Imsai CP-A User manual

IMSAI

CP-A

Copyright

©

2002

IMSAI

Division

Fischer-Freitas

Company

Orangevale,

CA

95662

Nade

in

the

U.

S.

A.

All

rights

reserved

worldwide

CP-A

Functional

Description

Revision

1

CP-A.

FUNCTIONAL

DESCRIPTION

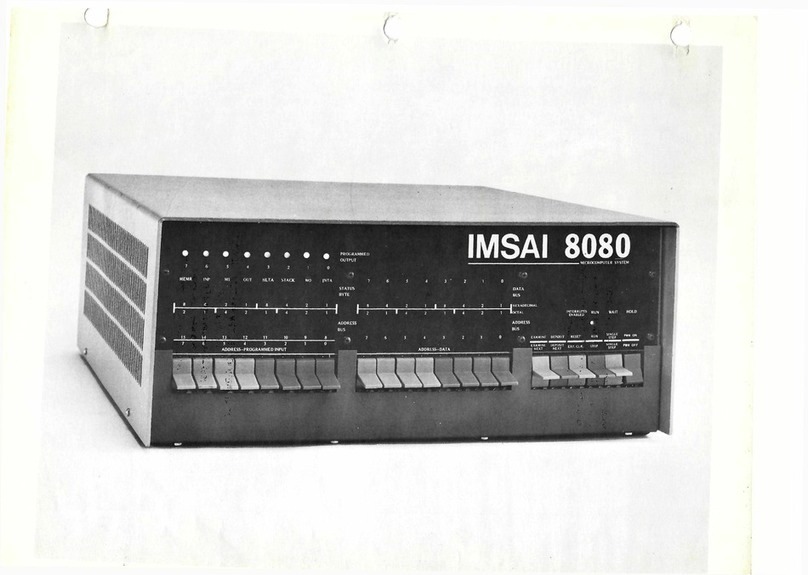

The

CP-A

board

is

the

operator's

panel

for

the

IMSAI

8080

System.

It

includes

operator

switches,

indicator

lights

and

all

logic

necessary

to

operate

the

IMSAI

8080

System.

The

panel

is

completely

self-contained

and

plugs

into

the

back

plane's

100

pin

edge

connector.

With

this

design

it

is

not

necessary

to

mount

the

CP-A

at

the

front

of

the

cabinet.

Instead,

the

board

can

be

plugged

(via

an

extender

card)

into

any

available

slot

in

the

back

plane.*

A

full

set

of

16

address

switches

and

6

control

function

switches

accept

operator

control

and

input.

LED

in-

dicators

are

provided

for

the

16

bít

address

bus,

the

8

bit

data

bus,

the

8

bit

status

byte

(control

indicators

for

INTERRUPTS,

ENABLED,

RUN,

WAIT

and

8

bits

of

Programmed

output.

The

CP-A

board

contains

the

logic

necessary

to

drive

the

8

programmed

output

indicators

and

the

logic

needed

to

read

an

8

-bit

input

byte

from

the

high-order

address

switches.

The

DATA

BUS

indicators

are

run

from

the

bi-directional

portion

of

the

data

bus

(via

a

flat

cable

to

the

MPU

board)

and

show

data

either

being

read

or

written

by

the

8080

processor.

The

indicators

on

the

panel

are

wide-angle-view

light

emitting

diodes

mounted

behind

a

contrast-enhancing

acrylic

panel

assembly.

All

indicators

and

switches

are

explicitly

marked.

The

photographically

produced

labels

are

very

clear,

protected

by

clear

acrylic,

and

can

never

wear

off.

Bit

positions

are

numbered,

and

binary

bit

values

are

labeled

for

both

hexadecimal

*The

switches

are

included

on

the

front

panel

whether

it

is

mounted

in

the

front

of

the

panel

or

not.

CP-A

Functional

Description

Revision

1

and

octal

formats.

Special

labels

may

be

easily

inserted

to

identify

special

functions

for

the

programmed

output

port.

Switches

on

the

panel

are

high-quality

paddle

switches,

and

are

color-coded

for

easy

and

error

free

use.

For

situations

in

which

it

is

not

desired

to

locate

the

operator's

panel

at

the

cabinet

front

(such

as

use

of

the

IMSAI

8080

as

a

dedicated

controller),

the

CP-A

front

panel

may

be

inserted

(via

extender

card)

into

any

back

plane

slot.

In

this

arrangement,

programs

may

be

easily

tested

and

debugged

without

time-consuming

mounting

and

un-mounting

of

the

front

panel.

For

these

applications,

the

front

slot

of

the

machine

can

be

re-

served

for

the

parailel

I/O

board

with

its

LED

indicators

showing

through

the

front

panel

mask.

CP-A

Theory

of

Operations

Revision

1

THEORY

OF

OPERATIONS

The

CP-A

front

panel

assembly

provides

machine

status

indicators,

user

controlled

switches,

and

control

functions

to

the

IMSAI

8080

operator.

The

CP-A

board

communicates

with

the

MPU-A

microprocessor

and

other

boards

through

the

8080

back

plane

and,

additionally,

connects

(via

16

conductor

flat

cable)

to

the

bi-

directional

data

bus

of

the

8080

microprocessor.

The

CP-A

panel

uses

44

Líght

Emitting

Diodes

as

front

panel

indicators.

Many

of

these

indicators

directly

correspond

to

signal

levels

on

the

IMSAI

8080

back

plane,

and

are

driven

directly

from

the

bus

with

no

intervening

logic.

Indicators

in

this

group

are

the

16

Address

Bus

LED's,

the

8

STATUS

byte

LED's,

the

INTERRUPT

ENABLED

LED,

the

WAIT

LED,

and

the

HOLD

LED

The

8080

microprocessor

chips

bi-directional

data

bus

levels

(provided

by

a

16-conductor

cable)

are

displayed

on

the

DATA

bus

indicators

via

the

74LS04

(low

power

schottky

hex

inverter)

sections.

Also

driven

from

the

bi-directional

bus

is

the

8212

8

bit

latch

used

to

drive

the

PROGRAMMED

OUTPUT

indicators.

The

RUN

indicator

is

driven

directly

from

the

run/stop

flip-flop

(74107)

on

the

CP-A

Board.

The

16

ADDRESS-PROGRAMMED

INPUT

and

ADDRESS-DATA

switches

allow

the

operator

to

place

desired

value

(program,

data,

addresses)

on

the

8080's

bi-directional

bus.

As

shown

on

the

schematic,

these

switches

connect

7405

(open

collector)

inverters

to

the

bus

in

a

wired-

AND

configuration.

Pullup

resistors

on

the

MPU

Board

ensure

that

the

bus

levels

are

all

high

unless

any

inverter

on

any

one

of

the

bus

lines

goes

low.

Thus,

if

an

inverter

goes

low,

(this

condition

will

be

discussed

shortly)

the

address

switch

can

be

used

to

put

either

a

high

or

low

value

on

that

line.

The

function

switches

provide

the

operator

with

direct

control

of

the

microprocessor.

The

RUN/STOP

switch

controls

the

X-READY

line

via

the

RUN/STOP

flip-flop.

CP-A

Theory

of

Operations

Revision

1

If

the

switch

is

set

to

RUN,

on

the

next

falling

edge

of

the

Phase

II

clock,

the

RUN'

and

X-READY

lines

are

set

high.

If

the

switch

is

set

to

STOP,

the

high

STOP

value

and

the

Phase

II

clock

are

NANDed

(.U16)

and

this

value

NANDed

with

the

DATA

OUT

5

bit

(fetch/status)

and

the

PROCESSOR

SYNC

line.

Thus,

when

the

processor

is

fetching

a

new

instruction,

the

RUN/STOP

flip-flop

will

be

reset,

the

processor

X-READY

line

goes

low,

and

the

processor

stops.

Several

CP-A

function

switches

operate

by

providing

the

8080

with

an

instruction,

executing

the

instruction,

and

then

stopping

the

processor

on

the

next

cycle.

The

open

collector

7405's

and

support

gating

put

these

instructions

on

the

8080's

bi-directional

bus.

The

EXAMINE

function

uses

a

jump

instruction

(hex

C3)

followed

by

two

bytes

of

the

address

selected

on

the

front

panel

switches.

This

operation

causes

the

processor

to

jump

to

the

selected

address

and,

then,

the

processor

is

stopped

during

the

next

cycle.

When

stopped,

the

processor

was

reading

the

selected

byte

from

memory

as

if

it

were

going

to

execute

it.

Therefore,

the

processor

stops

with

the

desired

address

displayed

on

the

address

bus

and

the

contents

of

that

address

is

displayed

on

the

data

bus.

If

the

RUN

switch

is

operated

at

this

time,

the

processor

will

continue

to

pull

the

selected

byte

from

memory

and

execute

it.

The

EXAMINE

NEXT

and

DEPOSIT

NEXT

switches

use

similar

schemes

and

the

NO

-OP

(hex

00

or

octal

000)

instruction

to

increment

the

address.

Much

of

the

remaining

logic

of

the

CP-A

is

used

tose-

quence

these

commands

to

provide

the

desired

functions.

The

RUN/STOP

flip-flop

line,

the

SINGLE

STEP

line,

the

EXAMINE

line,

and

the

EXAMINE

NEXT

line

are

alf

input

to

an

OR-gate

controll±hg

the

X-READY

line.

(The

X-

READY

line

must

be

high

for

the

processor

to

run.

Its

CP-A

Theory

of

Operations

Revision

1

function

is

identical

to

the

P-READY

line

used

by

the

memory

and

I/O

boards.

The

X-READY

line

is

reserved

for

use

of

the

front

panel

to

avoid

conflicts

of

two

gates

driving

the

same

backplane

line).

During

each

of

these

functions,

the

processor

is

permitted

to

execute

an

instruction,

and

then

is

stopped

in

the

next

cycle

in

a

manner

similar

to

the

RUN/STOP

flip-

flop

cycle

described

earlier.

For

the

SINGLE

STEP

function,

a

one-shot,

triggered

by

the

SINGLE-STEP

switch,

is

used

to

produce

a

pulse

and

the

trailing

edge

of

that

pulse

is

used

to

set

a

flip-

flop

which

controls

the

SINGLE

STEP

line.

This

permits

the

processor

to

execute

the

present

instruction.

The

SINGLE

STEP

flip-flop

is

reset

by

the

occurrence

of

the

sync

pulse

on

the

following

instruction,

thus

causing

the

SINGLE

STEP

level

to

be

removed

and

the

processor

to

stop

on

the

following

cycle.

The

EXAMINE-NEXT

flip-flop

is

siinilarly

controlled

by

the

leading

edge

of

a

pulse

from

a

one-shot

driven

by

either

the

DEPOSIT

NEXT

or

EXAMINE

NEXT

switch.

The

output

of

the

flip-flop

is

used

both

to

put

the

NO

-OP

(hex

00

or

octal

000)

onto

the

bi-directional

data

bus,

and

aiso

to

provide

the

READY

signal

so

that

the

pro-

cessor

will

execute

the

instruction.

It

is

reset

by

the

sync

pulse

on

the

following

cycle,

thus

stopping

the

processor

again.

The

EXAMINE

function

involves

a

4

-step

sequence

produced

by

two

flip-flops

arranged

as

a

counter.

The

pulse

pro-

duced

by

the

EXAMINE

switch's

one-shot

starts

the

counter

and

on

the

first

count,

the

jump

instruction

is

inserted

on

the

data

bus.

On

successive

counts

of

the

two

bit

counter,

the

lower

and

upper

address

byte

are

inserted

on

the

data

bus

in

turn,

and

on

the

4th

count

(that

is,

when

the

counter

is)nck

to

0),

the

processor

is

again

stopped

by

the

removal

of

the

READY

line.

Thus,

the

EXAMINE

logic

provides

the

processor

with

the

jump

instruction

and

the

two

address

bytes

that

the

processor

expects

after

a

jump

instruction

and

CP-A

Theory

of

Operations

Revision

1

stops

the

processor

during

the

fetch

of

the

designated

memory

byte.

Similarly,

the

DEPOSIT

switch,

when

operated,

prodnces

a

pulse

from

the

DEPOSIT

one-shot

which

is

buffered

to

the

MEMORY

WRITE

line

on

the

backplane.

The

leading

edge

of

this

pulse

also

starts

a

second

one-shot

with

a

much

longer

period

which

puts

the

data

from

the

data

switches

on

to

the

data

bus

for

the

duration

of

the

longer

pulse.

The

DEPOSIT

one-shots

are

triggered

either

by

the

operation

of

the

DEPOSIT

switch

or

by

the

trailing

edge

of

the

DEPOSIT

NEXT

one-shot

so

that

the

DEPOSIT

function

will

operate

at

the

end

of

the

EXAMINE

NEXT

cycle.

The

7427

gate

in

U15.5

is

used

to

insure

that

during

the

time

the

front

panel

is

inserting

any

information

on

the

bi-directional

data

bus,

the

MPU-A

board's

bi-

directional

data

bus

driver

is

not

also

trying

to

drive

the

bus

at

the

same

time.

The

inputs

to

this

gate

are

the

DATA

-ON

line,

the

EXAMINE

NEXT

line

and

the

EXAMINE

line.

These

are

the

three

functions

during

which

the

front

panel

is

transferring

data

or

instructions

to

the

bus.

The

inputs

to

the

7405

open-collector

inverter

bus

drivers

are

the

lines

NO

-OP,

C3,

HAD,

and

LAD.

These

levels

are

ANDed

with

the

PDBIN

signal

so

that

the

information

appears

on

the

bus

during

the

time

the

processor

is

expecting

to

see

it

there.

The

input

port

from

the

high

order

address

switches

is

implemented

simply

by

decoding

the

address

FF

and

ANDing

it

with

the

DBIN

signal

so

that

switch

values

appear

on

the

data

bus

during

the

time

that

the

processor

is

expecting

information

from

the

port

FF.

The

same

address

decode

signal

is

ANDed

witli

the

STATUS

OUT

line

to

enable

the

8212

8

bit

latch

which

drives

the

PROGRAMMED

OUTPUT

indicators.

The

information

on

the

bi-directional

data

bus

is

then

latched

onto

the

output

port

at

the time

of

the

processor

write

strobe.

CP

-A

Theory

of

Operations

Revision

1

The

STATUS

WORD

DISABLE

line

(SSWDSB

i

Pin

53

backplane)

is:gated

to

insure

that

no

conflicts

are

created

between

the

bi-directional

buedrivers

on

thelLIPU

and

CPA

boards.

This

signal

is

contr011ed

by

the

same

gating

_that

places

the

high

order

address

switch

values

on

the

data

bus

for

a

front

panel

(address

hex

FF)

read.

The

.

STATUS

WORD

DISABLE

line,

Pin

53

in

the

backplane,

is

ale°

run

by

the

signal

which

puts

the

high

order

addreSs

switches

onto

the

data

bus

for-the

port

FF

read

instruction

so

that

the

bi-díredtional:data

bus

is

not

being

driven

by

the

bidirectional

driVete::On

the

MPU

board

at

the

Same

time

that

the

frOnt,panel

is

insert-

ing

the

switch

inforMatiOn

on

the

data

buš..

The

RESET

switch

diredtly

gtounds

the

RESET

line

on

thé

backplane

which

is

detedtéd

by

the

MPU

board

and

pro-

cessed

to

form

a

RESET

pulse

which

re-appears

on

the

backplane

as

a

Power

On

Clear.

When

the

RESET

switch

is

thrOwn

.-

c:›EXTERNALCLEAR,

the

switch

directly

grounds

the

EXTERNAL

SWITCH

line

on

the

backplane.

There

is

á

:diode

between

thé

RESET

line

and

the

EXTERNAL:CLEAR

line

siothat

duting

a

reSet

operation

an

EXTERNAL

CLEAR

is

aleo

generated.

11;;;41'.190;M:

I

:4

•

>5

81.1,§4

&&&&

at,

1

,11

5

1

1

.

1

,

m

7,;;;0

--""

•

%1

op

g

-

".~

,

;

á

,

CP-A

R

EV

-4:

BOARD:

CP-A

ITEM

IMSAI

CP-A,

Rev.

4

Parts

List

QUANTITY

DESCRIPTION/IDENTIFYING

MARKS

PART

#

Solder

15-0000001

10'

Heat

Sink

16-0100002

1

Thermalloy/5106B-14

SCrew

20-2203001

22

43:14"

Slotted

Hex

Head,

Self-Tapping,

Type

A

Sheet

Metal

Screw

20-3203001

2

#63c14

Self-Tapping

Sheet

Metal

Screw

20-3302001

1

6-32x5/16"

Phillips

Pan

Head

Machine

Screw

20-3916002

8

6-32x1la"

Button

Head

Allen

Machine,

Black

Nut

21-3120001

1

6-32

Hex

Lockwasher

21-3350001

1

#6

Internal

Star

Lockwasher

Spacer

21-3600001

8

46x14"

White

Nylon

Spacer

21-3600002

8

7/16"

White

Nylon

Switch

26-1500001

8

Blue

Paddle

Switch,

on/none/on

Switch

26-1500002

8

Red

Paddle

Switch,

on/none/on

Switch

26-1500003

2

Red

Paddle

Switch,

momentary

Switch

26-1500004

3

Blue

Paddle

Switch,

momentary

Switch

26-1600001

1

Red

Rocker

Switch,

on/none/on

Resistor

30-3220362

44

220

Ohm,

k

Watt/red,

red,

brown

Resistor

30-4100362

9

IK

Ohm,

lží

Watt/brown,

black,

red

Resistor

30-5470362

6

47K

Ohm,

1

4

Watt/yellow,

violet,

black

Resistor

30-6270362

1

270K

Ohm,

1

4

Watt/red,

violet,

yellow

Capacitor

32-2000110

2

.001uP

Disk

Ceramic

Capacitor

32-2001010

1

.01uF

Disk

Ceramic

Capacitor

32-2010010

17

.1uF

Disk

Ceramic

4

-

15

CP-A,

Rev.

4

Parts

List

IMSAI

rTEM

PART

#

Capacitor

Diode

LED

8T97

7400

7402

7404

74LSO4

7405

7410

74LS10

7427

7430

74LS30

7805

8212

74107

74123

QUANTITY

DESCRIPTION/IDENTIFYING

MARKS

32-2233070

2

33uF

Tantalum

35-1000006

1

Signal

Diode/1N914

35-3000001

44

Light

Emitting

Diode/red

36-0089701

1

Rex

Tri

-State

Buffer/N8T97B

36-0740001

2

Quad

2

Input

NAND/SN7400N

36-0740201

2

Quad

2

Input

NOR/SN7402N

36-0740401

1

Rex

Inverter/SN7404N

36-0740402

2

Rex

Inverter

(Low

Power

Schottky)/SN74LSO4N

36-0740501

5

Rex

Inverter

Open

Collector/SN7405N

36-0741001

1

Triple

3

Input

NAND/SN7410N

36-0741002

1

Triple

3

Input

NAND

(LPS)/SN74LS10N

36-0742701

1

Triple

3

Input

NOR/SN7427N

36-0743001

1

8

Input

NAND/SN7430N

3670743002

1 8

Input

NAND

(LPS)/SN74LS3ON

36-0780501

1

5V

Positive

Volt

Regulator/MC7G05CP

36-0821201

1

I/O

Port/P8212/S1002

36-7410701

3

Dual

J

-K

Flip

Flop

With

Clear/SN74107N

36-7412301

3

Dual

Monostable

Multivibrator,

Retriggerable

with

Clear/SN74123N

Cable

Assembly

91-0400001

PC

Board

Plastic

Panel

93-3010006

Plastic

Panel

93-3010007

Bracket

Photo

Mask

93-3010015

Paper

Backing

93-3010016

4

-

16

1

Cable

K

Assembly

92-0000002

1

CP-A,

Rev.

4

1

Clear

Plastic

Panel

1

Red

Plastic

Panel

93-3010011

1

Switch

Bracket

1

1

CP-A

Rev.

4

Assembly

Instructions

CP-A

Rev.

4

ASSEMBLY

INSTRUCTIONS

1)

Unpack

your

board

and

check

all

parts

against

the

parts

lists

enclosed

in

the

package.

2)

If

gold

contacts

on

the

edge

connector

appear

to

be

corroded,

use

pencil

eraser

to

remove

any

oxidation.

NOTE:

Do

not

use

Scotchbright

or

any

abrasive

material

as

it

will

remove

the

gold

plating.

LED

INSTALLATION

3)

For

a

professional

appearing

finished

CP-A

Board

two

items

in.

the

assembly

are

important:

first,

the

mounting

of

the

LED

indicator

lamps,

and

second,

the

mounting

of

the

paddle

switches.

Care

is

necessary

in

the

mounting

of

both

of

these

items

to

insure

evenly

spaced,

sťraight

line

rows

of

compon-

ents.

If

they

are

assembled

carefully,

the

panel

will

have

a

professional

appearance.second

to

none.

If

these

two

items

are

assembled

haphazardly,

the

panel

will

function;

however,

.

it

will

have

a

distinctly

less

than

workmanlike

appearance.

For

maximum

ease

in

uniform

assemblinq,

the

LED

indicator

lamps

should

be

installed

on

the

board

first,

before

any

other

compon-

ents

have

been

installed.

They

should

not

be

pushed

fully

against

the

board,

but,

rather,

should

be

set

up

approximately

1/8

inch

to

place

them

closer

behind

the

acrylic

panel

mask;

this

provides

for

a

greater

viewing

angle

during

panel

operation.

A

small

easv-to-make

jig

is

extremely

useful

in

accurate

pos-

itioning

of

the

LEI/indicators.

This

mounting

aid

consists

of

1/8

inch

thick

material.

A

piece

of

1/8

inch

plastic,

al-

uminum

or

masonite,

or

two

pieces

of

1/16

inch

material

such

as

vector

board

or

old

printed

circuit

board

make

ideal

jigs.

A

3/4

square

inch

piece

of

the

1/8

inch

material,

or

two

of

the

1/16

inch

material

should

be

cut

and

a

narrow

slot,

such

as

would

be

produced

by

a

hacksaw

or

coping

saw

blade,

cut

into

one

side

a

little

bit

past

the

center.

As

each

light-

emitting

diode

is

installed

in

the

board,

leads

can

be

inserted

through

the

short

slot

čut

into

this

piece

and

then

through

the

board

and

the

LED

should

be

pushed

up

haÉd

against

the

1/8

inch

piece

so

that

its

base

sits

flat

and

it

will

be

held

accurately

1/8

inch

awav

from

the

surface

of

the

front

panel

board.

The

lead

should

be

soldered

from

the

back

while

some-

one

is

holding

the

LED

against

the

mounting

aid

from

the

front.

The

mounting

aid

can

then

be

slipped

out

from

under

the

LED.

Take

care

that

every

LED

is

mounted

in

the

correct

direction

with

the

cathode

down

towards

the

100

pin

edge

connector

at

A

-

CP-A

Rev.

4

Assembly

Instructions

,the

bottom

of

the

board.

The

cathode

can

be

recognized

by

its

proximity

to

the

flat

side

on

the

base

of

the

light

emitting

diode

4)

Insert

and

solder

each

of

the

forty-four

red

LED's

at

locations:

LOO

through

LO7

LAO

through

LA15

LDO

through

LD7

LSO

through

LS7

LIE,

ŽHD1,-LRN,

LWT

RESISTOR

INSTALLATION

5)

Insert

and

solder

each

of

the

forty-four

220

ohm

k

watt

resistors

(red/red/brown)

R16

through

R59.

See

Assembly

Diagram

for

location.

6)

Insert

and

solder

each

of

the

six

47K

ohm

k

watt

resistors

(yellow/

violet/orange)

R3,_

R4,

R5,

R8,

R9;

and

R12.

See

Assembly

Diagram

for

location.

7)

Insert

and

solder

one

270K

ohm

1

4

watt

resistors

(red/violet/yellL

Rl.

See

Assembly

Diagram

for

location.

8)

Insert

and

solder

each

of

the

nine

1K

ohm

14

.

watť_resistors

(brown/

black/red)

R2,

R6,

R7,

R10,

R11,

Ri3Fthrough

R15,

and

R60.

See

Assembly

Diagram

fór

location.,

IC

INSTALLATION

9)

Insert

and

solder

each

of

the

two

7400

IC's

at

locations

U14

and

U25.

10)

Insert

and

solder

each

of

the

two

7402

IC's

at

locations

U13

and

U16.

11)

Insert

and

solder

the

one

7404

IC

at

location

U10.

12)

Insert

and

solder

each

of

the

two

74LSO4

IC's

at

locations

U8

and

U15.

13)

Insert

and

solder

each

of

the

five

7405

IC's

at

locations

Ul,

U3,

U4,

U6,

and

U7.

14)

Insert

and

solder

the

one

7410

IC

at

location

U12.

15)

Insert

and

solder

the

one

74LS10

IC

ať

location

Ull.

16)

Insert

and

solder

the

one

7427

IC

at

location

U15.5.

4

-

18

CP-A

Rev.

4

Assembly

Instructions

17)

Insert

and

solder

the

one

7430

IC

at

location

U21.

18)

Insert

and

solder

one

74LS30

IC

at

location

U9.

19)

Insert

and

solder

each

of

the

three

74107

IC's

at

locations

U18,

U19,

and

U22.

20)

Insert

and

solder

each

of

the

three

74123

IC's

at

locations

U17,

U20,

and

U23.

21)

Insert

and

solder

the

one

8T97

IC

at

location

U24.

22)

Insert

and

solder

the

one

8212

IC

at

location

U5.

DISCRETE

COMPONENT

INSTALLATION

NOTE:

Lead

allowance

on

all

capacitors

must

be

long

enough

to

allow

them

to

be

flattened

(or

laid

down)

flush

on

the

board

or

chip

to

facilitate

front

panel

mounting.

23)

Insert

and

solder

each

of

the

seventeen

.luf

capaci-

tors

at

locations

Cl,

C2,

C5,

C6,

C7,

and

Cll

through

C22.

C2,

C3,

C5,

C6,

and

C7

should

be

laid

down.

24)

Insert

and

solder

each

of

the

two

.001

uf

capaci-

tors

at

locations

C3

and

C8.

25)

Insert

and

solder

the

one

.01

uf

capacitor

at

location

C4.

26)

Insert

and

solder

the

two

33

mf

25

volt

tantalum

capacitors

at

locations

C9

and

C10.

NOTE:

Observe

polarity

as

marked

on

board.

27)

Insert

and

soláer

the

1N914

diode

at

position

CR1.

REGULATOR

AND

BEAT

SINE<

28)

Before

installing

heat

sink

bend

all

the

heat

sink

fins

horizontally

(outward)

to

facilitate

front

panel

mounting.

The

middle

fin

located

on

the

right

band

side

of

the

board

(when

mounted)

should

be

brokeň

off

or

bent

inward

in

order

to

allow

space

for

the

INTERRUPT/ENABLE

LED

(LIE)

to

be

seen

through

the

front

panel.

4

-

19

CP-A

Rev.

4

Assembly

Instructions

29)

To

instáll

the

regulator

and

heat

sink

first

bend

the

7805

regulator

leads

at

90

degree

angles

to

a

length

which

allows

their

insertion

into

the

hole

pattern

of

the

CP-A

board.

Then

place

heat

sink

as

shown

in

Assembly

Diagram

and

insert

regulator

as

described

above.

Use

a

#6

screw

on

the

component

side

of

the

board

and

lockwasher

and

nut

on

the

solder

side

of

the

board.

Tighten

the

screw

care-

fully

to

insure

proper

alignment

of

the

heat

sink

to

prevent

shorting

to

adjacent

traces.

CP-A

TO

MPU-A

INSTALLATION

30)

Using

the

16

conductor

ribbon

cable

with

16

pin

3M

dual

inline

connector,

insert

one

end

into

the

hole

pattern

U2

from

the

back

side

of

the

CP-A

board

so

that

it

can

be

soldered

from

the

front

(component

side)

of

the

CP-A

board.

The

cable

should

be

mounted

so

that

it

extends

upward

from

the

top

of

the

chassis

when

the

board

is

mounted.

SWITCH

INSTALLATION

NOTE:

There

are

three

tyoes

of

switches

included

for

installation

on

the

front

panel

(disregarding

color).

They

include:

A.

One

2

position

red

rocker

switch.

This

is

the

AC

power

switch.

B.

5

momentary

3

position

with

spring

return

to

center

paddle

switches

identified

by

the

lack

of

a

Nipple

(raised

portion)

on

the

front

of

the

switch

mounting

tab.

C.

16

2

position

no

spring

return

paddle

switches.

NOTE:

Temporarily

plug

on

the

CP-A

Board

while

soldered

to

help

insure

the

PC

Board

and

switch

a

100

pin

edge

connector

switches

are

being

proper

spacing

between

bracket.

31)

The

last

step

is

the

assembly

of

the

switches

and

the

switch

mounting

bracket.

Note

that

the

front

panel

includes

switches

whether

mounted

in

the

front

of

the

cabinet

or

not.

The

POWER/ON/OFF

Rocker

Switch

mounts

at

the

extreme

right

switch

position.

The

Paddle

Switches

are

provided

in

both

two-position

and

center-off

spring

return

types.

The

two-position

switches

are

used

for

the

ADDRESS-DATA

and

ADDRESS

PROGRAMMED

INPUT

location

while

the

center

off-

spring

return

are

used

for

the

Control

Functions.

4

-

20

CP-A

Rev.

4

Assembly

Instructions

32)

When

the

entire

row

has

been

spaced

accurately,

the

board

should

be

turned

over

and

a

center

switch

should

be

soldered

in

place

taking

care

that

the

board

is

not

bowed

towards

or

away

from

the

switches.

When

the

board

is

positioned

correctly,

there

will

be

a

smalt

space

approximately

3/64

inch

or

slightly

under

1/16

inch

between

the

bottom

of

the

switch

and

the

front

of

the

front

panel

board.

The

two

end

switches

should

be

similarly

checked

to

make

sure

that

the

spacing

to

the

board

is

correct

and

soldered

in

place,

and

then

one

switch

each

at

the

positions

checked

as

to

spacing

from

the

board

and

soldered

into

place.

Then

the

remainder

of

the

switches

can

be

soldered.

Examine

visually

for

solder

splash

or

bent/unsoldered

pins.

PANEL

ASSEMBLY

Refer

to

the

diagram

to

see

how

the

clear

front

acrylic

piece,

the

photograph

mask,

the

die

cut

paper

backup

and

the

red

acrylic

panel

are

assembled

in

sequence

with

the

6/32

x

1;1

inch

button

head

screws.

BUTTON

HEAD

SCREWS

r

SWITCHES

CPA

BOA

RD

7/1

6°

SPACE

R5

PEM

NUT

PEM

NUT

W

.

SPACERS

CLEAR

ACRYLIC

FILM

MASK

WHITE

PAPER

MASK

1VITH

CUTOUT

Ť

CHASSIS

-1

PIECE

8

I

I I

I I

L

21

CP-A

Rev.

4

Assembly

Instructions

Both

the

Photographic

mask

and

the

paper

backup

sheet

should

.

be

trimmed

to

size

afterassernbly.

Marks

are

provided

on

both,

and

they

should

be

cut

out

carefully

using

a

straight

edge

and

a

very

sharp

knife

againsť

a

wooden

cutting

board.

Scissors

may

be

used

if

a

guide

line

is

first

drawn

on

the

sheets.

The

8

holes

for

the

assembly

screws

should

be

cut

out

on

the

mask

and

the

paper

sheet

as

indicated

in

the

diagram.

Then

the

protective

paper

may

be

removed

from

the

two

acrylic

sheets

and

the

sandwich

assembled

carefully.

Avoid

getting

duste

caught

in

between

any

of

the

pieces.

A

soft

lint-free

rag

verv

slightly

moistened

can

be

an

aid

in

cleaning

any

dust

off

plastic

or

file

surfaces.

When

the

acrylic

pieces,

film

and

paper

have

been

assembled,

eight

7/16

inch

spacers

may

be

slipped

over

the

screws

and

then

the

whole

assembly

inserted

through

the

mounting

holes

on

the

CP-A

board.

Take

care

that

there

is

no

interference

from

any

component

standing

too

high

and

that

the

acrylic

panels

sit

down

completely

on

the

7/16

inch

spacers

against

the

board.

Eight

i

inch

spacers

can

then

be

slipped

over

the

screws

behind

the

CP-A

board

and

eight

#6

nuts

and

lockwashers

can

be

put

on

ťo

hold

the

sandwich

together.

The

panel

board

should

now

be

ready

to

plug

in

and

use.

If

the

board

is

going

to

be

assembled

in

the

front

location

of

a

cabinet,

to

serve

as

a

permanent

front

panel,

the

eight

nuts

should

be

removed

at

this

time.

Install

the

cap

screws

in

the

PEM

nuts

in

the

front

panel

sheet

metal.

CP-A

User

Guide

Revision

1

USER

GUIDE

The

CP-A

board

contains

no

user

option

jumpers

or

any

other

special

connections

that

must

be

made

to

use

the

board.

If

the

panel

is

mounted

in

the

IMSAE8080

cabinet

then

the

power

on/off

switch

should

be

con-

nected

using

a

separate

wire

to

the

power

supply

section

as

described

in

the

Power

Supply

documentation.

If

the

panel

board

is

not

going

to

be

mounted

in

the

cabinet,

then

the

power

switch

should

not

be

connected.

In

this

case,

the

power

switch

on

the

inside

or

on

the

back

of

the

cabinet

would

be

used

for

controlling

power

to

the

IMSAI

8080.

Panel

installation

requires

a

backplane

slot.

The

panel

may

be

plugged

directly

into

the

front

slot

of

the

mother

board

(with

the

mounting

screws

from

the

acrylic

face

plate

assembly

extending

through

the

metal

panel

immed-

iately

behind

and

secured

with

lock

washers

and

nuts)

or

plugged

on

an

extender

card

into

any

location

in

the

back

plane.*

The

16

pin

DIP

plug

on

the

end

of

the

flat

cable

must

also

be

inserted

into.

the

corresponding

socket

in

the

upper

right

hand.corner

of.the

MPU-A

board.

Only

one

front

panel

should

be

plugged

into

the

bus

at

any

time

to

avoid

conflicts

between

multiple

driving

sources

on

the

same

signal

lines

for

some

of

the

control

lines

between

the

front

panel

and

the

system

bus.

The

front

panel

is

now

ready

to

operate.

The

16

ADDRESS-DATA

and

ADDRESS-PROGRAMMER

INPUT

switches

are

2

position

paddle

switches

and

represent

a

()

in

the

down

position

and

a

1

in

the

up

position.

The

switches

are

provided

in

two

colors,

and

can

be

arranged

either

in

color

groups

of

four

to

assist

programming

ín

hexa—

decimal

or

color

groups

of

3,

3

and

2,

to

aid

in

octal

programming.

The

iow

order

byte

of

address

switches,

serve

to

enter

into

memory

either

data

or

program

instructions.

Theše

switches

are

labeled

ADDRESS-DATA

0

through

7.

Each

byte

of

data

or

program

that

is

to

be

entered

from

the

front

panel

is

set

into

these

switches

after

the

approp-

riate

address

has

been

selected

and

entered.

The

switch

*switches

should

be

íncluded

whether

the

front

panel

is

mounted

in

the

front

of

the

cabinet

or

not.

4

-

23

CP-A

User

Guide

Revision

1

positions

are

not

indicated

on

the

indicator

lights

until

the

information

is

deposited

in

memory.

At

that

time

the

information

from

these

switches

appears

on

the

data

bus.

The

high

order

byte

of

address

switches

is

labeled

ADDRESS-PROGRAMMED

INPUT

and

these

switches

can

be

read

by

the

program

as

input

port

position

hex

FF

or

octal

377.

The

additional

labels

O

through

7

are

provided

above

these

switches

to

assist

in

inter-

preting

the

switch

positíons

when

being

used

as

an

input

port.

The

position

of

these

switches

does

not

appear

in

the

indicators

until

the

input

instruction

from

position

FF

is

executed,

during

which

ěxecution

time the

switch

positions

appear

on

the

data

bus

as

it

is

being

read

into

the

8080

processor.

The

six

control

switches

are

grouped

at

the

right

end

of

the

panel.

They

are

center-off

two-position

spring-

return

switches

with

the

exceptíon

of.

the

POWER

ON/OFV

switch,

which

is

a

rocker

type

to

eliminate

accidental

powerdowns.

The

function

switches

are

provided

in

alternating

colors

for

easy

identification

and

to

reduce

operator

error.

The

RUN/STOP

switch

controls

program

execution.

When

the

switch

is

pushed

to

the

RUN

position,

a

control

signal

is

sent

to

the

processor

board

and

enables

it

to

start

or

continue

executing

program

instruction

beginning

in-the

location

indicated

at

that

time

in

the

address

bus

lights.

When

the

address

switch

is

depressed

to

the

STOP

position,

this

enable

signal

is

removed

from

the

processor

board

at

the

beginning

of

the

next

instruction

cycle

so

that

the

processor

will

stop

executing

during

the

fetch

cycle

for

that

follow-

ing

instruction.

When

the

processor

is

enabled

to

RUN,

the

RUN

light

above

the

RUN/STOP

switch

will

be

lit.

When

the

processor

has

been

stopped,

the

WAIT

light

to

the

right

of

the

RUN

light

will

be

lit.

During

normal

operation,

the

RUN

light

will

be

on

full

and

the

WAIT

light

will

be

on

partially,

the

exact

amount

depending

on

how

many

wait

cycles

are

required

by

the

memory

and

peripheral

devices

being

run

by

the

processor

at

the

moment.

4

-

24

Table of contents

Other Imsai Computer Hardware manuals

Popular Computer Hardware manuals by other brands

Poppstar

Poppstar M.2 NVMe Instructions for use

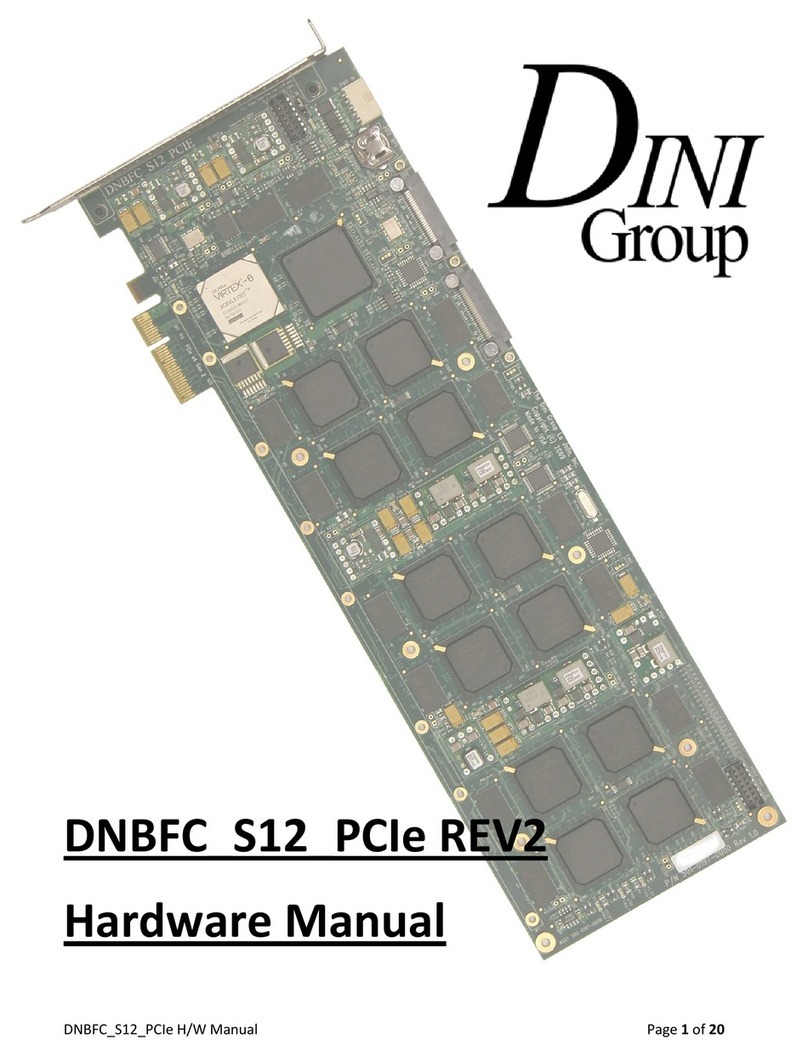

Dini Group

Dini Group DNBFC_S12_PCIe Hardware manual

Rockford Fosgate

Rockford Fosgate 3SIXTY.3 Installation & operation guide

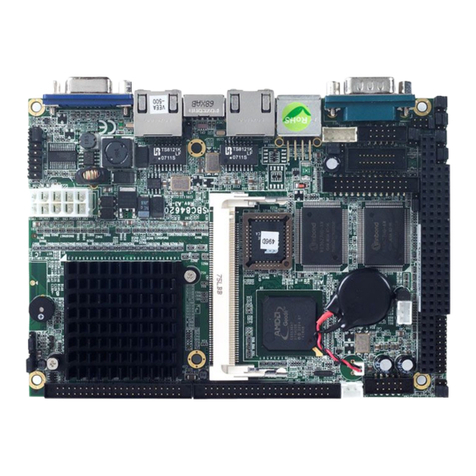

AXIOMTEK

AXIOMTEK SBC84620 Series user manual

ekwb

ekwb EK-Nucleus AIO CR360 Vision D-RGB instruction manual

Zoom

Zoom Zoom player 3000 Operation manual

Phytec

Phytec phyCORE-i.MX 8M Mini quick start guide

AEB

AEB COBRA AEB510N Fitting Instructions and Warranty Workbook

Intel

Intel SL6NQ - Xeon 2.4 GHz/533MHz/512 KB CPU Processor... specification

Pneumercator

Pneumercator MODBUS RTU RS-485 instruction manual

McIntosh

McIntosh MX160 owner's manual

SIIG

SIIG 104-0487A Quick installation guide