8

1-2

CAVO ALIMENTAZIONE

CAVO SONDA SOLARE

1-3

INSTALLERUSERMAINTENANCE TECHNICIAN

1.6 ELECTRICAL CONNECTION.

e “Hercules Solar 26 2 ErP” boiler has an

IPX5D protection rating for the entire appliance.

Electrical safety of the appliance is reached only

when it is correctly connected to an ecient

earthing system as specied by current safety

standards.

Attention: the manufacturer declines any re-

sponsibility for damage or physical injury caused

by failure to connect the boiler to an ecient

earth system or failure to comply with the refer-

ence standards.

Also ensure that the electrical installation cor-

responds to maximum absorbed power speci-

cations as shown on the boiler data nameplate.

Boilers are supplied complete with an “X” type

power cable without plug.

e power supply cable must be connected to

a 230V ±10% / 50Hz mains supply respecting

L-N polarity and the earth connection on

this network must also feature a multi-pole

circuit breaker of class III overvoltage category.

When replacing the power supply cable, contact

a qualied rm (e.g. the Authorised Aer-Sales

Technical Assistance Service).

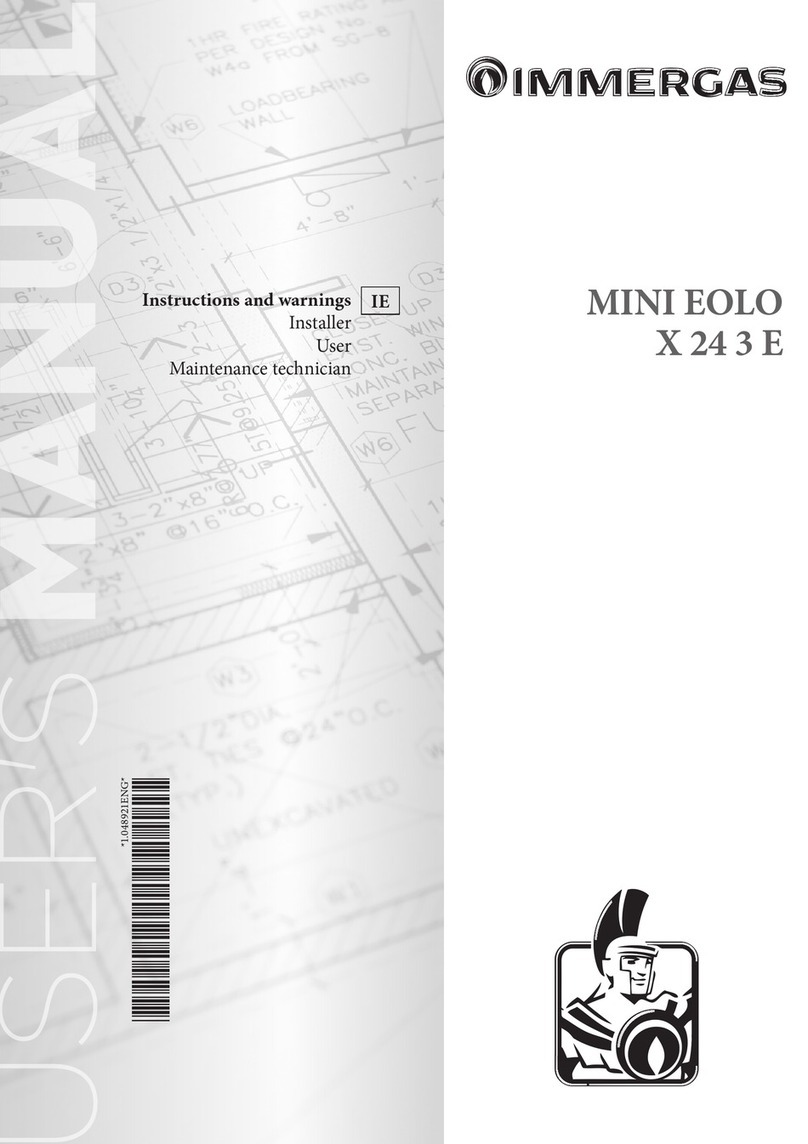

e power cable must be laid as shown (Fig. 1-3).

In the event of mains fuse replacement on the

P.C.B., use a 3.15A quick-blow fuse. For the main

power supply to the appliance, never use adapt-

ers, multiple sockets or extension leads.

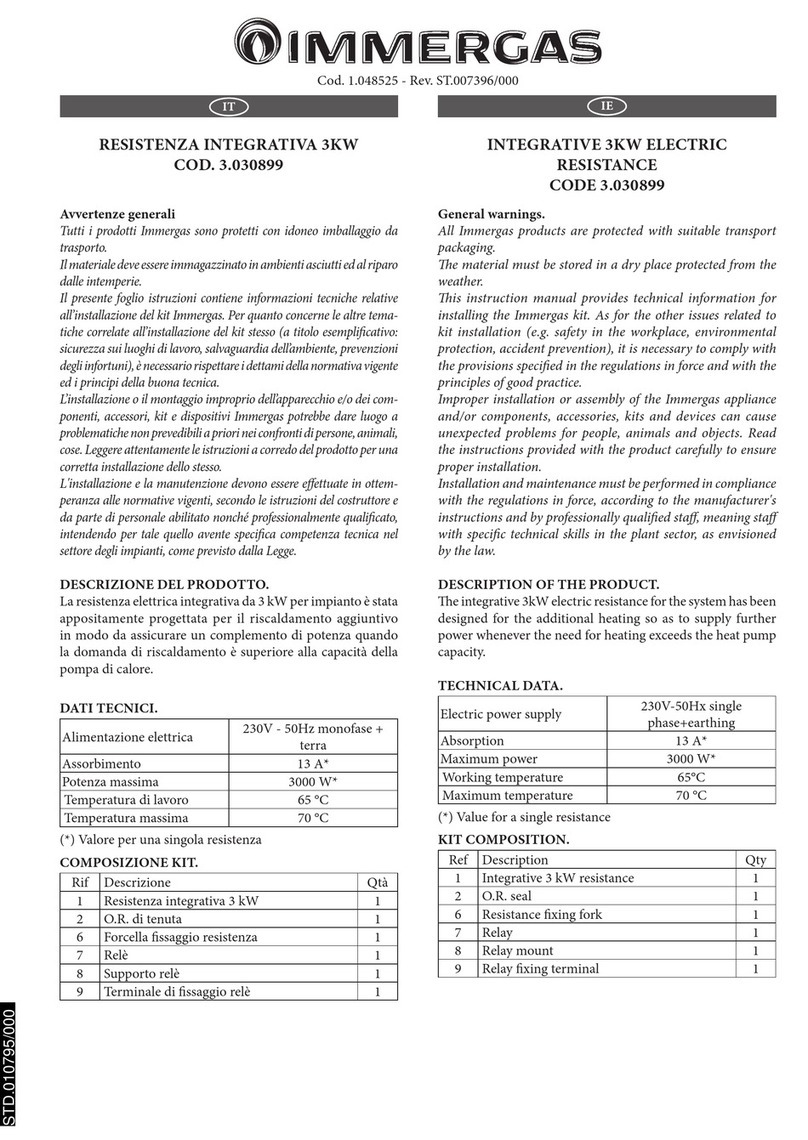

Solar panels electrical connection. Only use an

appropriately sized cable to make the connec-

tions. Making them follow the same route as the

power supply cable (in the relevant pipe), make

the connections on the control panel on clamps

45 and 46, eliminating the resistance R15 (Fig.

1-2). Connect the supplied probe on the solar

panel and position it in the relevant seat.

Installation with system operating at direct

low temperature. e boiler can directly feed a

low temperature system by acting on parameter

“P66” (Par. 3.8) and setting the delivery tempera-

ture adjustment range “P66/A” and “P66/B”. In

this situation it is good practice to insert a safety

device in series with the power supply and boiler.

is device is made up from a thermostat with

a temperature limit of 60°C. e thermostat

must be positioned on the system ow pipe at

a distance of at least 2 metres from the boiler.

1.7 REMOTE CONTROLS AND ROOM

CHRONOTHERMOSTATS

OPTIONAL.

The boiler is prepared for the application of

room chrono-thermostats or remote controls,

which are available as optional kits (Fig. 1-4

and 1-5). All Immergas chrono-thermostats are

connected with 2 wires only. Carefully read the

user and assembly instructions contained in the

accessory kit.

• On/O digital chrono-thermostat. e chrono-

thermostat allows:

- set two room temperature value: one for

daytime (comfort temperature) and one for

night-time (reduced temperature);

- set a weekly program with four daily switch

on and switch o times;

- select the required operating mode from the

various possible alternatives:

- manual mode (with adjustable temperature).

- automatic mode (with set program).

- forced automatic mode (momentarily

changing the temperature of the automatic

program).

e chrono-thermostat is powered by two 1.5V

LR 6 type alkaline batteries.

• ere are two types of remote controls avail-

able: Comando Amico Remoto remote con-

trolV2 (CARV2) and Super Comando Amico

Remoto remote control (Super CAR) both

with a climate chrono-thermostat operation.

In addition to the functions described in the

previous point, the chrono-thermostat panels

enable the user to control all the important

information regarding operation of the ap-

pliance and the central heating system with

the opportunity of easily intervening on the

previously set parameters without having to

go to the place where the appliance is installed.

e panel is provided with self-diagnosis to

display any boiler functioning anomalies.

e climate chrono-thermostat incorporated

into the remote panel enables the system ow

temperature to be adjusted to the actual needs

of the room being heated, in order to obtain

the desired room temperature with extreme

precision and therefore with evident saving in

running costs. e chrono-thermostat is fed

directly by the boiler by means of the same 2

wires used for transmitting data between boiler

and device.

Important: if the system is subdivided into areas

using the relevant kit, the CAR V2 and the Super

CAR must be used with its climate thermostat

function disabled, i.e. it must be set to On/O

mode.

CAR V2, Super CAR or On/O chrono-ther-

mostat electrical connection (Optional). e

operations described below must be performed

aer having removed the voltage from the appli-

ance. Any On/O room chrono-thermostat must

be connected to clamps 40 and 41 eliminating

jumper X40 (Fig. 3-2). Make sure that the On/

O thermostat contact is of the “clean” type, i.e.

independent of the mains voltage, otherwise the

P.C.B. would be damaged. Any CAR V2 or Super

CAR must be connected by means of terminals

IN+ and IN- to terminals 42 and 43 on the

P.C.B. (in the boiler), eliminating jumper X40

and respecting polarity (Fig. 3-2). Connection

with the wrong polarity prevents functioning, but

without damaging the CARV2 e boiler can only

be connected to one remote control.

Important: if the Comando Amico Remoto

remote controlV2 is used, arrange two separate

lines in compliance with current regulations

regarding electrical systems. No boiler pipes

must ever be used to earth the electric system or

telephone lines. Ensure elimination of this risk

before making the boiler electrical connections.

REMOTE CONTROL CABLE

SOLAR PROBE CABLE

POWER SUPPLY CABLE

Relay (Optional)

DIM (Op-

tional) Super CAR (Optional)

STD.002104/002