Improved Racing E5G-600 User manual

For contact information, visit www.improvedracing.com

Copyright © 2008-2019 Improved Racing Products, LLC. All rights reserved.

Rev 190528

OIL COOLER KIT FOR 2010-2011

CHEVROLET CAMARO V8

PART NUMBER: E5G-600

MADE IN USA

Important: Read these instructions in their

entirety prior to installation

2Visit www.improvedracing.com for additional support

APPLICATIONS

• Improved Racing’s E5G-600 oil cooler kit is designed for direct installa-

tion on the following vehicles:

◦2010-2011 Chevrolet Camaro V8 (SS & ZL1)

◦Z/28 Camaros may require additional parts for deleting the factory

installed heat exchangers and fans.

PARTS LIST & HARDWARE PACKS

Item

Qty

Part Number

Description

11 MHX-245 45-Row 3-Pass Heat Exchanger w/Hardware

21

EGM-114-TX

LSX Oil Pan Adapter for Heat Exchanger

32 OM-08-10 Adapter Fitting for Oil Pan Adapter

41 HCP-1016 1 inch ID Cushioned P-Clamp for Oil Lines

51 E5G-600-50 Line: 90° IN Adapter, 90° OUT Exchanger

61 E5G-600-51 Line: 0° OUT Adapter, 45°IN Exchanger

71 E5G-600-60 Upper Bracket & Hardware for Mounting MHX-245

81 E5G-600-61 Lower Bracket & Hardware for Mounting MHX-245

91 E5G-600-62 Rear Hose Clamp Hardware

10 1 E5G-600-64 Washer Fluid Tank Hose Tie Hardware

11 1 E5G-680

2010-2011 V8 Camaro Factory Oil Cooler Delete Kit

E5G-600-60 Hardware Pack Contents

Item

Qty

Part Number

Description

11 E5G-600-01 MHX-245 to Chassis Bracket - Top

22 HVR-1002 Rubber Isolator

32 HVR-1003 Rubber Isolator Bushing

42 HSC-1041 M8x1.25x25 Mounting Screw

E5G-600-61 Hardware Pack Contents

Item

Qty

Part Number

Description

11 E5G-600-05 MHX-245 to Chassis Bracket - Bottom

22 HVR-1002 Rubber Isolator

32 HVR-1003 Rubber Isolator Bushing

41 HSC-1054 1/4”-20 Type F Thread Cutting Screw

3

Visit www.improvedracing.com for additional support

E5G-600-62 Hardware Pack Contents

Item

Qty

Part Number

Description

11 CP-16 Billet Aluminum Hose Separator

21 HSC-1052 Grade 5 Hex Head Screw, , L = 2-3/4inch

32 HWA-1004 1/4inch Washer

E5G-600-64 Hardware Pack Contents

Item

Qty

Part Number

Description

11 HSC-1051 8.8 Class Alloy Steel M8x1.25x35 Screw

21 HWA-1005 M8 Zinc-Plated Steel Fender Washer

31 HNT-1018 M8x1.25 IFI Prevailing Torque Nut

42 HTD-1004 M8 Stud-Mount, High-Temperature Cable-Tie

E5G-680 Hardware Pack Contents

Item

Qty

Part Number

Description

11 22962571 2010-2011 V8 Camaro Upper Radiator Hose

21 12561663 LSX / Vortec Engine Block Coolant Plug

TECHNICAL SPECIFICATIONS

Maximum Operating

Temperature 302°F (150°C)

Minimum Operating

Temperature -22°F (-30°C)

Maximum Operating

Pressure 300 psi (20.68 bar)

Heat Exchanger

Material & Fabrication

45-Row Full Aluminum Tube & Fin Core with Turbulators, TIG

Welded Tanks, Billet CNC-Machined End Caps & Fittings

Adapter Fitting

Material & Fabrication

CNC-Machined 6061-T6 Aluminum, MIL-A-8625 Type II

Black-Anodize

HCP-1016 Info 1-1/2 inch (38 mm) ID P-Clamp, Zinc-Plated Steel, Black EPDM

Rubber , 210°F (99°C) Max Temp

22962571 Info Genuine GM 2010-2011 Chevrolet Camaro V8 Upper Radiator

Hose, Rubber, Black

12561663 Info Genuine GM LS / Vortec Family Engine Coolant Plug, 17 mm

Hexagon Drive, Yellow Brass, Thread-Lock Applied

E5G-600-50 Info

-10 Hose Assembly: 90° & 90° 6061-T6 Aluminum Hose-Ends,

ECO Rubber Outside Bonded to Viton Rubber Inside, Stainless

Steel Reinforced, Nylon Over-Braid, Fiberglass-Silicone Shield

4Visit www.improvedracing.com for additional support

E5G-600-51 Info

-10 Hose Assembly: 0° and 45° 6061-T6 Aluminum Hose-Ends,

ECO Rubber Outside Bonded to Viton Rubber Inside, Stainless

Steel Reinforced, Nylon Over-Braid, Fiberglass-Silicone Shield

E5G-600-60 Info

CNC-Pierced 5052-H32 Aluminum, Nitrile Rubber Vibration

Grommet, Zinc-Plated Carbon Steel Bushing, M8x1.25x16 10.9

Class Alloy Steel JIS Flange Screw

E5G-600-61 Info

CNC-Pierced 5052-H32 Aluminum, Nitrile Rubber Vibration

Grommet, Zinc-Plated Carbon Steel Bushing, M8x1.25x16 10.9

Class Alloy Steel JIS Flange Screw

WARNINGS & PRECAUTIONARY STATEMENTS

WARNING: NEVER work under a vehicle supported only by a jack.

WARNING: DO NOT CAP OFF THE OIL COOLER PORTS after the

adapter is installed. Running the engine with the ports capped will block

oil ow and result in catastrophic engine damage. If not using an oil

cooler, the IN/OUT ports must be looped together to prevent engine

damage.

WARNING: Thisproductshouldonlybeinstalledbyaqualiedme-

chanic. Improper installation could result in severe engine damage.

REMOVING THE BUMPER COVER

1.

Raise the vehicle and support with any automotive-use-approved frame

stands, lift, or ramps.

2. Open the hood of the vehicle.

3.

Apply masking tape to the fenders to prevent scratching when removing

the bumper cover.

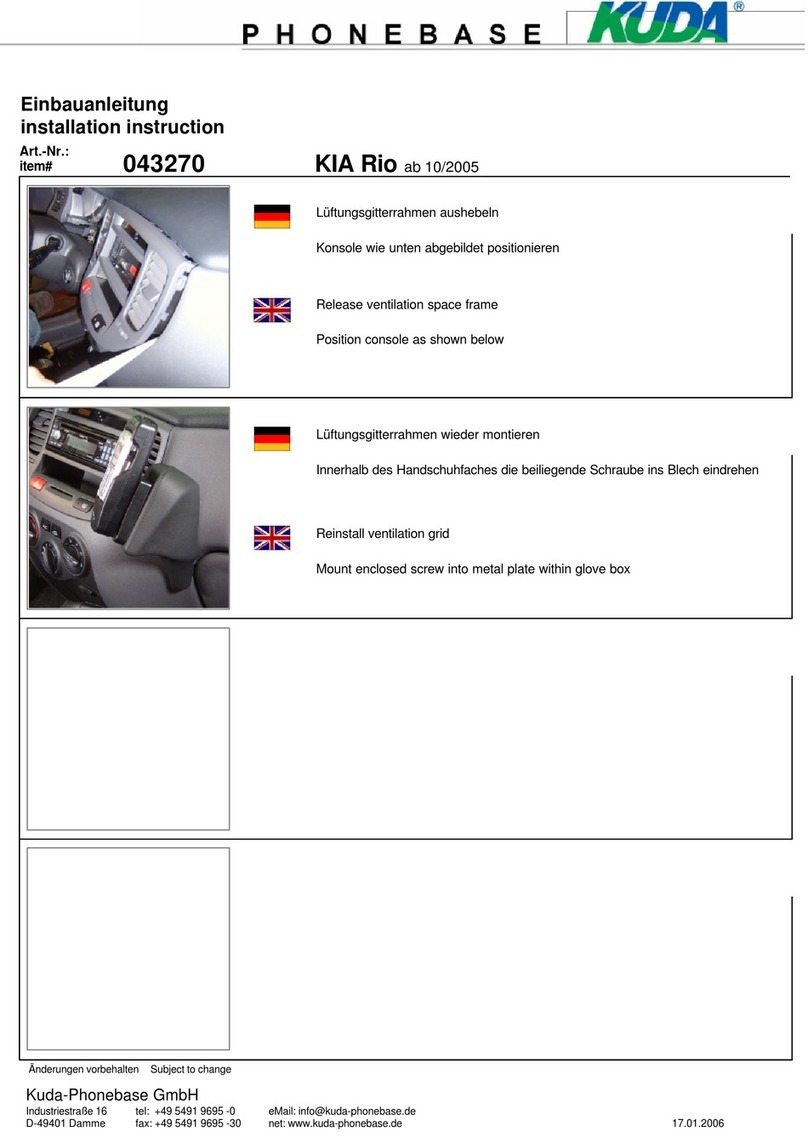

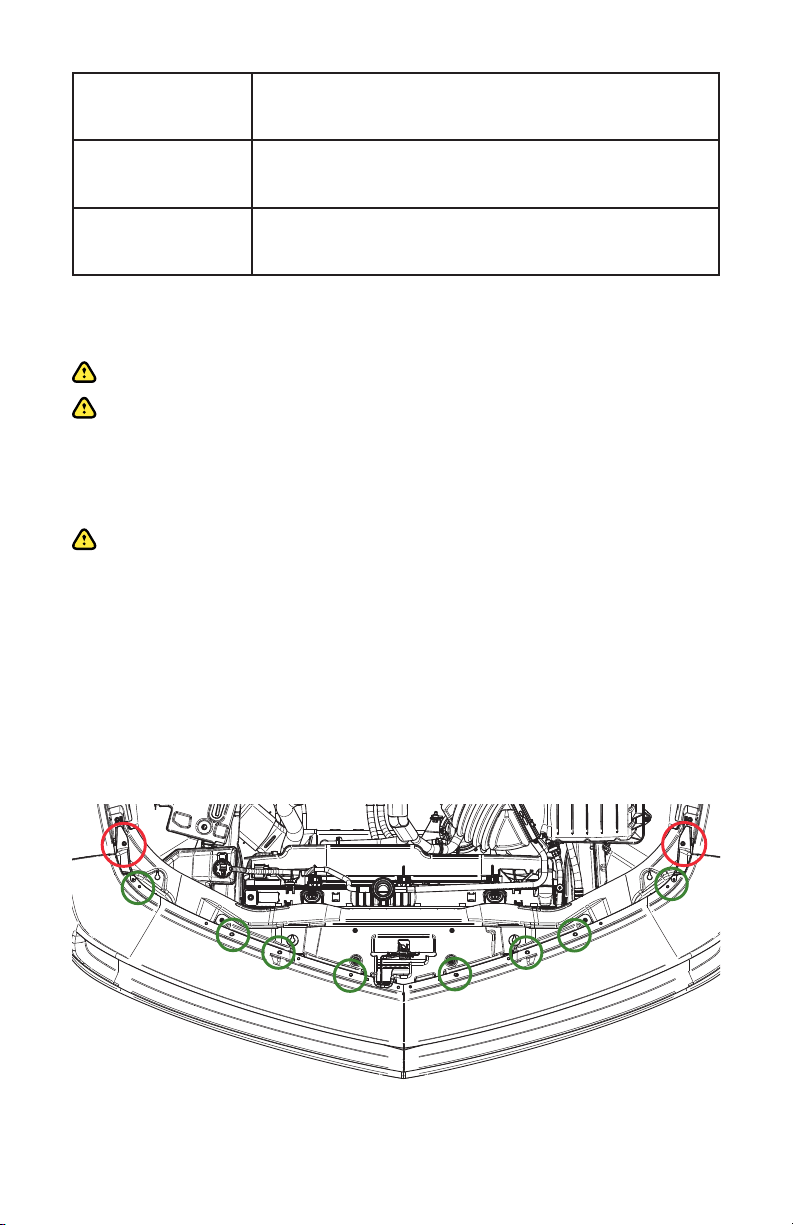

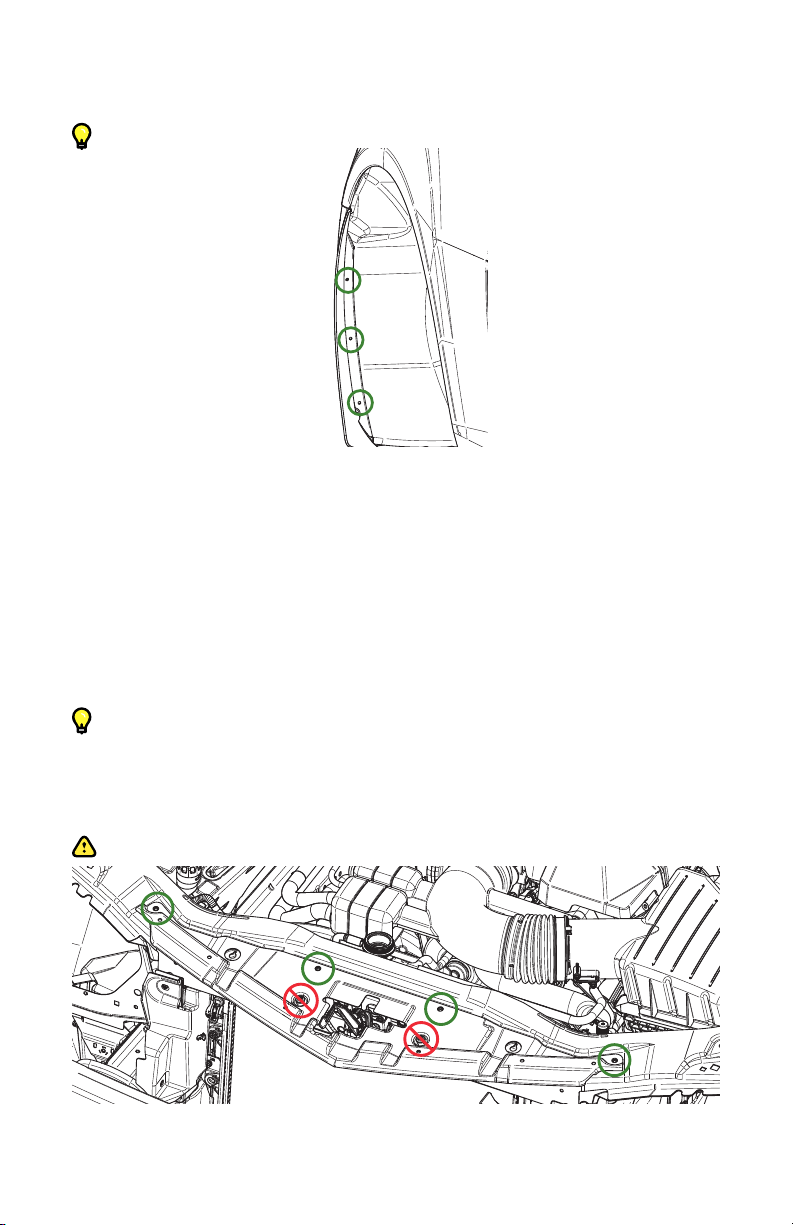

Figure 1 - Removing the Pop-Clips and Screws

5

Visit www.improvedracing.com for additional support

4.

Use a plastic prying tool to remove all of the plastic pop-clips underneath

the hood which pin the bumper cover to the radiator support, circled in

green on Figure 1.

5. Use a 10 mm tool to remove the screws at each corner under the hood,

circled in red on Figure 1.

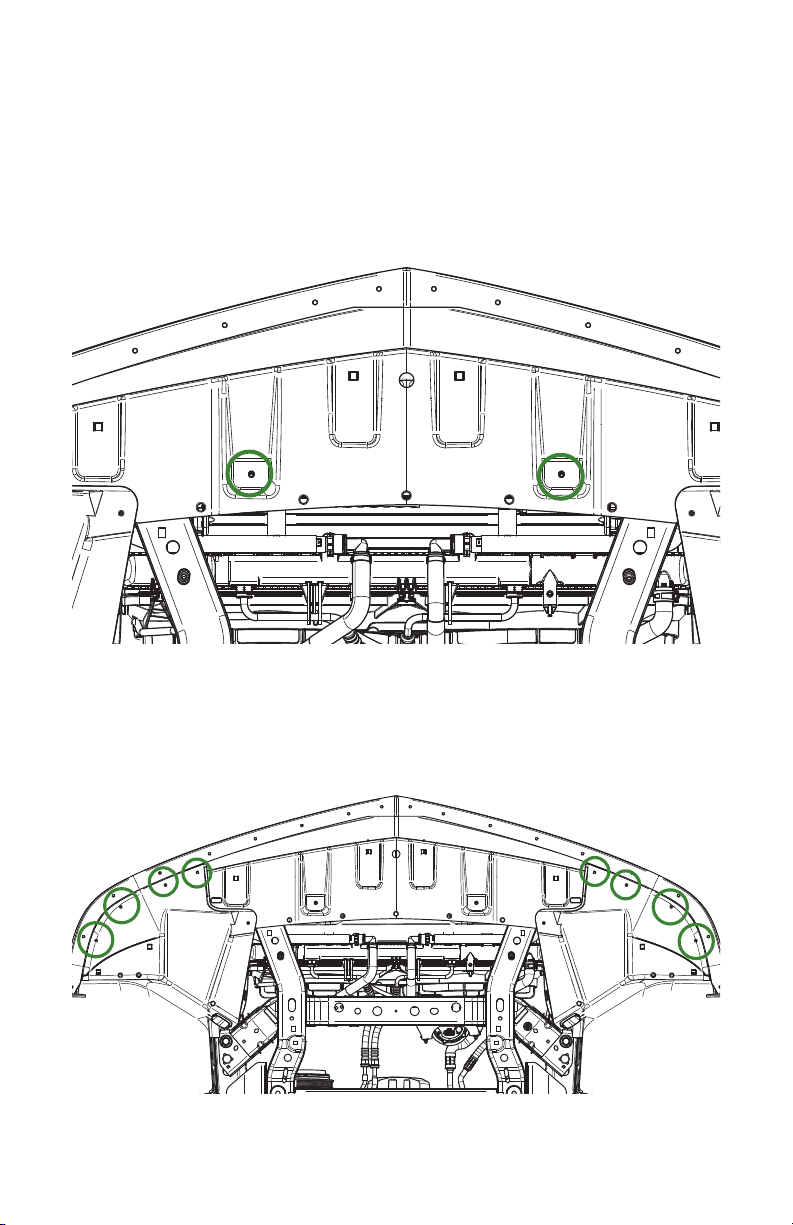

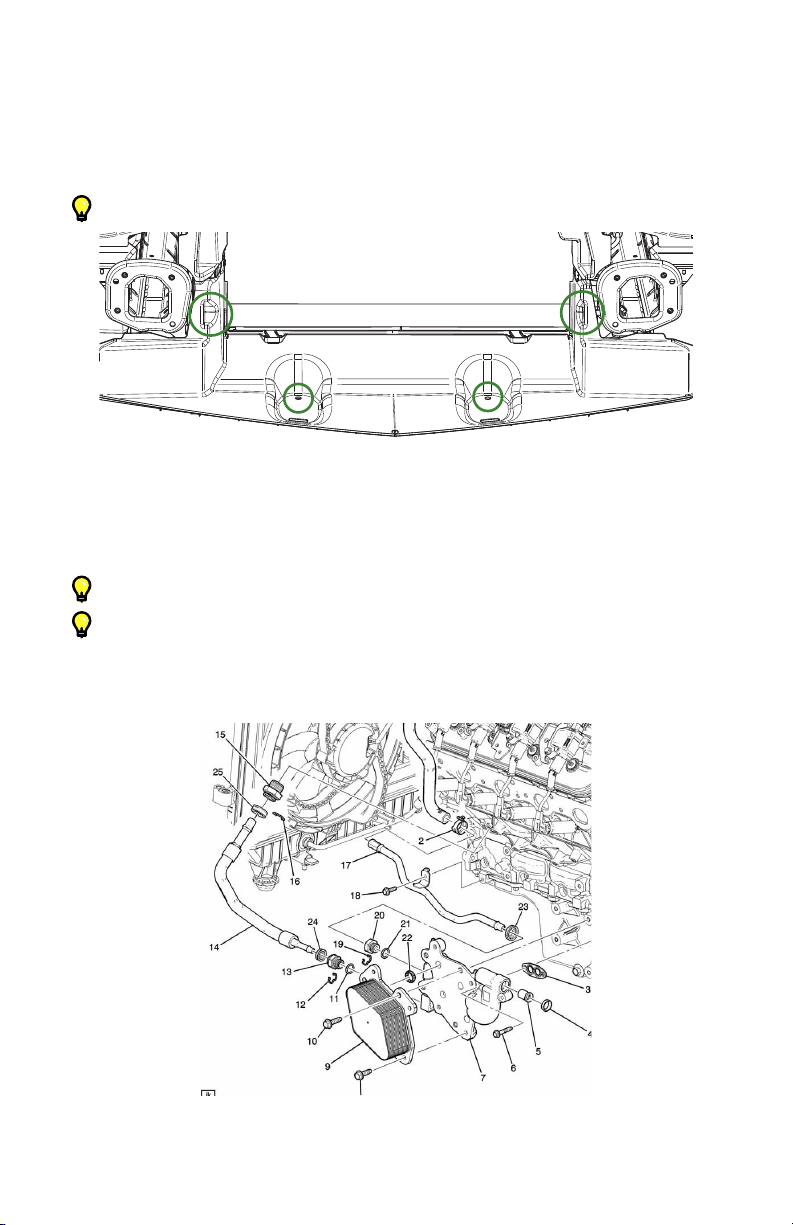

6. Underneath the car, use a 10 mm tool to remove the two screws which

hold the bumper cover to the chassis, circled in green on Figure 2.

7. Use a T20 tool to remove all screws underneath the bumper cover, im-

mediately in front of the wheels, circled in green on Figure 3. There are

four per side.

Figure 2 - Removing the Bottom Bumper Cover Screws

Figure 3 - Removing the T20 Torx Screws

6Visit www.improvedracing.com for additional support

8. Use a 7 mm tool to remove the screws in the wheel wells that attach to

the bumper cover, circled in green on Figure 4.

Tip: Take the wheels off to make this easier, or turn them side-to-side.

9. Peel-back the wheel-well linings on each side to:

a. Use a 7 mm tool to remove one screw securing the bumper cover to

the fender.

b.

Use an extended 10 mm socket wrench to remove four screws secur-

ing the bumper cover to the fender support.

c. Unplug all fog light harnesses.

10. With two people, carefully pull the bumper cover straight off the front.

Tip: Be ready to unplug the large wire harness with safety tab unlock.

11. Place the bumper cover in a safe spot until reinstallation.

12. Use a 10 mm tool to remove the four screws securing the black beak to

the front of the car, circled in green on Figure 5.

WARNING: DO NOT adjust Torx screws!

Figure 5 - Removing the Black Beak

Figure 4 - Removing the Wheel Well Cover to Bumper Cover Screws

7

Visit www.improvedracing.com for additional support

REMOVING THE FACTORY OIL COOLER

1. Placeadrainpanundertheoillterandremovethelter.

2. Remove the lower radiator shroud from the car by removing four push-

clips, circled in green on Figure 6.

Tip: Removing the bumper bar makes this easier

3. Locate the coolant lines for the factory oil cooler and pop-off the black

plastic protectors shown in Figure 7 to gain access to the clover-shaped

wireclipsthatsecurethefactorylinesintothettings.

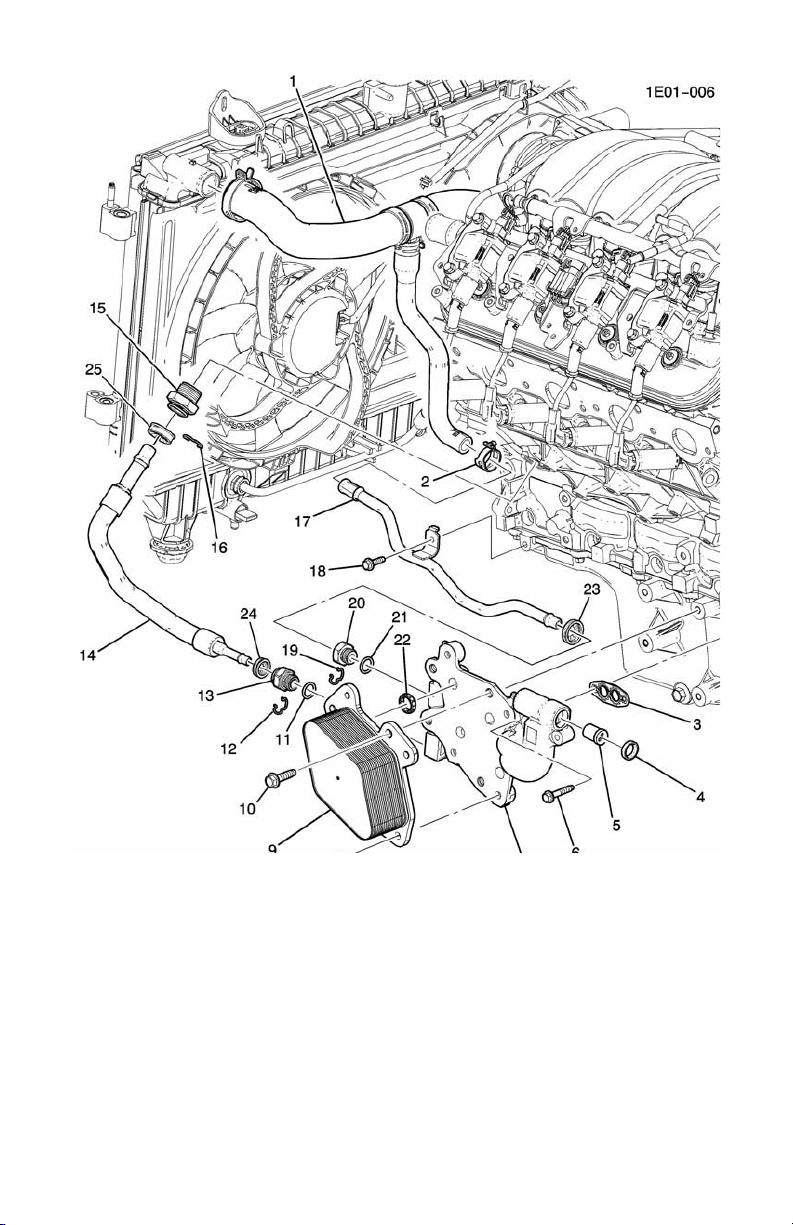

Tip: There are two caps on the front of the factory oil cooler (#23 & #24).

Tip: There is one cap on the larger line that goes into the side of the engine

block (#25).

4. Locate the #18 screw in Figure 7 that secures the factory oil cooler tube

to the oil pan and remove the screw with a 10 mm tool.

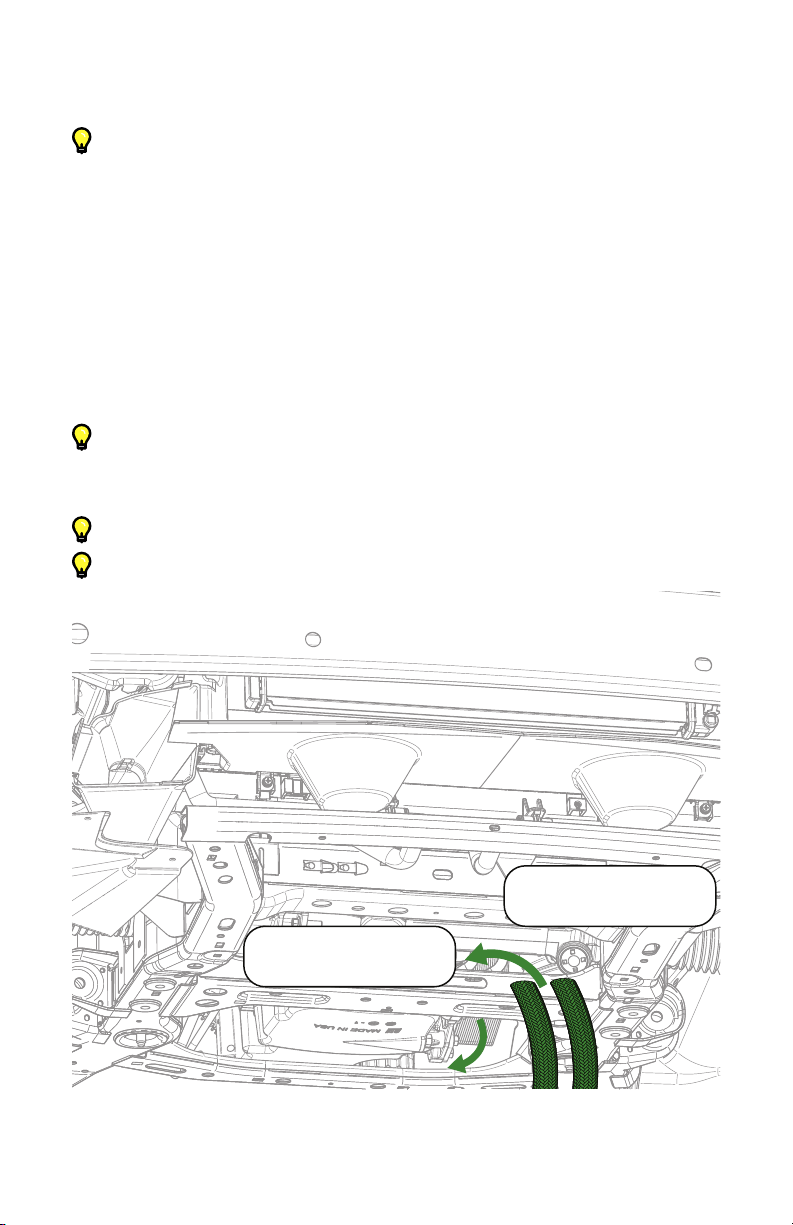

Figure 6 - Removing the Lower Radiator Shroud

Figure 7 - Removing the Plastic Caps & Oil Pan Screw

8Visit www.improvedracing.com for additional support

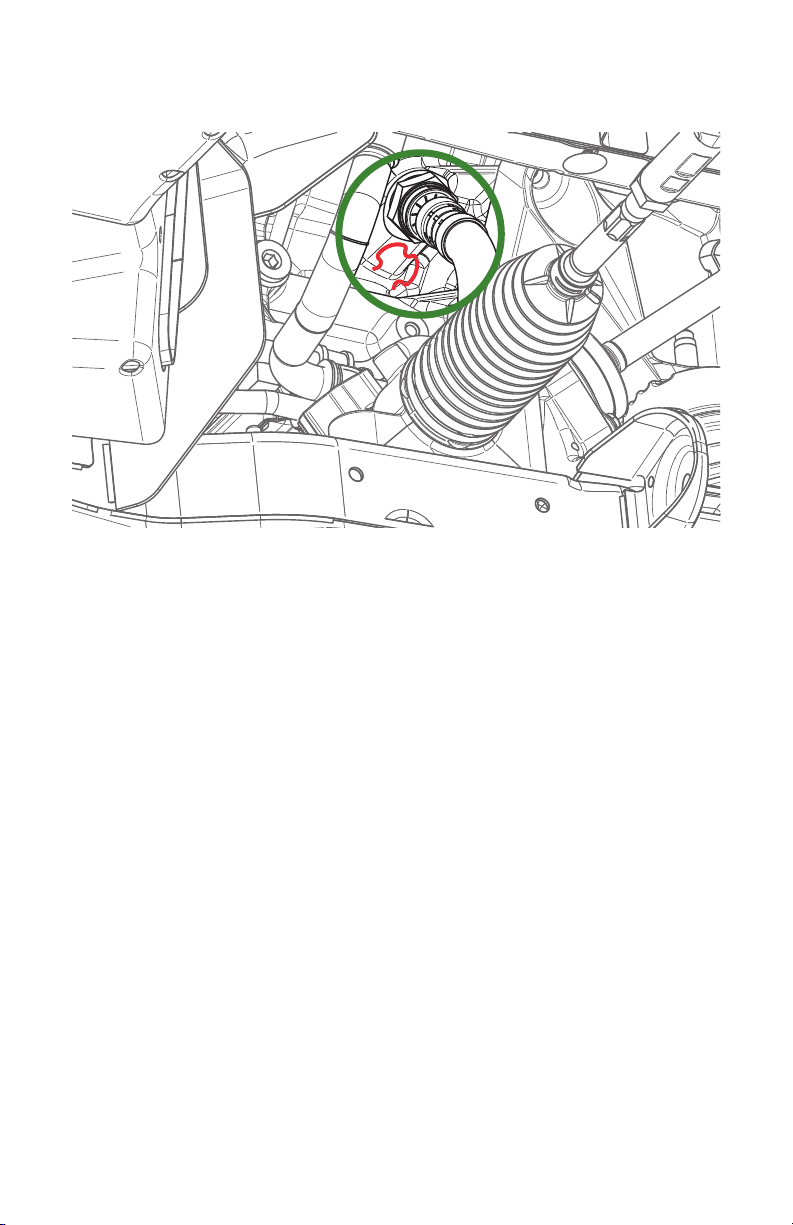

5.

Removetheclover-shapedwireclipfromthelargeenginecoolanttting

usingapicortwoatscrewdrivers,circledingreen on Figure 8.

6.

Completely disconnect and set aside the spark plug wire for Cylinder #1.

7. Place another drain pan underneath the car.

8. Use Figure 9 to:

a.

Popthe#14coolantlinefromthe#15enginetting.Allowthecoolant

todrainuntilnolongerowing.

b. Looselyplacethe#14linebackintothe#15enginetting.

c. Locate the radiator hose circuit that feeds the factory oil cooler.

d. Locate the tee junction on the upper radiator hose.

e. Follow the small line back to the lowest hose clamp and remove the

#2 hose clamp using channel lock pliers.

f. Pull-off the hose and allow all coolant to drain completely.

g.

Completely remove the #1 upper radiator hose from the vehicle

using channel lock pliers and a plastic prying tool.

9. Replace the upper radiator hose with GM part 22962571 from the kit.

10.

Completelyremovethe#14coolantlinefromthe#15enginettingand

breakthettingloosewithabreakerbaranddeepwell34mmsocket.

11. Completelyremovetheenginetting.Wipe-upanycoolantthatspills.

Figure 8 - Removing the Clover-Like Metal Clip

Visit www.improvedracing.com for additional support 9

12.

Use a 17 mm hex bit to install the new brass coolant plug, GM part

12561663, into the engine block.

13. Torque the coolant plug to 45 lb-ft (60 N-m), followed by a 1/4turn.

14. Use a 13 mm tool to remove the four M8 screws that hold the factory oil

cooler to the side of the oil pan.

15. Remove the factory oil cooler and set aside.

16.

Use a 13 mm tool to remove the screw at the bottom of windshield washer

uidtank,circledingreen on Figure 10.

Figure 9 - Components to Remove to Replace Radiator Hose

10 Visit www.improvedracing.com for additional support

17. Use HSC-1051 and HWA-1005 from the E5G-600-64 Hardware Kit to

replace the bottom tank screw removed in the previous step.

WARNING: DO NOT over-tighten.

18. Pre-llandreinstallanewengineoillterafterlubricatingthesealwith

engine oil.

19. Reconnect the spark plug wire for Cylinder #1.

20. Reinstall the bumper bar onto the car, if needed.

Tip: Line the screws up with their paint marks inside the bumper bar to

ensurethatthebumpercoverreinstallationtstayslikenew.

Figure 10 - Replacing the Windshield Fluid Tank Screw

11

Visit www.improvedracing.com for additional support

INSTALLING THE IMPROVED RACING KIT

1.

Familiarize oneself with EGM-114 and MHX-245 by reading the in-

cluded manuals.

2. InstalltheadapterttingsintoEGM-114.Torquethettingsto20lb-ft

(27 N-m).

3. Install EGM-114 using a 5 mm hex-drive tool.

Tip:Cuta5mmkeyontheshortsidetomakealowproletoolshould

your headers interfere.

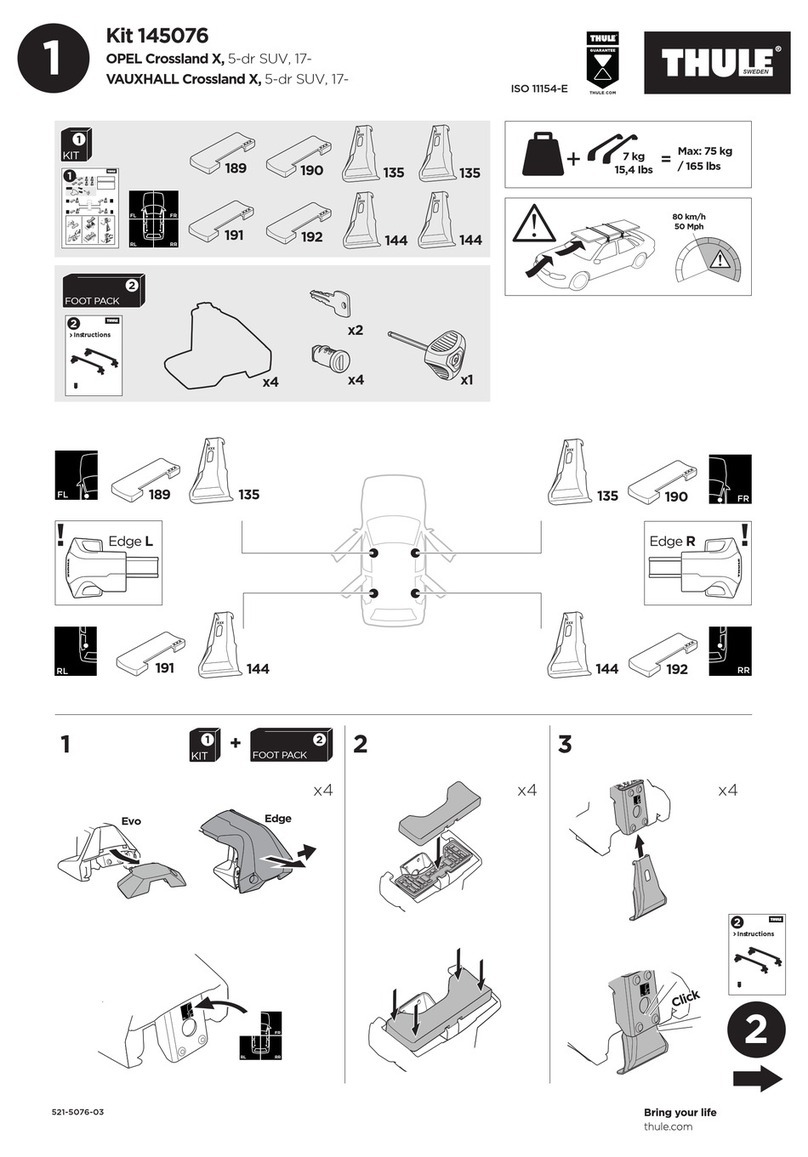

4. Use E5G-600-60 and E5G-600-61 Hardware Kits to secure the top and

bottom brackets to MHX-245, as shown in Figure 11.

5.

Use a 12 mm tool and two HSC-1041 screws from the E5G-600-60

Hardware Kit to secure the top bracket to the vehicle using the two holes

circled in green on Figure 12.

Tip:Ifthenut’sthreadsarelledwithpaint,runtheprovidedM8screws

through the hole(s) one to three times to clear the threads.

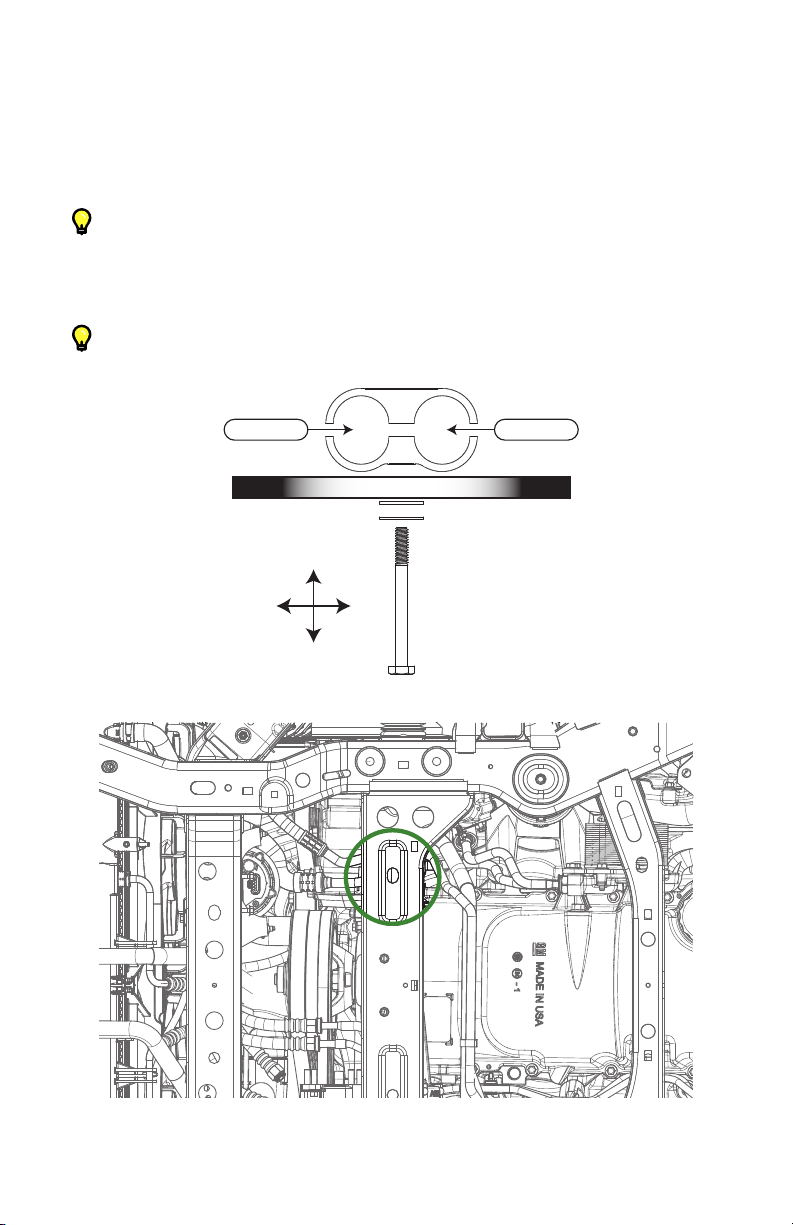

Figure 12 - Securing the MHX-245 & Brackets to the Car

Figure 11 - Brackets Attached to MHX-245

Visit www.improvedracing.com for additional support

12

6. Useananglendertomatchthe4°tiltofthefactoryradiatorstackand

hold this position to trace the hole for the lower bracket.

Tip: When on wheel ramps, re-measure the angle on your ramps.

7. Use a permanent marker to trace the hole outline for drilling.

8. Remove the cooler and bracket assembly from the car.

9. Strike the hole center with a punch and use a sharp #1 (.2280 inch) drill

bit to create the hole in the bumper bar for the bottom oil cooler bracket.

10.

Re-mountthecoolerandbracketassemblybackontothecarbyrst

securing the top bracket with a 12 mm tool and two HSC-1041 screws.

Torque the M8 screws to 24 lb-ft (33 N-m).

11.

Attach the bottom bracket to the bumper bar using a drill,

3

/

8

inch socket

and HSC-1054 thread cutting screw. DO NOT over-tighten.

Tip:Usealigned,rmpressurewithadrillsettolowspeed(Speed1).

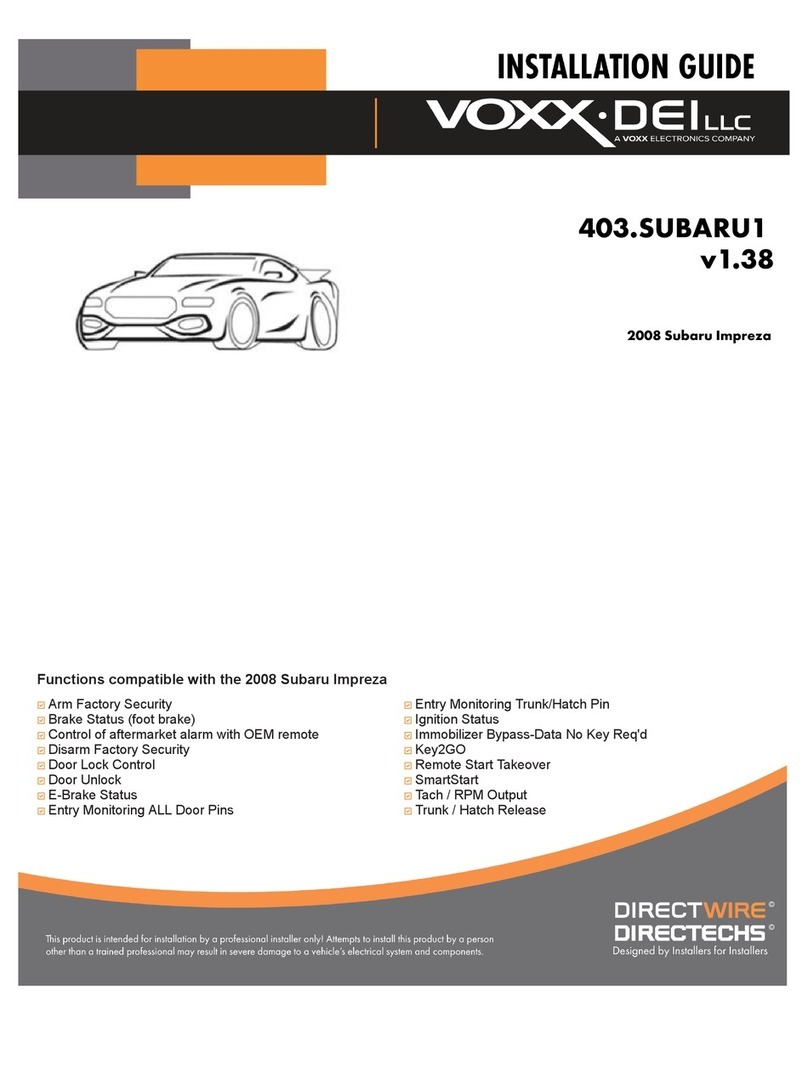

12. Grab the oil lines and route them towards the back of the car as shown

in Figure 13.

Tip: E5G-600-50 is biased towards the passenger side of the car.

Tip: E5G-600-51 is biased towards the driver side of the car.

E5G-600-50

E5G-600-51

Figure 13 - Routing the Oil Lines Rearwards

13

Visit www.improvedracing.com for additional support

13. Applyoiltotheadaptertting’sareontheOUTportofEGM-114,and

connect the straight hose-end of E5G-600-51. Torque the hose-end to

20 lb-ft (27 N-m).

14.

Repeat Step 13 of this section with E5G-600-50 for the IN port on EGM-

114. Torque the hose-end to 20 lb-ft (27 N-m).

Tip: Connect the 90° hose-end with heat shield at the adapter side.

15.

Arrange HSC-1052, HWA-1003 and CP-16 from the E5G-600-62 Hard-

ware Kit as shown in Figure 14, then secure the hoses to the chassis loca-

tion circled in green on Figure 15.

Tip: Use channel-lock pliers to keep the hose clamp straight while tight-

ening the screw.

CHASSIS

REAR

FRONT

DRIVERPASSENGER

E5G-600-50 E5G-600-51

Figure 14 - E5G-600-62 Hardware Pack Arrangement

Figure 15 - Chassis Location for Rear Hose Clamp

14 Visit www.improvedracing.com for additional support

16.

Use Figure 16 to locate the power steering line that is secured to the

chassis by a cushioned clamp and use a 10 mm tool to loosen the screw

holding the clamp.

17. Expand HCP-1016 and insert the oil lines through the cushioned clamp.

18. Remove the screw from the steering line clamp on the chassis and slide

HCP-1016 over/underneath the steering line clamp, depending on what

bestsuitsthelinecongurationandpowersteeringline.

19. Reinsert the screw into the chassis and tighten to no more than 7 lb-ft

(10 N-m).

20.

Peel-back the black plastic shroud circled in green on Figure 17 and route

the system lines up towards MHX-245.

21. Use two HTD-1004 from the E5G-600-64 Hardware Kit to secure the

hosesontotheM8screwthatwasinstalledintothewasheruidtank

previously, as shown in Figure 18.

22. Applysomeoiltothelowertting’sareonMHX-245andconnectthe

45° hose-end. Tighten the hose-end to 20 lb-ft (27 N-m).

23. Pre-lltheheatexchangerwithengineoilusingatubeandfunnel.

Tip:UseaexibletubewithaMAXO.D.of0.50”(12.7mm).

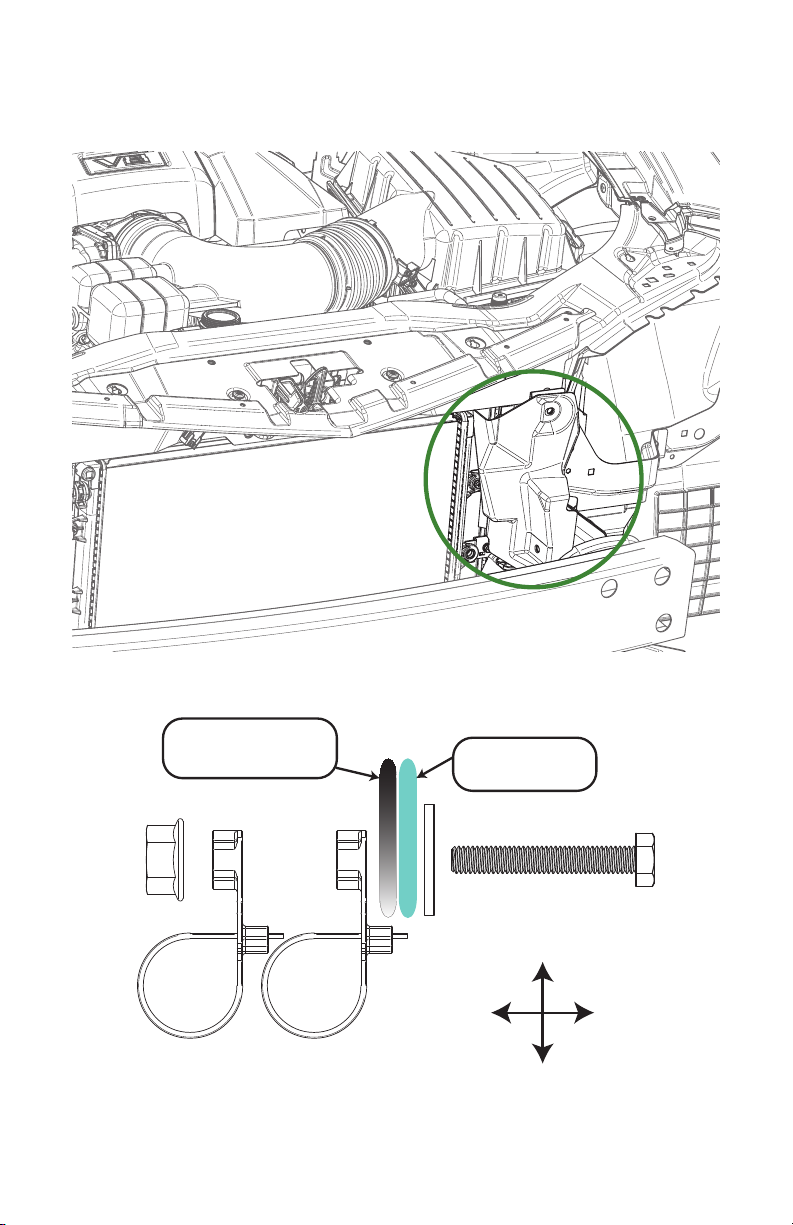

Figure 16 - Chassis Location for Factory Power Steering Clamp

15

Visit www.improvedracing.com for additional support

24. Remove the tube and funnel followed by connecting the 90° hose-end

tothetopttingontheoilcooler.Tightenthehose-endto20lb-ft(27

N-m). Wipe-up any oil that spills.

WASHER

BOTTLE

FRAME &

WELDED NUT

REAR

FRONT

DRIVERPASSENGER

Figure 18 - Securing the Hoses with the High-Temperature Cable Ties & M8 Nut

Figure 17 - Black Plastic Shroud to Peel-Back & Route Hoses

16 Visit www.improvedracing.com for additional support

PREPARING FOR STARTING

1. Check the engine oil level and add oil if necessary.

2. Remove the fuel injector fuses.

Tip: Consult the vehicle’s factory service manual for the fuse locations.

3. Cranktheengineoverforvesecondstobuildoilpressure,repeating

thiscyclethreetovetimes.

4. Replace the fuel injector fuses removed previously.

5. Check the engine coolant level and add coolant if necessary.

Tip: Consult the vehicle’s factory service manual for the correct inspec-

tionandllingprocedures

6. Start the vehicle and inspect for oil and coolant leaks.

Be sure the engine does not begin to overheat.

7. Turn-off the vehicle, inspect the engine oil and coolant level and add oil

or coolant when necessary.

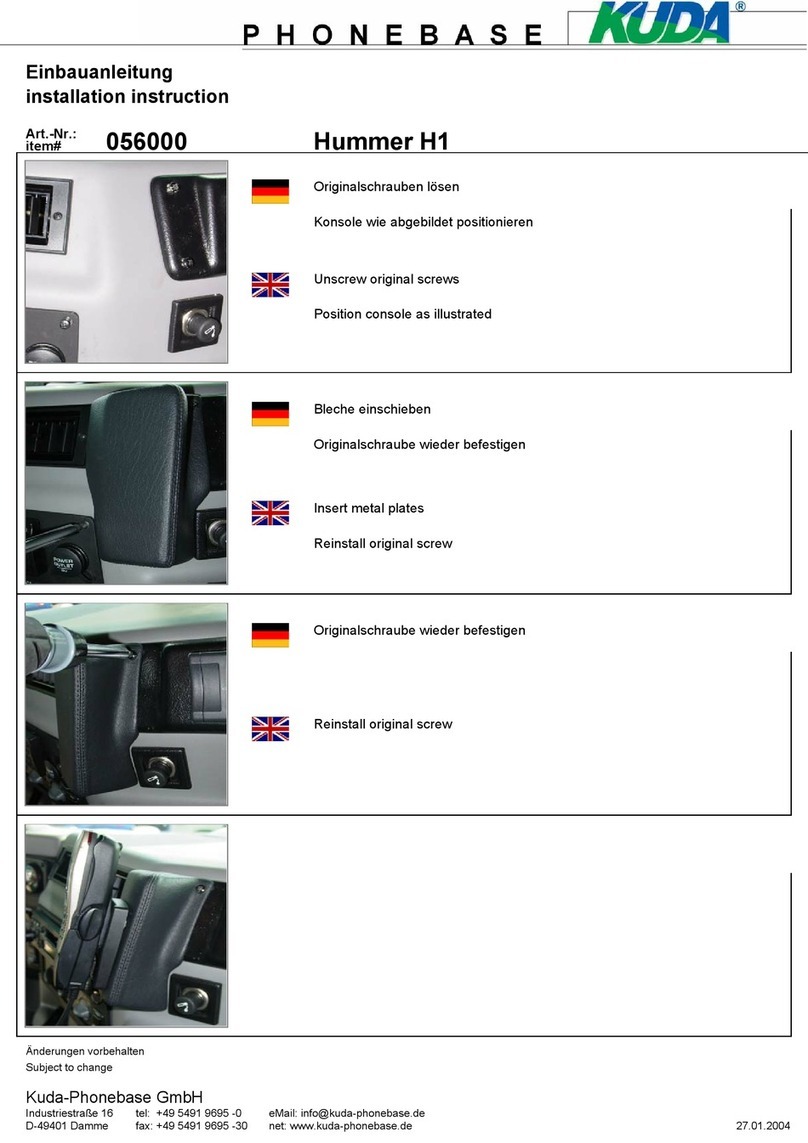

REINSTALLING THE BUMPER COVER

1. Use a 10 mm tool to replace the four screws securing the black beak to

the front of the car, shown in Figure 5.

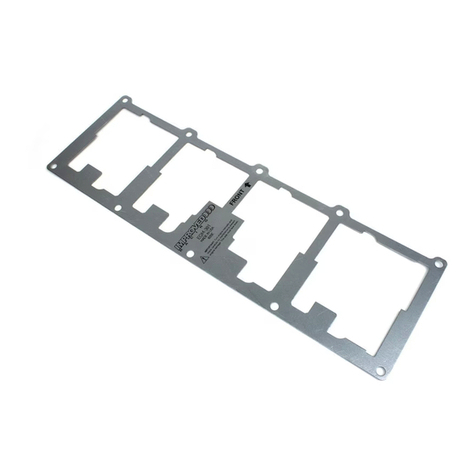

2. Cut the black plastic, lower radiator shroud as shown in Figure 19.

5” MIN

Figure 19 - Trimmed Black Plastic Lower Radiator Shroud

17

Visit www.improvedracing.com for additional support

3. Reinstallthemodiedblackplasticshroudontothevehiclebynagling

the hoses into the cutout, followed by reinserting the plastic push-clips.

4. With two people, carefully place the bumper straight onto the front of

the car.

Tip: Be sure to connect all wire harnesses and lock the safety tab!

5. Peel-back the wheel-well linings on each side to:

a. Connect all fog light harnesses.

b.

Use an extended 10 mm tool to replace the four screws securing the

bumper cover to the fender support

c. Use a 7 mm tool to replace one screw securing the bumper cover to

the fender.

6.

Use a 7 mm tool to replace all screws in the wheel wells. Cite Figure 4 for

locations.

7. Put the wheels back on, if applicable.

8. Use a T20 tool to replace all screws underneath the bumper cover, im-

mediately in front of the wheels. There are four per side. Cite Figure 5

for locations.

9. Use a 10 mm tool to replace the two screws on the bottom which hold

the bumper cover to the chassis. Cite Figure 2 for locations.

10. Use a 10 mm tool to replace the screws at each corner under the hood.

Cite Figure 1 for locations.

11. Replace all of the plastic pop-clips underneath the hood which pin the

bumper cover to the radiator support. Cite Figure 1 for locations.

12. Peel-off all masking tape from the fenders.

13. Close the hood and safely lower vehicle back onto the ground.

14. Take a test drive to ensure performance is as desired.

15. Checkforloosenedttingsandleaksafter50milesofdriving.

Installation is now complete. Thank you for purchasing an Improved Racing

product!

Table of contents

Other Improved Racing Automobile Accessories manuals

Improved Racing

Improved Racing EGM-201 User manual

Improved Racing

Improved Racing FSM -RKIT Series User manual

Improved Racing

Improved Racing EFR-600-TX User manual

Improved Racing

Improved Racing EGM-301 User manual

Improved Racing

Improved Racing ENV-131-TX User manual

Improved Racing

Improved Racing EFR-605 User manual

Improved Racing

Improved Racing EGM-502 User manual

Improved Racing

Improved Racing E5G-601 User manual