165910 Dew Point Meter 8072A Manual 6 June 2014

Operation

The 8072A is designed to sample process air that is near

atmospheric pressure, NOT compressed air. If you are

attempting to monitor compressed air, consult IMS Company

for other model options.

NOTE: For best sensor life and response time, avoid sampling

ambient air of high humidity. Leave unit off when not

monitoring a dryer or hopper.

CAUTION: The carrying case is not heat resistant. It may melt

or distort if left resting on the hot parts of a heated dryer. If a

surface is too hot to touch, it is too hot for the 8072A!

Sample Tubing Connection

To enable testing of your process air, you must provide fittings

in your drying system that will accept the 8072A’s 3/16” ID

sample tubing. This can be a barbed hose fitting or a piece of

¼” copper tube that penetrates your dryer’s air hoses. This

point of attachment must be secure and leak-free. Some dryer

manufacturers provide a port for sampling. Check your dryers

owner’s manual for its location if available.

The sampling tubing supplied with the monitor can tolerate

temperatures up to 275qF (135qC). Higher process air

temperatures can be cooled to a safe level by sampling through

a few feet of ¼” copper tubing.

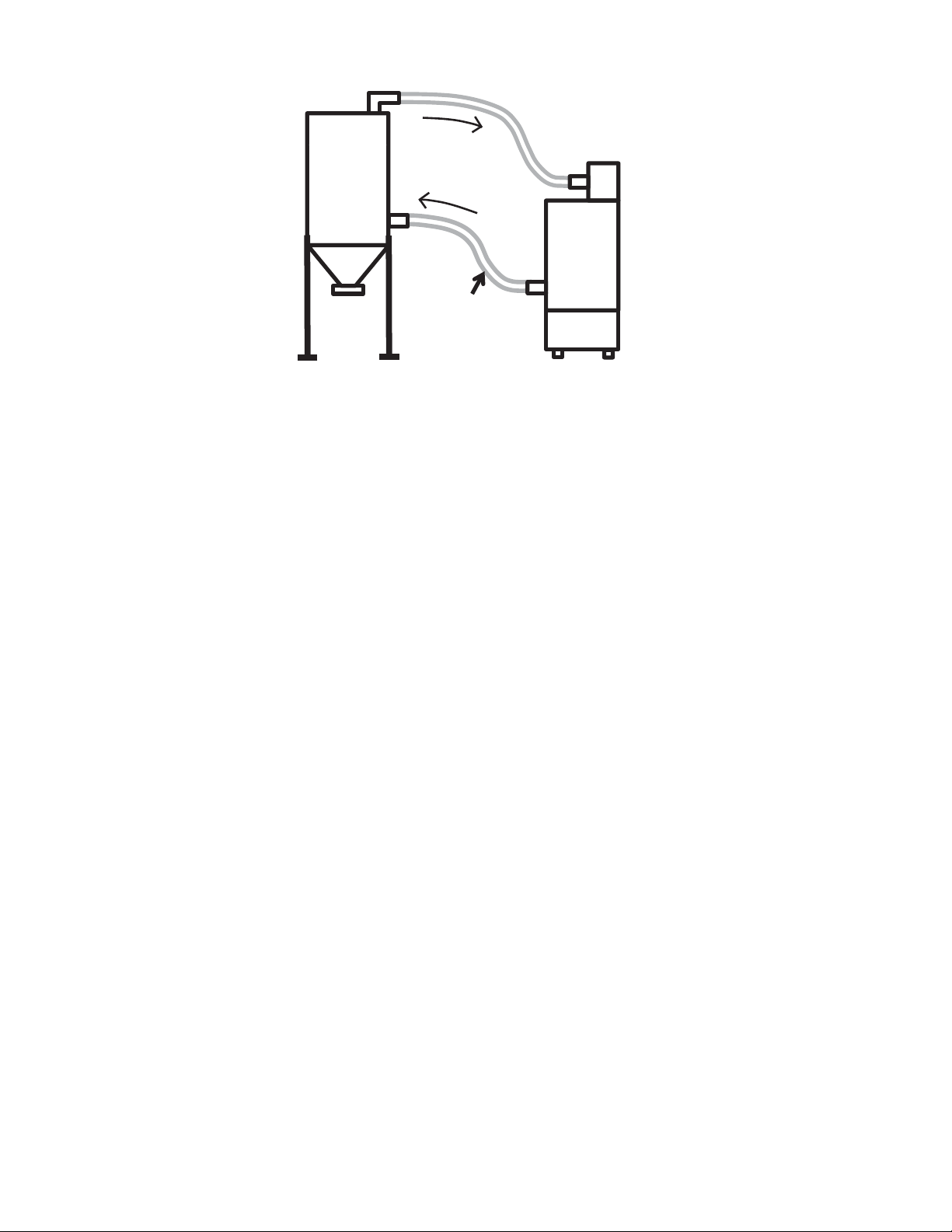

Select the sample locations based on your testing needs (refer

to diagram below). It is suggested that you have a permanently

accessible sample point. A barbed fitting with valve at the

output of the dryer is best.