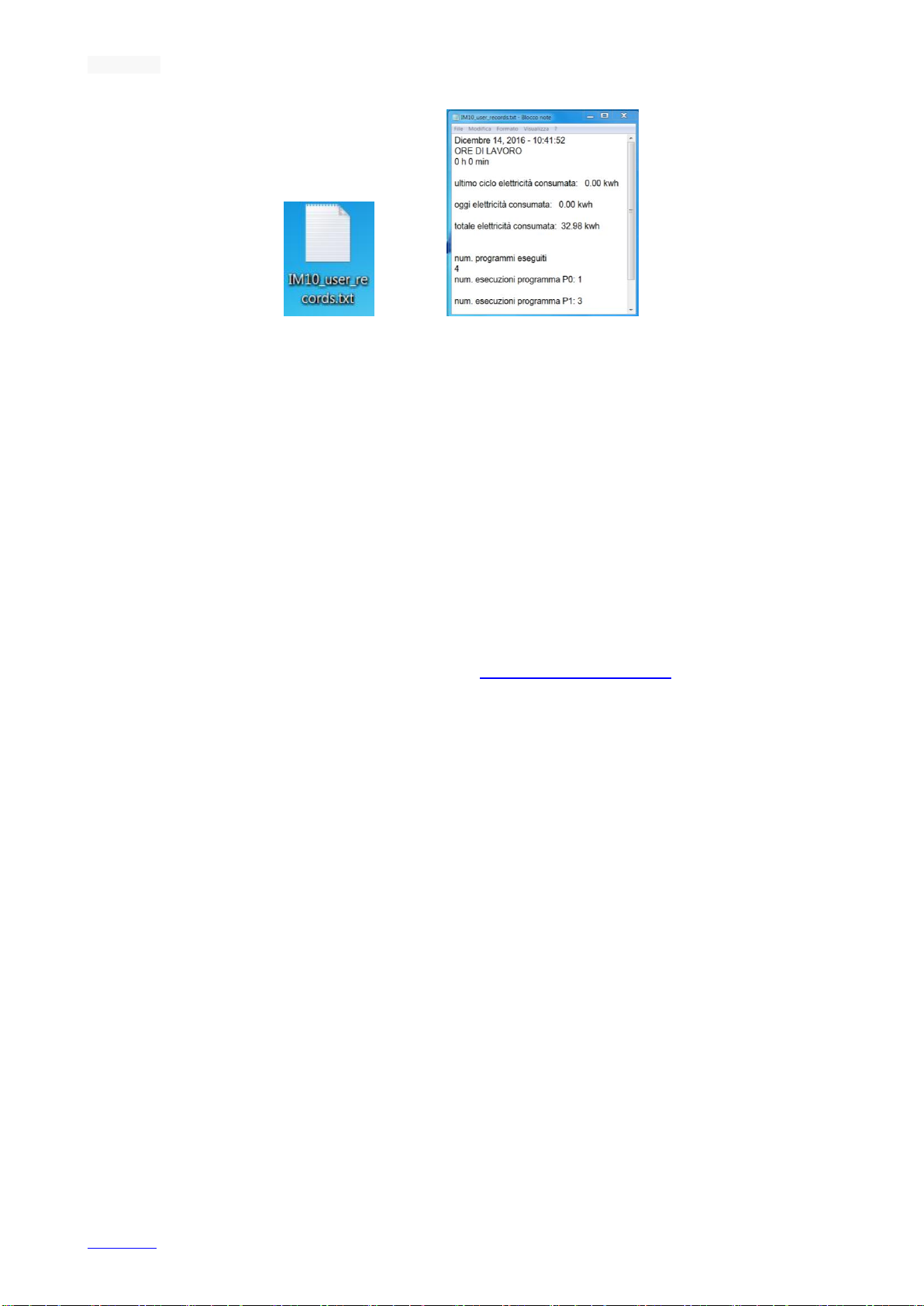

18 RECORDINGS DOWNLOAD

This function is available on the following path

:\USER\RECORDINGS\RECORDINGS DOWNLOAD.

It allows the downloading of a .txt file (IM10_user_records.txt ) which contains recorded

data of “PROGRAMA STATS”and “ENERGY STATS”.

E170203X 17/02/2017

SOMMARIO

13

TO DOWNLOAD THE .txt FILE

Enter the menu USER\RECORDINGS\RECORDINGS DOWNLOAD

On display INSERT USB DEVICE

All data automatically uploads on the USB once inserted creating a “.txt” file. It takes few

seconds. At the end, the display shows RECORDINGS OK.

Push OK.

19 ENERGY STATS

This function is available on the following path

:\USER\RECORDINGS\ENERGY STATS.

It allows reading effective consumption (on kW/h) recorded by the machine during its work.

The menu can display:

- Last cycle energy consumption

- Energy consumption per day

- Total energy consumption

All data are available for downloading on menu RECORDINGS STATS.

20 PARTIAL CREDIT (only with payment system on)

This function is available on the following path

:\ USER\RECORDINGS\PARTIAL CREDIT.

It allows reading partial credit counting accumulated during the day.

21 RESET PARTIAL CREDIT (only with payment system on)

This function is available on the following path

:\ USER\RECORDINGS\RESET PARTIAL CREDIT.

This is to display reset partial credit counting.

22 TOTAL CREDIT (only with payment system on)

This function is available on the following path

:\ USER\RECORDINGS\ TOTAL CREDIT.

This is to display total credit counting accumulated starting from the putting into service of

the machine.

23 RESET TOTAL CREDIT (only with payment system on)

This function is available on the following path

:\ USER\RECORDINGS \RESET TOTAL CREDIT.

It allows resetting the total credit counting.

E170203X 17/02/2017

SOMMARIO

14

4) PROGRAMS

1. SINGLE CYCLE

This function is available on the following path

:\USER\PROGRAMS\SINGLE CYCLE.

Enter the technical password (159357) to accede on SINGLE CYCLE where it is possible

to modify default value of time (5’) and of temperature (50°C).

Selecting SINGLE CYCLE from the starting screen, it will start an instantaneous program

where (starting from default value) the user can set (and change during the running cycle)

time and temperature values. They will be valid only for that single cycle and will not be

stored.

.

2. DEFAULT PROGRAMS

The machine has 30 programs stored and already set with complete features.

Here follow a summary scheme:

The default times of rotation for machines equipped with reversing drum are:

-Clockwise rotation: 40 seconds;

-Pause: 5 seconds;

E170203X 17/02/2017

SOMMARIO

15

-Counterclockwise rotation: 40 seconds

Rotation and pause times can be reprogrammed (see relevant paragraph).

On machines equipped with related options, the others default values are the same for all

programs:

-Heating power: level 3;

-Drum speed: 40 rpm;

-Fun speed: speed 2

Enter the programming area to modify features of stored by default programs or to add

new ones.

3. NEW PROGRAM

This function is available on the following path

:\USER\PROGRAMS\NEW PROGRAM.

The display shows: RUN? ADD NEW PROGRAM?

Touch “Ѵ”

A new program will be created and it is put at the end of existing programs with

progressive number. The new program will be called <NEW> and can be customized

setting all parameters described here below:

- NAME: this is the description of the program displayed during its selection and its

execution. There are 16 alphanumeric characters available.

- ECO MODE (only for programs with heating technology by HEATED PUMP):

oGREEN: Only after achieving Toset point, RISC2 will be deactivated and

kept on standby to reach its his own tp.

NOTE: compressors are detached on sequence: only at the first set point

achievement, RISC2 will be effectively detached. During the cycle, at the

thermostatic temperature control phase, attaching and detaching of RISC1

and RISC2 can be exchanged following times to stop tpof every compressor:

it depends on which one arrives first.

In case the temperature falls below the hysteresis loop (TEMPERATURE

HYSTERESIS, std machine hysteresis), RISC2 can be activated (only after

tp).

In case the temperature continues to rise over the hysteresis Tisteresi compressori,

then RISC1 is deactivated and kept on standby to reach its his own tp.

When last tpexpires, then RISC1 and RISC2 have activated again.

This is an active cycle and PRERISC lasts for a time t1.

During the entire cycle, PRERISC is no more activated excepting on the

following case:

RISC1 and RISC2 are stopped because of a pause or of the opening of a

door/filter.

PRERISC can be interrupted in advance only if:

(T0–TISTERESIprerisc) is reached before t1 on the restart of the first usable

compressor. (both 1 or 2)

oFAST: same explanation as on GREEN paragraph.

During the entire cycle, PREFERISC keeps activated.

It can be deactivated only on the following situations: interruption of the

cycle, open the door and so on: it actives after the restart.

Set point (T0- TISTERESIprerisc) is added.

NOTE: once deactivated, PREFERISC can be activated without pause times

E170203X 17/02/2017

SOMMARIO

16

(excepting hysteresis).

- PROGRAM TYPE: selecting this parameter the program runs in an automatic mode

(at the end of the cycle, residual humidity level must be set) or in standard mode

(defining cycle length):

oAUTOMATIC with residual humidity (heating with HEATING PUMP is

available and selectable only if cycle is a FAST type).

oTIME LIMIT

- HUMIDITY (only on programs supplied with “RESIDUAL HUMIDITY”). Select the

final humidity value after that, the program must stop:

oIRON DRY (ready to iron)

oDRY (standard dry)

oEXTRA DRY (super dry)

- MULTISTEP (only on programs at “FIXED TIME”). Programs at “FIXED TIME” can

be split into one or more steps. Each step has the possibility to set different duration

time and temperature:

oStep 1 enable step: PRESENT

Step 1 drying time: 40’ (default)

Step 1 drying temperature: 60°C (default)

oStep n enable step: PRESENT

Step n drying time: ..’

Step n heating temperature: ..°C

- DRYING TIME (only on programs at “FIXED TIME”): it is the duration time of the

heating time.

ATTENTION: when INITIAL COOLING is available, this timeframe must be added

to the time of DRYING TIME.

- CYCLE TEMPERATURE: this is to set the temperature to be reached and

maintained during the drying cycle.

- COOLING TIME: it is the cooling duration at the end of the drying cycle. On that

stage, it is possible to maintain linen on movement with a fan on and heating off.

Reducing in advance the COOLING END TEMPERATURE, it reduces automatically

this value. Default = 3’

- COOLING END TEMPERATURE: it is the cooling temperature when the drying

cycle ends. This value is automatically reduced if the DRYING TIME is reached in

advance. When the temperature is reached within the time set on DRYING TIME

parameter, the machine will automatically off. Default = 40° C

- REVERSING DRUM (only when activated by the technic menu):

oPRESENT

oABSENT

When this parameter is active, there is the possibility to activate it or deactivate it on

every program. REVERSING DRUM PRESENT allows setting the “rhythm” of

rotation defining:

For how long the drum must rotate clockwise direction

For how long drum must stop

For how long drum must rotate on counter clockwise direction

- DRUM FORWARD: TIME (only when REVERSING DRUM is PRESENT). It defines

for how long the drum must rotate clockwise direction Default = 20”

- DRUM BACKWARD: TIME (only when REVERSING DRUM is PRESENT). It

defines for how long the drum must rotate counter clockwise direction. Default = 20”

- DRUM PAUSE: TIME (only when REVERSING DRUM is PRESENT). It defines for

how long the drum must stay still between one direction and the other one.

Default = 3”

E170203X 17/02/2017

SOMMARIO

17

- FAN SPEED (only when FAN INVERTER is PRESENT): motor speed can be set for

a certain program. This parameter is shown on m3/h and it means air volume

displaced related to motor speed in Hz. Default= 50 HZ corresponds to 1200 m3 /h.

ATTENTION: the fan rotation speed is excluded on GAS heated machines

(gas machines need a constant fan speed). Machines with ELECTRIC

heating FAN MINIMUM SPEED MUST BE EQUAL OR HIGHER THAN 1000

m3/h (on lowest speed, the air volume displaced turns out to be insufficient

causing the RUPTURE OF RESISTANCES for overheating).

- DRUM SPEED (only when DRUM INVERTER is PRESENT): this parameter defines

the drum rotation speed on each program expressed on rpm. Default = 40 rpm.

- POWER LEVEL CONTROL (for machines with power level control): this parameter

allows deciding when and how heating power available for the electrical battery can

be reduced.

oNORMAL

oHIGH

oMAXIMUM

- INITIAL COOLING: this is the time to execute an initial step before drying cycle.

During that stage, the drum is moving and ventilation is active (the heating starting

is delayed). Default = 0’

- SALE BASE TIME (only for payment system on): that parameter informs about how

much time the user has bought to use the chosen program. Default = 0’

- SALE BASE TIME PRICE (only with payment system on): that parameter defines

the purchasing price of a program about which it will be available during the SALE

BASE TIME. Default = 0,00 €

- SALE STEP TIME (only for payment system on): that parameter defines how much

time is added to the running program every time an extra time is requested. Default

= 0’

- SALE STEP TIME PRICE (only for payment system on): this parameter defines the

cost of the SALE STEP TIME PRICE. Default = 0 €

SECTION “D” – EXPERT MENU PARAMETERS

1) ACCESS TO TECH MENU

Tech menu contains all functional parameters of the IM10 logic board. Here follow the path

to access:

On standard configuration (excepting for self-service): Touch symbol “⋮”on top right

and digit password “159357”.

On self-service configuration: turn the machine on, when programs icons come out,

on the top right symbol “⋮”will be available for maximum 30 seconds that allows

entering to password input screen. Digit password “159357”.

The numbers of figures that can be entered are not fixed so the correct password must be

entered to access to menus. Numbers entered can be cancelled using “⌫”.

To escape the page press “X”.

When a password is confirmed, the rectangle view becomes green and the blue

confirmation and entry command on the desired menu “Ѵ” lights up.

In the case of impossible entry through default password, this means it has already been

changed. Call for IMESA SPA technical department default password recovery.

E170203X 17/02/2017

SOMMARIO

18

2) SETTINGS

1. MOTORS

- REVERSING DRUM:

oPRESENT

oABSENT

REVERSING DRUM PRESENT allows defining the “rhythm” of drum rotation

individually on each program. See the menu “:\USER\PROGRAMS\PROGRAM n”,

changing following parameters:

oDRUM FORWARD: TIME

oDRUM PAUSE: TIME

oDRUM BACKWARD: TIME

- FAN INVERTER: this parameter allows the inverter adjusting fan speed control.

Default = ABSENT.

When FAN INVERTER is set on PRESENT, the user can select the suction speed

on both setting stage and running stage.

In case this parameter will be set on PRESENT but the machine has no inverter, it

appears “INVERTER ALARM IB1 (fan): DISCONNECTED”.

NOTE: Selecting FAN INVERTER = PRESENT, the display shows following

parameters:

oFAN HZ CONVERSION: it corresponds to speed value shown on display

while machine service. Default = 50 Hz.

oFAN m3 CONVERSION: it corresponds to flow rate value shown on display

while machine service. Default = 1200 m3 /h.

oFAN MAXIMUM Hz: it defines the maximum settable speed. Default = 80 Hz.

- DRUM INVERTER: this parameter allows setting the inverter to manage drum

speed. Default= ABSENT.

In the case of accidental setting on PRESENT with no installed inverter, the display

shows “INVERTER ALARM IB2 (drum): DISCONNECTED”.

IMPORTANT: With DRUM INVERTER PRESENT, the menu shows as available

parameters “PULLEY REDUCTION RATIO NUMERATOR” and “PULLEY

REDUCTION RATIO DENOMINATOR” that define pulleys rotations and that must

not be modified.

- THERMAL SWITCH N.O./N.C.: this parameter defines the relay for the thermal

signal to work as NO or NC.

2. ENERGY

- HEATING MODE: On that menu heating can be set following machine equipment.

oELECTRIC: with that heating the menu :\TECH MENU\SETTINGS\ENERGY

enables parameter POWER LEVEL CONTROL .

oGAS: the menu enables parameter GAS TYPE from :\TECH MENU\

SETTINGS\ENERGY

oSTEAM

oHEAT PUMP: the menu enables parameter “HEAT PUMP PARAMETERS”

from :\TECH MENU\SETTINGS\ENERGY

- HEAT PUMP PARAMETERS:

oPREHEATING TIME: it is the time requested by electrical resistance to heat

up.

oNO-RETURN TIME: setting of the compressor-running time limit; over that

setting, it cannot be restarted.

oCOMPRESSOR PAUSE: over that set time, the compressor cannot be

started again.

E170203X 17/02/2017

SOMMARIO

19

o2nd COMPRESSOR HYSTERESIS: it is the compressor temperature

hysteresis for a disconnection on second.

oPREHEATING HYSTERESIS: it is referred to set point temperature of cycle

T0as detached by PROBE1 (drum probe).

It helps to avoid that PRERISC and first compressor stop as T0are reached.

In this way, only PRERISC will be stopped avoiding bad consequences in

case of compressor stops.

oGROUP 1 FAN ACTIVATE: reaching a limit temperature, the cooling fan on

the group 1 gets activated.

oGROUP 1 FAN DEACTIVATE: reaching a limit temperature, the cooling fan

on the group 1 gets deactivated.

oGROUP 2 FAN ACTIVATE: reaching a limit temperature, the cooling fan on

the group 2 gets activated.

oGROUP 2 FAN DEACTIVATE: reaching a limit temperature, the cooling fan

on the group 2 gets deactivated.

oACTIVATE PREHEATING: it refers to temperature reached during the

execution of a cycle. Reaching that temperature, the preheating gets active.

It is not a delta °T value: it is a temperature value in relation to gas

temperature on the circuit of the pump.

That value is affected only by the closed circuit operation of the gas, not by

the set point of the program!

PREHEAT activates when the second compressor probe (PROBE2 and

PROBE3) falls below TPRERISCattacca

oDEACTIVATE PREHEATING: temperature of deactivation of PREHEAT

during the execution of a cycle and it corresponds to the maximum

temperature allowed to the gas on the pump circuit. The PRERISC

deactivates when the first of the two compressor probes (PROBE2 and

PROBE3) goes up to temperature TPRERISCstacca. This value is not affected by

the program set point.

oSTOP COMPENSATION: when this parameter is ON during GREEN cycle

the IM10 independently extends the cycle duration for the corresponding

time compressors were stopped due to a pause or to the opening of

filter/door. This is not valid in the case of a power failure.

oFAN SPEED: it allows setting fan suction speed (HZ).

- TEMPERATURE OFFSET: it indicates an error in positive or in negative to the

correct reading of temperature probe. Default = 0°C

There is the possibility to distort the reading of a probe anticipating or delaying the

heating range.

- TEMPERATURE HYSTERESIS: it defines the temperature margin for the heating

restart (differential). Default = 1°C.

It is the difference between set point temperature (temperature set on the program)

and the restart of the heating system during thermoregulation phase.

To add delays on the heating restart, change the value.

Do not set 1°C value because it will start many times and it damages resistors

contactors or steam solenoid valve.

E170203X 17/02/2017

SOMMARIO

20

- INSTALLED POWER: the user can fill in the value of installed power as per

machine setting.

Enter on the menu: \USER\RECORDINGS\ENERGY STATS machine consumption

can be monitored. Stats data will be available only if the installer correctly sets

following parameters:

oDRUM MOTOR POWER

oFAN MOTOR POWER (Kw)

oELECTRIC HEATING POWER 1 (Kw)

oELECTRIC HEATING POWER 2 (Kw)

oNATURAL GAS HEATING POWER (m3 /h)

oPROPANE GAS HEATING POWER (Kg/h)

oSTEAM HEATING POWER (Kg/h)

oCOMPRESSOR POWER (Kw)

- POWER LEVEL CONTROL (only on ELECTRIC HEATING MODE):

oABSENT

oPRESENT

At POWER LEVEL CONTROL PRESENT, you can set the reduction of power

heating on every program as ON, OFF and the way of execution in the menu.

:\USER\PROGRAMS\PROGRAM n

- GAS TYPE (only on GAS HEATING MODE): this parameter states the gas type can

power the heating battery. The gas type must correspond to heating battery

configuration.

oNATURAL GAS

oPROPANE (LPG)

3. PAYMENT SYSTEMS

- ACTIVATION/DEACTIVATION: at PAYMENT SYSTEM ACTIVATED, the machine

starts on self-service configuration. The modes are CENTRAL CASH or COIN BOX.

oABSENT

oPRESENT

- PAYMENT TYPE: choose the payment system set on the machine.

oCOIN BOX

oCENTRAL CASH

- PERSONALIZED CURRENCY: possibility to name a currency and select it from the

menu MONETARY UNIT.

Table of contents

Popular Touchscreen manuals by other brands

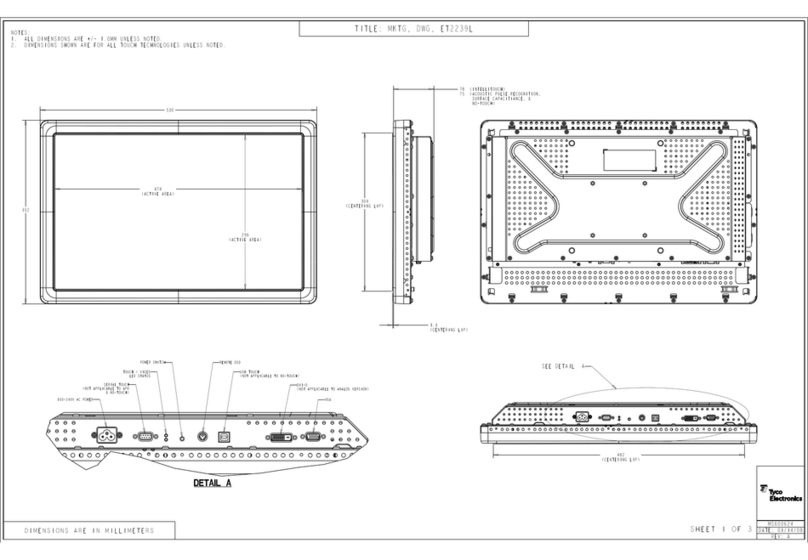

Elo TouchSystems

Elo TouchSystems 2239L Product dimensions

Bosch

Bosch Solution 2000 quick start guide

Avalue Technology

Avalue Technology ARC-1200 Quick reference guide

Sanuvox

Sanuvox Bio Smart Screen instruction manual

Tempress Systems

Tempress Systems M440-01 Reference manual

Crestron

Crestron TPMC-V12 & TPMC-V15 operating guide