2

10/2018 EN1377027BA

1.6 Improper use

Only operate the valve within approved opera-

ting limits.

In the following cases it is prohibited to opera-

te the valve:

•The valve is not used for the designated

purpose.

•The valve is used beyond the permitted

operating limits. The permitted temperature

and pressure ranges are exceeded.

•Damages to the valve – e.g. cracks,

deformation – were detected but the valve

remains in operation.

•Malfunctions were detected but the valve

remains in operation.

We do not accept any liability for damages

caused by improper use.

Our guarantee expires in the following cases:

•Undue intervention and altering are done to

the valve.

•This documentation or the operating limits as

shown in the data sheet are not observed.

1.7 Obligations of operator

Product

→Over the entire life cycle of the valve all

applicable regulations must be observed.

The instructions of this operation manual

must be observed and followed.

→Initiate a risk assessment of the overall

installation, to detect potential dangers that

may occur in combination of the valve with

other components.

Persons

→Initiate the instruction of each person who

is working with the valve.

Applicable regulations about occupatio-

nal safety ad safety engineering must be

known and applied.

Documentation

→This documentation must be fully read and

understood.

→The instructions given in this operation

manual must be put into practice.

→This documentation must be available at

any time.

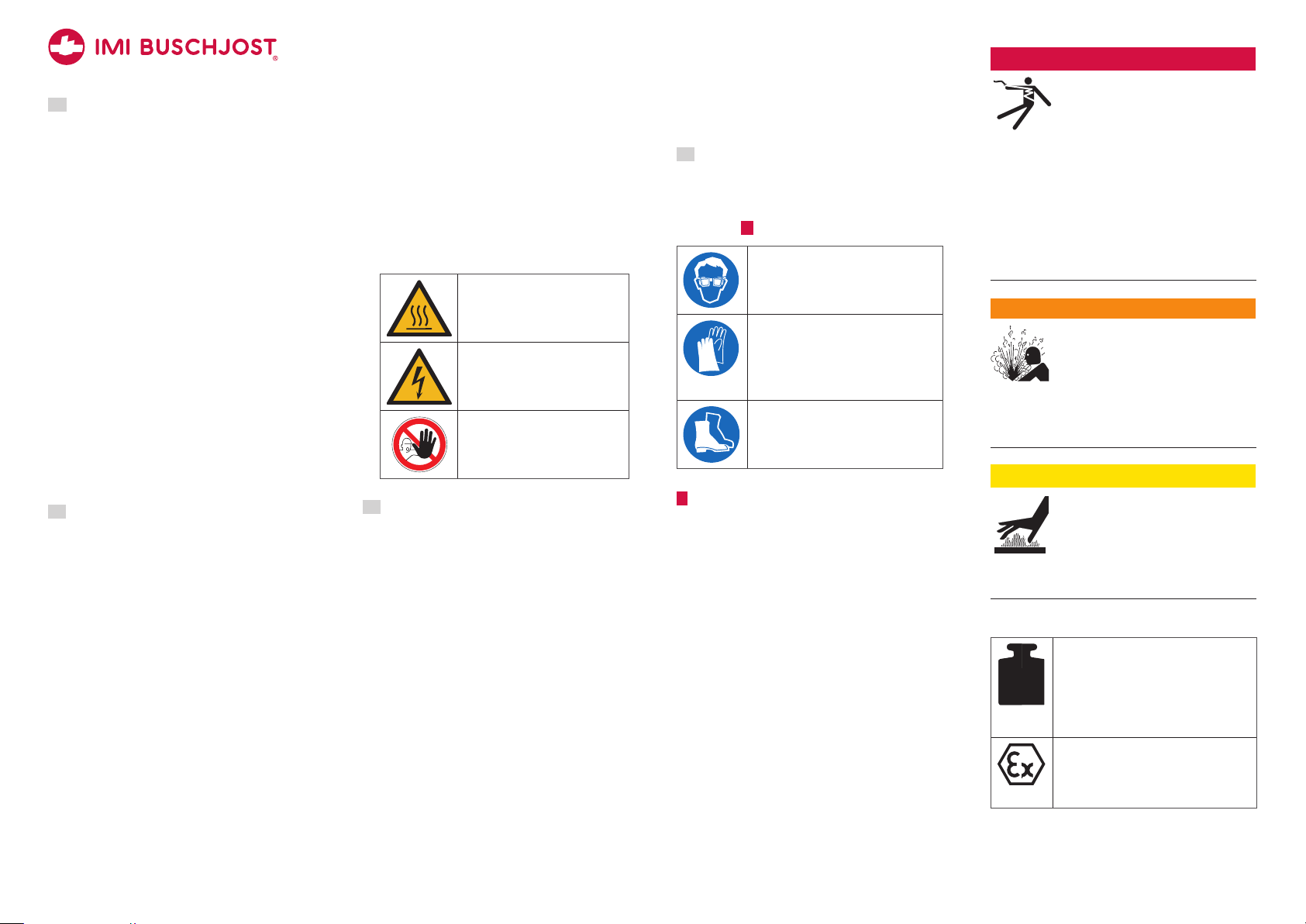

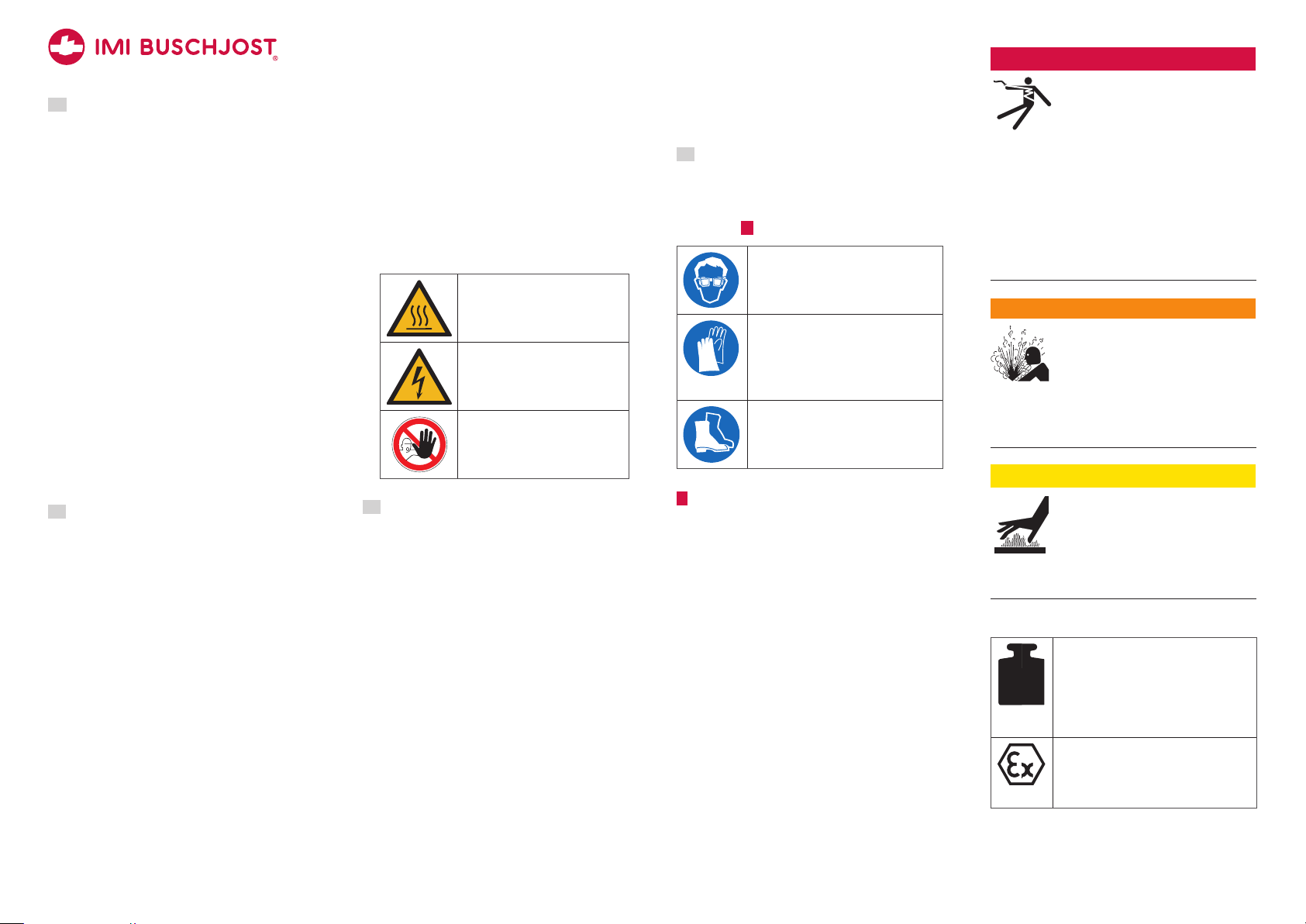

Markings at the operating site

→Ensure adequate warning of the risks linked

to the valve. Use in the area of the installed

valve the following warning and prohibition

sings in compliance with EN ISO 7010 and

BGV A8 (VBG125):

Warning sign to indicate risk of

burns at the solenoid

Warning sign to indicate elec-

trical hazards at the solenoid

Prohibition sign to

prevent people from entering

hazardous areas

1.8 Personnel qualification

→Ensure as operator that persons who work

on or with the valve are sufficient qualified

for this job.

→Comprehensively train the operating per-

sonnel in terms of safety.

→Only allow trained specialists to perform

electric connections, commissioning, main-

tenance and trouble shooting

Demands

Operating personnel must be instructed on

operational sequences and procedures.

Operating personnel must know its responsi-

bilities regarding the work to be performed.

Trained specialists must possess profound

knowledge in mechanical engineering, electri-

cal engineering, hydraulic und pneumatic.

Trained specialists must be authorized to

commission, ground and designate devices,

systems and power circuits according to the

standards of safety technology.

Trained specialists must possess profound

knowledge about design and principle of ope-

ration of the valves and the plant.

1.9 Personal protection equipment

→Wear appropriate protection equipment.

Observe the personal protection equipment

as requested in “residual risks” (refer to

chapter 2 ).

Protective eye glasses

to protect from escaping fluids or

exhausting compressed air

Protective gloves

Resistance to cutting to pro-

tect from sharp edges or ridges;

resistance to acids to protect from

hazardous fluids

Protective footwear

to protect from parts or tools falling

down

2 General safety instructions

These safety instructions are only related to

the single valve. In combination with other

plant components there may be other potential

dangers, which must be taken into account by

carrying out a risk analysis for the system.

→Compare the details on the rating plate and

data sheet to the operating data. The parti-

cular application must not exceed the given

limits (e.g. pressure, temperatures).

→You must depressurize the pipe system and

de-energize the solenoid prior to perform

mounting and maintenance works.

→Prime the valve slowly when commissio-

ning. Fast pressurizing will cause the valve

to open briefly.

→Strength tests with the valve seat open are

permitted maximum up to 1.5 times of the

nominal pressure rating (PN) at room tem-

perature. Do not operate valve during test.

!DANGER

Hazardous electrical voltage

(>25V AC; >60V DC)

There are risks from electrical

voltage during assembly and

maintenance.

→The electrical connection of the solenoid

must be carried out only by a qualified

electrician.

→You may only plug the device socket in

de-energized state.

→Disconnect the power supply off the sole-

noid prior to assembly or dismantling.

!WARNING

Danger from pressurized

pipelines

Pressurized pipelines may burst

resulting in injuries.

→Depressurize pipe system and block the

fluid stream prior to opening or unmoun-

ting the valve.

!CAUTION

Risk of burns at the solenoid

Solenoid is heating up during

operation. Touching the solenoid

leads to risk of burns.

→Leave the solenoid to cool down before

working at the valve.

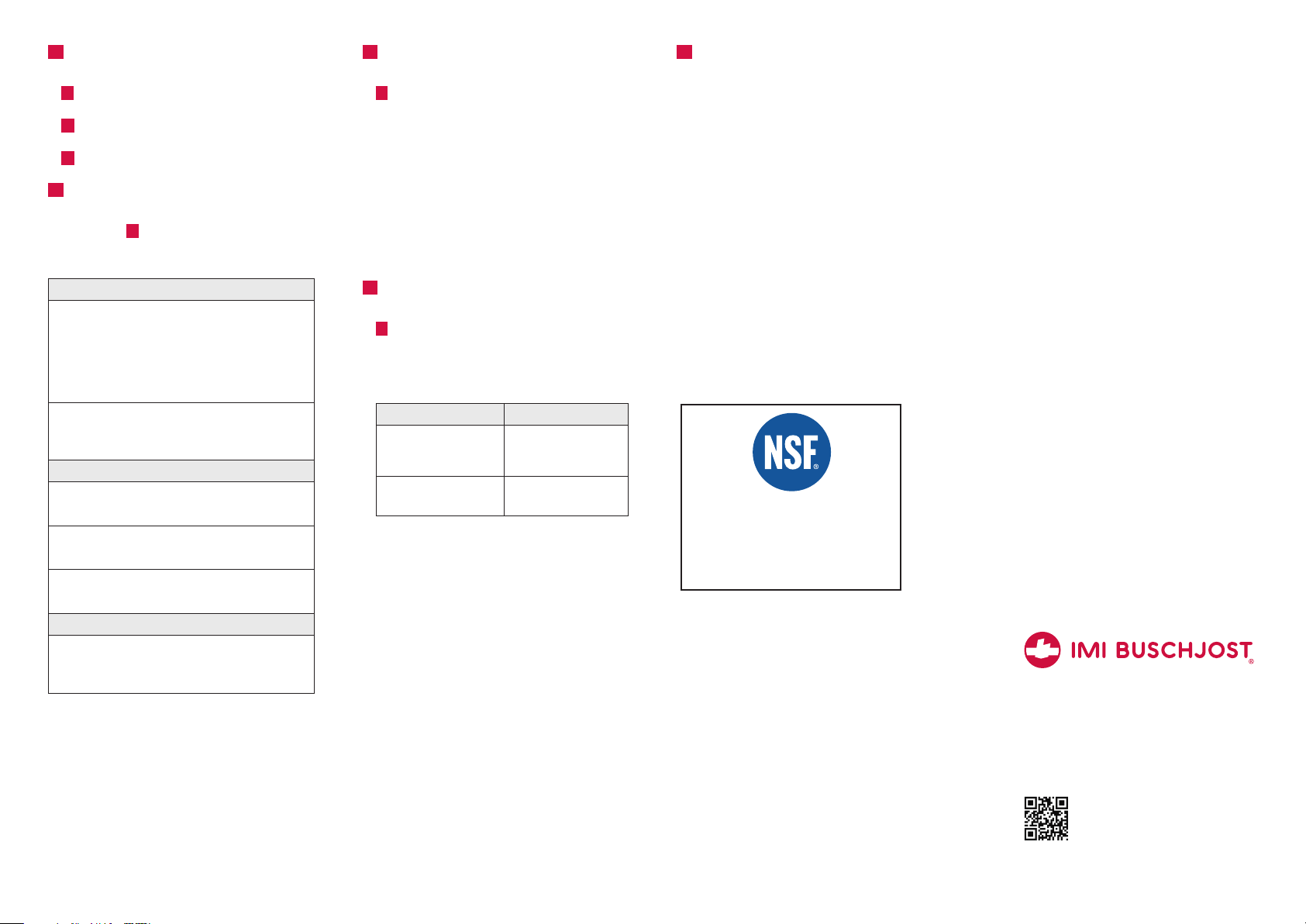

Residual risks

kg

Weight of the valve

Phases: transport, storage, assembly,

maintenance, disposal

Risk: falling off, tipping over

Personal protection equipment

(PPE): Protective footwear

Potentially explosive atmosphere

Risk: danger of explosion

!WARNING: Use solenoids and

device sockets with Ex-protection.

A2