Impact Pumps SolarPlex SPX-800-5 Setup guide

Other Impact Pumps Water Pump manuals

Popular Water Pump manuals by other brands

Davey Water Products

Davey Water Products TotalFlo TF180S Installation and operating instructions

SHURflo

SHURflo R30GN operating instructions

Draper

Draper SWP220A Instructions for use

SOLIDSVAC

SOLIDSVAC SV800-CAROUSEL Operation manual

MagnaFuel

MagnaFuel PRO STAR 500 Series Installation and operating instructions

SprayTECH

SprayTECH GPX 1250 owner's manual

Beckett

Beckett Fountain Pump M250AUL16 Specifications

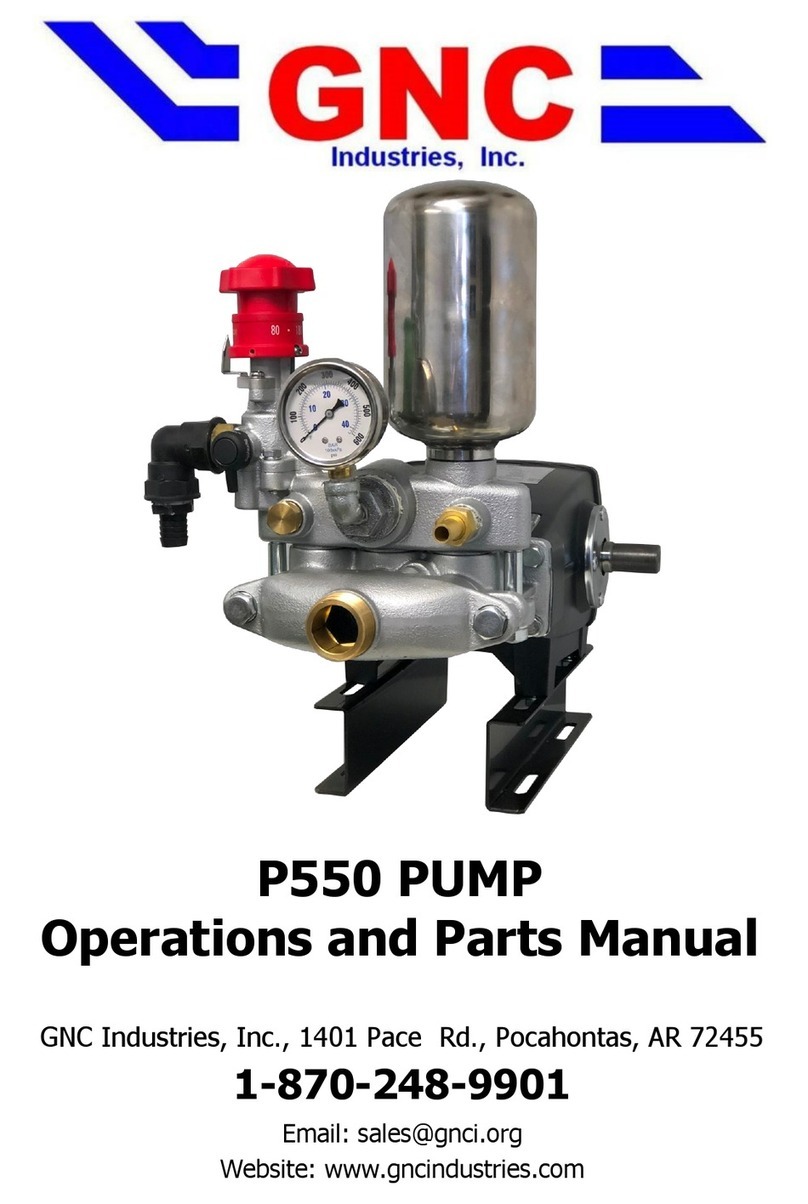

GNC

GNC P550 Operation and parts manual

Elmo Rietschle

Elmo Rietschle F-CEVF Series operating instructions

Grundfos

Grundfos SCALA1 Installation and operating instructions

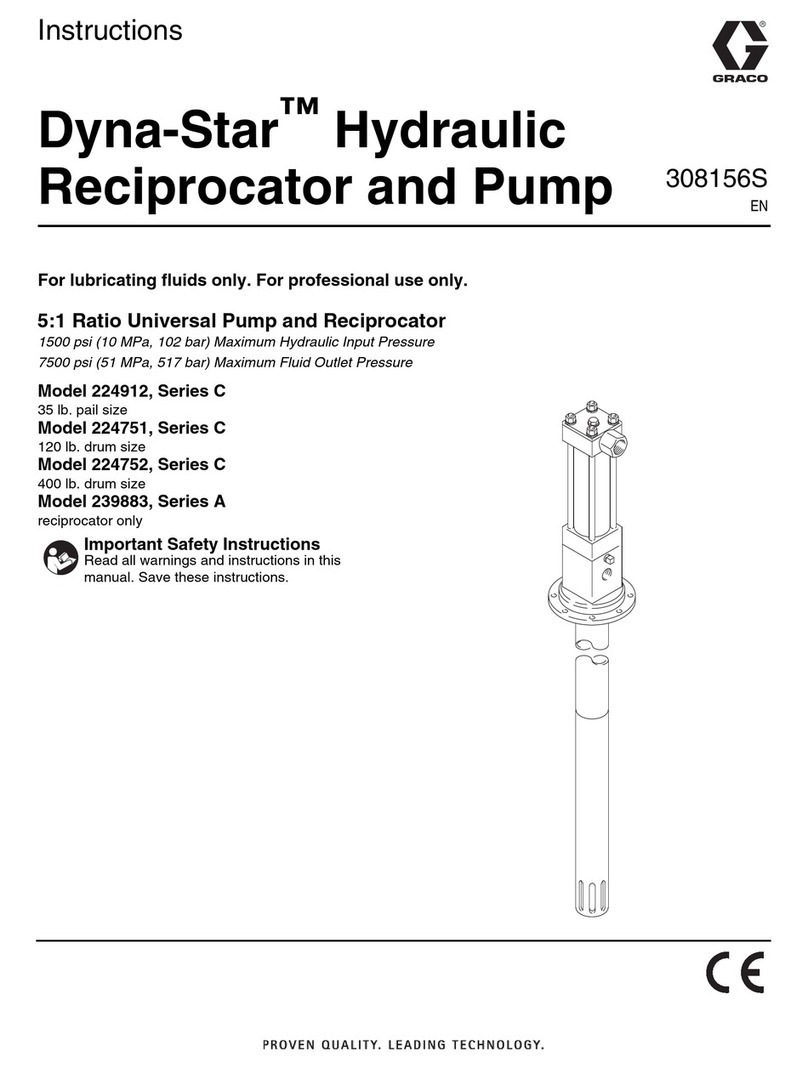

Graco

Graco Dyna-Star 224912 instructions

Equalizer

Equalizer HP350SD Operator's instruction manual

Zoeller

Zoeller AqyaNot 508 Active installation instructions

Etatron

Etatron eSelect M 1 CI Operating instructions and maintenance

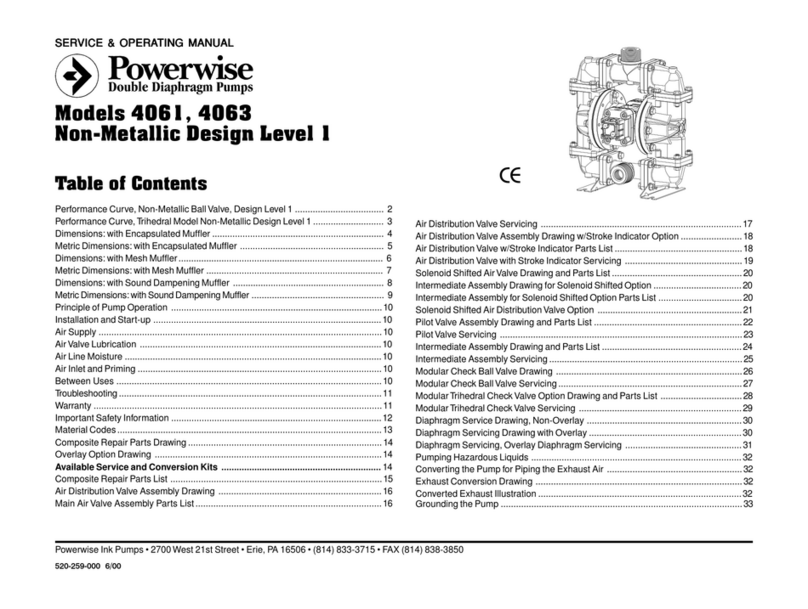

PowerWise

PowerWise 4061 Service & operating manual

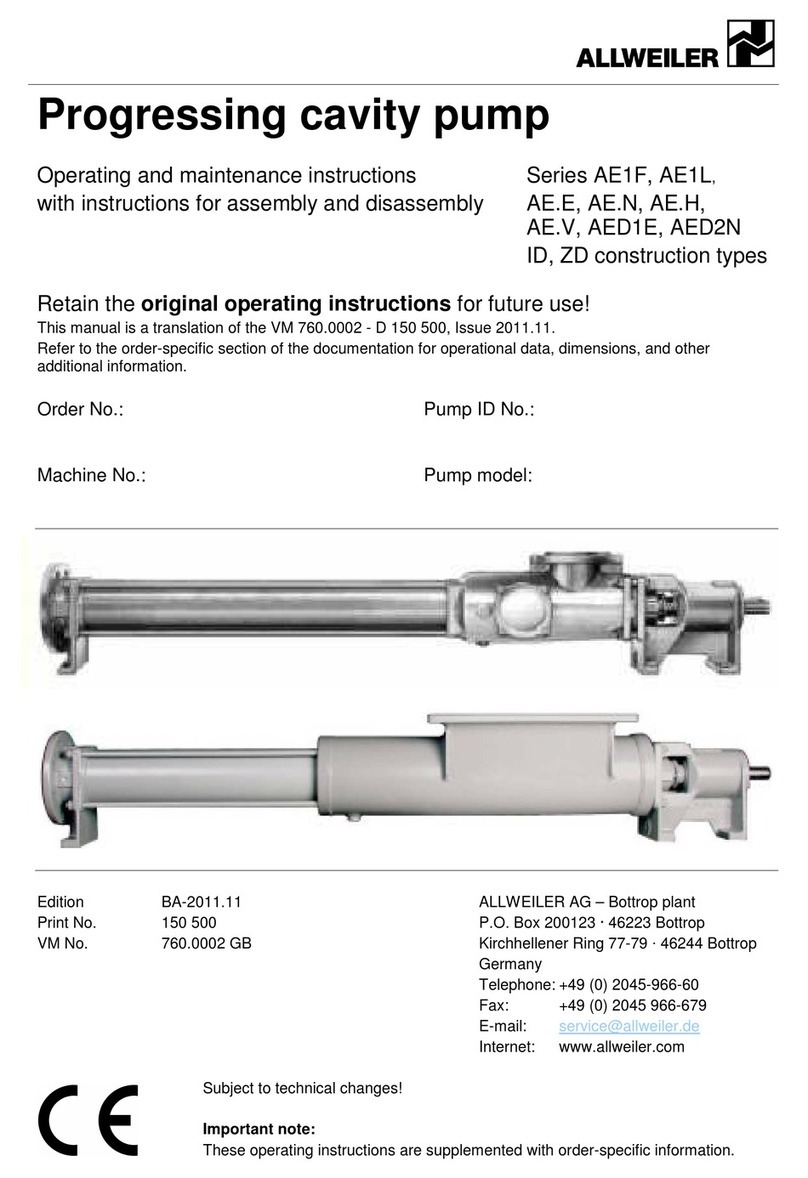

Allweiler

Allweiler AE1F Series Operating and maintenance instructions with instructions for assembly and disassembly

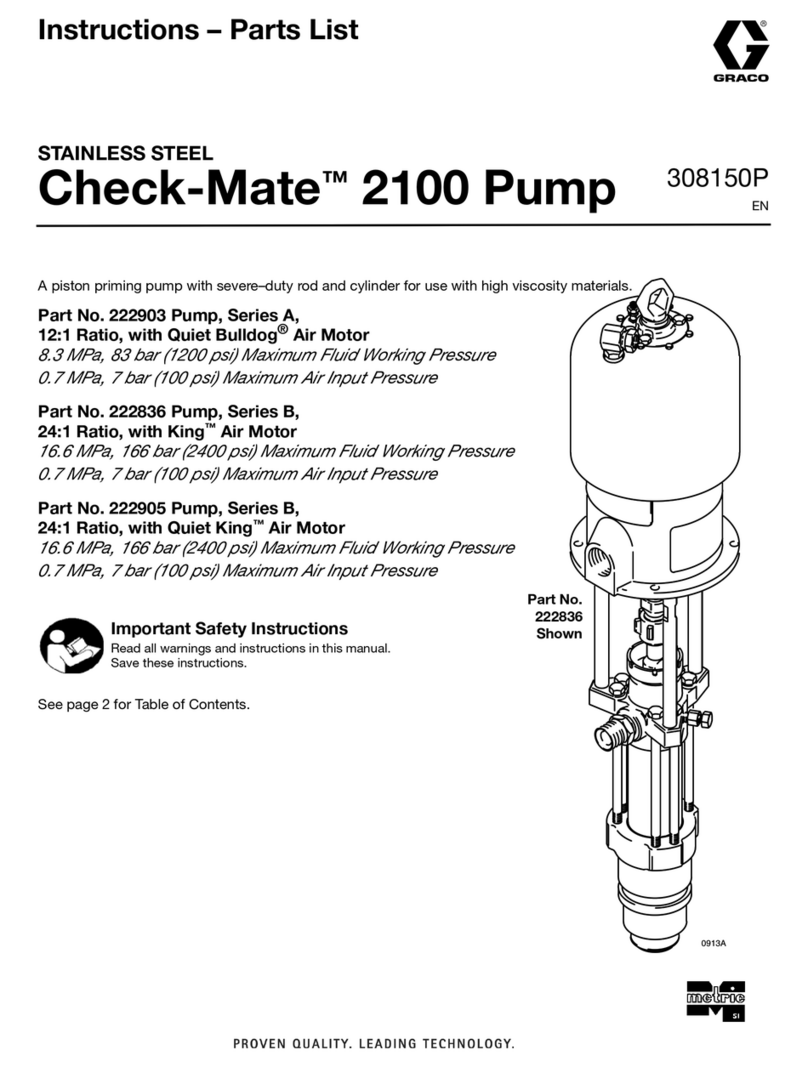

Graco

Graco Check-Mate 2100 Instructions-parts list

SPIDO

SPIDO PC 300 instruction manual