5

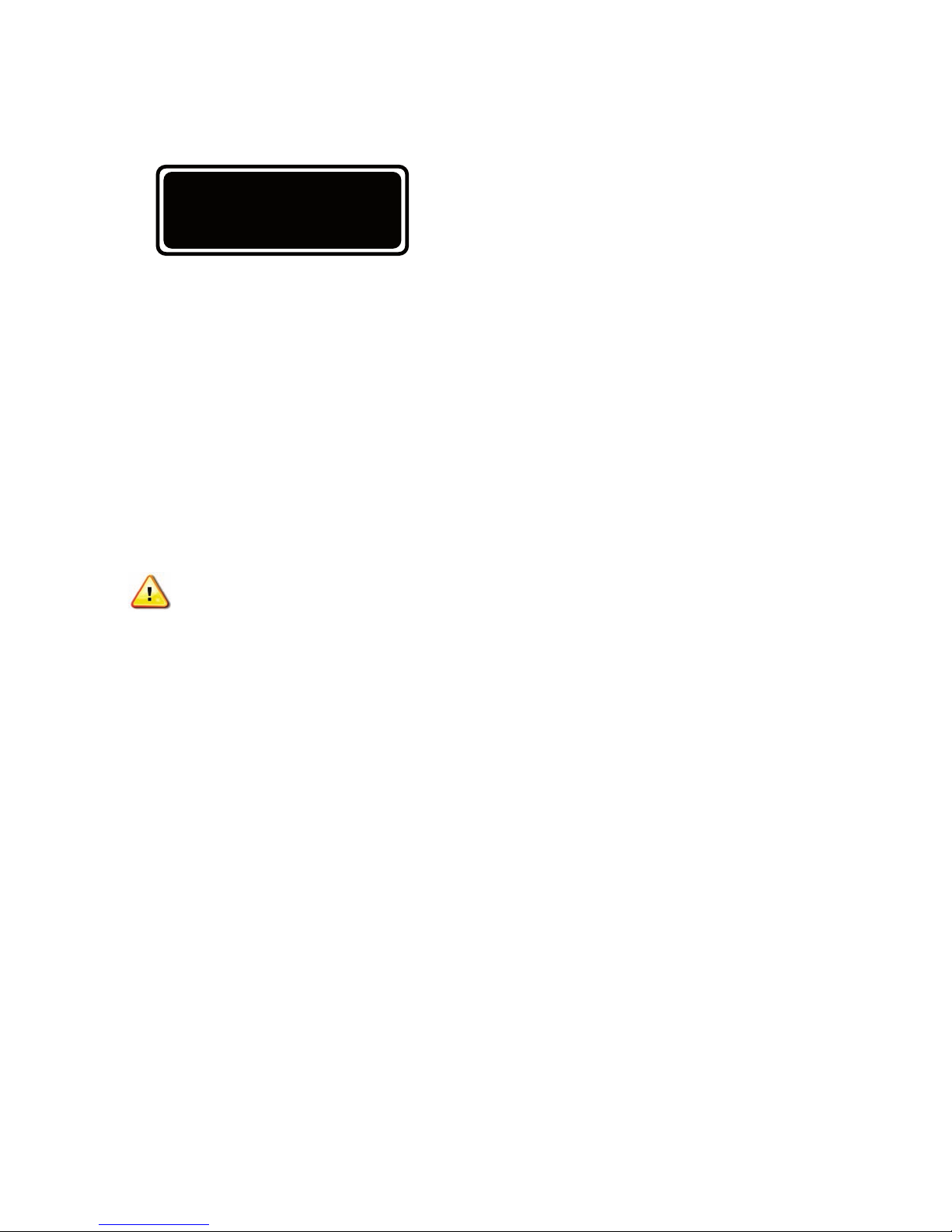

IMPERIAL TRUCK MOUNTED VACUUM TANKER MANUAL

SAFETY PRECAUTIONS

General Safety Precautions

Follow these safety precautions,and insist that those

working with you follow them.

Most industrial equipment accidents can be avoided

by observing safety precautions.Remember:a careful

operator is the best insurance against an accident.

Safety Precautions for Handling Effluent

DANGER: DO NOT stand near the oil catch

muffler or discharge valve when loading or unloading

the tank. Sewer gases vented out of the oil catch

muffler will settle downward.Sewer gases can also be

expelled out of the discharge valve when releasing

tank pressure.Inhaling sewer gases can cause severe

injury or death.

WARNING:DONOTallowchildrenorirresponsible

people near your work area or equipment.Fatalities

have occurred when children have fallen or climbed

into unattended septic/holding tanks. Secure your

work area from entry of unauthorized persons in

the vicinity.

WARNING: Secure all access covers against

unauthorized entry after pumping a septic/holding

tank. Fatalities have occurred where children have

fallen into septic/holding tank openings that had not

been properly secured. Securely chain and padlock

above ground access openings. Bury underground

access openings by at least six inches of dirt.

WARNING: Always wear protective gloves, eye

protection and,appropriate clothing when working

with sewage effluent or septage. These materials

may contain hazardous chemicals, disposed of

through the drain, which can cause severe injury

or even death due to contact. These effluents also

contain bacteria,which can be a source of infection,

especially if exposed to open cuts or sores.

Safety Precautions for Entering Tanks

DANGER: DO NOT enter a transport, septic, or

holding tank without first cleaning and providing

adequate ventilation to the interior of the tank.

Sewer gas is deadly if inhaled;in addition,it depletes

the oxygen in a confined space, which can cause

asphyxiation.

DANGER: DO NOT enter a transport, septic, or

holding tank without using a respirator that supplies

grade D breathing air or a self-contained breathing

apparatus. In addition, DO NOT use this equipment

without training and familiarity with it. Entering a

tank exposed to sewage effluent without a correct

breathing apparatus, or with improper use of it, can

cause death.

DANGER: DO NOT enter a transport, septic, or

holding tank without protective clothing.Sewer gas

can be absorbed through the skin causing serious

injury or death.

WARNING:When entering a transport,septic,or

holding tank, always have someone standing by to

provide assistance,and always have a respirator that

supplies grade D breathing air or a self-contained

breathing apparatus on hand for them. In the event

of an attempted rescue,this equipment is necessary

to prevent death of the rescuer.

WARNING: Attach a safety-harness and rope to

any person that enters a transport,septic,or holding

tank.Have the safety-harness rope held by a person

standing by to provide assistance outside the tank.

An attempted rescue without the advantage of

a rope and harness can be life threatening to the

rescuer.

WARNING: Entry into a transport, septic, or

holding tank is confined space entry. Persons

entering these tanks for any purpose must be

trained in and follow OSHA confined space safety

procedures.

DANGER

DANGER