Visit www.improvedracing.com for additional support 5

5. Remove all parts from the bumper bar for drilling.

6.

Drill a 3/8 inch hole into the bumper bar using a sharp, high-quality, cobalt

steel drill bit.

The bumper bar is made from hardened steel; a sharp drill bit is required

to cut through it.

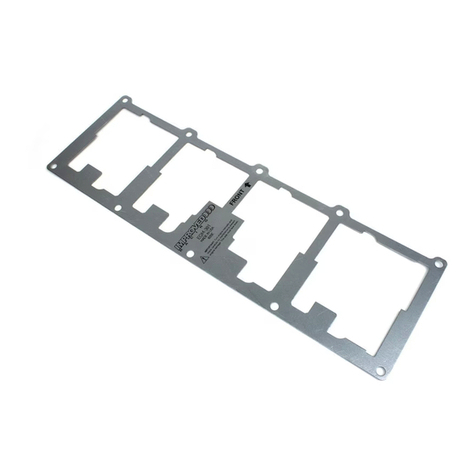

7. Use a 10mm tool to secure the mounting bracket to ENV-170 with the

provided M6 screws.

8. Use a 12mm tool to install ENV-170 onto the bumper with the backing

plate using two M8 screws from the hardware kit.

9. TorquetheM8bracketscrewsto20lb-ft(27N-m).

10. Reinstall the bumper bar onto the vehicle and use the old paint marks to

get alignment correct.

11. Torque the bumper bar screws according to factory spec.

INSTALLING THE OIL COOLER & BRACKETS

1.

Remove the black plastic fascia panel in the driver side wheel well by

using a forked prying tool to remove three push-in fasteners.

Refer to Figure 4 if unsure what panel this is.

2. Use an 8mm tool to remove the power steering cooler from the radiator

support when you car is equipped with a power steering cooler.

3.

Use cable ties or string to hang the power steering cooler from the bottom

of the radiator support to reduce stress on the hoses and lines.

4.

Familiarize yourself with MHX-520 by reading over the product manual.

5.

Locate the EFR-600-60 Bracket Kit, then install the top bracket onto

MHX-520 using the supplied M8 screws and a 12 mm tool.

The ports on MHX-520 face the long arm of the bracket.

6. TorquetheM8screwsto20lb-ft(27N-m).

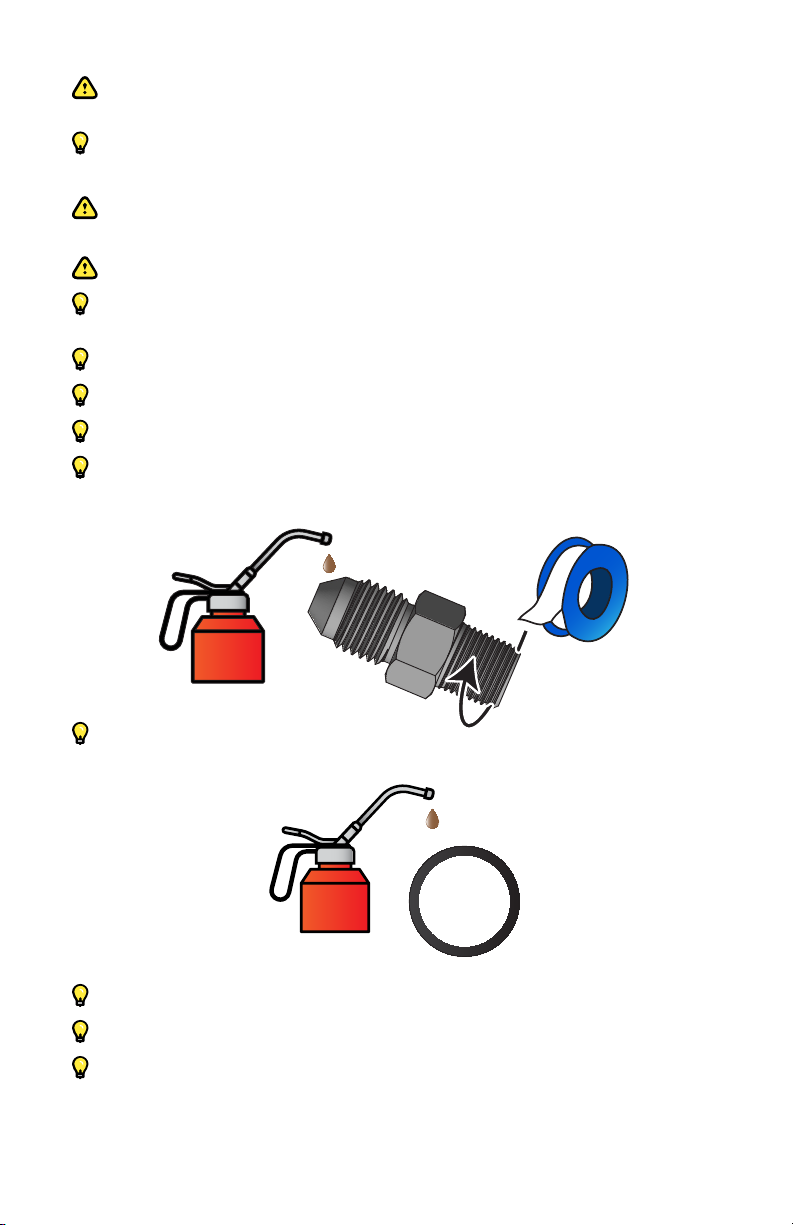

7. Usea1inchtooltoinstalltwoOM-10-10ttingsintoMHX-520.

8. Torquetheadapterttingsto25lb-ft(34N-m).

9. Use a 12 mm tool and the remaining screws and washers from the EFR-

600-60 Bracket Kit to loosely secure the top bracket to the radiator

support, as shown in Figure 2.