Impact Instrumentation 326M Series User manual

INSTRUCTION

MANUAL

OPERATION

&

SERVICE

326M

SERIES

SUCTION

APPARATUS,

SURGICAL,

AND

GASTROINTESTINAL

ABDOMINAL

DRAINAGE

PORTABLE,

AC/DC/RECHARGEABLE

BATTERY

CONTRACT

NO.

SPO200-98-D-8703

IMPACT

INSTRUMENTATION,

INC.

Rev.

G

(12/00)

Manual

P/N

906-0326-03

TABLE

OF

CONTENTS

SUBJECT

LIST

OF

ILLUSTRATIONS

SHIPPING

CONTENTS

ACCESSORIES

LIST

LIMITED

COPYRIGHT

RELEASE

CALIBRATION

NOTICE

UNPACKING

LOCATION

OF

USE

WARNINGS

REGARDING

USE

ASSEMBLY,

INTERCONNECTIONS

AND

INITIAL

ADJUSTMENTS

ASSEMBLY

INTERCONNECTIONS

INITIAL

ADJUSTMENTS

USAGE

APPLICATIONS

SECTION

I.

OPERATION

INTRODUCTION

OPERATION

DESCRIPTION

OF

CONTROLS,

CIRCUIT

BREAKER,

CONNECTORS

AND

INDICATORS

OPERATING

POWER

SELECTION

&

STOPPING

SUCTIONING

VACUUM

REGULATOR

(LIMITER)

COLLECTION

CANISTER

OPERATOR

PERFORMANCE

CHECKS

BATTERY

CARE

ROUTINE

CARE

AND

MAINTENANCE

CLEANING

Component

Removal

Exterior

Case

Collection

Canister

Hydrophobic/Bacterial/Overflow

Filter

MAINTENANCE

IN

CASE

OF

DIFFICULTY

OPERATOR

CORRECTIBLE

PROBLEMS

OPERATOR

PROBLEMS

REQUIRING

SERVICE

STORAGE

INFORMATION

PAGE

iii

vi

vi

vi

vi

vi

viii

1-1

1-1

1-1

2-1

3-1

4-1

5-1

TABLE

OF

CONTENTS

(CONT’D)

SUBJECT

LIMITED

WARRANTY

SPECIFICATIONS

SECTION

II

SERVICE

INTRODUCTION

CAUTIONARY

NOTES

OPERATING

VOLTAGES

PRECAUTION

INTERNAL

RECHARGEABLE

BATTERY

HELPFUL

HINTS

DISASSEMBLY/REASSEMBLY

BOTTOM

COVER

BATTERY

COMPARTMENT,

CLEAR

FRONT

COVER

&

TOP

COVER

SWITCHER

PRINTED

CIRCUIT

BOARD

REGULATOR

PRINTED

CIRCUIT

BOARD

MAIN

PRINTED

CIRCUIT

BOARD

CONNECTOR

PANEL

PUMP/MANIFOLD

FRONT

PANEL

CALIBRATION

PROCEDURE

REQUIRED

EQUIPMENT

PROCEDURES

CIRCUIT

DESCRIPTIONS

EXTERNAL

AC

POWER

SUPPLY

INTERNAL

POWER

SUPPLIES

DC

TO

DC

CONVERTER

6-VOLT

POWER

SUPPLY

5-VOLT

&

25.6-VOLT

POWER

SUPPLIES

ISOLATED

6-VOLT

POWER

SUPPLY

PUMP

CIRCUIT

SOLENOID

CIRCUITS

TIMING

CIRCUITS

BATTERY

CHARGER

CIRCUIT

BATTERY

LEVEL

MONITORING

CIRCUIT

PREVENTATIVE

MAINTENANCE

INSPECTIONS

VISUAL

CHECKS

PERFORMANCE

CHECKS

CLEANING

TROUBLESHOOTING

GUIDE

TECHNICAL

DOCUMENTATION

BLOCK

DIAGRAM

BILLS

OF

MATERIAL

WIRING

DIAGRAM

&

ELECTRICAL

SCHEMATICS

WIRE

LIST

IMPACT

INSTRUMENTATION,

INC.,

27

Fairfield

Place

West

Caldwell,

NJ

07006

aie

PAGE

5-1

6-1

7-1

7-1

10-1

12-1

13-1

LIST

OF

ILLUSTRATIONS

FIGURE

#

DESCRIPTION

PAGE

iN

Model

326/326M

Main

Features

iv

2-

Interconnection

Diagrams

vii

Suction

Apparatus

shown

with

hydrophobic/bacterial/overflow

filter

3

Panel

Controls,

Circuit

Breaker,

Connectors

and

Indicators

1-1

4.

Composite

Illustration

Depicting

Major

Sub-Assemblies

13-1

至

Bottom

Cover

Assembly

13-2

6.

Top

Cover

Assembly

13-3

Pã

Connector

Panel &

Battery

Pack

Assemblies

13-4

8.

Pump

&

Manifold

Assemblies

13-5

9.

Front

Panel

Assembly

13-6

10.

AC

Charger

Rectifier

Assembly

13-7

11.

Collection

Canister

&

Auto

Power

Cable

Assemblies

13-8

12.

Wire

Harness

Assembly

13-9

19.

Accessory

Kit-Air

Force

Assembly

13-10

14.

Accessory

Kit-Army

Assembly

13-11

15:

Switcher

Printed

Circuit

Board

Assembly

13-12

16.

Regulator

Printed

Circuit

Board

Assembly

13-13

17.

Main

Printed

Circuit

Board

Assembly

13-14

18.

Block

Diagram

13-15

Wiring

Diagram

&

Electrical

Schematics

(5

pages)

-

iii

-

13-37

thrul3-41

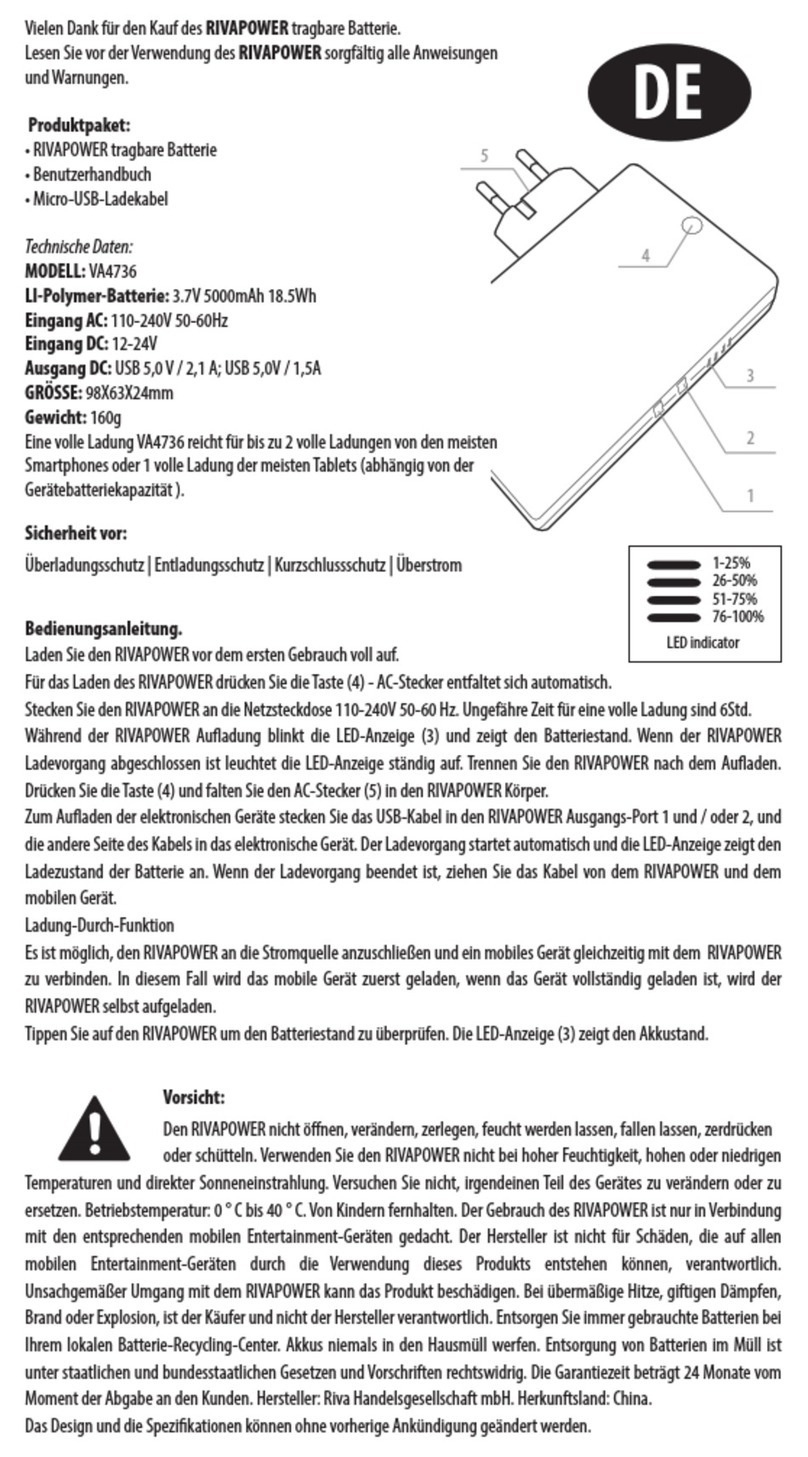

Injection

Molded

Case

Dual-Scale

Vacuum

Gauge

Carrying

Handle

Circuit

Breaker

Vacuum

Inlet

Fitting

External

Power

Input

Jack

a

a

TS

Va

c

| |

U

External

Power

Suction

Interval

n

Lamp

Timer

Controls

TT

lle

soma

Pal

TTT

로

E .

0

.

>

.

0

©

|

10

Di

„©

Battery

Charge

_|||1Il_

一

© ©

(+)

rel

.

개

BATTERY

CHARGE

MODE

M

i

o|

PS

Power

€

Mode

レレ

に

Selector

Switch

Charge

Lamp

<|

,

©

i

+

IMPACT

«

Collection

Canister

Mounting

Bracket

Vacuum

Regulator

VE

Collection

Canister

Mounting

Bracket

FIGURE

1

MODEL

326/326M

MAIN

FEATURES

df:

326MFIG1.CDR

(Rev

0,

04/97)

SHIPPING

CONTENTS

Each

Model

326

is

shipped

with

the

following

contents:

.

Apparatus,

Suction,

Portable

lea.

Hose,

Clear,

PVC,

1’

Long

Assembly, Auto

Power

Cable

lea.

Hose,

Clear,

PVC,

18"

Long

Suction

Hose,

Sterile,

Clear,

6’

Long

lea.

Hose,

Clear,

PVC,

2’

Long

.

AC/DC

Power

Supply

(115/230

VAC,

lea.

Universal

Canister

Attachment

Bracket

50/60/400

HZ

input;

nominal

lea.

Fuse,

Spare

12

VDC

output)

lea.

Instruction

Manual,

Operation

Each

Model

326M

is

shipped

with

the

following

contents:

lea.

Apparatus,

Suction,

Portable

The

following

are

provided

with

NSN

6515-01-435-0050

lea.

Assembly,

Auto

Power

Cable

lea.

Suction

Hose,

Sterile,

Clear,

6’

Long

2ea.

Collection

Canister

Assembly,

Autoclavable

2ea.

Fuse,

Spare

2ea.

Filter,

Disposable,

Hydrophobic/Bacterial/Overflow

lea.

AC/DC

Power

Supply

(115/230

VAC,

(for

use

with

reusable

canisters

only)

50/60/400

HZ

input;

nominal

lea.

Carry-all

Case

with

Label

12

VDC

output)

lea.

Hose,

Clear,

PVC,

1’

Long

The

following

are

provided

with

Air

Force

Accessory

Kit

2ea.

Hose,

Clear,

PVC,

18"

Long

2ea.

Hose,

Clear,

PVC,

2’

Long

2ea.

Disposable

Collection

Canister

&

Lid

2ea.

Universal

Canister

Attachment

Bracket

lea.

Catheter,

14

French

2ea.

Instruction

Manual,

Operation

&

Service

1ea.

Catheter,

18

French

lea.

Case,

Padded,

Aspirator

2ea.

Strap,

Velcro®

ACCESSORIES

LIST

The Accessories

List

contains

common

items,

required

from

time

to

time.

Each

item

is

preceeded

by

its

part

number.

Accessories

may

be

ordered

direct

from

Impact.

When

ordering,

please

include

the

part

number,

description

and

quan-

tity

required.

Send

written

purchase

orders

to:

Impact

Instrumentation,

Inc.

P.O.

Box

508

Telephone

orders:

973/882-1212

27

Fairfield

Place

FAX

orders:

973/882-4993

West

Caldwell,

New

Jersey

07006

PART

NUMBER

“DESCRIPTION

465-0005-00

Filter,

Disposable,

Hydrophobic/Bacterial/Overflow

540-0068-00

Hose,

Clear,

PVC,

1’

Long

540-0055-00

Hose,

Clear,

PVC,

18"

Long

540-0051-00

Hose,

Clear,

PVC,

2’

Long

703-0326-07

Assembly,

Collection

Jar

703-0326-06

AC/DC

Power

Supply

820-0018-00

Tubing,

Suction,

Sterile,

9/32"

LD. X

6”

906-0326-03

Instruction

Manual,

Operation

&

Service,

Model

326M

906-0326-01

Instruction

Manual,

Operation,

Model

326

906-0326-04

Instruction

Manual,

Operation

&

Service,

Model

326

LIMITED

COPYRIGHT

RELEASE

Permission

is

hereby

granted

to

the

Department

of

Defense

to

reproduce

all

material

furnished

under

this

contract

for

use

in

a

military

service

training

program

and

other

technical

training

programs.

CALIBRATION

NOTICE

_

This

device

should

be

incorporated

ito

a

regular

preventative

maintenance program

to

insure

compliance

with

operat-

ing

specifications.

Calibration

measurements

should

be

made

on

a

biannual

basis

unless

significant

usage

warrants

a

shorter

period

between

preventative

maintenance

inspections.

A

calibration

check

should

be

made

following

each

DER

of

300

hours

of

operation.

Recommended

maintenance

checks

can

be

found

in

the

SERVICE

section

οἱ

anual.

UNPACKING

Check

the

contents

of

the

shipping

case(s)

against

the

enclosed

packing

list.

Examine

the

instrument

for

any

obvious

signs

of

shipping

damage.

If

there

is

no

apparent

sign

of

mechanical

damage,

read

the

instructions

contained

within

this

manual

before

attempting

to

operate

the

instrument.

LOCATION

OF

USE

The

Model

326/326M

is

a

transportable

device,

therefore,

its

physical

area

of

use

will

vary.

When

operated

in

a

wet

en-

vironment,

a

should

take

precautions

and protect

this

device

by

covering

it

with

a

protective

barrier

(small

tarp, plas-

tic

sheet,

etc.).

WARNINGS

REGARDING

USE

Caution:

Federal

law

restricts

this

device

to

sale

by

or

on

the

order

of

a

physician.

This

equipment

is

intended

for

use

by

qualified

medical

personnel

or

person(s)

under

the

guidance

and

instruction

of

certified

medical

therapists.

Danger

-

Possible

explosion

hazard

if

used

in

the

presence

of

flammable

anesthetics.

Caution

-

Electric

shock

hazard,

do

not

remove

inside

cover.

Refer

servicing

to

qualified

biomedical

equipment

tech-

nicians

only.

See

section

entitled

SERVICE.

Do

not

operate

this

instrument

prior

to

reading

the

instructions

contained

within

this

manual.

Disposable

hydrophobic/bacterial/overflow

filter

is

for

use

only

with

reusable,

autoclavable,

collection

canisters.

Do

not

clean

collection

canister

with

abrasive

cleansers

or

(See

ROUTINE

CARE

AND

MAINTENANCE

section

CLEANING).

ASSEMBLY,

INTERCONNECTIONS

AND

INITIAL

ADJUSTMENTS

ASSEMBLY:

No

assembly

is

required

before

placing

this

device

into

operation.

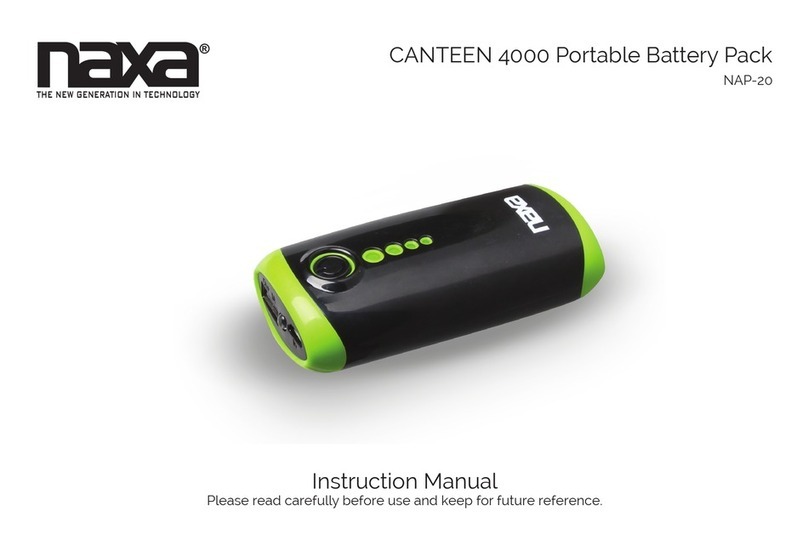

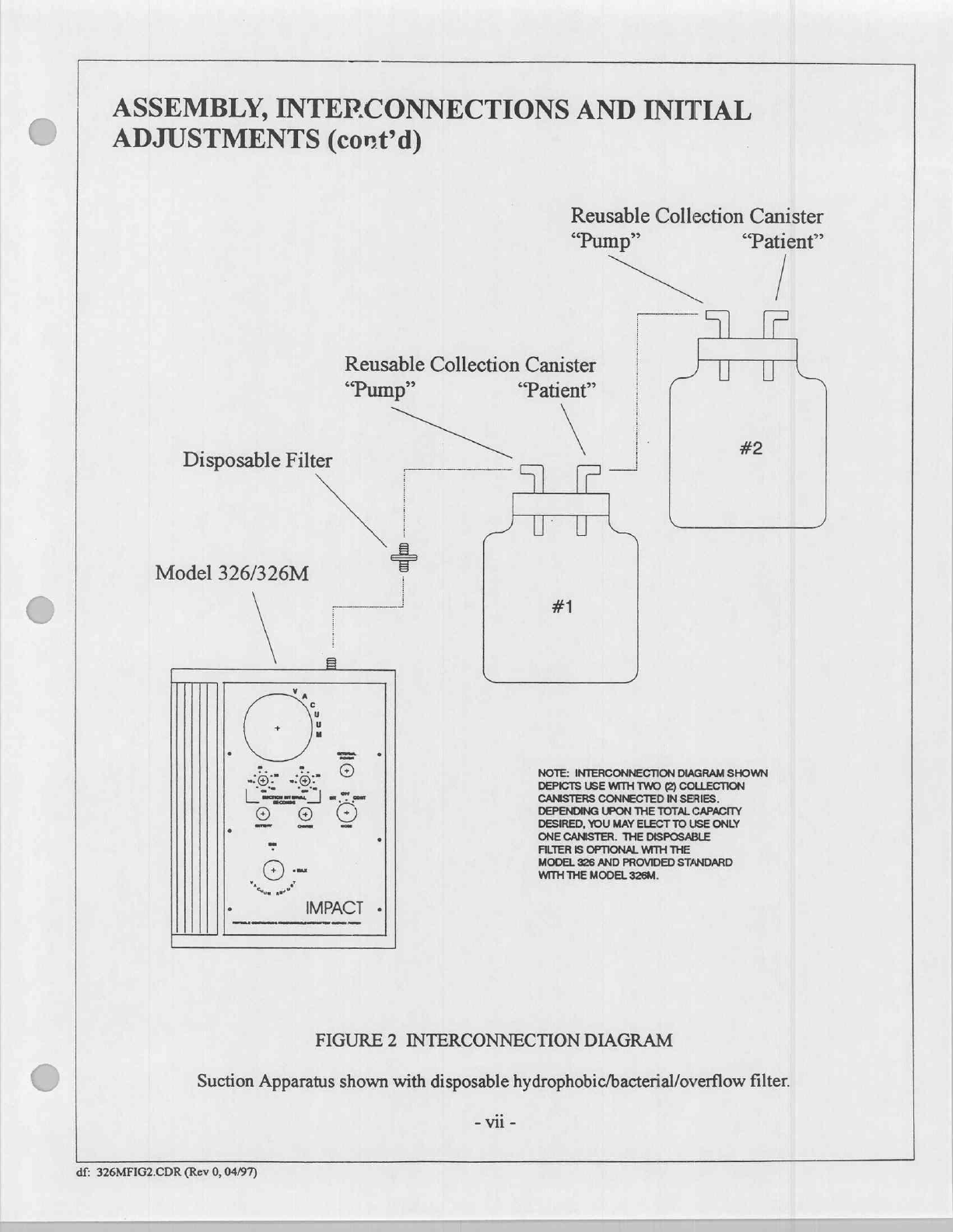

INTERCONNECTIONS:

Tubing

interconnections

are

required

before

placing

this

device

into

operation.

Figure

2

depicts

the

interconnections

required

to

connect

the

Model

326/326M

to

the

reusable

collection

canisters

(in

series)

and

disposable

hydrophobic/bacterial/overflow

filter.

INITIAL

ADJUSTMENTS:

Before

placing

this

device

into

operation

read

the

section

entitled

OPERATION,

|

DESCRIPTION

OF

CONTROLS,

CIRCUIT

BREAKER,

CONNECTORS

AND

INDICATORS.

Make

control

settings

and

verify

device

performance

prior

to

interfacing

with

patient.

i

ASSEMBLY,

INTERCONNECTIONS

AND

INITIAL

ADJUSTMENTS

(cont’d)

Reusable

Collection

Canister

“Pump”

Disposable

Filter

Model

326/326M

Reusable

Collection

Canister

“Pump”

πε

(l

im

“Patient”

AE

ML

#1

IMPACT

-

FILTER

IS

OPTIONAL

WITH

THE

WITH

THE

MODEL

326M.

FIGURE

2

INTERCONNECTION

DIAGRAM

“Patient”

|

U

U

#2

NOTE:

INTERCONNECTION

DIAGRAM

SHOWN

DEPICTS

USE

WITH

TWO

(2)

COLLECTION

CANISTERS

CONNECTED

IN

SERIES.

DEPENDING

UPON

THE

TOTAL

CAPACITY

DESIRED,

YOU MAY

ELECT

TO

USE

ONLY

ONE

CANISTER.

THE

DISPOSABLE

MODEL

326

AND

PROVIDED

STANDARD

Suction

Apparatus

shown

with

disposable

hydrophobic/bacterial/overflow

filter.

-

vii

-

df:

326MFIG2.CDR

(Rev

0,

04/97)

USAGE

APPLICATIONS

-

DEEP

DRAINAGE/GASTRO-INTESTINAL

SUCTION

IMPACT

MODELS

306/306M

AND

326/326M

PORTABLE

ASPIRATORS

Deep

drainage/gastro-intestinal

suction,

frequently

referred

to

as

Wangensteen

suction

(after

Dr.

Owen

H.

Wangensteen*),

requires

a

thorough

understanding

of

"mild

suction"

procedures

including

collection

bottle

placement

and

tubing

lengths.

The

following

data

is

for

reference

only

and

specific

applications

may

warrant

deviations

and/or

additional

considerations.

The

Impact

Models

306/306M

and

326/326M

are

capable

of

maintaining

precise

vacuum

and

airflow

levels.

ON/OFF

cycling

times

may

be

varied

from

patient

to

patient

effectively

optimizing

drainage

intervals.

Cycling

oe

are

ea

arbitrary.

It is

recommended

that the

user

select

intervals

consistent

with

past

practices

and

protocols.

The

gastro-intestinal

tract

represents

a

pliable

area

which

when

subjected

to

continuous

negative

pressure

will

collapse

around

an

implanted

drainage

tube.

Such

a

collapse

can

cause

continuous

suction

in

a

specific

tissue

area,

thus

preventing

additional

drainage

while

fluids

accumulate

and

potential

ulcerations

can

lead

to

perfora-

tions

and

hemorrhage

at

the

collapsed

site.

The

intended

action

of

intermitte

at

suction

is

to

provide

a

hydraulic

effect

whereby

drainage

fluids are

pulled

and

pushed

during

ON

and

OFF

cycles.

The

"pull"

effect

occurs

as

suction

is

applied

to

the

gastro-intestinal

tract,

thus

removing

accumulated

fluids.

The

"push"

effect

occurs

when

fluid

in

the

elevated

connecting

tubing

(18"

maximum

height)

flows

back

into

the

drainage

site,

washing"

the

implanted

catheter

away

from

the intes-

tinal

wall,

thus

relocating

it

in

time

for

the

next

ON

cycle.

It

is

important

to

note

that

the

height

of

the

collection

canister

and

placement

"dressing”

of

the

connecting

tubing

each

has

a

critical

effect on

overall

performance.

Under

normal

conditions,

vacuum

levels

of

90

mmHg

and

120

mmHg

would

raise

a

column

of

water

approximately

4’

and

5’

respectively.

It

is

possible

that

mild

suc-

tion,

involving

particulate

matter

(solids),

blood

clots,

and viscous

secretions

could

present

a

situation

whereby

the

delivered

suction

strength

can

only

raise

the

drained

contents

to

a

height

of

roughly

3’

to

4’.

To

compensate

for

this

effect,

the

user

is

cautioned

not

to

exceed

an

18"

height

between

collection

bottle

entry

point

and

the

dis-

tal

end

of

the

implanted

suction

catheter.

The

user

should

also

be

discouraged

from

using

excessive

lengths

of

connecting

tubing.

Since

mild

suction

consists

of

minimal

airflow,

excessive

tubing

lengths

could

prevent

fluid

from

actually

entering

the

collection

canister

prior

to

the

beginning

of

the

next

OFF

cycle.

The

actual

length

of

the

ON

cycle

can

be

extended

to

compensate

for

this,

however,

the

clinician

must

always

recognize

that

an

in-

creased

possibility

of

tissue

occlusion

exists.

The

hydraulic

action

previously

discussed

is

only

possible

when

the

collection

canister

is

at

a

height

greater

than

the

distal

end

of

the

implanted

catheter.

During

OFF

cycles,

the

Models

306/306M

and

326/326M

vent

to

atmospheric

pressure,

enabling

a

gravitational

backflow

to

occur.

If

the

collecting

jar

is

positioned

below

the

height

of

the

distal

end

of

the

implanted

catheter,

a

siphoning

effect

can

occur.

Siphoning

will

act

as

a

con-

tinuous

suction

presence

between

patient

and

collection

canister

which

is

undesireable.

Cycling

between

the

Models

306/306M

and

326/326M

and

collection

canister

will

continue

despite

siphoning.

Clinicians

may

have

visual

objections

to

the

appearance

of

drained

fluids

and

seek

options

regarding

collection

canister

placement.

The

factors

involving

the

time

cycles

(ON

and

OFF),

collection

canister

height

and

connecting

tubing

must

be

considered

in

order

to

have

safe,

effective

intermittent

suction.

*"INTESTINAL

OBSTRUCTIONS"

by

Owen

H.

Wangensteen,

M.D.,

C.C.

Thomas,

Publisher,

Springfield,

Illinois:

Chapter

VI.

df:

326USAGE.CHP

vio

SECTION

L

OPERATION

INTRODUCTION

The

Impact

Model

326/326M

is

a

self-contained,

multi-purpose,

suction

apparatus

designed

for

removing

secretions

from

the

upper

airway

during

oropharyngeal,

nasopharyngeal

and

tracheal

suctioning

procedures;

programmable

gastrointestinal

and

abdominal

wound

drainage;

or

surgical

site

debris

in

field

hospitals.

The

apparatus

includes

EMI/RFI

suppression

circuitry

and

is

suitable

for

use

in

desert,

tropic,

arctic

or

aeromedical

environments.

Simul-

taneous

operation

and

battery

recharge

is

permitted

from

either

115/230

VAC,

50-400

hz

using

the

provided

AC-DC

Power

Supply

or

12

VDC

using

the

provided

Auto

Power

Cable

accessories.

Simultaneous

operation

and/or

recharge

from

aircraft

electrical

systems

(24

to

28

VDC)

is

permissible

with

an

appropriate

cable.

The

Model

326/326M

is

designed

to

accept

DC

power

sources ranging

from

11 to

30

volts,

positive

or

negative

ground.

The

Model

326/326M

is

a

completely

self-contained

suction

source

complete

with

vacuum

pump,

controls

and

DC

power

supply

circuits;

a

dual-scale

vacuum

gauge

with

adjustable

vacuum

regulator

(limiter);

circuit

breaker,

collection

canister

mounting

brackets,

accessories

and

attachment

tubing

is

provided.

The

complete

device

is

housed

within

an

in-

jection

molded

case

which

includes

a

locking

battery

compartment

door,

a

locking

control

panel

door

(clear),

carrying

handle

and

mounting

interface

for

wall,

bulkhead,

pole

or

cart

mounting.

This

device

is

intended

for

use

in

non-explosive

atmospheres.

Read

the

instructions

contained

within

this

manual

before

attempting

to

operate

this

instrument.

OPERATION

DESCRIPTION

OF

CONTROLS,

CIRCUIT

BREAKER,

CONNECTORS

AND

IN-

DICATORS

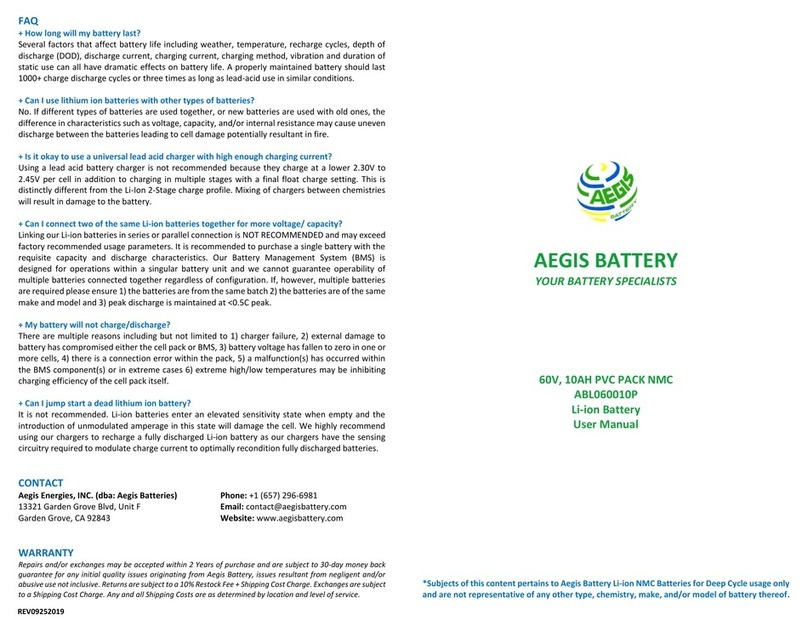

Refer

to

the

reference

pictorial

below.

Numbers

contained

within

this

text

(in

parenthesis)

correspond

to

the

numbers

indicated

in

the

pictorial.

(1)

Circuit

Breaker

(4)

(1) (2)

(3)

и

8

Z

(2)

Vacuum

Inlet

Fitting

(3)

External

Power

Input

Jack

с,

(4)

Dual-scale

Vacuum

Gauge

(5)

| A

し

(11)

(5)

"ON

TIME”

Suction

Interval

Control

a

[ῃ

ia

(6)

"OFF

TIME"

Suction

Interval

Control

a

(6)

(7)

Battery

Charge

Indicator

a

0)

|

jin

(9)

(8)

Charge

Lamp

T

O

cene

®

(9)

Power

&

Mode

Selector

Switch

i

=

IMPACT

-

(10)

Vacuum

Regulator

Control

ei

E

(11)

External

Power

Lamp

Figure

3.

Fanel

Controls,

Circuit

Breaker,

Connectors

and

Indicators

1-1

OPERATION

(cont'd)

DESCRIPTION

OF

CONTROLS,

CIRCUIT

BREAKER,

CONNECTORS

AND

IN-

DICATORS

(cont'd)

(1)

Circuit

Breaker

-

Protects

pump

motor

from

drawing

excessive

current.

(2)

Vacuum

Inlet

Fitting

-

Vacuum

source

connection

to

filter

and

collection

canister(s).

(3)

External

Power

Input

Jack

-

Connection

for

external

operating

and

battery

recharging

power.

Input

accomodates

11

to

30

VDC

input,

positive

or

negative

ground.

(4)

Dual-scale

Vacuum

Gauge

-

Displays

vacuum

developed

within

the

patient

circuit.

(5)

"ON

TIME"

Suction

Interval

Control

-

Setting

determines

how

long

intermittent

suction

will

last.

(6)

"OFF

TIME"

Suction

Interval

Control

-

Setting

determines

how

long

before

the

next

intermittent

cycle

begins.

(7)

Battery

Charge

Indicator

-

Displays

battery

charge

status.

Green

area

portrays

the

charged

zone,

the

red

area

portrays

the

discharged

zone.

(8)

Charge

Lamp

-

Indicates

the

presence

of

battery

charging

current

from

an

external

power

source.

(9)

Power

&

Mode

Selector

Switch

-

Turns

operating

power

Off

or

On

when

the

continuous

"CONT"

or

intermittent

"INT"

suction

mode

is

selected.

CONT

-

Selects

continuous

suctioning,

vacuum

adjustable

from

0

to

550

mmHg

INT

-

Selects

intermittent

suctioning,

vacuum

adjustable

from

0

to

200

mHg.

Time

interval

combinations

are

selectable

between

5

and

40

seconds

ON,

and

5

and

40

seconds

OFF.

(10)

Vacuum

Regulator

(Limiter)

Control

-

Limits

the

maximum

deliverable

vacuum

level.

(11)

External

Power

Lamp

-

Illuminates

when

connected

to

a

"live"

AC

mains.

OPERATING

POWER

SELECTION

&

STOPPING

The

Model

326/326M

is

designed

to

operate

from

external

power

or

internal

rechargeable

batteries.

The

Power

&

Mode

Selector

Switch

(9)

acts

as

a

master

power

switch

to

start

and

stop

operation.

SUCTIONING

1.

Insure

that

all

suction

tubing

is

properly

secured

to

respective

fittings.

Verify

that

collection

canister

lids

are

proper-

ly

secured,

fittings

in

place

as

shown

(Figure

2),

and

no

kinks

in

connecting

tubing.

2.

Charge

Lamp

(8) will

illuminate

during

operation

if

external

operating

power

is

applied.

3.

Turn

Power

&

Mode

Selector

Switch

(9)

to

the

appropriate

position:

CONTinuous

or

INTermittent.

The

internal

vacuum

pump

should

begin

operation.

4.

Adjust

Vacuum

Regulator

(Limiter)

Control

(10)

to

the

maximum

desired

vacuum

level

by

"pinching"

and

holding

the

vacuum

tubing

going

to

the

collection

canister.

Deliverable

vacuum

levels

will

not

exceed

the

preset

maximum

level.

Adjusted

and

delivered

vacuum

levels

are

displayed

on

the

Dual-scale

Vacuum

Gauge

(4).

1-2

OPERATION,

(cont’d)

SUCTIONING,

(cont'd)

5.

A

disposable

hydrophobic/bacterial/overflow

filter

is

provided

for

use

with

Impact’s

standard

autoclavable

collec-

tion

canisters.

This

filter

connects

between

the

Vacuum

Inlet

Fitting

(2)

and

collection

canister

(Figure

2).

This

filter

should

be

replaced

when

discoloration

of

its

membrane

occurs,

the

membrane

contacts

aspirate,

or

following

150

cumulative

hours

of

use.

This

filter

is

designed

to

retain

bacteria

which

would

otherwise

be

exhausted

into

the

im-

mediate

vicinity.

The

filter’s

retention

of

aerosolized

aspirate

and

will

create

more

resistance

to

airflow

resistance.

It is

important

that

the

operator

be

aware

of this

and

replace

the

filter

accordingly.

6.

Disposable

collection

canisters,

traditionally

include

a

built-in

filter

and

may

be

used

with

your

Model

326/326M.

It

is

not

necessary

to

use

the

disposable

filter

in

conjunction

with

disposable

canisters.

7.

Reusable

canisters

should

be

used

with

the

disposable

filter

to

prevent

inadvertent

overflow,

damage

or

contamina-

tion

of

the

pump

mechanism.

VACUUM

REGULATOR

(LIMITER)

The

Vacuum

Regulator

(Limiter)

(10)

works

in

conjunction

with

the

Vacuum

Gauge

(4).

Vacuum

levels

may

be

selected

by

rotating

the

Vacuum

Regulator

(Limiter)

(10):

clockwise

to

increase

vacuum;

counterclockwise

to

decrease

vacuum.

Vacuum

regulator

adjustments

should

be

made

to

the

maximum

desired

vacuum

level

by

"pinching"

and

hold-

ing

the

vacuum

tubing

going

to

the

patient.

Deliverable

vacuum

levels

will

not

exceed

this

preset

maximum.

Adjusted

and

delivered

vacuum

levels

will

continuously

display

during

operation

on

the

dual-scale

Vacuum

Gauge

(4).

COLLECTION

CANISTER

Protect

the

suction

mechanism

from

overflows

which

may

permanently

damage

the

vacuum

pump

if

not

properly

and

promptly

cleaned.

Use

the

disposable

filter

in

conjunction

with

reusable

collection

canisters.

Collection

canisters

may

be

repeatedly

sterilized

via

autoclave,

ethylene

dioxide

gas

or

cold

liquid

sterilants

(diluted

in

accordance

with

their

respective

instructions).

DO

NOT

use

abrasive

cleansing

agents.

To

determine

compatibility

with

commercially

available

cleanser/disinfectants

please

note

the

following

material

content:

Collection

Canister

Bottle:

Polysulfone/Polycarbonate

Collection

Canister

Cap:

EPDM

Hose

Fittings:

Stainless

Steel

OPERATOR

PERFORMANCE

CHECKS

Before

placing

this

device

into

service,

the

operator

can

perform

various

checks

to

insure

proper

device

performance.

1.

Verify

operating

power

selections

from

external

power

sources

or

internal

rechargeable

batteries.

2.

Verify

continuous

operation,

verify

intermittent

operation.

3.

Test

the

Vacuum

Regulator

Limiter

(10)

for

correct

operation

at

various

vacuum

settings.

4,

Insure

that

all

hoses

and

fittings

¿re

properly

connected.

1-3

BATTERY

CARE

The

Model

326/326M

utilizes

sealed

G=L

cell

batteries

which

offer

excellent

charge

retention

characteristics,

par-

ticularly

during

long

periods

of

storage.

This

ensures

an

ample

amount

of

power

during

emergencies

and

transitory

pro-

cedures.

The

battery

pack

in

this

device

is

not

intended

for

use

as

the

primary

power

source,

therefore,

it

should

be

used

with

discretion

and

its

design

understood.

To

provide

long

life

and

maximum

performance

capabilities,

the

Model

326/326M

requires

16-hours

to

fully

recharge

its

fully

discharged

batteries.

Of

course,

the

batteries

are

rarely

discharged

this

much

so

the

subsequent

recharge

time

is

usually

less.

GEL

Cell

batteries

require

little

user

care

to

provide

optimum

performance

and

life

expectancy.

Because

their

self-discharge

rate

is

extremely

low

(approximately

1

1/2%

per

month),

lengthy

periods

of

disuse

without

replenishment

charging

is

possible.

If

long-term

disuse

is

common,

it

would

be

advise-

able

to

recharge

the

unit

once

every

two

months.

This

will

insure

that

battery

charge

is

maintained

at

80%

capacity

or

better.

Continuous

battery

recharging

from

the

AC

mains

is

permissible

but not

required.

Recharging

from

115

or

230

VAC

is

accomplished

using

the

AC/DC

Power

Supply

accessory

supplied

with

the

Model

326/326M.

Batteries

can

be

recharged

from

an

external

12VDC

power

source

too.

For external

12VDC

operation

or

recharge,

a

connecting

cable

with

automotive

plug

is

furnished.

The

External

Power

Input

Jack

(3)

is

located

on

the

connector

panel

adjacent

to

the

Vacuum

Inlet

Fitting

(2).

The

External

Power

Input

Jack

(3)

will

accept

voltages

ranging

between

11

and

30

VDC

for

device

operation

and/or

battery

recharging.

An

appropriate

cable,

to

interface

between

the

External

Power

Input

Jack

(3)

and

the

power

source

is

required.

The

life

of

these batteries

depends,

to

a

great

extent,

upon

the

care

they

receive.

Following

these

simple

guidelines

will

prevent

premature

charge

depletion

and

reduction

of

battery

life.

1.

DO

NOT

operate

this

instrument

where

the

temperature

range

exceeds

-60‘C

to

60‘C

(-76F

to

140‘F).

2.

DO

NOT

charge

this

instrument

where

the

temperature

range

exceeds

-20'C

to

50‘C

(-4‘F

to

122F).

3.

DO

NOT

store

this

instrument

with

the

batteries

discharged.

Always

store

in

a

charged

condition.

4.

For

long-term

storage,

the

optimum

storage

temperature

range

is

10°C

to

30°C

(50'F

to

80“F).

ROUTINE

CARE

AND

MAINTENANCE

CLEANING

Note:

Routine

decontaminations

which

do

not

involve

the

removal

of

aspirate

can

be

effected

using

a

spray

disinfec-

tant.

With

the

device

operating,

simply

spray

a

small

amount

of

disinfectant

directly

into

the

collection

canister

and

shortly

thereafter

into

the

Vacuum

Inlet

Fitting

(2).

This

should

be

performed

after

each

use

to

avoid

risk

of

bacterial

growth.

In

the

event

of

an

aspirate

overflow,

remove

the

pump

head

assembly

(SECTION

IL.

SERVICE,

DISASSEMB-

LY/REASSEMBLY).

All

pump

head

components

may

be

sterilized

using

a

liquid

disinfectant,

a

mild

spray

disinfectant

or

ethylene

oxide

gas.

DISCONNECT

AC/DC

POWER

SUPPLY

OR

AUTO

POWER

CABLE

FROM

MODEL

326/326M

PRIOR

TO

CLEANING.

©

Component

Removal

The

collection

canister(s)

and

filter

should

be

detached

to

facilitate

cleaning.

e

Exterior

Case

Periodically

or

when

applicable,

clean

the

exterior

case

using

a

mild,

non-

abrasive

cleanser.

Disconnect

Remove

col-

lection

canister(s)

and

filter.

DO

NOT

immerse

or

allow

liquids

to

enter

the

case.

A

damp

cloth

will

suffice

in

most

in-

stances.

Disinfectant

spraying

is

recommended

at

regular

intervals.

Allow

to

dry.

e

Collection

Canister

Impact’s

reusable

collection

canisters

may

be

repeatedly

sterilized

via

autoclave,

ethylene

oxide

gas

or

cold

liquid

sterilants

(diluted

in

accordance

with

their

respective

instructions).

Do

not use

abrasive

cleansing

agents.

To

determine

compatibility

with

commercially

available

cleanser/disinfectants

please

note

the

following

material

content:

Collection

Canister

Bottle:

Polysulfone/Polycarbonate

Collection

Canister

Cap:

EPDM

Hose

Fittings:

Stainless

steel

1.

Thoroughly

clean

collection

canister(s),

and

fittings

after

each

use.

Handy

hint:

Before

emptying

collection

canister,

cap

both

hose

fittings

with

a

short

length

of

tubing.

This

will

prevent

accidental

spillage

of

aspirate.

2.

Tubing

is

considered

disposable

and

should

be

discarded

following

each

use.

3.

Insure

that

all

parts

are

securely

fastened

and

properly

connected

after

cleaning.

4.

Orient

collection

canister

and

route

tubing

as

shown

in

Figure

2

following

cleaning.

5.

To

prevent

risk

of

cross

contamination

and

the

spread

of

airborne

particulate

matter,

the

use

of

bacterial

filters

is

recommended.

If

filters

are not

used,

this

device

should

be

disinfected

and

cleaned,

following

each

use,

as

described

ear-

lier

within

this

section.

Disposable

filters

connect

between

the

collection

canister

and

Vacuum

Inlet

Fitting

(2).

The

filter

contains

a

hose

barb

at

each

end

to

facilitate

quick

connections

to

the

collection

canister

and

Vacuum

Inlet

Fitting

(2).

6.

Disposable

filters

may

be

obtained

from

Impact.

When

ordering,

specify

Impact

part

number

465-0005-00.

Filters

may

be

used

repeatedly

until

discolored

or

contact

with

aspirate

and/or

fluids

occurs.

As

filters

become

occluded

with

particulate

matter

during

repeated

usages,

a

reduction

in

device

airflow

will

become

evident.

Filter

replacement

will

re-

store

the

device

to

its

original

airflow

levels.

ROUTINE

CARE

AND

MAINTENANCE

(cont’d)

e

Bacterial/Overflow

Filter

Do

not

attempt

to

clean

disposable

bacterial/overflow

filters.

This

item

is

disposable

and

should

be

replaced

whenever

it

becomes

discolored

or

contacts

aspirate,

airflow

is

impeded,

or

following

150

cumulative

hours

of

use,

whichever

comes

first.

Do

not

bypass

this

filter.

Its

intended

use

is

to

retain

bacteria

which

would

be

expelled

through

the

exhaust

port

or

al-

lowed

to

accumulate

in

the

pump

head

_

As

filters

become

occluded

with

particulate

matter during

repeated

usages,

a

reduction

in

device

airflow

will

become

evident.

Filter

replacement

will

restore

device

performance

to

its

normal

airflow

levels.

MAINTENANCE

Routine

maintenance

should

be

performed

on

this

apparatus

at

regular

intervals

and

prior

to

its

being

placed

into

ser-

vice.

Routine

maintenance

should

consist

of

the

following:

1.

Cleaning

checks

-

as

described

above.

2.

Filter

checks

-

replace

when

discolored,

contact

with

aspirate

occurs, airflow

performance

diminishes

considerably

or

following

150

hours

of

cumulative

nse.

3.

Operational

checks

-

as

described

in

OPERATOR

PERFORMANCE

CHECKS.

4.

Tubing

checks

-

replace

crimped, cracked

or

worn

tubing

as

required.

3-2

IN

CASE

OF

DIFFICULTY

Authorization

to

service

this

instrument

by

other

than

factory-trained

or

certified

personnel

will

not

be

given,

nor

does

Impact

Instrumentation,

Inc.

assume

any

responsibility

and/or

liability

resulting

from

such

unauthorized

servicing.

Impact

will,

upon

request,

provide

competent

biomedical

engineering

departments

with

service

data

and schematics.

Such

departments

are

encouraged

to

contact

the

factory

for

assistance

when

needed

and

it

is

recommended

that

staff

members

attend

a

factory

training

course. Details

may

be

obtained

by

contacting

the

Impact

Customer

Service

Depart-

ment.

OPERATOR

CORRECTIBLE

PROBLEMS

Common

problems

may

be

quickly

rectified

by

users.

Should

the

Model

326/326M

fail

to

operate

properly,

verify

the

integrity

of

all

tube

connections,

tubing,

fittings,

and

control

settings.

One

can

quickly

isolate

problems

to

an

accessory

item

or

the

suction

apparatus

by

testing

for

vacuum

at

various

locations.

To

isolate

a

problem,

check

for

vacuum

at

the

inlet of

each

item,

tracing

backwards

through

the

system,

i.e.:

vacuum

from

the

collection

canister

to

the

to

the

Vacuum

Inlet

Fitting;

or

if

a

filter

is

used:

vacuum

from

the

collection

canister

to

the

filter,

then

vacuum

from

the

filter

to

the

Vacuum

Inlet

Fitting.

OPERATOR

PROBLEMS

REQUIRING

SERVICE

If

the

tests

described

above

do

not

resolve

an

operating

problem,

service

is

required.

Should

servicing

be

necessary,

contact

your

nearest

Impact

representative

or

the

Impact

Customer

Service

Department

(973)

882-1212.

Please

have

the

Model

and

Serial

Numbers

ready

and

any other

pertinent

data

you

wish

to

include

in

your

service

re-

quest.

The

Model

326/326M

Serial

Number

is

located

on

the

outer

case

identification

label.

STORAGE

INFORMATION

For

prolonged

storage

periods,

the

Model

326/326M

should

be

stored

indoors.

The

environment

should

be

clean,

and

pui

of

direct

sunlight.

Storage

temperatures

should

range

between

5‘F

and

104‘F (-15°C

to

40°C),

humidity

should

be

low.

When

batteries

are

in

extended

storage,

it

is

recommended

that

they

receive

a

refresh

charge

at

recommended

inter-

STORAGE

AMBIENT

-RECHARGE

INTERVAL

Below

68'F (20'C)

18

months

68“

to

86F

(20º

to

30'C)

12

months

86°

го

104

(30º

to

40'C)

6

months

Following

periods

of

extended

storage

in

non-controlled

environments,

allow

the

Model

326/326M

sufficient

time

to

stabilize

to

a

temperature

within

its

specified

operating

range

(see

BATTERY

CARE).

LIMITED

WARRANTY

Impact

Instrumentation,

Inc.

warrants

this

instrument

to

be

free

from

all

defects

in

materials

and

workmanship

for

a

period

of

one

(1)

year.

Batteries,

which

by

their

nature

are

consumable

and

subjected

to

environmental

extremes,

will

be

warranted

only

for

defects

of

manufacturing

origin

for

a

period

of

ninety

(90)

days.

Disposable

accessories,

con-

sumable

in

usage,

will

be

warranted

only

for

defects

of

manufacturing

origin

prior

to

their

initial

use.

This

warranty

is

neither

assignable

nor

transferable,

no;

does

it

apply

if

this

instrument

is

tampered

with,

misused

or

serviced

by

un-

authorized

personnel.

All

warranty

repairs

shall

be

subject

to

return

postage

billing.

SPECIFICATIONS

VACUUM

RANGE

(Continuous):

(Intermittent):

FREE

AIRFLOW:

0-550

mm/Hg

(0-22

inches/mercury)

0-200

mmHg

(0-8

inches/mercury)

30

Liters

Per

Minute

(LPM)

TEMPERATURE

OPERATING

RANGE:

-20°C

to

49°C

(-4°F

to

120°F)

CONTROLS:

DISPLAYS:

CONNECTORS:

PUMP

PROTECTION:

POWER:

External:

115/230

VAC,

50-400

Hz:

12

VDC:

11-30

VDC:

Internal:

Battery

Pack,

12

VDC:

Recharge

Time:

COLLECTION

CAPACITY:

WARRANTY:

CASE:

Material:

Size:

Weight:

Power

&

Mode

Selector

Switch

(Power

OFF/CONTinuous/INTermittent

Vacuum

Regulator

(Limiter)

"ON

TIME"

Suction

Interval

Control

(5-40

seconds,

continuously

variable)

"OFF

TIME"

Suction

Interval

Control

(5-40

seconds,

continuously

variable)

Power

Source

Select

Switch

(115/230

VAC,

located

on

AC/DC

Power

Supply)

Charge

Indicator

Lamp

External

Power

Lamp

Battery

Charge

Indicator

(Meter)

Vacuum

Gauge,

Dual-Scale

(Metric/English),

2

1/2"

diameter.

Vacuum

Inlet

Fitting

External

Power

Input

Jack

Circuit

Breaker

Continuous

operation

and/or

recharge

with

supplied

AC/DC

Power

Supply

Continuous

operation

and/or

recharge

with

supplied

Auto

Power

Cable

Continuous

operation

and/or

recharge

(cable

not

supplied)

Operating

Time,

2-hours

(minimum,

when

cycled

as

specified)

16-hours

(maximum)

1200

ml

X

2

(Air

Force)

1100

ml

X

2

(Model

326M

NSN:

6515-01-435-0050

only)

One

(1)

year,

limited,

as

specified

Polycarbonate,

color-through,

injection-molded

24.1

cm

W

x

29.2

cm

H

x

12.4cm

D

(9.5"

W x

11.5"

Hx

4.87"

D)

5.5

kg

(12

Ibs)

SPECIFICATIONS,

(cont’d)

MODEL

326

(Included

Accessories):

lea.

Apparatus,

Suction,

Portable

lea.

Assembly,

Auto

Power

Cable,

6°

Long

lea.

Suction

Hose,

Sterile,

Clear,

6’

Long

lea.

Hose,

Clear,

PVC,

1’

Long

lea.

Hose,

Clear,

PVC,

18"

Long

lea.

Hose,

Clear,

PVC,

2’

Long

lea.

Universal

Canister

Attachment

Bracket

lea.

Fuse,

Spare

lea.

AC/DC

Power

Supply

lea.

Padded

Case,

Aspirator

lea.

Instruction

Manual,

Operation

MODEL

326M

(Included

Accessories):

lea.

Apparatus,

Suction,

Portable

lea.

Assembly,

Auto

Power

Cable,

6’

Long

lea.

Suction

Hose,

Sterile,

Clear,

6’

Long

2

ea.

Fuse,

Spare

lea.

AC/DC

Power

Supply

lea.

Hose,

Clear,

PVC,

1’

Long

2

ea.

Hose,

Clear,

PVC,

18"

Long

2ea.

Hose,

Clear,

PVC,

2’

Long

2ea.

Universal

Canister

Attachment

Bracket

lea.

Padded

Case,

Aspirator

2

ea.

Strap,

Velcro®

2

ea.

Instruction

Manual,

Operation

&

Service

The

following

are

provided

with

NSN

6515-01-435-0050

2

ea.

Collection

Canister

Assembly,

Autoclavable

2ea.

Filter,

Disposable,

Hydrophobic/Bacterial/Overflow

lea.

Carry-all

Case

with

Label

The

following

are

provided

with

Air

Force

Accessory

Kit

2ea.

Disposable

Collection

Canister

and

Lid

lea.

Catheter,

14

French

lea.

Catheter,

18

French

SPECIFICATIONS

CONTAINED

HEREIN

REPRESENT

TYPICAL

DEVICE

PERFORMANCE

6-2

SECTION

IL

SERVICE

INTRODUCTION

The

information

contained

herein

is

intended

only

for

use

by

factory-trained,

and

certified

personnel

or

military

per-

sonnel

trained

in

the

care

and

servicing

of

this

product.

The

manufacturer

does

not

authorize

or

assume

any

obligations

resulting

from

unauthorized

servicing

nor

will

it

be

held

liable

for

any

injuries

or

damages

incurred

therefrom.

Impact

Instrumentation

will

provide

service

training

at

the

manufacturing

site

at

no

schooling charge

to

users;

however,

travel

and

meal

costs

resulting

therefrom

shall

be

borne

by

the

user.

Impact

will

perform

training

at

the

customer’s

site

if

requested.

The

customer

will

be

responsible

for

costs

incurred

by

Impact

personnel

for

travel,

meal,

and

time

-

at

prevailing

rates.

The

Impact

service

facility

encourages

dialogue

from

user

service

personnel

towards

rectifying

any

service

related

mat-

ter.

All

service

requests

may

be

addressed

to

the

Service

Manager,

Impact

Instrumentation,

Inc.,

27

Fairfield

Place,

West

Caldwell,

New

Jersey 07006;

via

telephone

973/882-1212;

or

fax

973/882-4993.

CAUTIONARY

NOTES

OPERATING

VOLTAGES

PRECAUTION

Prior

to

servicing

this

device,

be

aware

of

the

presence

of

potentially

dangerous

operating

voltages.

INTERNAL

RECHARGEABLE

BATTERY

Military

contracts

may

require

this

product

to

be

shipped

with

its

battery

pack

contained

within

a

separate

carton.

Prior

to

placing

this

device

into

operation,

insure

that

its

battery

pack

is

installed

and

recharged.

DO

NOT

operate

this

unit

until

its

battery

pack

is

installed.

HELPFUL

HINTS

Before

attempting

to

repair/calibrate

this

instrument,

please

take

a

few

moments

to

insure

that

the

problem

is

not

ac-

cessory

related.

Check

the

integrity

of

all

vacuum

hoses

and

tubing.

Verify

that

the

tubing

has

no

crimps

or

cuts

in

it.

Insure

that

collection

canisters

seal

properly,

overflow

shut-off

valves

do

not

stick,

and

bacterial

filters

(if

used)

are

not

clogged.

Refer

to

the

enclosed

schematic,

assembly

drawing,

and

pictorials

when

electrically

troubleshooting.

Isolate

each

problem

to

a

functional

segment

of

the

circuitry.

Verify

the

integrity

of

circuit

ground

and

the

presence

of

correct

power

supply

voltages.

ALWAYS

safeguard

your

personal

well

being

when

troubleshooting

electronic

circuitry.

Remove

jewelry,

such

as

rings

and

bracelets,

and

keep

liquids

away

from

the

vicinity

of

live

circuitry.

Table of contents

Other Impact Instrumentation Batteries Pack manuals