7

SHURflo Operating Instructions, Performance,

Specifications and Parts Manual

Models R30GN, R50GN and R102N

Form L-4095 (12/09)

Check motor.

It may be equipped

with an automatic resetting thermal

protector and may restart unexpectedly

(see specifications chart). Protector tripping

is an indication of motor overloading as a

result of operating the pump at too high a

pressure (over 25 PSI or 60 feet of head), too

high of viscosity, too high of specific gravity,

excessively high or low voltage, inadequate

wiring, incorrect motor connections, too

small a motor (sized incorrectly, not enough

HP), or a defective motor or pump.

Do not handle pump with wet hands or

when standing in water. Failure to follow the

General Safety Information and all warnings

could result in fatal electrical shock!

Installation

IMPORTANT: In any installations where

property damage and/or personal

injury can occur when the pump is

not operating due to power outages,

discharge line freezing, or any other

reason, a back-up system(s) and/or

warning system(s) should be used.

In order to safely use this product,

familiarize yourself with this pump and

also with the liquid (chemical, etc.)

that is going to be pumped through

the unit. This pump is not suitable for

many liquids.

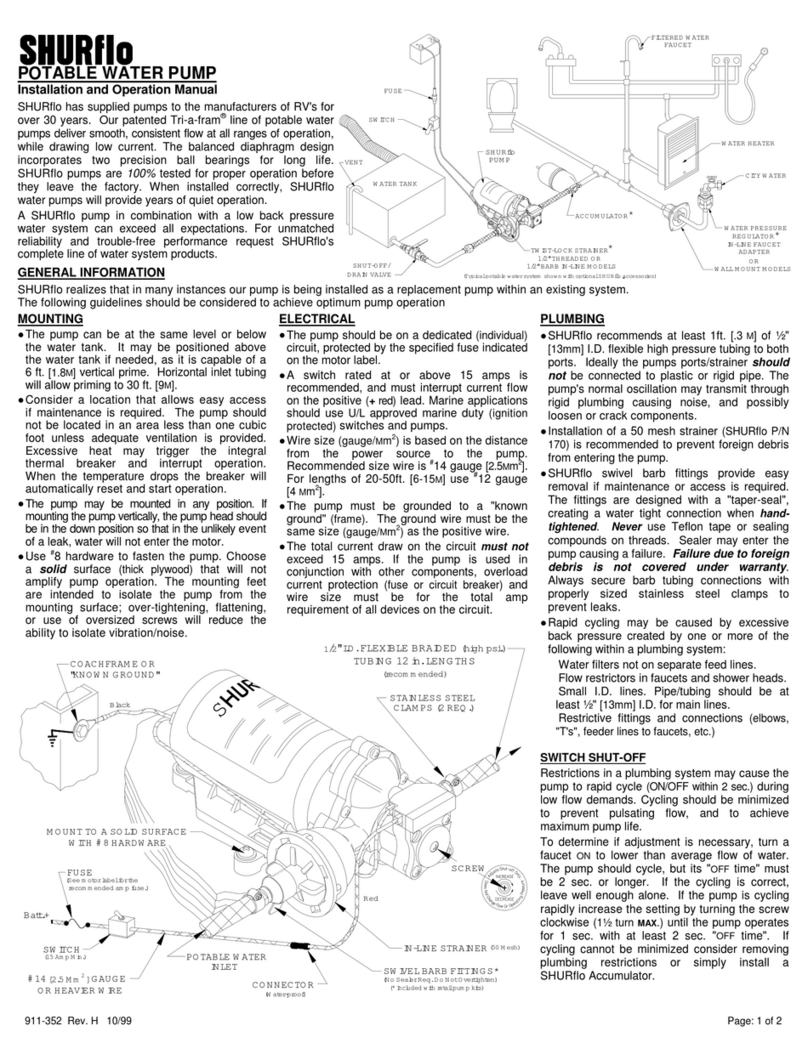

1. Locate the pump as close to the

liquid source as possible, making

the suction line as short and direct

as possible.

PIPING

SUCTION

2.Avoid excessive lengths or number of

fittings and bends in the suction line.

3. Attach suction line to suction inlet

(See Figure 1 for proper rotation).

NOTE: An optional vacuum switch (pump

protector) is recommended to prevent

pump dry run. It should be mounted on

the suction side of the pump. Refer to

installation/operation instructions

provided with vacuum switch.

4. It is recommended that same size

pipe as pump ports be used or, in

cases requiring lengthy piping, the

next larger size pipe be used.

5. If suction level is greater than what

is indicated in the performance

chart, attach a foot valve below

liquid level at end of suction line to

ensure positive priming. Also note:

If fluid specific gravity is greater

than 1.0 or viscosity greater than

500 SSU, a foot valve is also

recommended.

NOTE: If a foot valve (or check valve) is

not used in the suction line, it may be

necessary to refill the pump every time

the unit is stopped and you wish to restart

the pump. This depends on the length of

time between starts and whether or not

the impeller is wet enough to close cavities

to affect a prime.

6. If solid contaminates are suspected

in a liquid, place a filter in the

suction line.

7. Be certain all suction piping connec-

tions are airtight.

NOTE: Assure airtight pipe connections

with the use of a pipe joint sealant.

DISCHARGE

8. Attach discharge piping to the

discharge outlet.

Support pump and

piping during assembly

and after installation. Failure to do so may

cause piping to break, pump to fail, motor

bearing failures, etc., all of which can result in

property damage and/or personal injury.

NOTE: Should the pump need to be

self-draining, the pump head should be

mounted in the vertical position with

the suction port facing down. When

pumping high viscosity fluids, the

vertical position can be used with the

suction port facing up and the pump

mounted under the source. Increasing

the suction pipe size and eliminating

bends and elbows also assists in pump-

ing high viscosity fluids. Max. viscosity is

500 SSU at 1725 RPM.

9. If a shut-off valve or handgun is

required in discharge line, provide

apressure relief valve for pump

protection.

Shutting off

discharge without

providing pressure relief can cause extreme

overpressure which can result in pump

and/or motor failure. Do not exceed 25 PSI

(or 60 feet of head) pump or system pressure.

10. Operation under shut-off discharge

conditions will overheat and

damage pump and impeller.

NOTE: Globe valve or other restrictive

valves should not be used as shut-off

mechanism as they are restrictive in

nature and will seriously affect pump

performance.

11. After all piping and controls (not

supplied with unit) have been

installed, unit is ready for operation.

Operation

Do not run pump

dry, as permanent

damage to the pump impeller, seal, pump

housing and wear plates will result. Suction

pressure should never be greater than the

discharge pressure. Dry running will result in

immediate failure of impeller and cause

extreme pump temperature (do not handle

pump when hot). Impeller damage is not

covered under warranty.

1. All pumps must be primed before

start-up and filled with fluid (See

Figure 3). Never operate a pump

unless it is secured to a solid foun-

dation and all safety shields are

installed.

Upon start-up, maintain a minimum

of 15 PSI (1 BAR) operating pressure

on the pump. This will allow any

remaining air to be driven from the

seal chamber and will ensure liquid

circulation to the seal.

2. Flexible impeller pumps are built

to very close tolerances and this