TM

/

OK

FFB

0

Y

OK

FFB

0

Y

PD[

PP

PD[

PP

PP

PP

0LQ

PD[

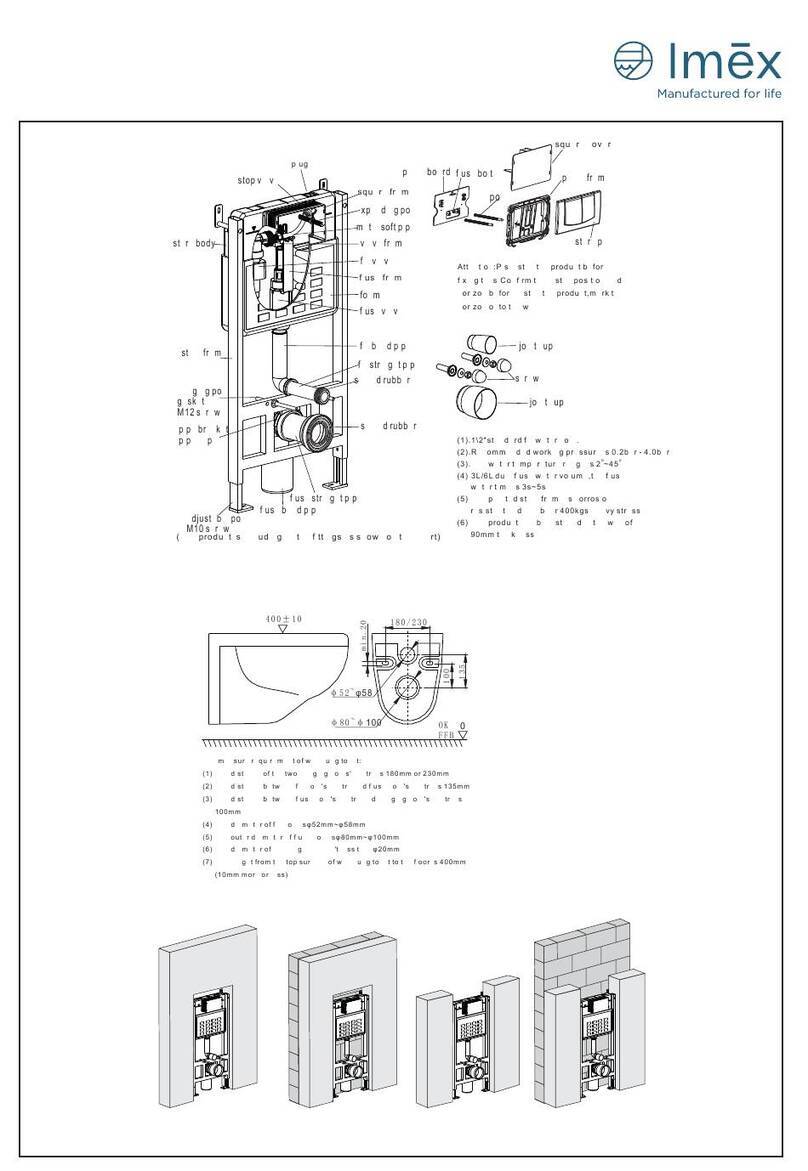

7.Install fill water pipe

Loosen the screws and

removefrom the panel

board.

Attention: There may be debris in the new pipe,pls repeat open and close the stop valve several times,

flush out the dirt by open & close the water source several times,till appear clean water.At the same time,

pleases wash the dirt from the cistern.

Remove the panel board,pull

it upward and take it out at an

angle.

6.Install flush pipe

The way of connect the flush bend pipe:

HDPE plastic: weld the flush bend pipe by heated steel board,connect the flush

bend pipe and flush pipeline by rubber tie-in.ABS plastic: smear glue onto the

flush bend pipe,connect the flush bend pipe and flush pipeline by rubber tie-in.

pipe installed above the floor pipe installed under the floor

Fix the position of flush bend pipe according to the height of Y

which had measured,turn the flush bend pipe as needed.

connect the flush bend pipe with flush straight pipe ,fix the

flush bend pipe with linker.

8.Preparative before build wall

Insert the two hooks of panel

board into the flush valve.

9.Build the wall 10.Install cistern panel

The surface of expanding pole is

5mm lower than the wall surface.

Fix the panel frame onto the

expanding pole by screw.

Adjust the

outer part of

pole to be

about 28mm.

Fasten the bottom of cistern

panel onto the panel frame,

push the cistern panel upward,

close the cistern panel onto the

panel frame.

11.Adjust straight pipe

Measure the length of L+3mm at the edge of

straight pipe and cut it down.Rub the cut edge

of straight pipe by file to remove rough edge.

Insert the straight pipe into the bend

pipe,make mark on the pipe where

is balance to the wall.

Insert the straight pipe into the hole of standing

floor toilet,make mark on the pipe where is

balance to the surface of standing floor toilet.

Measure the distance

between the two marks.

L1mm

L2mm

mark

L1+3mm

L2+3mm 1.5mm

45°

the cut part

Smear silicon oil onto the sealed rubber

of bend pipe equaly,insert straight pipe

into the bend pipe.

Measure the depth " L" of hanging hole of

standing floor toilet,smear small sealant

onto the side surface of standing floor toilet

where connecting to the wall.

Install the standing floor toilet onto the hanging pole,

set decorated ring,gasket,screw & decorated cup

onto the hanging pole orderly.

Smear silicone glue onto the side of

standing floor toilet where connecting

to the wall.

12.Install standing floor toilet

13.Install effect

Press the four knot and take

out the square cover

Connect the fill water pipe with angle iron and

connect the metal flexible pipe with angle iron

(If the flush valve can not stop water,

maybe is the pole too long;if the flush

valve flush volume too small,maybe is

Cut the part which is

protruding of tile flat

with the wall

The interval of tile and

the square cover no

bigger than 5mm

Cover the system of

concealed cistern by

plasterboard or

composite board.

Stick tile onto the

finished wall. The thickness

range of tile onto the finished

wall is 20mm~70mm.

Insert the panel board into the

cavity at an angle

Twist the panel board

with screw tightly

Cover the square cover

(to prevent the dirty and

prevent the deformation)

CC100F

Super slim concealed insulated cistern with chrome front

mounted dual ush plate

the pole is too short)