Imsai 8080 User manual

-~

ARTISAN

®

~I

TECHNOLOGY

GROUP

Your definitive source

for

quality

pre-owned

equipment.

Artisan Technology

Group

Full-service,

independent

repair

center

with

experienced

engineers

and

technicians

on staff.

We

buy

your

excess,

underutilized,

and

idle

equipment

along

with

credit

for

buybacks

and

trade-ins

.

Custom

engineering

so

your

equipment

works

exactly as

you

specify.

•

Critical

and

expedited

services

•

Leasing

/

Rentals/

Demos

• In

stock/

Ready-to-ship

•

!TAR-certified

secure

asset

solutions

Expert

team

ITrust

guarantee

I

100%

satisfaction

All

tr

ademarks,

br

a

nd

names, a

nd

br

a

nd

s a

pp

earing here

in

are

th

e property of

th

e

ir

r

es

pecti

ve

ow

ner

s.

Visit our website - Click HERE

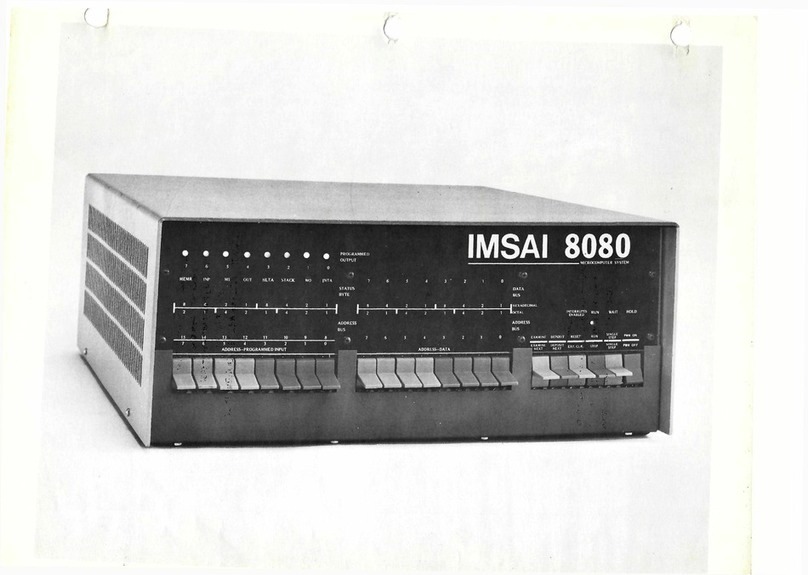

INTRODUCTION

IMSAI

8080

System

Introduction

The

documentation

for

the

IMSAI

8080

Microcomputer

System

consists

of

several

books.

This

volume,

the

IMSAI

8080

Microcomputer

System

User

Manual,

contains

a

detailed

description

of

the

features

and

configuration

of

the

com-

puter

as

a

complete

system.

It

also

describes

the

printed

circuit

boards

that

form

the

system

building

blocks.

The

chapter

format

begins

with

a

functional

description

of

the

system

or

board,

including

brief

notes

about

all

the

fea-

tures.

The

actual

operation

of

the

system

or

board

is

then

described

in

a

theory

of

operations

section.

The

physical

and

electronic

arrangement

of

the

system

or

board

are

next

shown

with

a

photograph

and

a

schematic

•.

Assembly

of

the

board

from

a

kit

is

described

by

assembly

drawings

or

photos,

a

complete

parts

list,

and

assembly

instructions

in

each

chapter.

Finally,

the

information

that

tells

th~

user

how

to

use

the

design

features

of

the

board

to

imple-

ment

various

functional

options

is

contained

in

a

user

guide

section

for

each

board.

Operation

of

the

computer

as

a

system

is

documented

in

the

IMSAI

8080

Microcomputer

System

User

Manual

in

the

chapter

General

Assembly

and

Test

Instructions

and

also

in

the

chapter

on

the

CP-A

(Front

Panel

Control

Board).

The

software

supplied

with

the

basic

uni~,

consisting

of

a

resident

monitor,

assembler

and

text

editor

is

described

in

the

last

chapter

of

the

IMSAI

8080

Microcomputer

System

User

Manual.

This

chapter

includes

both

a

description

of

the

software

and

a

complete

object

listing.

Supporting

documentation

is

provided

by

a

copy

of

the

Intel

8080

Microcomputer

System

Users

Manual,

supplied

in

every

system

kit

to

give

IMSAI

users

the

primary

source

of

detailed

information

about

the

function

and

instruction

set

of

the

logic

implemented

by

the

intergrated

circuit

chip

set

used

in

the

IMSAI

8080.

A

handy

reference

card,

the

Intel

8080

Assembly

Language

Reference

Card,

is

suppl~ed

to

summarize

much

useful

information

from

this

manual.

To

assist

users

in

gaining

a

full

perspective

on

the

design

and

use

of

microprocessor-based

computer

systems,

IMSAI

includes

a

basic

text,

An

Introduction

to

Microcomputers.

IMSAI

is

currently

working

intensively

on

both

additional

hardware

(more

peripheral

systems,

the

Shared

Memory

Facility,

etc.)

and

system

software.

Full

documentation

of

these

addi-

tions

will

be

made

available

to

IMSAI

owners

as

it

is

produced;

the

charge

will

be

a

nominal

fee

to

cover

the

cost

of

repro-

duction.

12

System

Features

IMSAI

8080

MICROCOMPUTER

SYSTEM

FEATURES

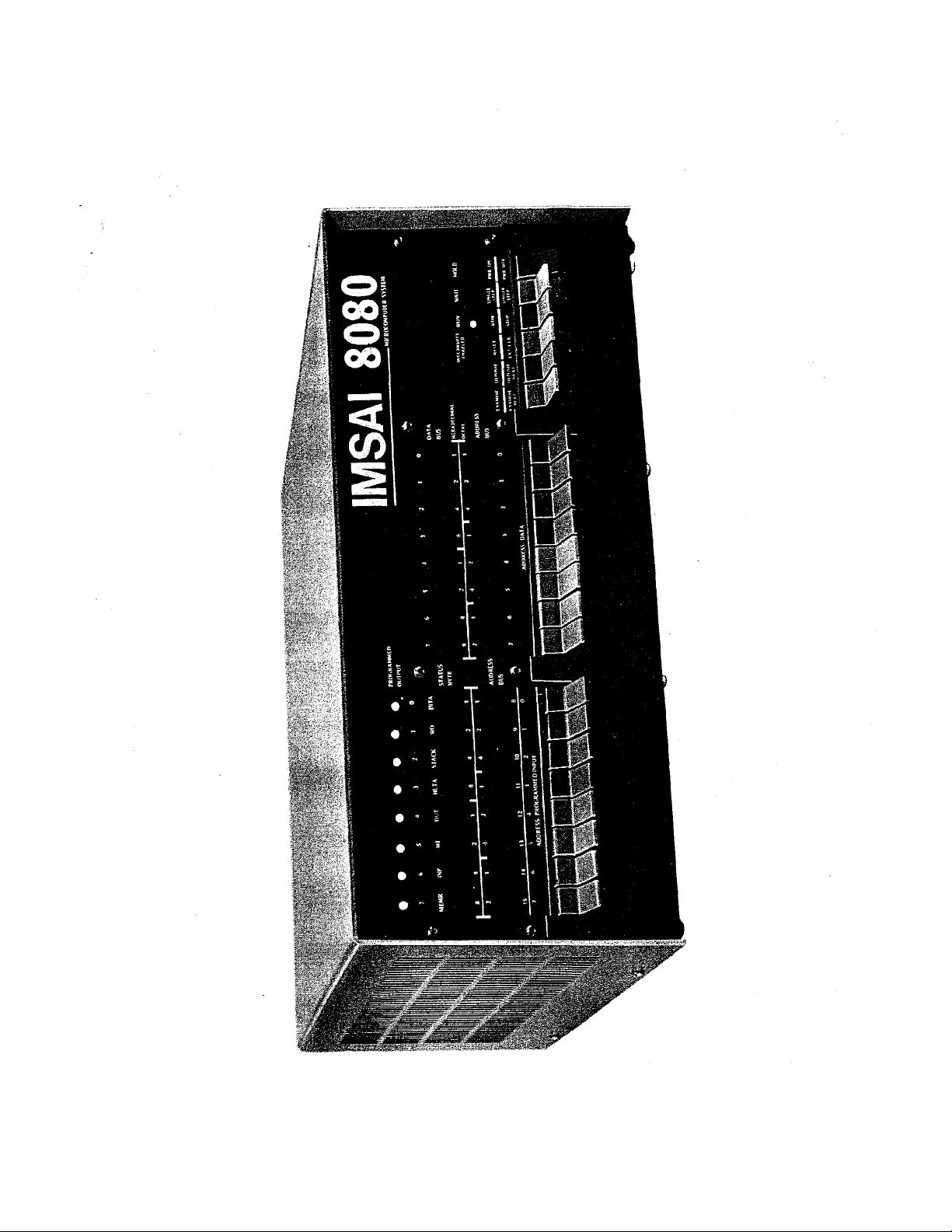

The

IMSAI

8080

is

a

high

quality

microprocessor

based

computer

system

offering

outstanding

capability

and

flexibility

at

low

cost.

Designed

to

facilitate

simple

modular

expansion,

the

system

has

both

the

power

and

the

versatility

to

handle

a

broad

range

of

data

processing

needs.

The

IMSAI

8080

is

currently

supported

by

a

broad

range

of

peripheral

devices

and

interfaces,

and

comes

with

a

basic

resident

monitor,

assembler,

and

text

editor,

free

of

charge.

A

broad

range

of

high

level

system

software

is

now

under

development,

and

will

be

available

soon

in

both

source

and

object

form

to

registered

IMSAI

8080

owners

at

the

cost

of

reproduction

and

handling.

The

IMSAI

8080

is

available

in

kit

or

assembled

form.

While

primarily

designed

as

a

commercial

computer,

the

unit

is

configured

to

facilitate

cons~ruction

by

any

careful

assembler.

High

grade

industrial

quality

design

and

com-

ponents

are

used

in

both.kits

and

assembled

units.

Complete

documentation

is

provided

with

each

system,

including:

IMSAI

8080

Microcomputer

System

User

Manual

(this

book).

Intel

8080

Microcomputer

Systems

User's

Manual,

completely

describing

the

integrated

circuits

used,

and

the

instruction

set.

An

Introduction

to

Microcomputers,

a

fundamental

textbook

on

the

use

of

microcomputer

systems.

a

90

day

warranty

on

the

system

is

provided.

Full

factory

service

is

available

at

a

cost

commensurate

with

the

work

required.

13

IMSAI

8080

System

Functional

Description

SYSTEM

FUNCTIONAL DESCRIPTION

The

IMSAI

8080

Microcomputer

system

is

a

full-scale

general

purpose

digital

computer.

Although

small

in

size

and

low

in

cost,

the

system

is

exceedingly

versatile

and

capable

of

data

processing

in

the

complete

spectrum

of

practical

applica~

tions.

The

IMSAI

8080

used

an

8080A

microprocessor

LSI

chip

to

perform

the

cen-tral

processing

function.

The

instruction

set

provided

by

the

8080A

is

described

fully

in

Chapter

4

of

8080

Microcomputer

System

User's

Manual,

provided

as

part

of

the

IMSAI

8080

documentation

package.

The

IMSAI

8080

system

is

capable

of

unlimited

expansion,

due

to

the

bus

structure

and

IMSAI's

exclusive

shared

memory

facility,_

which

permits

parallel

processing.

The

computing

power

that

can

be

made

available

with

the

IMSAI

8080

system

building

blocks

exceeds-

that

of

any

currently

available

minicomputer.

The

operation

of

the

IMSAI

8080

is

described

in

the

manual

chapters

titled

"General

Assembly

and

Test

Instructions"

and

in

the

CP-A

Front

Panel

Control

Board

chapter.

Input/output

features

are

described

in

the

I/O

board

chapters

including

SIO

(Serial

Input/Output

board},

PIO

(Parallel

Input/Output

board)

and

UCRI

(Cassette

Recorder

Interface

board).

IMSAI

8080

SOFTWARE

FEATURES

Basic

system

software

(resident

monitor,

text

editor

and

assembler)

distributed

in

object

form,

with

listing,

and

free

of

charge.

Future

software

releases

are:

14

4K

BASIC -

upward

compatible

to

DEC

standard

SUPER-BASIC

8K BASIC -

Upward

compatible

to

DEC

standard

SUPER-BASIC

12K

BASIC -

DEC

standard

SUPER-BASIC

compatible

Floppy

Disk

Operating

System

Linkage

Editor

Macro-Assembler

with

relocatable

code

generation

12K

FORTRAN

compiler

IMSAI

8080

System

Hardware

Features

IMSAI

8080

HARDWARE

FEATURES

Flat

cable

interconnection

used

throughout.

Absolute

minimum

point-to-point

w1r1ng.

Front

panel

has

programmed

output

port

with

LED

indicators.

Front

panel

has

large

easy-to-use

paddle

handle

switches.

Front

panel

legends

are

produced

photographically

and

mounted.

behind

acrylic

panel

for

protection.

Front

panel

has

filler

to

increase

contrast

of

LED

indicators.

Long-life

LEDs

used

throughout.

Front

panel

circuit

designed

so

that

one-shot

timing

links

are

non-critical.

No

point-to-point

wiring

to

connect

or

disconnect

front

panel

to

or

from

system.

·

Attractive

custom

designed

cabinet

and

panel.

Rackmount

cabinet

available

as

special

option.

Cabinet

designed

to

facilitate

customizing

front

panel.

Sturdy

card

cage

construction.

Room

for

22

cards.

Power

supply

subchassis

with

high-current

transformer

and

computer-grade

electrolytic

capacitors.

Heavy

duty

power

supply

supplies

power

sufficient

for

a

full

complement

of

cards

{28

amps,

up

to

500

watts).

Straight-through

back

plane

wiring.

No

special

purpose

slots.

Front

panel

plugs

into

any

slot

to

operate

machine.

Double-sided

print~d

circuit

boards

with

plated-through

holes

and

solder

mask.

All

board

contact

fingers

are

gold-plated

over

nickel.

PC

board

material

is

glass-fiber-reinforced

epoxy

laminate.

On-board

power

regulation.

Power

is

regulated

by

integrated

circuit

regulators

with

thermal

current

limits.

Tantalum

board

decoupling

capacitors.

Ample

.luf

disk

ceramic

power

decoupling

capacitors.

Designed

with

latest

LSI

and

MSI

components.

Package

count

minimized.

Heavy

current

tri-state

bus

drivers

used

throughout

the

system.

System

designed

from

initial

concept

for

multi-processor,

shared

memory

options.

15

IMSAI

8080

Microcomputer

System

Specifications

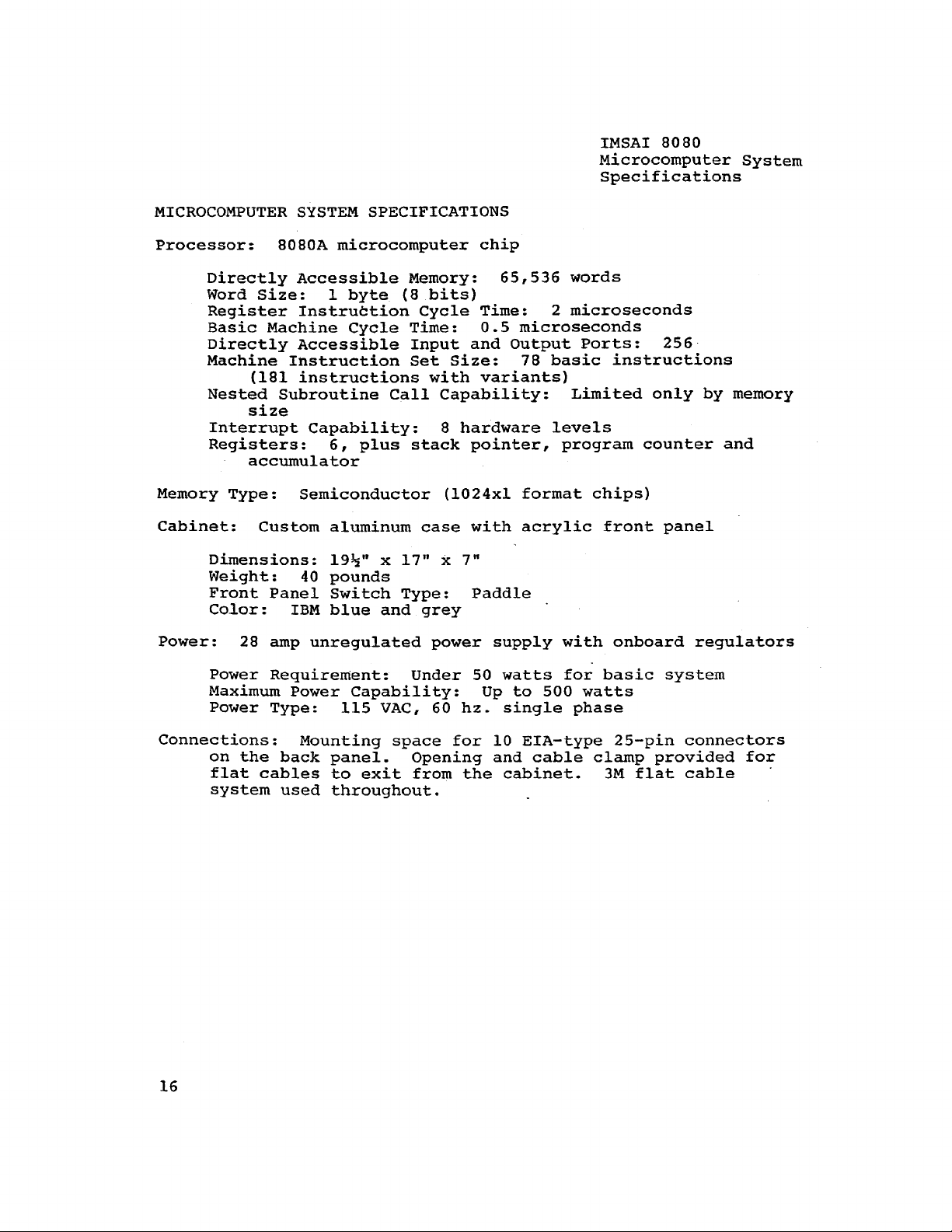

MICROCOMPUTER

SYSTEM

SPECIFICATIONS

Processor:

8080A

microcomputer

chip

Directly

Accessible

Memory:

65,536

words

Word

Size:

1

byte

(8

bits)

Register

Instruction

Cycle

Time:

2

microseconds

Basic

Machine

Cycle

Time:

0.5

microseconds

Directly

Accessible

Input

and

Output

Ports:

256

Machine

Instruction

Set

Size:

78

basic

instructions

(181

instructions

with

variants)

Nested

Subroutine

Call

Capability:

Limited

only

by

memory

size

Interrupt

Capability:

8

hardware

levels

Registers:

6,

plus

stack

pointer,

program

counter

and

accumulator

Memory

Type:

Semiconductor

(1024xl

format

chips)

Cabinet:

Custom

aluminum

case

with

acrylic

front

panel

Dimensions:

19~"

x

17"

x

7"

Weight:

40

pounds

Front

Panel

Switch

Type:

Paddle

Color:

IBM

blue

and

grey

Power:

28

amp

unregulated

power

supply

with

onboard

regulators

Power

Requirement:

Under

50

watts

for

basic

system

Maximum

Power

Capability:

Up

to

500

watts

Power

Type:

115

VAC,

60

hz.

single

phase

Connections:

Mounting

space

for

10

EIA-type

25-pin

connectors

on

the

back

panel.

Opening

and

cable

clamp

provided

for

flat

cables

to

exit

from

the

cabinet.

3M

flat

cable

system

used

throughout.

16

IMSAI

8080

System

Cabinet

Assembly

Instructions

CABINET

ASSEMBLY

INSTRUCTIONS

Begin

by

installing

the

correct

number

of

plastic

card

guides

on

the

chassis

part

C's.

The

card

guides

should

be

placed

from

the

front

backwards,

an

equal

number

on

each

piece

C,

taking

care

that

the

wedge

-

shaped

opening

of

the

slot

is

positioned

upwards.

Note

that

the

two

ends

of

piece

C

arerot

symmetrical.

The

end

with

the

wider

space

between

the

last

small

hole

for

mounting

the

card

guide

and

the

end

flange

is

placed

toward

the

back

of

the

cabinet,

so

that

the

guides

will

line

up

with

the

connectors

on

the

Mother

board.

The

card

guides

should

be

assembled

starting

from

the

front

end

(with

card

guide

mounting

holes

placed

closer

to

the

end

flange).

Make

sure

you

place

the

card

guide

so

as

to

form

a

left

hand

and

a

right

hand

mounting-rail

piece.

If

this

is

not

done,

then

the

card

guides

will

be

upside

down

on

one

of

the

two

piece

'C's

when

they

are

mounted

into

the

cabinet.

The

card

guides

are

most

easily

mounted

using

a

small

press

and

placing

the

tab

of

each

card

guide

in

position

started

into

the

hole

and

pressing

them

into

place

un-

til

the

mounting

tabs

snap

through.

A

drill

press

with

a

large

flat

-

headed

screw

mounted

in

the

chuck

works

well

with

this

op-

eration.

(Alternately,

the

card

guides

may

be

installed

very

care-

fully

using

needle

nosed

pliers).

care

should

be

taken

that

the

tabs

are

started

into

the

hole

when

beginning

to

press

the

guide

into

place,

otherwise

one

or

both

may

be

bent

out

flat

and

bro~en

off.

One

end

of

the

guide

at

a

time

should

be

inserted

rather

than

trying

to

press

both

ends

in

simultaneously.

If

a

fan

is

to

be

installed

in

the

chassis,

it

should

be

assembled

on

the

back

frame

piece

Al

at

this

time

using

the

hardware

in

the

fan

kit.

The

fan

terminals

should

be

towards

the

top

and

towards

the

Mother

board

side

of

the

chassis.

Next,

the

power

cord

should

be

inserted

using

the

special

gronunet

in

the

hole

provided

on

the

back

panel.

4

to

6

inches

of

the

power

cord

should

be

left

on

the

inside

of

the

cabinet.

If

the

power

cord

grommet

is

squeezed

together

with

a

pair

of

pliers

before

in-

sertion

into

the

cabinet

back,

it

will

ease

the

job

of

inserting

this

tight

fitting

grommet.

To

insert

the

grommet,

the

power

cord

should

be

pulled

through

the

hole

nearly

to

the

point

where

the

grommet

has

been

placed

around

the

power

cord,

then

the

outer

edge

of

the

grommet

can

be

grasped

with

a

pair

of

pliers

and

squeezed

slightly

and

inserted

in

the

hole

and

worked

in

while

slight

tension

is

also

being

put

on

the

cord

from

the

back

side

to

assist.

Work-

ing

this

grommet

in

by

rocking

it

back

and

forth

works

better

than

just

pushing

harder.

The

front

and

back

frames

can

now

be

screwed

to

the

base

plate

using

6-32x5/l6"

machine

screws.

Note

that

the

back

frame

fits

under

the

base

plate

and

the

front

frame

fits

on

top

of

the

base

plate,

set

back

about

l"

from

the

front

edge

of

the

base

plate.

Next,

install

1 - 1

IMSAI

8080

System

Cabinet

Assembly

Instructions

the

two

card

frames

between

the

front

and

back

frames.

Use

two

6-32x5/l6"

machine

screws

at

each

end

of

each

card

frame.

The

front

and

back

frames

have

slotted

holes

allowing

the

card

frames

to

be

adjusted

slightly

when

the

Mother

board

is

installed

on

the

base

plate

and

boards

are

inserted

in

the

card

frames.

The

self-adhesive

rubber

feet

can

then

be

separated

from

each

other,

the

protective

backing

removed,

and

placed

on

the

bottom

of

the

cabinet

spaced

3

inches

along

the

left

hand

and

right

hand

edge

of

the

bottom,

to

support

the

cabinet

weight.

BASE PLATE

HOLE

IDENTIFICATION

The

base

plate

currently

being

shipped

is

a

universal

base

plate,

with

extra

holes

for

accomodating

two

styles

of

mother

board

mount-

ing

systems

and

two

styles

of

power

supplies.

For

the

power

supply

and

mother

board

systems

shipped

with

your

kit:

1.

Place

the

Power

Supply

p.c.

board

in

the

base

plate

cavity

and

line

up

the

holes

in

the

p.c.

board

with

the

correspon-

ding

holes

in

the

base

plate

and

mark

(e.g.,

with

a

felt-

tip

pen)

which

holes

are

to

be

used.

2.

The

mother

board

mounting

system

use's

the

two

rows

of

12

holes

each

on

the

left

side

of

the

base

plate.

SWITCH

ESCUTCHEON

INSTALLATION

When

the

CP-A

Front

Panel

Assembly

has

been

mounted,

the

Switch

Escutcheon

{piece

A2B)

can

be

installed

on

the

.base

plate

at

the

front

of

the

computer

using

four

6-32x5/16"

Phillips

pan

head

machine

screws.

Note

that

the

Escutcheon

should

fit

under

the

base

plate.

CABLE

CLAMP

INSTALLATION

Cables

that

do

not

fit

the

connector

holes

on

the

back

frame

of

the

chassis

may

be

clamped

for

strain

relief

at

the

top

of

the

back

frame

using

the

L -

shaped

aluminum

bar,

piece

K.

Install

using

two

6-32x~"

Phillips

pan

head

machine

screws.

Depending

on

the

thickness

of

the

cables

being

clamped,

either

of

the

two

sides

of

the

angle

may

be

used.

TABLE TOP

COVER

INSTALLATION ·

To

install

the

table

top

c·over,

slide

the

cover

carefully

over

the

chassis

frame

and

hold

in

place

with

four

6-32x~"

Phillips

pan

head

machine

screws.

Refer

to

Appendices

for

an

exploded

view

of

·the

chassis

cabinet.

1 - 2

IMSAI

8080

System

Cabinet

Assembly

Instructions

RACK

MOUNT

SYSTEM

ASSEMBLY

INSTRUCTIONS

For

the

rack

mount

system,

begin

by

installing

the

rack

mount

cover

on

the

chassis.

Use

five

6-32x5/16"

Phillips

pan

head

machine

screws.

Next

install

the

left

and

right

side

plates

to

the

chassis

with

the

front

flanges

pointing

outwards.

Use

four

6-32x~"

Phillips

pan

head

machine

screws

on

each

side

plate.

The

forward

holes

in

each

pattern

on

the

side

plates

should

be

used.

Next

mount

the

assembly

in

the

rack

using

two

screws

on

each

side

of

the

front

flanges.

Hardware

requirements

for

mounting

the

assem-

bly

into

the

rack

will

vary

according

to

the

individual

rack.

It

is

suggested

that

the

rear

of

the

assembly

also

be

supported

in

the

rack.

Finally,

mount

the

front

face

panel

onto

the

side

plate

flanges

using

four

#10

round

head

screws

and

clips.

NOTE:

for

installations

without

slides

where

easy

removal

of

the

computer

~s

desired,

the

side

plates

can

be

mounted

directly

in

the

rack

and

the

computer

can

be

slid

on

its

rubber

feet

en

the

bottom

flanges

of

the

side

plates.

The

rear

of

the

side

plates

in

this

case

should

be

fastened

securely

to

t~e

back

of

the

rack

cabinet.

1 - 3

ITEM

.

Screw

Screw

Screw

Screw

Nut

8080

Rack

Mount

Parts

List

IMSAI

PART i QUANTITY DESCRIPTION

93-3010008

93-3070001

93-3070002

93-3010012

20-3302001

20-3502001

20-5707001

20-5708001

21-5650001

1

1

1

1

5

8

4

4

8

Rack

Mount

Front

Panel

Rev.

C

Rack

Mount

Left

Slide

Rev.

C

Rack

Mount

Right

Slide

Rev.

0

Rack

Mount

Cover

Rev.

B

6-32x5/16"_Phillips

Pan

Head

Machine

Screw

6-32x~n

Phillips

Pan

Head

Machine

Screw

il0x3/4n

Flat

Head

Type

B

Self-Tapping

Sheet

Metal

Screw

il0x3/4"

Button

Head

Type

B

S~lf-Tapping

Sheet

Metal

Screw

.

Speed

Nut,

Tinnerman

c

9031-loz.-1

1 - 7

IMSAI

8080

Chassis

Parts

Li.st

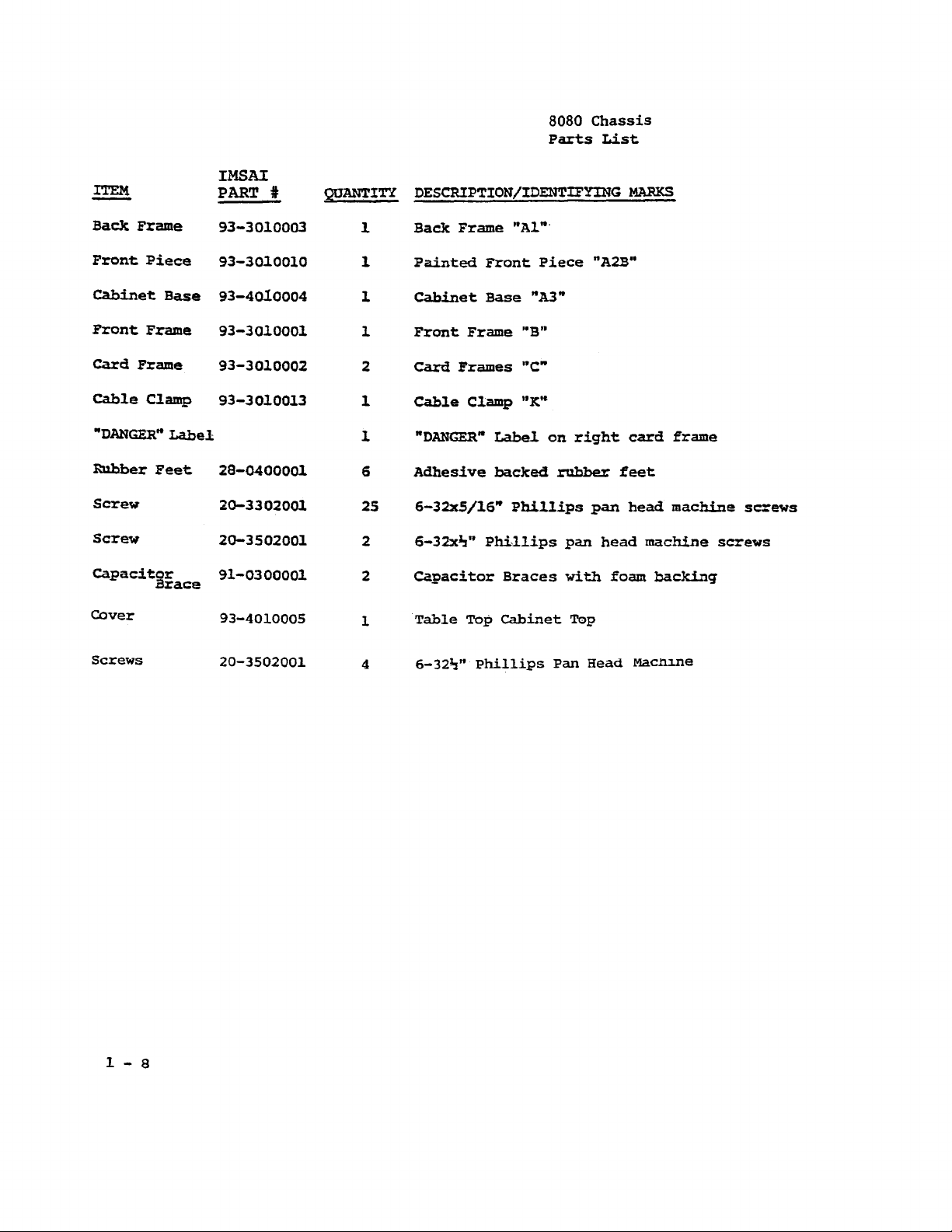

ITEM

PART

i QUANTITY DESCRIPTION/IDENTIFYING

MARKS

Back

Frame

93-3010003

1

Back

Frame

"Al"·

Front

Piece

93-30~0010

1

Painted

Front

Piece

"A2B"

cabinet

Base

93-4010004

l

cabinet

Base

"A3"

Front

Frame

93-30~0001

1

Front

Frame

"B"

Card

Frame

93-3010002

2

Card

Frames

"C"

cable

Clamp

93-3010013

1

Cable

Clamp

"X"

"DANGER"

Label

l

"DANGER"

Labe~

on

right

card

frame

Rubber

Feet

28-0400001

6

Adhesive

backed

rubber

feet

Screw

2Q-3302001

25

6-32x5/l6"

Phillips

pan

head

machine

screws

Screw

2Q-350200l

2

6-32x~"

PhiJ.lips

pan

head

machine

screws

capacitor

91-0300001

Brace

2

capacitor

Braces

with

foam

backing

Cover

93-4010005 1

Table

Top

Cabinet

Top

Screws

20-3502001

4

6-32~"

Phillips

Pan

Head

Mac.l:une

1 - 8

INTRODUCTION

This

chapter

contains

the

following

sections:

1.

Kit

Unpacking

Instructions

IMSAI

8080

System

General

Assembly

and

Test

Instructions

2.

Construction

Hints

-

general

notes

on

how

to

build

your

kit.

3.

Recommended

Overall

Order

of

Assembly

(includes

cross-reference

to

chapters

where

specific

assembly

instructions

for

the

various

subrnodules

will

be

found).

4.

Mainframe

Assembly

-

assembly

instructions

for

integrating

Chassis

with

Power

Supply,

Mother

board

and

Front

Panel,

and

instructions

for

testing

the

Power

Supply.

5.

System

Functional

Test

-how

to

check

out

your

overall

system.

17

18

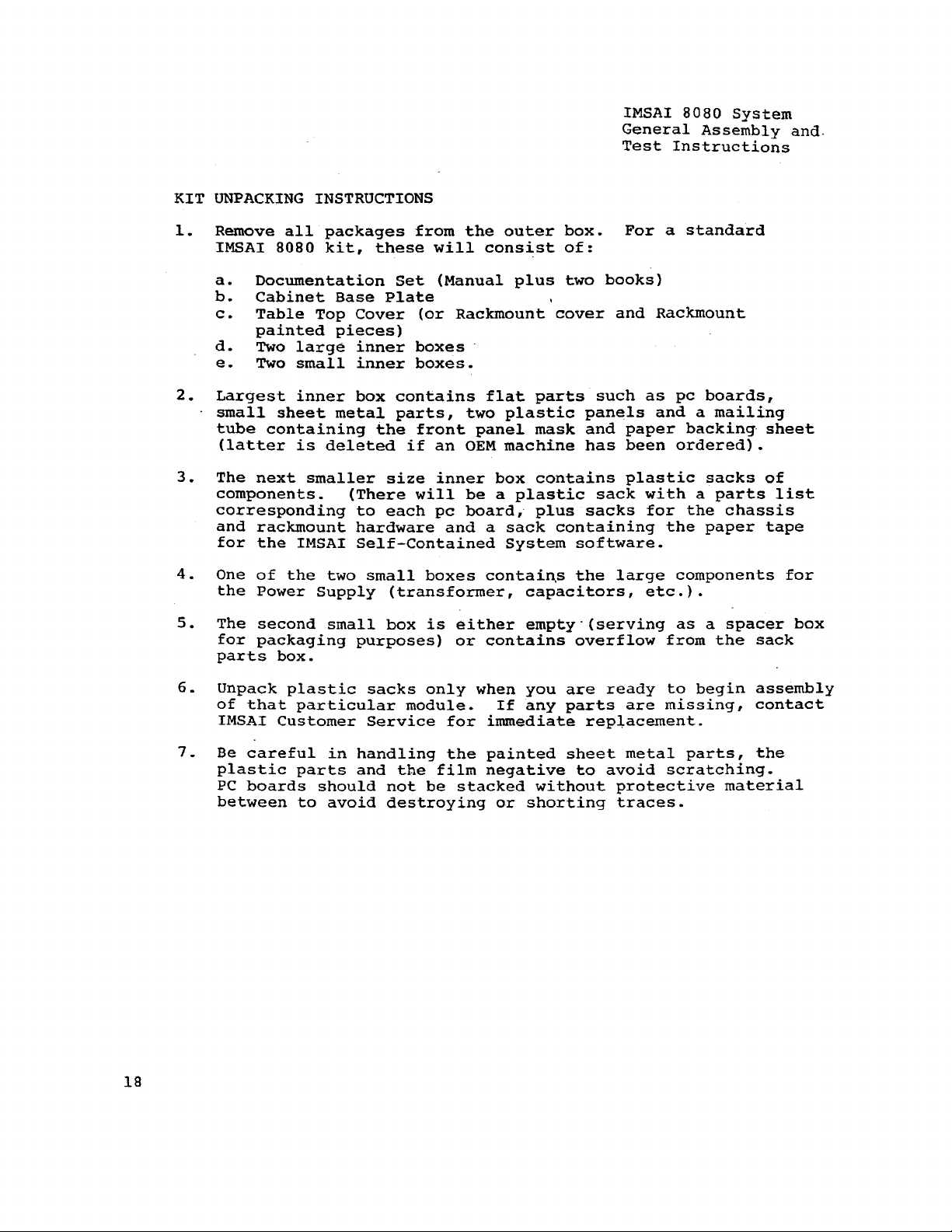

KIT

UNPACKING

INSTRUCTIONS

IMSAI

8080

System

General

Assembly

and.

Test

Instructions

1.

Remove

all

packages

from

the

outer

box.

For

a

standard

IMSAI

8080

kit,

these

will

consist

of:

a.

Documentation

Set

(Manual

plus

two

books)

b.

Cabinet

Base

Plate

c.

Table

Top

Cover

(or

Rackmount

cover

and

Rackmount

painted

pieces)

d.

Two

large

inner

boxes

e.

Two

small

inner

boxes.

2.

Largest

inner

box

contains

flat

parts

such

as

pc

boards,

small

sheet

metal

parts,

two

plastic

panels

and

a

mailing

tube

containing

the

front

panel

mask

and

paper

backing·

sheet

(latter

is

deleted

if

an

OEM

machine

has

been

ordered).

3.

The

next

smaller

size

inner

box

contains

plastic

sacks

of

components.

(There

will

be

a

plastic

sack

with

a

parts

list

corresponding

to

each

pc

board,

plus

sacks

for

the

chassis

and

rackmount

hardware

and

a

sack

containing

the

paper

tape

for

the

IMSAI

Self-Contained

System

software.

4.

One

of

the

two

small

boxes

contai~s

the

large

components

for

the

Power

Supply

(transformer,

capacitors,

etc.).

5.

The

second

small

box

is

either

empty·(serving

as

a

spacer

box

for

packaging

purposes)

or

contains

overflow

from

the

sack

parts

box.

6.

Unpack

plastic

sacks

only

when

you

are

ready

to

begin

assembly

of

that

particular

module.

If

any

parts

are

missing,

contact

IMSAI

Customer

Service

for

immediate

replacement.

7.

Be

careful

in

handling

the

painted

sheet

metal

parts,

the

plastic

parts

and

the

film

negative

to

avoid

scratching.

PC

boards

should

not

be

stacked

without

protective

material

between

to

avoid

destroying

or

shorting

traces.

CONSTRUCTION HINTS

GENERAL

IMSAI

8080

System

General

Assembly

Notes

The

IMSAI

8080

microcomputer

is

a

complex

piece

of

electronic

equipment.

This

section

covers

a

number

of

items,

each

of

which

must

be

followed

to

insure

a

working

system

at

the

completion

of

assembly.

This

entire

section

must

be

read

completely

before

beginning

assembly,

and

the

builder

must

refer

back

to

the

notes

in

this

section

often

enough

to

in-

sure

that

no

components

are

installed

incorrectly.

While

each

assembly

step

is

easy

to

do

correctly,

there

are

many

steps

and

it

is

also

easy

to

do

one

or

more

incorrectly,

and

much

more

time

will

be

spent

solving

a

problem

than

would

have

been

needed

to

prevent

it.

There

may

be

items

about

which

you

are

not

completely

sure

during

assembly.

Should

this

occur,

DO

NOT

CONTINUE.

Study

the

manual

to

see

if

you

can

resolve

your

question,

or

seek

the

help

of

someone

more

knowledgeable

in

digital

electronics.

If

you

feel

your

questibn

is

not

resolved

by

further

study

or

asking

whoever

is

available

to

you,

call

IMSAI.

This

will

enable

you

to

do

a

better

construction

job,

and

it

will

enable

us

to

revise

the

manual

so

that

it

will

be

of

more

assistance

to

you.

We

recognize

that

some

builders

will

have

had

very

little

experience

in

assembling

electronic

kits,

and

it

is

our

intention

to

continually

revise

the

manual

based

on

comments

by

users,

so

that

even

the

most

inexperienced

build-

er

can

achieve

the

best

unit

available

with

a

minimum

of

effort.

No

question

is

too

simple

to

call

about

if

you're

not

sure

about

it.

TOOLS

AND

WORKPLACE

It.is

next

to

impossible

for

even

an

experienced

builder

to

produce

a

good

machine

unless

proper

tools

and

an

adequate

workspace

are

available.

Thekit

does

not

require

much

space

to

work

in,

but

enough

table

surface

should

be

available

for

the

piece

being

worked

on,

all

the

tools

needed

for

that

piece,

and

an

orderly

arrangement

of

the

components

which

wil.l

be

used

in

assembling

that

piece.

The

work

area

should

be

very

well-lit,

with

no

shadows.

If

the

entire

room

is

not

well-lit

by

ceiling

or

window

light,

then

at

least

two

bright

lamps

should

be

used,

preferably

one

on

either

side

and

slightly

behind

the

chair

to

help

eliminate

shadows.

You

may

want

to

protect

the

table

surface

with

cardboard

or

newspaper.

19

20

IMSAI

8080

System

General

Assembly

Notes

The

most

important

single

item

in

assembly

is

the

solder-

ing

iron.

It

is

critical

enough

that

a

separate

part

of

this

section

is

devoted

to

it.

Other

tools

which

are

ab-

solutely

necessary

to

do

an

adequate

assembly

job

are

screw-

drivers

to

fit

the

screws

used

in

the

kit

(both

straight

slot

and

phillips),

a

small

pair

of

diagonal

cutters

(pre-

ferably

a

4"

pair,

flush-cutting),

small

needle-nosed

pliers,

and

a

wire

stripper.

A

1/4"

nut

driverwi.ll

make

cabinet

assembly

very

much

easier,

as

the

sheet-metal

screws

used

are

designed

primarily

to

use

a

nut-driver.

A

voltmeter

should

be

available·for

testing.

Any

inexpensive

meter

(VOM)

with

DC

voltage

scales

between

5

and

30

volts

should

do.

Do

not

attempt

to

assemble

the

kit

until

you

have

the

tools

necessary;

damaged

parts

cannot

be

replaced

under

warranty.

SOLDERING

Almost

every

problem

with

an

assembled

kit,is

a

soldering

problem.

If

you

have

never

soldered

before,

or

_if,

you

have

done,some

soldering

but

do

not

yet

have

facility

in

making

good

soldering

joints

both

quickly

and

every

time,

practice

before

beginning

assembly

on

the

IMSAI

8080

boards.

Obtain

some

extra

#20

hook-up

wire

and

solder

locally

and

solder

pieces

together

until

you

feel

comfortably

able

to

quickly

make

a

good

joint.

The

importance

of

good

solder

joints

is

just

too

great

to

convey·

adequately

here;

but

don't

be

scared

off,

because

once

you

get

the

hang

of

it,

they're

very

easy

to

do.

Soldering

Irons

There

are

a

great

many

tools

available

with

the

name

"solder-

ing

iron".

Two

thirds

of

these

are

not

appropriate

to

small

electronics

assembly

and

if

used

are

almost

certain

to

damage

both

parts

and

boards.

The

problem

with

most

of

these

are

that

they

are

too

big

and

too

hot.

Note

that

most

every

soldering

"gun"

is

in

the

too

big,

too

hot

class.

Proper·

soldering

irons

are

easily

available

at

any

local

hobbyist

electronics

outlet,

and

they

are

not

expensive.

Use

a

30-40

watt

iron

with

a

small

tip,

such

as

an

Ungar

776

with

a

7155

tip.

If

you

wish

to

invest

in

a

top-quality

tool,

a

temper-

ature-controlled

tip

model

such

as

the

Weller

W-TCP

with

a

small

700°F

tip

is

well

worth

the

extra

cost.

Many

irons

are

available

with

either

unplated

copper

tips

or

plated

tips.

Though

slightly

more

expensive,

the

plated

tips

last

very

much

longer

and

give

superior

service.

Solder

IMSAI

8080

System

General

Assembly

Notes

Using

the

proper

solder

is

as

important

as

using

the

proper

iron,

and

there

are

many

solders

to

choose

among.

In

normal

electronics

assembly,

separate

paste

or

liquid

flux

is

not

used.

Rather,

.a

solder

with

a

"core"

of

rosin

(or

resin)

base

flux

is

used.

This

flux

(contained

in

the

hollow

center

of

the

solder)

should

be

sufficient.

Absolutely

avoid

any

solders

using

an

acid

flux.

(Or

any

cans

of

acid

flux

-

unless

a

can

of

flux

says"rosin"

you

may

safely

assume

it

is

an

acid

flux.

Acid

fluxes

are

used

for

mechanical

sold-

ering

where

the

surfaces

are

not

as

clean

as

those

in

elec-

tronic

assembly.

They

are

corrosive

and

will

typically

damage

a

printed

circuit.

Also

very

important

is

the

rat~o

of

tin

to

lead

used

in

the

solder.

Best

to

use

is

63%

tin,

37%

lead,

called

63/37

or

eutectic.

Much

more

common

is

60/40,

which

is

still

a

very

good

solder.

Avoid

using

50/50

or

40/60,

even

though

they're

a

little

cheaper.

The

higher-lead

ratios

solidify

gradually,

while

the

63/37

solidifies

almost

instantaneously,

making

"cold

solder

joints"

very

much

less

likely.

Also

important

is

the

gauge

(or

diameter)

of

the

solder.

For

fine

electronics

work

a

fine

gauge

should

be

used,

such

as

#20

(from

#19

to

#22

is

OK).

Again,

the

correct

solder

is

easy

to

obtain

from

any

local

hobbyist

electronics

outlet

or

TV

repair

shop.

ERSIN

Multicore

or

KESTER

are

two

brands

you

can

count

on

for

good

results.

The

solder

in-

cluded

in

the

kit

should

be

sufficient.

If

for

some

reason

it

is

not,

and

you

cannot

obtain

the

proper

solder

locally,

DO

NOT

USE

any

substitutes.

More

solder

of

the

proper

type

can

be

<btained

from

IMSAI •

Soldering

Technique

For

a

joint

to

solder

correctly,

enough

heat

must

be

applied

so

that

both

pieces

of

metal

get

hot

enough

to

melt

the

solder.

The

tip

of

the

iron

should

be

applied

so

.that

it

touches

both

the

wire

and

the

foil

pad

on

the

board.

The

end

of

the

solder

should

then

be

touched

to

the

junction

of

the

iron,

lead,

and

pad,

so

that

a

small

amount

melts

and

"wets"

the

joint

(flows

smoothly

on.

both

the

lead

and

pad).

As

soon

as

the

joint

has

wet,

the

iron

can

be

removed,

and

the

joint

inspected

immediately.

Careful

inspection

of

each

joint

is

the

key

to

successful

soldering.

While

the

solder

is

being

applied,

watch

the

joint

carefully.

You

should

be

able

to

21

22

IMSAI

8080

System

General

A~sembly

Notes

see

the

solder

flow

onto

the

two

surfaces.

It

should

flow

around

the

lead,

and

if

you

see

that

the

solder

has

flowed

only

on

one

side

of

the

lead,

the

iron

should

be

re-applied

(while

watching

the

joint)

to

heat

the

joint

enough

for

the

solder

to

flow.

(The

typical

reason

for

solder

to

flow

only

half-way

around

a

lead

is

that

not

enough

heat

was

applied.)

For

the

normal

joint;

only

a

small

amount

of

solder

is

needed

(approximately

1/8"

of

20

gauge

solder

wire)

for

it

to

flow

all

the

way

arqund

the

lead.

Also,

for

the

normal

joint,

only

2

to

4

seconds

of

heat

applied

from

the

iron

is

necessary.

More

heat

and

solder

will

be

.needed

for

some

joints

with

larger

leads

and

holes

or

large

foil

areas,

but

if

more

heat

or

solder

is

needed

on

typical

component

leads

(like

IC's),

it

is

an

indication

that

some-

thing

is

not

right.

Since

nearly

all

the

holes

in

IMSAI

printed

circuit

boards

are

plated-through

(the

inside'

walls

of

the

hole

have

a

metal

surface,

connecting

the

pads

on

the

opposite

sides

and

providing

greater

area

for

solder

to

adhere

to)

some

solder

will

typically

wick

through

and

be

visible

on

the

top

side

of

the

board.

This

is

normal.

If

small

drops

of

solder

appear

on

the

top

side,

it

is

an

indication

that

too

much

solder

is

being

applied,

along

with

more

than

suf-

ficient

heat.

These

balls

of

solder

can

easily

short

to

neighboring

pins

and

must

be

avoided.

If

the

correct

amount

of

heat

or

less

than

the

correct

amount

was

used

along

with

too

much

solder,

the

solder

remains

on

the

bottom

of

the

board

(the

side

the

solder

is

_always

applied

from)

and

forms

a

blob

which

can

easily

short

to

neighboring

pads

or

traces.

If

one

of

the

small

gaps

between

fo~l

pads

or

traces

has

been

shorted

with

too

much

solder,

it

can

often

be

un-

shorted

by

running

the

hot

iron

lightly

down

the

shorte~

trace,

re-melting

the

solder

at

the

shorted

point

and

pulling

it

away

with

the

iron.

Do

not

leave

iron

on

traces

or

pads

too

long

when

soldering

or

fixing

a

short,

as

overheated

traces

easily

come

off

the

board.

As a

result,

very

special

care

must

be

exercised

for

any

component

removal

operation.

The

tip

of

the

iron

must

be

kept

clean

to

work

well.

Most

stores

that

carry

irons

also

carry

small

sponges

in

holders

designed

for

cleaning

hot

~ips.

The

tip

is

simply

wiped

on

the

wet

sponge

quickly.

A

damp

rag

will

serve

as

well

though

less

convenient.

The

tip

must

be

kept

adequately

tinned

at

all

times

to

avoid

an

oxide

coating

forming.

It

should

appear

bright

and

shiny.

A

small

amount

of

solder

should

be

melted

onto

the

tip

each

time

it

is

cleaned

unless

IMSAI

8080

System

General

Assembly

Notes

a

joint

is

to

be

made

immediately.

If

a

tip

becomes

oxidized,

dipping

it

in

a

can

of

rosin

flux

is

usually

sufficient

to

enable

solder

to

flow

on

it

again.

They

may

be

cleaned

of

oxide

by

fine

steel

wool

or

other

abrasive,

but

a

plated

tip

should

never

be

filed.

The

tip

of

the

iron

should

never

have

enough

solder

on

it

that

it

could

drip

off.

If

you

find

that

solder

tends

to

drip

off

the

tip,

you

are

undoubtedly

using

too

much

solder.

A

solder

drip

on

a

P.C.

board

is

often

extremely

difficult

to

see,

since

it

is

the

same

color

as

the

traces,

and

it

is

sure

to

short

several

traces

and

cause

trouble

or

damage

components

when

the

board

is

operated.

Inspect

your

boards

very

carefully

for

any

such

solder

drips,

shorts

near

soldered

leads,

incompletely

soldered

leads,

and

unsoldered

leads.

A

100%

inspection

of

soldering

should

catch

99%

of

all

problems

before

the

board

is

even

turned

on.

When

soldering

components

with

long

leads

(resistors,

etc)

we

suggest

clipping

the

leads

after

soldering

so

that

lead

clipping

gives

you

an

easy

and

positive

way

to

check

all

the

joints

on

those

components.

A

completed

unit

will

typically

run

when

first

turned

on

if

the

soldering

was

done

correctly.

MOS

IC.HANDLING

Some

of

the

chips

in

the

kit

are

MOS

type

chips

(such

as

the

8080A,

8111

and

8251).

MOS

chips

are

sensitive

to

static

electricity

and

other

large

transient

voltages.

In

order

to

prevent

damaging

these,

some

precautions

should

be

followed.

They

all

relate

to

avoiding

the

discharge

of

static

through

the

pins

on·one

of

these

chips.

Avoid

working

in

a

room

with

very

low

humidity.

Wearing

cotton

fabric

or

other

non-static

forming

fabrics

will

help.

Air

directly

from

a

heater

vent

is

typically

ex-

tremely

low

in

humidity

and

should

be

avoided

in

the

work

area.

Keeping

everything

involved

(chip,

board,

iron,

tools,

boxes,

chip

containers,

work

surfaces

and

you)

at.the

same

potential

is

required,_and

the

biggest

step

in

achieving

this

is

continuous

physical

contact

between

them.

For

example,

before

removing

a

chip

from

a

box

and

setting

it

on

the

table,

the

box

should

be

set

on

the

table,

you

should

touch

the

table,

and

only

then

pick

up

the

chip

to

place

it

on

the

table.

Try

to

handle

the

chip

from

the

ends

rather

than

the

pins

as

23

24

IMSAI

8080

System

General

assembly

Notes

much

as

possible,

and

always

touch

the

chip's

container

or

surface

which

it

is

touching

before

picking

up

the

chip.

Also

touch

a

surface

or

container

before

placing

the

chip

back

in

it.

Touch

a PC

board

before

inserting

the

chip.

Touch

the

soldering

iron

to

the

work

surface

or

to

a

small

piece

of

metal

foil

on

the

work

surface

before

touching

it

to

the

PC

board

for

soldering.

In

general,

make

sure

the

chip

is

not

the

path

for

any

static

discharge.

Save

MOS

IC

insertion

as

the

last

steps

in

assembly

to

avoid

unnecessary

exposure.

POLARITY

Many

electronic

components

will

not

work

if

they

are

connected

backwards.

Any

component

which

it

is

important

to

insert

one

way

only

will

have

a

mark

of

some

sort

to

indicate

which

way

is

which.

The

board

where

they

go

will

have

some

sort

of

corresponding

mark

at

each

place,

or

an

indication

that

all

such

components

go

the

same

way

as

a

marked

"typical"

one.

I

.c.

Is

All

I.e.'s

must

be

inserted

with

~in

1

in

the

correct

location

to

avoid

damaging

the

I.e.

Pin

1

is

indicated

on

the

chips

by

several

different

marks.

The

most

common

is

a

rounded

or

square

notch

in

the

center

of

the

end

near

Pin

1.

Another

common

one

is

a

slightly

depressed

or

raised

dot

in

the

corner

of

the

chip

next

to

Pin.l

..

One

or

both

of

these

will

always

be

present

to

indicate

:Pin

l.

Sometimes

there

are

other

circular

markings

on

the

centerline

of

the

chip,

usually

towards

one

or

both

ends~

these

should

be

ignored.

Often

there

is

some

kind

of:?in

1

mark

on

the

bottom

of

the

chip

also.

(Note:

Many

I.e.'s

have

a

code

for

date

of

manufacture

which

is

a 4

digit

code.

e.g.

7425

would

indicate

manufacture

in

the

25th

week

of

1974.

Do

not

confuse

these

with

the

device

number.

The

code

will

be

alone,

the

device

number

will

have

manufacturer-dependent

suffixes

and

prefixes.

e.g.,

SN7404N

is

a

7404

type

chip.

On

the

PC

board,

some

Pin

1

indication

will

be

found,

such

as

a

square

pad,

a

dot,

an

arrow

showing

_Pin

1

direction

with

the

note

"typical"

(indicating

all

chips

on

the

board

face

the

same

way),

or

similar

mark.

Other manuals for 8080

2

Table of contents

Other Imsai Computer Hardware manuals