Cromemco 299B User manual

r @ e # @ ''

2 9 9 8 D IS K D R IV E

T E C H N IC A L M A N U A L

C R O M E M C O . Inc .

2 8 O B e rn a rd o A v e nu e

M o unta in V ie w , C A 9 4 0 4 3

P a rt N 0 .0 2 3 - 6 0 0 0 A p ril 1 9 8 1

C opyright (C) 19 80

B y C R O M E M C O , lnc .

A L L R IG H T S R E S E R V E D

FUNCT ION OF H ICROPROCESSOR IN 299 6

Tbe m icroprocessor implementation on 299 B performs three malor functlons .

T he se a re se rvo co n tro l , re ady sta tu s , and e ra se de lay t im ing . The p ro ce sso r

co n t inuo us ly execu te s a sequence o f rout ine s w h lch t rack the sta tus o f ready

and se rve func t ions , and test the co nd lt io n o f the se le ct l ine s to d e te rm ine

w he the r to o u tpu t suc h sta tus . Be ca u se se ek ing and w r lt ing a re m u tua lly ex -

c lu s îve func t io n s . T he p ro ce s so r a lso ha s t im e to ca lcu la te e ra se t lm ing .

Se rvo Co n t ro l

R he n the po s it po ne r 7s bo ld ing o n track , the p roce sso r is o u t o f the se rvo

loo p , a llow ing 1' F INE POS IT IO N SENS E '' to kee p the po s ît ione r Cn p lace . khen

seek ing to a track , the processo r outpu ts a ve loc ity va lue wh ich d irect ly co n-

tro ls the po s it io ne r w h ile co un t lng s te p and de ten t pu lse s . T he p roce sso r a lso

de te rm lne s w he n to sw itch itse lf in to a nd o ut o f the fee d ba c k loo p . To e n su re

m in im um re spon se t im e to change s in se rvo status , b0 th ET EP pu lse s and DET ENT

pu lse s a re t ied to the INTERRU PT in pu t o f the p roce sso r . T h us , w hene ve r a

st im u lu s îs re ce ived , the p ro ce sso r sto ps w ha tev e r it w a s do ing a t the t /me ,

iden t if ie s the sou rce o f the inte rrupt , and tre a ts it app ro p r ia te ly . T he ve l-

oc ity fo r the se rvo is de penden t upo n the d istance rem a in in: to t rave l , and a

va lue fo r each ha lf-track of rema ln ing d istance up to 63 tracks is sto red

in a look-up table ln memory . For greater than 6) tracks the max imum ve loc ity

b o u tpu t . T he D IRECT IO N l ine ls sam p led a t the sta rt o f a seek and s to red fo r

the d u ra t io n o f tha t se e û . lt is o u tp u t to the D to A co n ve r te r a s th e m o s t s ig -

nificant bit or slgn bit. By inlecting a current equal to one half the full

sca le output through R1O3 and R10ù înto the D-A converter output , a un i-po la r

de v lce ca n be used to p ro v ide s ig ned dua l po la r ity o u tpu t .

U pon reach lng a d lffe ren ce o f ze ro be tw ee n ste ps a nd d ets n ts , the se rvo îs

sw itched to the HO LD mode fo r f lna l sett ling to t rack . The proce sso r c leans up

reglsters and track counters, and samples TKCENT (track center) and TKJ; (track

zero), storing them for future outgut conditîonal on selected status.

T he p ro ce s so r a lso co n t ro ls the R EST O R E f unc t îo n . R EST O R E m a y be în it ia te d

by the ho s t v la the R E ST O R E in pu t , o r w il l o c c u r if a n il leg a l see k is co m -

manded ltoo many step pulses) or Cf a detent is received while holdin: on track.

The bu ilt- in exe rc iser on the 29j 8 automat ica lly w r ite-pro tec ts tbe d rive

by ho ld ing SEEK COMPLETE fa lse in the exe rc zse r mo de .

Re ady S ta tu s

T he p roce sso r w atche s the fo ur index lln e s fo r c hange s . A com p le te low -h igh-

1ow se que nce be lng de tec ted o n e ithe r d lske tte s ta rt s a t ime r fo r tha t d iske tte .

The coun t ls te sted frequen tly , and shou ld 2Q0m S e lapse be fo re anothe r index

pulse is sensed , the diskette îs logged not ready . In 299 B it is stored

In te rna lly a nd o u tpu t o n ly fo r the se le c ted d iske tte . Two -s zd ed index is sam p led

when '' E ITHER INDEX 11 is h lgh and sto red fo r output to the ho st .

E ra se De la y T im ing

The u se o f tunne l-e rase head s mandates a de lay changes in % R IT E GAT E and

ERASE GATE. The processor allows a refinement of this delay by adlustlng it

acco rd ing to the track loca t ion . The INT ERRUPT c lrcu it is conf lgu red such that

either edge of WRITE GATE (turn-on or turn-off) causes an lnterrupt. When thls

inte rrupt is ldent if îed , R R IT E GAT E STA T U S is te ste d a nd the a pp ro pr îate de lay

Is ge ne ra ted ; longe r de lays fo r tu rn-o ff and va ry lng leng ths dependen t upo n the

track loca t lon . Dense r fo rma ts than we re ava ilab le w ith f ixes de lay s can be

o bta lne d .

TABLE OF CONTENTS

PAGE

SECT IOK 1 - INSTALLAT ION ................................ . . . . . . . . . 1-1

INSTALLAT ION CHECK LIST .................,....... . . . . . . . . . . . . . . . . . 1-1

14isua1 Ins;)(,c1;1-()n .......................... . . . . . . . . . . . . . . . . . 1-1

hltlChan 1*(:a1 Ch(,ckS .................................. . . . . . . . . . 1-3

1::1(512 1::11::jlkhdr152!14*% 1::2iilkI1:i*1-1'4'11!g4l ........................... . . . . . . . . . . . . . . . . . -1---111:

P3 - DC power Connector ................................ . . . . . 1-4

/1C P0k:er Cab)1ng ............................................ )-4

?4 - /$C C0nneCt0r ..................,................ . . . . . . . . 1-4

S1-gna1 Cabl1-ng ...............................-......... . . . . . 1-S

h1;t1-ng C0nneCtOrS ..........*..............,......... . . . . . . . . 1-7

INSTALL D ISKETT E DRIVE .................................. . . . . . . . . . )-7

Vertical lg-inch Retma Rac k Installation ............... . . . . . 1-7

Horizontal 19-1'nch Retma Rack lnstallat l'on .................. 1-8

E)(!Sk 17()p h1()unting ...................................... . . . . . 1-E$

Diskette Load ing and onload p'ng ......................... . . . , . 1-8

ChaSSI'S Ground ...................................,.......... 1-10

Drive Select Options ........................................ 1-10

17kk() ()r1-vt! ()pt)-()n -..-..-..................-.................. ) 1)

0ne Drive (Rotary) Option ................................... 1-11

F()ur ()r1-vi? ()pt 1-()n .-..................-..-.........-. . . . . . . . . 1-11

E1-ght D4%7-v(, ()pt1on ...,................................. . . . . . 1-11

L7-n(, lr(,ywrr1-nat1-()n ......--............................... . . . . . )-11

lndex/sector ................................................ 1-13

Independent Index/sector Lines .............................. 1-13

Sepa rated Index and Secto rs .,......,.,....... . . . . . . . . . . . . . . . 1-13

(2h1*1;$((,1:17(? !!J-(!(21: ...........,................... . . . . . . . . . . . . . . . 1--1:$

l!1k,1*1)(! F'ke(:p1:(,(:1: .............................. . . . . . . . . . . . . . . . . . 1--1dl

l'lanual Eject Inhibit ........................................ 1-15

Diskette Eject Request ................................,..... 1-15

Dat; Se P;r;t1'09 .................................... . . . . . . . . . 1-16

FM Data Separat0r ........................................... 1-1S

0ne. ShOt Emulation .......................................... 1-15

PhaSe L0C ked C1Ock ........................-........ . . . . . . . . . 1-15@FH Data Separation ........................... . . . . . . . , . 1-15MFH/H

FR Data Separator Adjustment ..........................,..... 1-162FM Data Separator Adjustment ....................,..... 1-16HFM/M

Double Density Data Com pensatl'on .....,.........,...,........ 1-17

Configuration of Opt ions .................................... 1-17

1

TABLE 0F CONTENTS (Continued)

PAGE

SECT ION 2 - HAINTENANCE

PREVENT IVE HA INTENANCE SCHEDULE

kuarterly Cleanl'ng ..,....................................... 2-1

DriMe Sy stem Test ......................,.................... 2-1

FREkENT IVE HA INTENANCE PROCEDURES .......,........................ 2-1

Splndle Drive Sy stem ....................,................... 2-1

Drive Belt Tensl'on .......................................... 2-2

Read/krl'te Data Amplitude ....,.............................. 2-2

MA INTENANCE PROCEDURES ........................................... 2-2

Tools and Test Eqe l'pment ..............,..................... 2-2

JACQS and P1u9S ............................................. 2-3

Drive Elect'ronl'cs PCB ....................................... 2-4

PCB Replacement .......................................,..... 2-4

Voltage Adjustment .......................................... 2-4

Drive Hotor and Belt Checks .................,............... 2-6

Drive Belt Tenslon Adjustment ............,.................. .2-6

Drive Belt Replacement ...................................... 2-7

lndex Transducer and Logic Checks ........................... 2-7

lrldex Transducer A ll'gnment .................................. 2-8

Index Transducer Replacement ................................ 2-9

Spindle Cone Check .......................................... 2-10

Spindle Cone Replacement .................................... 2-12

Positl'oning Sy stem .......................................... 2-12

Positioner Servo Check .,.................................... 2-12

Head Assembly Track All'gnment and Haciine Azimuth ........... 2-13

Positioner Servo Adjustment ........,...,..........,......... 2-16

prell'minary Adjustments ............................,..,..... 2-16

Final Adjustments ...............................,........... 2-17

Head Assembly Trac k and Head Azimuth All'gnment Side 2 ....... 2-18

Head A ssembly Track and Head Azimuth Allgnment Side 1 ....... 2-19

Load Cam Shutter Alignment .................................. 2-19

Eject Motor Cam Allgnment Check ............................, 2-20

Crank Cam Alignment Check ................................... 2-20

Crank Cam Alignment procedure ............................... 2-21

DISKETTE DRIVE EïERCISER ..............

.

. . . . . . . . . . . . . . . . . . . . . , . . . . . 2-22

Contrcls , Indicators . and Test Po 'lnts ..............,....,... 2-22

Draw 1-ngs and Hater1a1 L 1sts

1 1

L ISI 0F ILLUSTRAT IONS

FIGURE T ITLE PAGE

1-1 Diskette Drive Shipplnq Conflguration .................... 1-2

l-2 Pro per Load ing of Dlskette ............................... 1-3

)-3 Slide Hountinq Dlmenspons ..... ,......................... 1-7

1-4 Vert ical Retma Rack Hount lng .. .......................... 1-9

1-5 Horizontal Retma Rack Mountinq ........................... 1-9

1-6 Outline ol'mensïons - ........- ........................... 1-10

1-7 Hrl'te ? rotect Notch Location .- ....................,..... 1-14

2-1 P1ugs and Jac ks Identîflcation .....,............... . . . . . . 2-5

2-@ Dr1've S# StQm .................. ....................... . . . 2-6

2-3 Index Pulse and lata Burst .... .............. ........... 2-8

2-4 Index Transducer and Coce Assem bly ................. . . . . , . 2-10

2-5 Exam ple of Good Cone ......... ...............,........... 2-11

2-6 Trac k A lïjnment ....................................... . . . 2-13

2-7A Head A ssembly Hountqnç Screw s S lde 2 ................. . . . . 2-14

2-78 Head Assembly Mountlnj Screw s Slde 1 .............. . . . . . . . 2-14

2-7C Cat Eyes and Head Azimuth Display ................. . . . . . . . 2-15

2-7D Head Azl'muth A lignment ................................... 2-15

2-8 Dr ive E lectronl'cs PC8 .................................... 2-16

2-9 Load Cam Shutter Alignment ............................ . . . 2-20

2-10A Eject Motor Cam Alignment Check-carrier Open ............. 2-21

2-10B Eject Hotor Cam Alignment Check-carrier Clnsed ........... 2-21

2-11 Crank Cam Alignment Check .......................... . . . . . . 2-22

2-12 Contro l pane l , D iskette Exe rc iser , Mode l 499 ............. 2 -23

LIS T OF TA8LES

NUH8Eq T ITLE FAGE

7-1 Installation Check Llst ........ ........... . . . . . . . . . . . . . 1-1

l-2 Inte rface P1n Connect l'ons ......,............ . . . . . . . . . . . . . 1-6

1-3 Binary Selectlon of Four Drq'ves ............. . . . . . . . . . . . . . 1- 12

1-4 Binary Selection of Elçht Drives ......... . . . . . . . . . . . . . . . . 1-12

l-5 Opt ion Components , Jumpers , and Irace Cuts . . . . . . . . . . . . . . . 1-18

2-1 JackS and P1ugS .... ........-...... . . . . . . - - . . . . . . . . . . . . . . 2-3

2-2 Po sitioner Servo Prelim lnary Adlustments .. . . , . . . . . . . . . . . . 2-17

2-3 Exerc iser Sw itch , lnd icator and Test Po int Functions . . . . . 2 -24

7 1 1

SECT ION )

IhSTALLAT ION

This section contains procedures to verîfy the operational integrity nf

the d iskette drive pr ior to on-line operation .

INSTALLAT IOh CHECK L IST

The installation check llst , Table 1-1 , is desijned for trained personnel

to use as a guide in performing installation checks necessart for proper

operation . If more detaqled installation information is deslred . refer

to the appropriate paragraph in this sect ion .

TABLE 7-1 . INSTALLAT ION CHECK LIST

Visual In spectlon

a . Remove a1l packing m aterial .

b . Check packing list .

c . Check for shlppins dam age .

d . Remove carriage restra int inserted in S ide 1 .

Hechan ical Checks

a . Check that carrïage dssembly moves freely over entlre stroke .

Cables

a . Fabricate DC and signal cables .

b. Check pin to pin resistance (a11 cables).

c. Check pin to conductor continuity (a11 cables).

d. Check for prcper pin alignments (a11 cables).

Hount ing

a . Install d iskette drive ,

b . Connect cables to d iskette drive .

Chec ko ut

a. Operational checkout with exerciser (optional).

b . Operational checkout w ith sy stem .

kisual Inspec tion

The d iskette drive is packaged to ensure adequate protectîon for shipping

and handling (See Figure 1-1).

1-1

ûUTSIOE CARDBOARD B0X - -

%

%

x e N x

8 CORNER BLOCKS .-

l

%. I

l

*

-*

I

I I l

1 -- INNER

CARDBOARD

- B0XNx N -DRIVE

CARRIAGE

RESTRAINT - e

Figure 1-1 . Diskette Drive Shipping Conf iguration

Inspect the shiqping container for evidence of any in-transit damage.

If damage is evltent :

a . Contact the carrier .

b . Contact the manufacturer .

Unpac king

After perform ing a prelîm inary inspection , unpack the dîskette drive as

follows :

a . Remcve a11 material from shipping container . Remove inner packing

materlal .

b . Check material received against packîng list . If packing shortage ,

contac t manufac turer .

c. kîsually insqect a11 items received for physical damage. lf

dam age qs ev ldent :

Contact the carrier .

Contact the manufacturer .

1-2

- , ' A

x

LA BEL

d

!

N

<

HEAD SLOT

FORHARD

INDEï HOLE

Fijure 1-2 . proper Load ing of Diskette

Mechcn lcal Checks

To check the proper loading and unload ing of a diskette , the d iskette power

cable must be connected . A button is located at the front of the bezel

adjacent to the diskette aperture. Hhen the button is pressed, the load

mechanism moves to the open position and the diskette is ejected. The

load mechanism w ill automatically close when the d iskette is fully inserted .

a . Insert a d iskette and ver ify that the load mechan ism closes .

b . press the button and Merify that the load mecNan ism releases and

that the diskette is ejected approximately 1/2'%

CABLES

Three cables are necessary to connect power to the d iskette drive and signals

tn the host sy stem .

DC Power Cable

AC Power Cable

Slgnal Cable

DC power Cabling

A11 DC power l lnes shall have lengths and w ire diameters consistent with

meeting the power regulation reguirements of the d iskette dr ive as fcllows :

1-3

15V DE l 5% 2 .0 Amps Max ., 50 mv p-p ripple

-

5k DC à 5% 0 .25 Amps M4x ., 50 mv p-p ripple

+24/ DC 1 5% 1 .0 Amps Yax . seekinj w ith 2 .0 Amps

Max . peak

Seven lines are used to transmit DC power throu:h the power connector from

the power supply into a diskette drive. Qne lqne palr (high and ground)

is used for +5V DC , nne for +24V DC . and one for -5V DC . Iq addltïon , one

extra ground and one chassls :round are provsded .

Five-foot lengths of 418 AHG wire are normally acceptable for use as DC

power lines between the drive and ty pical pcwer Gources.

Fabricate and check pcwer cable as listed f0r ?3 .

P3 - DC Pow

-e r -connectp r

10 Pin Molex - 0 .156'' center

Pin Function Pin Functlon Mating

-c

-c nce cto r

1 Chassis Gnd 6 Ground Connector Molex 09-50-3101

2 +5V DC 7 Grcqnd Term lnal Mo lex 08 -50-0106

3 Spare 8 Ground Polarizinq Key Holex

15-04-0219

4 Key 9 Ground

5 +24: DC 10 -5V DC

AC Power Cabling

AC power cabling should be fabricatrd from U.L. accepted ccrd capable Qf

carry ing 1 amp at the Moltage at whlch the drive is to be operated .

P4 - AC Connector

3 P1n Amp

Pin Functfon Hatinq Connector

1 Motor Power ''A'' Houssng Amp 35076 6-1

2 Frame Groepd Termlnal Amp 350550-3

3 Hotor Power ''B''

1-4

AOTE

For re liab le o pe ratpon of the 2998 d iskette drive , or most

computer perlphera l equipment . an AC line filter on a11 AC

inc lud ing that to the OC power supply is required .

S lgnal Cabling

Sy stem connec tlon betw een the contro ller and d iskette drive is opt ionally

connected in either a rad lal or da isy cha in arrangement . T0 accommodate

either applicatlon , plug-in term inators are prov ided .

a . Hult iple D is kette Dr ive A pplicat ion s

Term inato rs must be removed from a 11 but the drive electrically furthest

from the controller ; the last drive term înates the line .

b . Sinqle Diskette Drlve Application

For single drive apqlication, the terminated diskette drive is used

for the diskette drlve-to-controller connection. The I/0 cable is

sim ply connec ted to the connecto r .

c . S ignal Cable Fa brica t io n

1. Fabricate the interface signal cable accord ing to Table 1-2 by

using tbe appropriate connectors . The interface signal cable

should be a tw isted pa ir w ith return grounds on odd num ber pins .

I/0 wire is No. 24 or No. 26 AHG conductor . approximately 30

tw ists per foot . w ith maximum length of 20 feet. A lternately

an equivalent flat cable may be used .

2 . T he ground side o f each tw isted païr term inates w ithin a few

inches of the line rece iver or transm itter ground on the d isk-

ette dr îve .

3 . Usinj a V0H . check each cable for pin-to-pin shorts .

4 . Chec k fo r continuity between each pin and its conductor , at the

opposite end of the cable .

5 . After checking a 11 cables connect them into the sy stem .

1-5

TABLE 1 .2 INTERFACE PIN CONNECT IONS

(50 P1N EDGE CONNECTOR - 0.1.'CENTERS)

GND P IN S IGNA L PIN S IGNA L NAHE

1 2 -SIDE SELECT (CUST. OPTION)

3 4 -DISKETTE SELECT 4 (9S4)

5 6 -THO-S IDED

7 8 -INDEX

9 10 -SEEK COHFLETE

11 12 -RESTORE

13 14 -REMOTE EJECT (CUST. OPTION)

15 16 -HEAD LOAD

17 18 -DISKETTE SELECT 3 (DS3)

19 20 -INDEX/SECTOR

21 22 -READ?

23 24 -DOUBLE DENSITY S/NC

25 26 -DISKETTE SELECT 1 (DS1)

27 28 -DISKETTE SELECT 2 (DS2)

29 30 -DISKETTE EJECT RECUEST

(CUST. OPTION)

31 32 -PHASE LOCKED CLOCK

33 34 -DIRECT ION SELECT

35 36 -STE?

37 38 -HRITE DATA

39 40 -HRITE GATE

41 42 -TRAC K 00

43 44 -HRITE PROTECT

45 46 -READ DATA

47 48 -SEP. DATA (0pTI0N)

49 50 -SEP. CLOCK (0PTl0N)

1-6

Hating Connectors

Vendor

kendor Part N-um ber comment

Scotch Flex 3415-0000 Flat Cable

T & B Ansley 609-5005 Flat Cable

Viking 3VH25/1JN-5 Solder

Texas Instruments H312125 Solder

INSTALL D ISKETTE DRIVE

There are two methods of installing the d iskette drive in a lg-inch Retma

rac k ;

Vertical - 4 maximum

Horizontal - 2 max imum

a . kertical 19-înch Retma Rack Installation

For vertical rack mounting the use of a slide (Figure 1-3) mounted to

the top of the d iskette drive is optional. If a slide is used the w ide

portion of the slide should be mounted to the upper inside surface of

the sy stem enclosure . The narrcwer portion of the slide is fastened

to the upper edge of the d iskette d rive frame via Three 8-32 Screw s 0 .25

long . Tapped holes on the lower edge o f the d iskette drive may be used

to secure the d iskette drive tn a hold ing member w ith in the system

enclosure .

V .0â.û3 Y-TRAVELàœ X-LENGTH1.X

' 11.t02 ' ç . VK*** R-QQ< l '

- #- - - -.+ . -+ - --+ -+- -+----Y -# j

= - - . .

.r .c - - . . l

i A j.75M Dq752X.tQ2 B c - F G

H

c L E N G T H JT q A V E L v lEwA U A C H T O D 8 IV

x Y A B C () E F G 8

STA N D A R (7 M O U N T IN G 14 1s 4 a ) 8 00 12 (% 1 (m a 6,3 8 50 11 50 12 508 O L E S 4Z E !77 (3 IA

Figure 1-3 . S11de Hounting Dimens1ons

1-7

Alternatively îf a slide is not used , ''skid rails'' within the system

enclosure m ay be used . Up to four dr ives m ay be moqnted vertically

in a lg-inch Retma rack. (Flgure 1-û.) The vertical orientation of

the diskette drive must be as shnwn . Vertical mounting of the diskette

drive is preferred over horizontal mounting .

b . Horizontal lg-inch zetm-

a R-ack Insta

.llatîon

If two drïves are mounted horizontally, ''sk#d Rails''must be used as

there is insufficïent space to use slldes . lf a sfngle d iskette drive

is mounted horizontally s tw0 slides , cne on each side of the d fskette

frame , shou ld be used . The w ide po rticn of the sllde should be fastened

t: the system enclcsure and the narrow portion to the diskette frame.

The horizontal orientaticn of the drive is shown in Figure 1-5 .

Power and signal cables may be connected to the drive prior to slld ing

into the sy stem enclosure provid ing there ls enough service loop . or

if there is rear access to the sy stem enclosure , the power and slgna!

cables can be installed after the d bskette drlve is mounted .

Drive assembly heat d issipation under maximum seek activity is 291

BTU/hr (85 watts). To limit the maximum allowable operating tempera-

ture of the media to 125 F (46.1 C). an unrestrlcted flow of 30 cubic

feet per minute (CFH) cooling eir is reqoired.

Desk Top Mounting

The dbskette drlve may be desk top mounted , i.e ., Positioner Vertical .

Proper compensation is automatically made for the mass of the carriage

assemblies .

Diskette Load inq and Unlo.ad ïng

Proper load ing of the diskette is vital to the operat ion of the diskette

drive . Figure 1-2 show s the proper location of the diskette openinj for

load ing .

Procedure for loading/unlcad ing the diskette is ûs fcllows :

a . lnsert the d iskette into the desired side Df the diskette drive such

that the label is at the opposite end of the slot from the pushbutton

eject switch. A sensing devïce in the drbve will automatically close

the carrier w hen the d ïskette ïs inserted . D iskette 1 is on the left

side of an observer fac ing the drïve w hich is mounted such that the

slot ïs vertïcal . Dïske tte 2 ïs then on the rîght side .

b . To remoke the d iske tte , press the pushbutton located near the slo t con-

taining the dïskette. The diskette w111 be ejected to where dt can

easily be remc ved from the drive .

1-8

@ *

* *

@ *

ê *

* #

. *

. @

@ @

Flgure 1-4 . Vertlcal Retma Rack Mountlng

e @

@ .

: @

11

@ @

Figure 1-5. Hor izontal Retma Rack Hounting

l-9

SLIDE MTG .

8 .00 .80 opy loNAk

2 MTG . HOLES Typ

98-32. .38 DEEP 2.19 j--

' ! !I 1

'

#

' 1

1

1

l

l

O 8 54

1 I I $

l : DIs- rIs-

4 HOLES *8-32 , .38 DEEP KETTE xgyyE

4 .00 ) ?0N 4

.00 CE8TERS TYP

15 .00 u .2s = 4 .38

Figure 1-6. Outline Dimensions

OPT IONS

ln ork er to meet varying requïrements of different customers , persci provides

the follow ing Customer-lnstallable Optîons :

Chassis Ground

Chassi! grcund is bcnnected tc signal grqund near the power ccnnector on

the drlve electronlcs PCB . This connectpon îs easily broken by cutting

trace cut A . Trace cut A îs located near the chassis ground inj lead . If

this trace cut is made , P1n 1 of the power connector becomes a chassis ground

line only .

Dr ive Selec-t Options

Fcur d iskette select inputs and a side select input are provided . The

normal configuraticn uses Diskette Select 1 and 2 to select the diskette .

and side select to select the side of the d iskette . Side select high w ill

select the normal side of the d iskette . and 10W the reverse side .

1-10

Two Drive Option

Th is ncrma l configuratïon is de fïned as Drive 1 o f 2 dr ïves . To o pe ra te

two drives in parallel , one drive m ust be this Norma l 1 of 2 , a nd the

other m ust be configured as Drive 2 of 2 drives . Dr ive 2 uses oiskette

Select 3 and Diskette Select 4 to select the d ïskette and side select f0r

the side Gf that d iskette . Drive 2 of 2 drives is option 2 . Refer to

Table 1-5 for the connections regu ired for these configurations .

One Drive (Rotary) Option

The one drive (rotary) option uses the 4 diskette select lines to select

the d iskette and side of the d iskette . T he side select line must be left

high or o pen for th is conf igura t ion .

Diskette select 1 (DS1) selects Diskette 1 Side 0 (normal), DS2 selects

Diskette 1 Side 1 (reverse), DS3 selects Diskette 2 Side 0 (normal)! and

DSô selects Diskette 2 Side 1 (reverse). This configuration is Optlûn

3 , and may be im plemented by maklng the connectbons found Jn Table 1-5 .

Four Drive Option

Four drives may be operated in parallel using the diskette select linesi

n a binary code to select each of the 8 diskettes and slde select to

obta in two-sided recording . ln this mode cf operation , DS1 is used as

un enable line . 1ow to enable ; and DS2 , DS3 . and DS4 are decoded ln a

binary fashion . Diskettes are selected according tn Table 1-3 . Binary

Selection nf 4 Drives. This confisuratinn is option 4 . and can be imple-

mented by referring to Table 1-5 to determ ine the connections required by

each of the 4 drives .

Eight Drtve Opt

-i

-o n

Eight drives may be operated in parallel us ic: the four diskette select

lines in a binary code . See Table 1-4 . If a11 e fght drfves are used . n o

state w ill be available f0r a11 drives to be de-selected . i.e ., there w i11

alway s be one drive selected . This conflguratbon ls optson 5 and can be

implemented by making the required connectfons as defined by Table 1-5 .

Line Term ination

A 220/330 chm resistor pack is iqstalled in U8. This kûck is used to match

the impedance of the input sijnal line pairs. Mhen drlves are used ln

parallel , this resistor pack must be removed from a11 drives but the 0ne

electrically farthest from the controller. The 220/330 ohm resistor pack

must be left in the drive electrically farthest from the controller to

ma intain proper line term ination .

1-11

TABLE 1-3. BINARY SSLECT ION 0F FOUR DRIVES

System

Drjve/Diskette Sllected Dqskette

DSl DS2 DS3 DS4 Drlve Dlskette Se lected

HIGH ANY ANY ANY NONE hONE NONE

L0H H IGH H IGH H IGH 1 1 1

L0H L0% H IGH H IGH 1 2 2

L0k HIGH L0% HIGH 2 1 3

L0H L0k L0% HIGH 2 2 4

L0% HIGH HIGH L0% 3 1 5

L0H L0H H IGH L0% 3 2 6

L0k H IGH L0k L0% 4 1 7

L0M L0H L0H L0H 4 2 8

TABLE 1-4 . B INARY SELECT ION 0F EIGHT DRIVES

Svstem

orive/Diskette Selected Diskette

DS1 :S2 DS3 DS4 prive Diskette Selected

L0H H IGH H IGH H IGH 1 1 1

L0H L0H H IGH H IGH 1 2 2

L0H H IGH L0H H IGH 2 1 3

L0H t0% L0% H IGH 2 2 4

L0N HIGH HIGH L0H 3 1 5

L0H L0H HIGH L0H 3 2 6

LO% HIGH L0% L0l4 4 1 7

L0H L0M L0H L0H 4 2 8

H IGH H IGH H IGH H IGH 5 1 9

H IGB L0H H IGH H IGH 5 2 10

H IGH H IGH L0% H IGH 6 1 11

HIGH L0: L0: HIGB 6 2 12

H IGH H IGH H IGH L0% 7 1 13

H IGH L0% B IGH L0% 7 2 14

HIGH H IGH L0M L0H 8 1 15

HIGH L0M L0% L0H 0 2 16

1-12

He ad Load

The noçma l con f7gurat qon ls such that if a d iskette is selected . the heads

are loaded . Head load input , P in 16 . serves as an OR function w ith select ;

thls lnput may be used to load the head s of the non-selected drives in

antlc lpatlon of read/wrïte activïty . The normal connection utilizes a

75451 ln the U26 qosition. Head unload ls delayed approximately 5 seconds

for accessin: varlous diskettes without Waiting fcr head 7oad when the

Se lect comes back to the orïg ina l head .

Optbonally , the 75451 can be removed from U26 and a 75453 installed . This

makes head load an AND function With diskette select, allowing ready, index

two -sided and w rite protect funct ions of a selected drive to be mon ltored

w ithout load ing the heads . T his is Option 6 .

lndex/sector

The drive normally comes from the factory w ired to prcduce a 1 ms pulse

from hlgh to 1ow logic level at Pins 8 and 20 each time an index or sector

hole is sensed on the se lected d Jskette . Refer to Table 1-5 for the connec-

tions of this im plemen tat ion .

Independent Index/sector Lines

Optjon 10 allows independent monitoring Qf index/sectors from each diskette

of a drive . Pin 20 will have index/sector pulses from Diskette 1 and Pin 8

wil) have index/sector pulses from Diskette 2 . When either diskette is

selected . This option may be configured by makin: the connections found

ïn Table 1-5 .

Sepa rated Index and Sectors

Opticns 11 . 12 . and 13 provide for separatinq the index pulse from the

sector pulses on a hard sector diskette . 32 . 16 . or 8 sectors can be pro-

vided . The lndex pulse appears on pin 8 while the sector pulses appear

on Pin 20 of the I/0 connector. -

lm plementation is accomplîshed by making the connections listed in Table

1-5 .

Although only the selected diskette 's index and sectors are available .

separatlon and countdown are maîntained for both diskettes to prevent

loss of synchron ization for an unse lected d iskette .

Diskette Eject

The Model 2998 comes from the factory confijured such that diskettes may

be ejected (whenever write gate is false) elther by a nushbutton switch

at the bezel or. (for the selected diskette only) by a 100 ns minimum

pulse or level to logic 1ow on the ssgnal interface Pin 14 . Refer to

Table 1-5 for connection deta ils of this configuratlon .

1-13

III()E'ï HOtE

v = 6.175 z .005 (156.8 :!: .l nml (SINGLF SIDE.D)

x = .150 :t .005 (3.810 :t .1 mm)

Y = .200 :!: .010 (5.080 :!: .?50 mm) INDEï HOLE

(DUAL SIDED)

Z = .075 :f .005 (:.905 :f .1 mm) O

Z

HEAD ACCESS

OPEN ING

Y

.= k > - 't y

Figure 1-7. Vrite Protect Notch Lccation

krite Protect

The 299 drive as supplied from the factory implements ANS I proposed Optlon

1 , utilizing a nctched diskette . An optical sensor is installed to sense

the notch in the diskette . Tc un-prctect a d iskette s cover the notcb w ith

an opaque tape (Avery DGF-KI-D-IZ or equivalent). See Fiqure 1-7.

Hritinq is inhibited on a write protected diskette and the write protect

output . Pin 44 , îs 1ow when the write protected diskette is selected .

Customer- lnstallable Opt ion 14 W ill prevent writlng off-speed data during

însertion or ejection of a diskette. lkrite protect logic is actîvated

durinq insertion or ejection, by remote eject, or bezel switch. of eîther

d iskette . H rite is inhibited and Write protect output ls true turinj these

o perat ions . lf the insert ion takes place w hile W rite qate is true , the

carrier closure Js depayed until write gate is false. lf an eject command,

either from the bezel switch or controller is gqven while write gate is

true, then the eject coFmand is ignored.

This option may be implemented by installing jumpers in G1 to G2 and G3

to G4 .

Optionally, write protect can be defeated by removing U35 (AH5072). This

is Optlon 15 .

1-14

Table of contents

Other Cromemco Computer Hardware manuals

Cromemco

Cromemco 64KZ User manual

Cromemco

Cromemco D+7A I/O User manual

Cromemco

Cromemco BIART User manual

Cromemco

Cromemco Multi-User BASIC User manual

Cromemco

Cromemco BYTESAVER User manual

Cromemco

Cromemco ZPU User manual

Cromemco

Cromemco Dazzler User manual

Cromemco

Cromemco Z80 User manual

Cromemco

Cromemco 32K Bytesaver User manual

Popular Computer Hardware manuals by other brands

AXIOMTEK

AXIOMTEK SBC81872 user manual

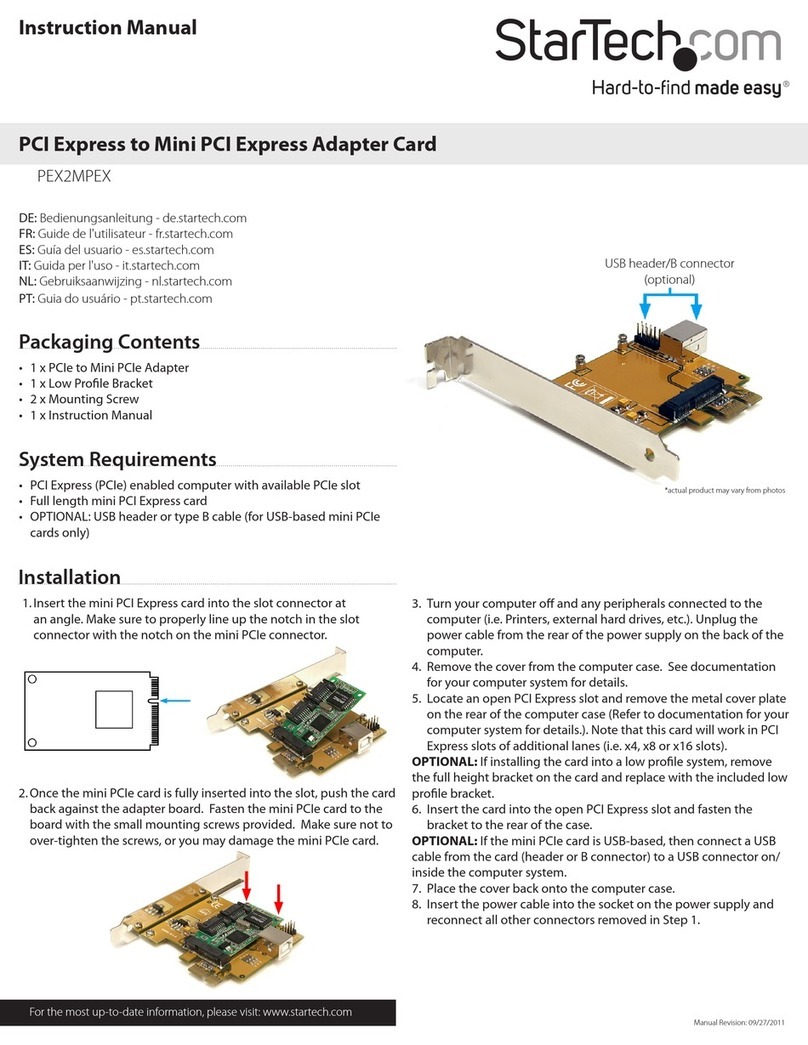

StarTech.com

StarTech.com PEX2MPEX instruction manual

Silex technology

Silex technology SX-59HLS-EVK manual

Faroudja

Faroudja DVP3000 Installation and operation manual

Texas Instruments

Texas Instruments DEM-DAI1802 user guide

Joranalogue

Joranalogue DELAY 1 quick start guide