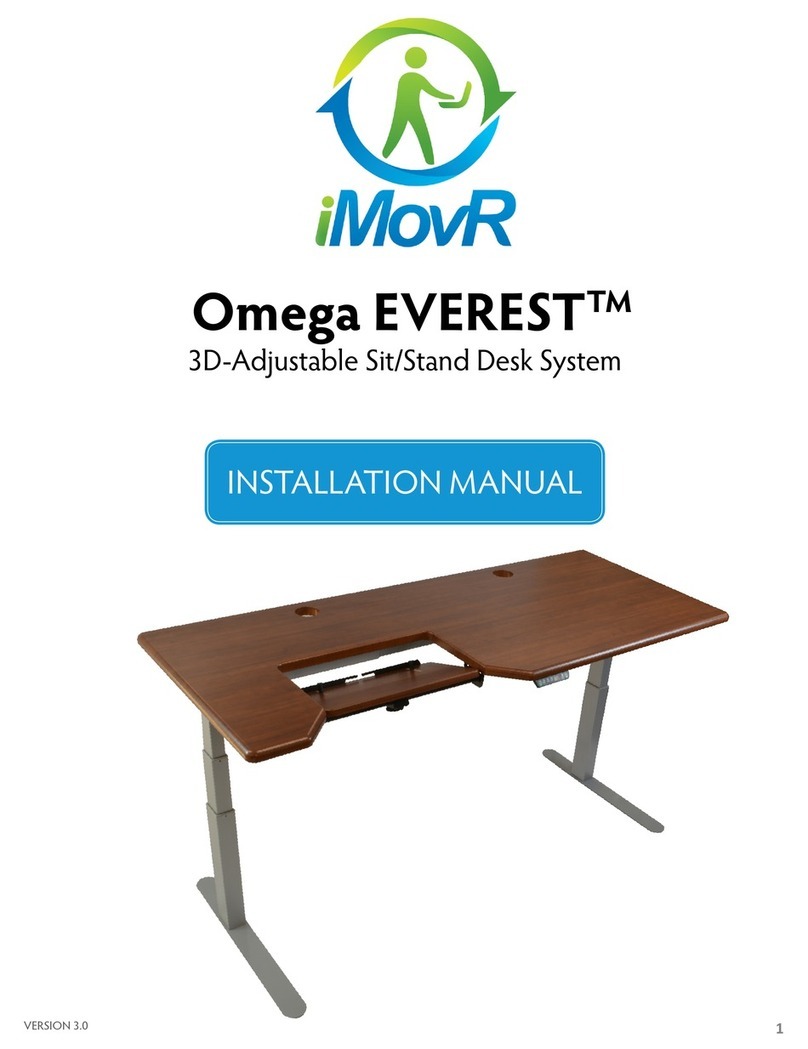

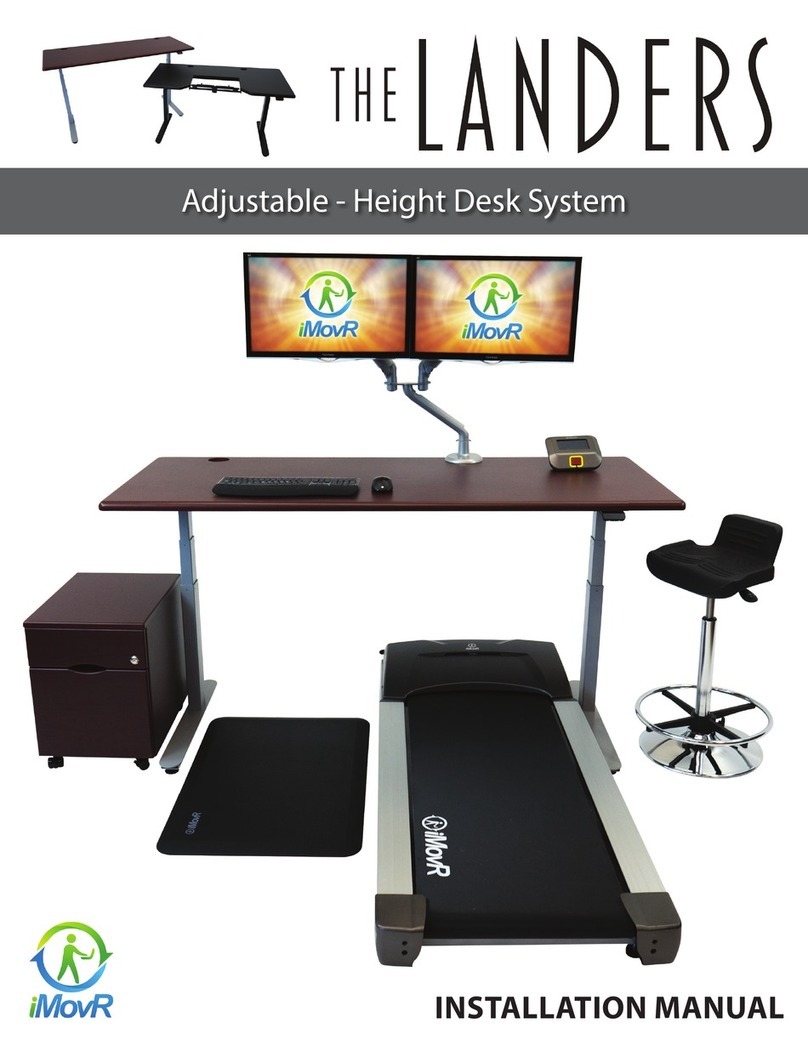

imovr Cadence User manual

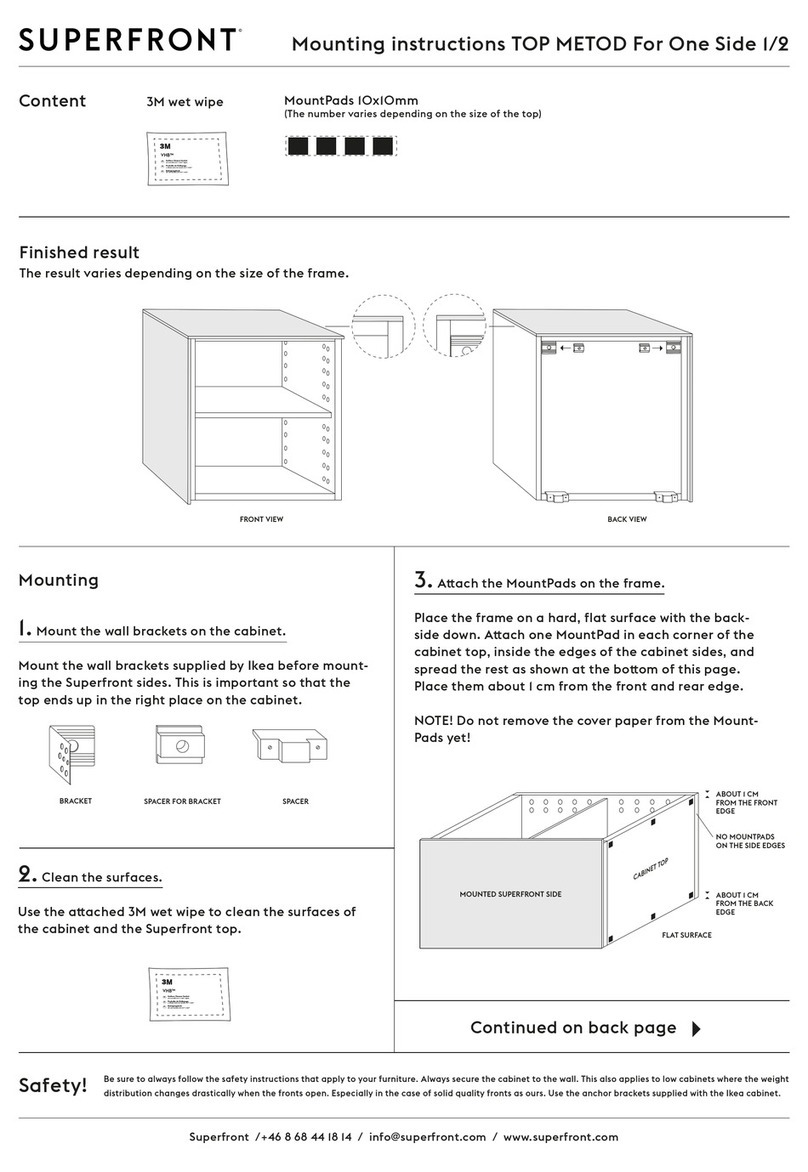

INSTALLATION MANUAL

Standing Desk Converter

iMovR Cadence

6011180 Rev. G

INSTALLATION MANUAL

FOR SIT-STAND WORKSTATION

Weight Capacity: 6.5-25 lbs.

Monitor Weight: 5-20 lbs.

Contents

Tools Required / Supplied Part Kits / Warnings/Disclaimers.........2

Base Installation

Clamp Mount Base Orientation .......................................... 3

Grommet Mount Base Orientation ...................................... 4

Installing the Pivot Limiter (Optional) ......................................... 4

Attaching the Arm to the Base ( Pivot Limiter Option).................. 4

Attaching the Arm to the Base .................................................. 5

Installing Work Surface ............................................................ 5

Installing Keyboard Tray ........................................................... 5

Keyboard Tilt........................................................................... 6

Keyboard Storage Stop ............................................................ 6

Installing the Monitor ............................................................... 6

Cable Management Installation................................................. 7

Arm Counterbalance Adjustments ............................................. 7

Tray Leveling Adjustments (Left to Right) ................................... 8

Tension Adjustment for the Monitor........................................... 8

Monitor Tilt Tension Adjustment ................................................ 8

INSTALLATION WARNINGS:

•Read the entire instruction manual before beginning any installation or assembly.

• The installer must verify that the attachment surface can safely support the

combined weight of all the attached equipment and hardware.

• Improper installation of this product may cause extensive property damage

or serious personal injury, either during or after installation.

DISCLAIMERS:

• The manufacturer will bear no responsibility for any damages of any kind

arising from improper installation of this product.

•In no way will the manufacturer be held liable for any damage to the monitor,

property or personal injury should an outside force either intentionally or

unintentional be applied to the monitor or monitor mounting bracket

ADJUSTMENT NOTIFICATIONS:

•Routine maintenance checks and adjustments are suggested to properly

support the quality and optimal performance of this product.

Refer to adjustment suggestions on last page of booklet, or contact your

distributor for further detailed information.

• Over tightening of bolts during installation or adjustments can damage

the product and affect the function and warranty.

Allen Keys,

1/8",3/16",

7/32",1/4"

(provided)

3/8" Wrench

(for Dual Monitor option)

Tools Required

Supplied Part Kits

#2 Phillips

Screwdriver

Level

Warnings/Disclaimers

KIT A: Arm Bolt/Washer Kit

KIT D: Grommet Mounting Bolt KIT E: Pivot Limiter Kit

KIT B: Work Surface Mounting Kit KIT C: VESA Mounting Plate Kit

2Installation Manual: SIT-STAND WORKSTATION

3

Installation Manual: SIT-STAND WORKSTATION

The unit can be installed on a 24" or 30" deep rectangular or corner desk using the integral desk clamp or grommet

mounting hardware provided.

Base Installation

Clamp Mount Base Location

Determine desired installed tray location. Offset base location by 7" left or right for a 24" deep desk or

place in desired installed location for a 30" deep desk.

STEP 1

7”

24" DEEP DESK 30" DEEP DESK

Slide the angle bracket assembly onto the back of the desk.

Secure the clamp plate to the underside of the desk with the

supplied bolts. Use a 7/32" Allen Key to tighten to 75 in/lbs.

To reverse the bottom clamp, remove the three screws using a 3/16" Allen

Key and reinstall the Bottom Clamp in the DOWNWARD position. Slide the

angle bracket assembly onto the back of the desk. Secure the clamp plate

to the underside of the desk with the supplied bolts. Use a 7/32" Allen Key

to tighten to 75 in/lbs.

Bottom Clamp is UPWARD. Bottom Clamp is DOWNWARD.

DESK THICKNESS - 3/4" - 1 1/2"DESK THICKNESS - 1 1/2" - 2 1/2"

STEP 2

The thickness of the desk will determine the orientation of the bottom clamp. The product comes pre-configured for a 3/4" - 1 1/2" desk.

Bottom

Clamp

Bottom

Clamp

Angle

Bracket

Angle

Bracket

Clamp

Plate

Clamp

Plate

If installer is drilling their own hole, ensure that the diameter is a minimum of 1/2".

Grommet Mount Base Orientation

Installing the Pivot

Limiter (Optional)

STEP 1

Secure the pivot limiter to the base with

two screws (KIT E: Pivot Limiter Kit)

NOTE: Ensure the pivot limiter slot is

oriented to the back of the desk and the

screw heads are seated flush to the top

surface of the pivot limiter. (The image

shown is the base installed in the 30”

orientation)

STEP 2

Press fit the spring pin (KIT E: Pivot

Limiter Kit) into the rear hole of the

arm base. A light tap of a hammer

may be required depending on the fit.

The pin should only protrude ¼"

once fully seated.

4Installation Manual: SIT-STAND WORKSTATION

If using the Pivot Limiter option, make sure the pin remains engaged

in the arm base when the arm is attached to the desk mount base.

Attaching the Arm to the Base

(Pivot Limiter Option)

Remove

Angle Bracket

STEP 1

Detach the angle bracket assembly (not used in a

grommet application) by removing the 4 screws

with a 7/32" Allen Key.

STEP 2

Insert the grommet bolt through the washer

(KIT D: Grommet Mounting Bolt) and upward

facing clamp plate. From under the desk

insert the grommet bolt assembly through the

desk into the center hole of the base.

STEP 3

Tighten the bolt securely under

the desk using a 7/32" Allen Key

to 75 in/lbs.

PIVOT LIMITER ALLOWS 180° ROTATION

Position pin at 12:00 to prevent the arm

from coming in direct contactwith the

wall on either side

180°

Lightly tap the pin to ensure it

stays in place during installation.

The pin should only protrude

1/4" once fully seated.

With the base already installed on the desk.

Attaching the Arm to the Base

Installing Work Surface

Installing Keyboard Tray

STEP 1

Slide the large nylon washer

(KIT A: Arm Bolt/Washer Kit)

over the bottom pin of the arm.

STEP 2

Set the main arm bottom pin

into the base.

STEP 1

STEP 2

STEP 3

While holding the arm in the

lowest position remove the trim

cap at the back of the arm.

STEP 4

Hold the arm in the lowest position

to prevent it from springing up,

insert the bolt/washer assembly

(KIT A: Arm Bolt/Washer Kit)

through the back of the arm and

into the base. Ensure the washers

are as illustrated.

STEP 4

STEP 5

Keeping the arm down tighten

the bolt with the 1/4" Allen Key

until the bolt is seated and snug.

Tighten or loosen bolt to obtain

desired resistance for left to right

arm movement.

STEP 6

Replace the trim cap at the back

of the arm.

STEP 5

STEP 6

STEP 1

Position the work surface on the tray support arm aligning all six

holes and securing the tray with the four screws (KIT B: Work Surface

Mounting Kit). Use the 1/8" Allen Key to tighten.

STEP 2

Note, work surface can be mounted forward on the tray support

by using the front four mounting hole locations.

STEP 1

STEP 1

Slide the keyboard tray

head assembly into

place as shown.

STEP 2

Insert the screw into the threaded hole of the keyboard tray

head and tighten with 3/16" Allen Key until snug. Releasing

and securing the screw will allow for independent keyboard

tray height adjustment.

STEP 1

STEP 2

STEP 4

Use two-sided Hook and

Loop pads to secure

keyboard to tray.

STEP 3

To attach the palm rest,

remove the adhesive backing on the tape

and apply to the underside of the palm rest.

Remove the remaining backing on the adhesive

tape and position palm rest in the desired

location on keyboard tray.

NOTE: Ensure

nylon bushing is

on the arm post

when inserting the

arm into the base.

SIDEVIEW

OF ASSEMBLY

5

Installation Manual: SIT-STAND WORKSTATION

Do not overtighten bolt as

this may cause damage

to the product.

!

Use the screw from (Kit B:

Work Surface Hardware kit)

Plastic

Steel

Keyboard Tilt

(+4° to -15°)

Keyboard Storage Stop

To adjust the tray angle, place tray in desired tilt

position and adjust front set screw with the 1/8"

Allen Key.

To adjust the maximum storage angle, place tray in

the maximum storage location and tighten rear set

screw with the 1/8" Allen Key.

For this step, the installer needs to determine if they wish to use the Quick Connect adapter

supplied or mount the monitor directly to the VESA mount on the Float Tower.

Installing the Monitor (5 lbs. to 20 lbs.)

SINGLE-MONITOR

If using the Quick Connect adapter, mount the Quick

Connect adapter (Kit C: VESA Mounting Plate Kit) to back

of the monitor with the screws provided.

Use a #2 Phillips screwdriver to secure screws. Lift monitor

into position and slide the Quick Connect onto the VESA.

If not using the Quick Connect adapter, mount the

monitor directly to the VESA mount on the Float Tower

with the screws provided. Use a #2 Phillips screwdriver

to secure.

DUAL-MONITOR (Optional Dual Monitor Kit)

Attach the dual bracket to the Float Tower VESA with the hardware

provided in the Dual Monitor Kit.

To attach monitors see steps for single-monitor.

NOTE: Adjustable bracket supports most 24" monitors weighing up to 8 lbs. each.

6Installation Manual: SIT-STAND WORKSTATION

After the technology has been installed, ensure there is enough slack in the

cables from the monitor, keyboard and mouse along with any other peripherals.

Arm adjustment is to be made after all technology has been installed from 6.5 lbs. to 25 lbs.

Cable Management Installation

Arm Counterbalance Adjustments

ATTENTION:

Arm must be held down to perform this adjustment.

STEP 1

Remove the trim cap at the back

of the arm.

STEP 2

Keeping the arm down, use

a 1/4" Allen Key to turn the

middle bolt at the back of

the arm. Turning the bolt

CLOCKWISE decreases the

spring force reducing the counter

balance load. Turning the bolt

COUNTERCLOCKWISE increases

the spring force increasing the

counter balance load.

STEP 3

Adjust the middle bolt until the

arm counter balance is acceptable.

STEP 4

Replace the trim cap at the back

of the arm.

+–

+–

+–

+–

COUNTERBALANCE

ADJUST

Do not overtighten bolt as

this may cause damage

to the product.

!

1/4"

Allen Key

STEP 2 & 3

STEP 4

7

Installation Manual: SIT-STAND WORKSTATION

STEP 1

Locate the two cable management

clips under the arm. Gently open

each of the clips.

STEP 2

Place all required technology cables

(power cord, mouse cable, VGA etc.)

through the clips under the monitor

arm. Make sure to leave enough

slack in the cables to allow the

arm to move freely.

STEP 3

Gently close the clips to secure

the cables in place. Re-adjust

slack in the cables if necessary.

Tray adjustment is to be made after all technology has been installed.

Tray Leveling Adjustments (Left to Right)

STEP 1

Remove the trim cap at the back of the arm.

STEP 2

Keepint the arm down, use the 3/16" Allen Key to turn

the top bolt at the back of the arm. Turn the bolt until

the tray is level.

STEP 3

Confirm that surface is level with spirit level.

STEP 4

Replace the trim cap at the back of the arm.

+–

+–

+–

+–

LEVEL

ADJUST

3/16"

Allen

Key

ATTENTION:

Tray must be parallel to the work surface and swiveled

90° to the base when adjusting.

STEP 3

STEP 2

1. Adjust tension as necessary

2. Repeat on alternate side

Light

monitor

Heavy

monitor

123

4

123

4

Tension Adjustment for the Monitor

Monitor Tilt Tension Adjustment

STEP 1

Use the 3/16" Allen Key to remove the two

bolts securing the plastic top cap of the

Float Tower. Remove cap.

STEP 2

Remove and install pins as necessary per the

drawing while holding the monitor in the highest

position. If pins are not needed, keep them inserted

in the bracket hole for possible future use.

STEP 3

Once tension is acceptable, replace the cap and

secure with the screws mentioned in STEP 1.

Tighten with 3/16" Allen Key.

STEP 1

To adjust the monitor tilt tension, use a 3/16"

Allen Key to adjust the tension setting on both

sides of the VESA plate. Setting number 1 is for

light monitors and 4 is for heavier monitors.

The factory default setting is 1.

STEP 2

Adjust the setting screw until a desirable tension

is achieved.

6011180 Rev. G

STEP 1 & 2

STEP 4

1. Remove

top cap

3. Remove/install pins as necessary

Light monitor Medium monitor Heavy monitor

TENSION ADJUSTMENT

ATTENTION:

Before adjusting the tension of the Float

Tower, ensure that the monitor is in the

highest position on the Tower so that the

spring tails are no longer in tension.

STEP 1 & 3

2. Hold monitor in the highest position. Re-install pins so

they are not lost.

Do not over rotate the dial beyond

“1” or “4” position or possible

damage to the dial may occcur.

!

Table of contents

Other imovr Indoor Furnishing manuals

imovr

imovr ThermoDesk ELLURE Base User manual

imovr

imovr Omega EVEREST User manual

imovr

imovr Cascade Standing Desk User manual

imovr

imovr Lander Lite User manual

imovr

imovr TEMPO TREAD TOP STOOL User manual

imovr

imovr ZipDesk User manual

imovr

imovr OMEGA DENALI User manual

imovr

imovr Omega Olympus User manual

imovr

imovr FLY DECK User manual

imovr

imovr Lander User manual

Popular Indoor Furnishing manuals by other brands

highwood

highwood Weatherly Counter Chair with Arms Assembly guide

PARAMOUNT BED

PARAMOUNT BED PE-6001 instruction manual

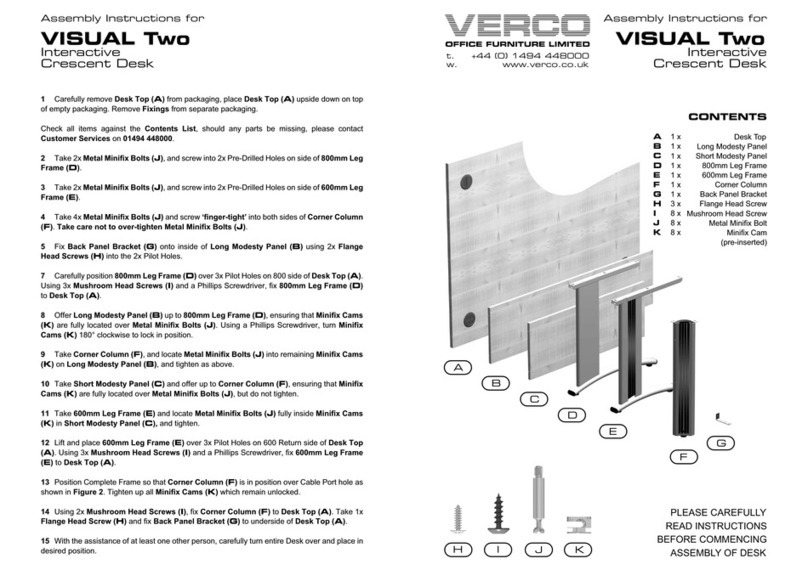

Verco

Verco VISUAL Two Assembly instructions

Mooreco

Mooreco Flipper-72 Assembly instructions

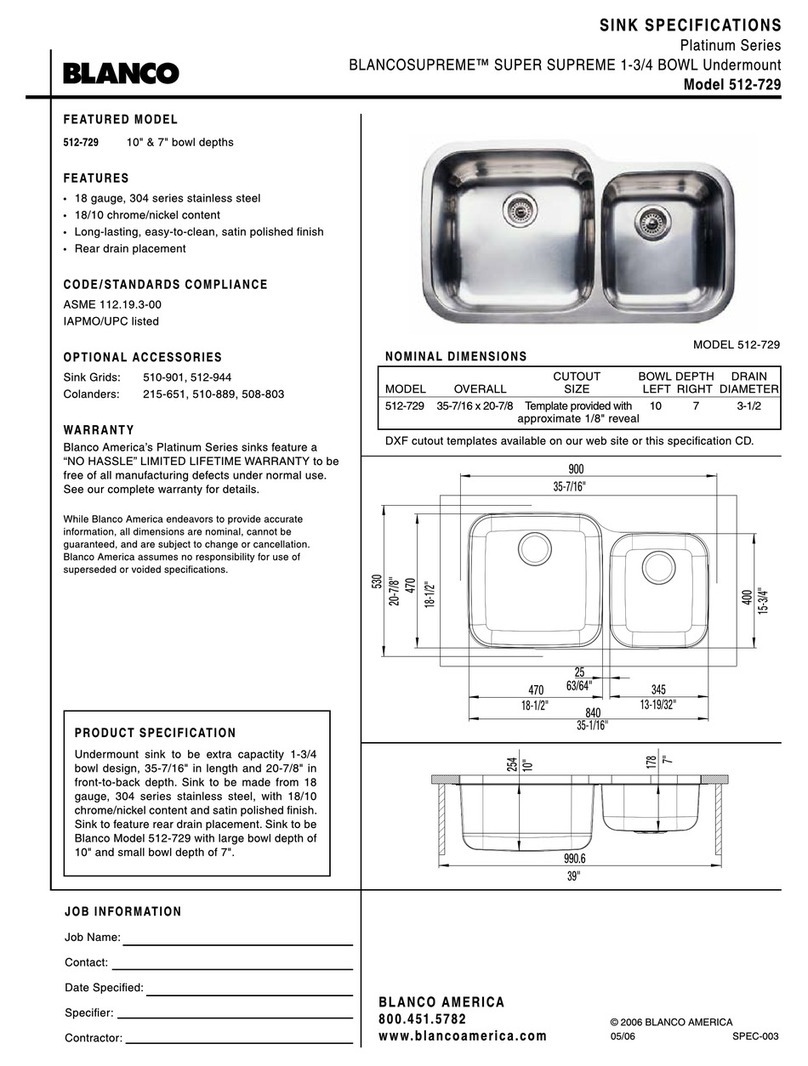

Blanco

Blanco BLANCOSUPREME 512-729 Specification sheet

FourStarGroup

FourStarGroup 11222812 manual