INAZUMA ITF-30 septem User manual

www. inazuma- online.com

Drum Filters

ITF-30 septem

ITF-50 septem

ITF-80 septem

ITF-120 septem

ITF-160 septem

ITF-240 septem

ITF-30 Biokompakt septem

ITF-50 Biokompakt septem

ITF-80 Biokompakt septem

ITF-120 Biokompakt septem

ITF-160 Biokompakt septem

ITF-240 Biokompakt septem

Control WebCSAV2

Installation and operating instructions

Control WebCSAV2

2

FILTER TECHNOLOGY MADE IN GERMANY

page

1. General information....................................................................................................... 3

1.1. Introduction ...................................................................................................................................................................3

1.2. Important safety notes and warnings ..........................................................................................................................3

1.3. Warning label ................................................................................................................................................................3

1.4. WEEE-registration .........................................................................................................................................................3

1.5. EC declaration of conformity .......................................................................................................................................3

1.6. Utility model protection................................................................................................................................................3

1.7. Alteration and modication..........................................................................................................................................3

1.8. Spare parts ....................................................................................................................................................................3

1.9. Description and function of the product .....................................................................................................................3

1.10. Transport........................................................................................................................................................................4

1.11. Installation guidelines...................................................................................................................................................4

1.12. Warranty ........................................................................................................................................................................5

1.13. Additional information..................................................................................................................................................5

2. Installation and connection........................................................................................... 5

2.1. Before installation .........................................................................................................................................................5

2.2. Case cover .....................................................................................................................................................................5

2.3. Installation: gravity driven setup & water level ..........................................................................................................6

2.3.1. ∙ Connections gravity driven setup ..............................................................................................................................6

2.4. Installation: pump driven setup....................................................................................................................................7

2.4.1. ∙ Connections pump driven setup ................................................................................................................................7

2.4.2. ∙ Pump driven setup: Removal of the overow sheets................................................................................................7

2.4.3. ∙ Important notes on the pump driven setup ...............................................................................................................7

2.5. Installation Control WebCSAV2 / Initial commissioning of the lter ............................................................................8

2.5.1. ∙ Settings / conguration...............................................................................................................................................8

2.5.2. ∙ WebCSAV2 App ............................................................................................................................................................8

2.6. Mounting of the two oat switches..............................................................................................................................9

2.6.1. ∙ Mounting of the oat switch 1 – pump & gravity driven setup.................................................................................9

2.6.2. ∙ Mounting of the oat switch 2 – gravity driven setup .............................................................................................10

2.6.3. ∙ Mounting of the oat switch 2 – pump driven setup ...............................................................................................10

2.7. Magnetic valve for the gutter ush ............................................................................................................................ 11

2.8. Cover switch ................................................................................................................................................................ 11

2.9. Immersion-UVC...........................................................................................................................................................12

2.9.1. ∙ BioKompakt models..................................................................................................................................................12

2.9.2. ∙ Filters without a biochamber ....................................................................................................................................12

2.10. Mounting of the gear protection plate .......................................................................................................................13

2.11. Biological lter material Planet Bio............................................................................................................................13

2.12. Factory settings operating durations / ushes ..........................................................................................................13

2.13. Maintenance................................................................................................................................................................14

2.13.1. ∙ High pressure pump..................................................................................................................................................14

2.13.2. ∙ Prelter ......................................................................................................................................................................14

2.13.3 ∙ High pressure nozzles ...............................................................................................................................................14

2.13.4. ∙ Drum seal...................................................................................................................................................................14

2.13.5. ∙ Screen mesh and stripping brushes.........................................................................................................................14

2.13.6. ∙ Waste ow trench ......................................................................................................................................................14

2.13.7 ∙ Calcication / faults ...................................................................................................................................................15

2.13.8. ∙ Winter operation........................................................................................................................................................15

2.13.9. ∙ Operation in a swimming pond ...............................................................................................................................15

2.14. Technical data..............................................................................................................................................................15

3. Exploded drawing and spare parts list ....................................................................... 16

Certicate of quality................................................................................................................ 17

Service order / repair note...................................................................................................... 19

Index

3

www. inazuma- online.com

1. General information

1.1. Introduction

Congratulations on your new acquisition – a drum lter

made by Inazuma.

To avoid restrictions on function and warranty it is important

to read this manual carefully.

To make sure your lter works as supposed to, we ask you to

follow the manual, the user- guide and additional notes that

are provided with this product, closely.

In the event of emerging questions not addressed in this

manual we ask you to get in contact with your (local) dealer.

If your pond is extremely dirty / there is sludge or

similar deposits on the ground, we recommend

performing a basic cleaning prior to operating the

drum lter..

1.2. Safety notes and warnings

Please store this manual at an accessible location to be

able to address emerging questions about installation,

function and debugging.

It is recommended to keep a copy of this manual close to

the lter so e.g. technicians are able to get quick access to

all informations needed.

1.3. Warning Label

The sign next to this text points out important

warnings or signicant Informations.

1.4.WEEE-registration

iThe WEEE-registration ensures that the producers

are assuming liability for their electrical and electronic

equipment, especially the responsibility for recycling and

disposing of these according to the “ElektroG”.

The Federal Environment Agency of Germany

(Umweltbundesamt) conrms the registration of this product

under the following number:

WEEE-Reg.-Nr. DE 19429673

1.5. EC-Declaration of Conformity

Manufacturer: Inazuma

Johannes Kurzweil GmbH

Eisackstraße 16

DE – 86165 Augsburg

Tel.: +49 821-72 919 72

Fax.: +49 821-72 919 73

E-Mail: info @inazuma-online.com

Internet: www.inazuma-online.com

DeviceType:

Drum lter including electronic control and

high-pressure pump

!

Directives in use:

Machinery Directive: 2006/42/EG,

“Low Voltage” Directive: 2006/95/EG,

General Product Safety Directive: 2001/95/EG

Swiss implementations SR 819.14, SR 930.11 and SR 734.26.

Furthermore, the EN ISO 12100:2010 applies.

The manufacturer declares hereby the conformity of the

product with the safety requirements mentioned above.

1.6. Utility model protection

Gutter ush “Speed Flush” German utility model protection

Nr.20 2015 001 594.8

Cleaning brush “Clean Brush” German utility model

protection Nr.20 2015 001 595.6

1.7. Alteration and modication

We point out that every alteration or modication without

written approval by Inazuma or one of its authorized

suppliers will cause the immediate annulment of the CE

conformity assessment.

Inazuma will not assume liability for damages on persons

or property emerged by unauthorized alterations or

modications.

1.8. Spare parts

Only spare parts provided by Inazuma or one of its

authorized suppliers are approved for installation. In the

event of usage of non-authorized parts the warranty will

expire and Inazuma will not assume liability for damages.

Only use special tooling.

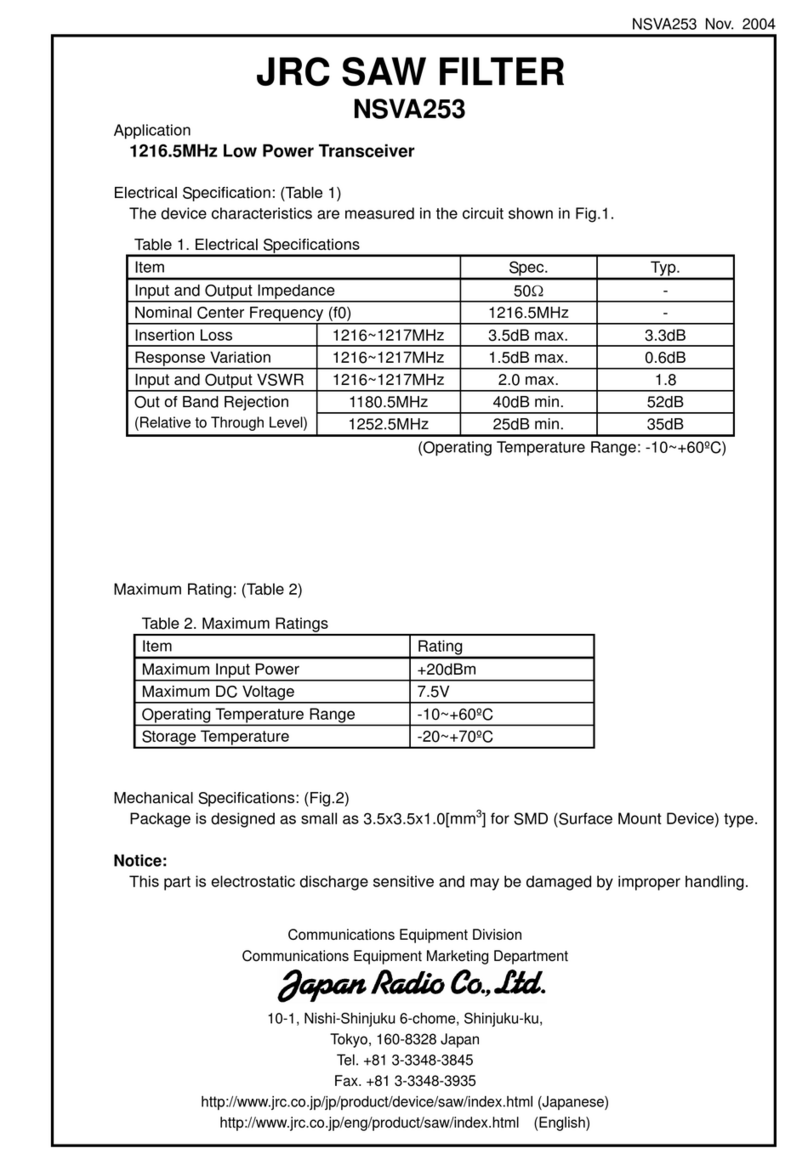

1.9. Description and function

The Inazuma®Drum Filter is a fully automatic, mechanical

lter for removing dirt particles from water circuits

(especially sh and koi ponds).

The drum lter is not suitable for liquids other than water.

!

!

CAUTION

The manufacturer will not assume

responsibility for any damages emerged

by misuse of the product or parts of it or by

non-observance of rules, guides and manuals

provided in this document and additional

documents (including stickers and warning

signs) provided with the product.

Operate the device only when nobody is in the

water!

The device can only be operated, if your house

wiring owns a ground fault circuit interrupter

(GFCI) / residual-current device (RCD) (30 mA

for humid environment) and the power supply

is connected to said system.

It is also recommended to use an overvoltage

protection class D or 3 (depending on your local

guidelines).

4

FILTER TECHNOLOGY MADE IN GERMANY

1.12. Positioning

Your drum lter must be installed in a way, so that it is

always accessible for maintenance work and replacement

of spare parts. For this, a minimum distance of 60 cm at

engine and inlet side, as well as 20 cm at the other two

sides must be observed.

The lter must stand on a rm and stable surface.

Furthermore, this must be a at surface (max 1% slope).

No liability is assumed for damage to the lter caused

by improper transport or the use of improper lifting

equipment.

1.10.Transport

The lter must be transported in an upright position.

Do not lift the product by using force against the engine

skid plate.

The drum lter may only be lifted at the designated load

handling points by using the Inazuma

lifting device.The set is available in

two variants:

for ITF 30 - 80, article number IK6010

for ITF 120 - 240, article number

IK6020

Remove the plugs from the top

corners of the lter. Do not throw

them away.

Guide the lifting bar through the lter

on the left and right side.Thread the

xing rings on the bar inside of the

lter.

Align the rod in the center and tighten

the clamping rings on the housing

wall of the lter.

Now the lter can be lifted by means

of a sling or lifting belt at the 4

suspension points.

No liability is assumed for damage to the lter caused

by improper transport or the use of improper lifting

equipment.

1.11. Installation guidelines

Distances

Your drum lter must be set up so that it is accessible at all

times for the replacement of spare parts and maintenance

work.There is a minimum distance of

60 cm on the engine and inlet side

20 cm on the other two sides

The lter must be freely accessible from the top up to a

height of 1.2 m

Please have the specications in accordance with

this installation plan checked or carried out by e.g.

a construction company / electrician BEFORE

starting the construction / lter installation!

!

If the lter is framed/ obstructed with wood or other

materials, these must be removed by the customer before

starting the service work. Any additional effort due to

non-existent minimum clearances must be borne by the

customer.

Ground

The lter must be on a rm and stable surface.

Furthermore, this must be a at surface (max. 1% incline).

Connection requirements

Operating voltage 230 V

Number of cables / wires x

cross section

1 cable / 3 x 2.5 mm² (valid up to a

maximum cable length of 25 m)

Fuse ratings 1 x 16 A (only use fuses with tripping

characteristic C)

Fault-current circuit breaker 16 A – 30 mA

Grounding to be connected to the ground screw of a

ground pole of min. 50 cm in length and

a cable diameter of 6 mm² (earthing pole

item no. IK6000)

If you have any questions, please contact the Inazuma

customer service onTel. (+49) 821 - 7291972.

The requirements must be carried out according to the

plan. In the event of deviations and the resulting delays or

a renewed travel, Inazuma reserves the right to charge the

additional work.

In the event of non-compliance, we assume no liability for

damage to property or personal injury.

5

www. inazuma- online.com

1.12. Warranty

The 2-year guarantee is a voluntary manufacturer’s

guarantee in accordance with the following guarantee

conditions. In addition, the guarantee conditions apply,

which can be viewed at www.inazuma-online.com.The

customer’s statutory warranty rights remain expressly

unaffected.

Warranty services apply for the specied duration,

calculated from the handover of the product to the

customer (invoice date). Provided warranty services do

not result in an extension of the warranty period or a

new warranty period for replaced or repaired parts.The

additional optional warranty extension for 2 more years

can only be acquired within 6 months after the lter

purchase.

If the item is resold, the guarantee is not transferable.

This guarantee does not apply to commercial use, here a

6-month guarantee applies.

Any changes to the device, control or connecting cables

and plugs will invalidate the guarantee.

The manufacturer is generally not liable for damage

resulting from an accident or improper installation or use

and consequential damage.

1.13. Additional information

ATTENTION

food additives, treatment with salt, use of tools

Numerous food and care products for koi and other shes

contain a high proportion of additives like iron. Please

make sure that all additives in use are classied for use in

combination with stainless steel.

Improper additives, the treatment of sh with salt and the

use of tools made out of steel are likely to cause damages

to the lter system.

Damages caused by improper additives, salt or the use of

inappropriate tools are excluded from warranty.

!

2. Installation and connection

The installation and connection of the drum lter

should only be carried out by qualied personal.

2.1. Before installation

Please examine the product before the beginning of the

installation procedure.

Ensure that neither the product itself nor the wrapping is

damaged.

Make sure that the lter does not contain any objects.

Before commissioning, you must remove

the transport lock (see picture below), or else

mechanical damages might occur.

(TheTransport lock is not included in all models!)

!

!

!

2.2. Case Cover

The case cover of each drum lter model can be mounted

mutually.You can therefore adjust the direction of the

opening to the situation on site.

If you want to mount the cover turned by 180°, the

following order of installation must be followed.

Non-observance will damage the drum screen

(gauze).

This is not subject to the guarantee / warranty!

1. In the rst step, the splash guard (1) must be transferred

to the designated location (2).

2. Only in the next step, the lter cover can be remounted.

You nd all necessary drill holes for the hinges and cover

lockings on opposite sides of the drum lter. For some

models, only one cover locking can be mounted after the

conversion due to their design.

!During installation, make sure that moving parts

of the lter can not be blocked by cables!

1 2

6

FILTER TECHNOLOGY MADE IN GERMANY

2.3.1. Connections gravity driven setup

*Make sure that the drain reaches a much lower level.The slope will prevent blockages.

Connections gravity driven setup for biochamber lters Connections gravity driven setup – lters without a biochamber

waste water outlet*waste water outlet*

Connections pump

(dry position)

connections for the pump

(immersed)

returns to pond/pool or

external biochamber

inlets

inlets

!

!

2.3. Installation: gravity driven setup &

water level

The lter must be installed on even and solid ground.

After positioning the lter, both axes (longitudinal and

transverse) must be aligned by using a spirit level.

Make sure that none of the tubes puts mechanical

load on the case of the lter.

Make sure that the

lter, arranged in the

gravity driven setup,

is positioned in the

right level within the

water-level.

You can nd a sticker

marking the right level

near the connections

on the front of the

lter.

gravity driven setup

7

www. inazuma- online.com

2.4. Installation pumped version

The lter must be installed on even and solid ground.

After positioning the lter, both axes (longitudinal and

transverse) must be aligned by using a spirit level.

Make sure that none of the attached tubes puts

mechanical load on the case of the lter.

IMPORTANT NOTE FORTHE PUMP DRIVEN SETUP

In a pump driven setup the amount of inlet

connections must be reduced.

Cover all unused inlet connections with caps.

!

!

2.4.1. Connections

pump driven setup

Reux connection:

In the pump driven setup it is

recommended to use anT-pipe/

branch pipe (open to the top)

at the reux connections to

ventilate the run-back line.

pump driven setup

*Make sure that the drain reaches a much lower level.The slope will prevent blockages.

Connections pump driven setup for biochamber lters Connections pump driven setup for lters without a biochamber

waste water outlet *waste water outlet *

close these connections with caps

returns to pond / pool

returns to pond/pool

(only use the top ones)

close the bottom connections with caps

inlets

inlets

2.4.3. Important notes for the pump

driven setup

1.To prevent the loss of water in the event of malfunction,

remove the premounted sheet metal parts and store them.

2. We recommend powering the pumps using an external

system.The Inazuma Control WebCSA

V2 provides this

function. In case of a malfunction or an error, the Control

WebCSA

V2 shuts the pumps down automatically.

In the pump driven setup the oat switch must be

installed in the prechaber of the lter.

!

Pumped version

remove closed sheet metal parts

2.4.2. Pumped version: Removal of the

overow sheets

8

FILTER TECHNOLOGY MADE IN GERMANY

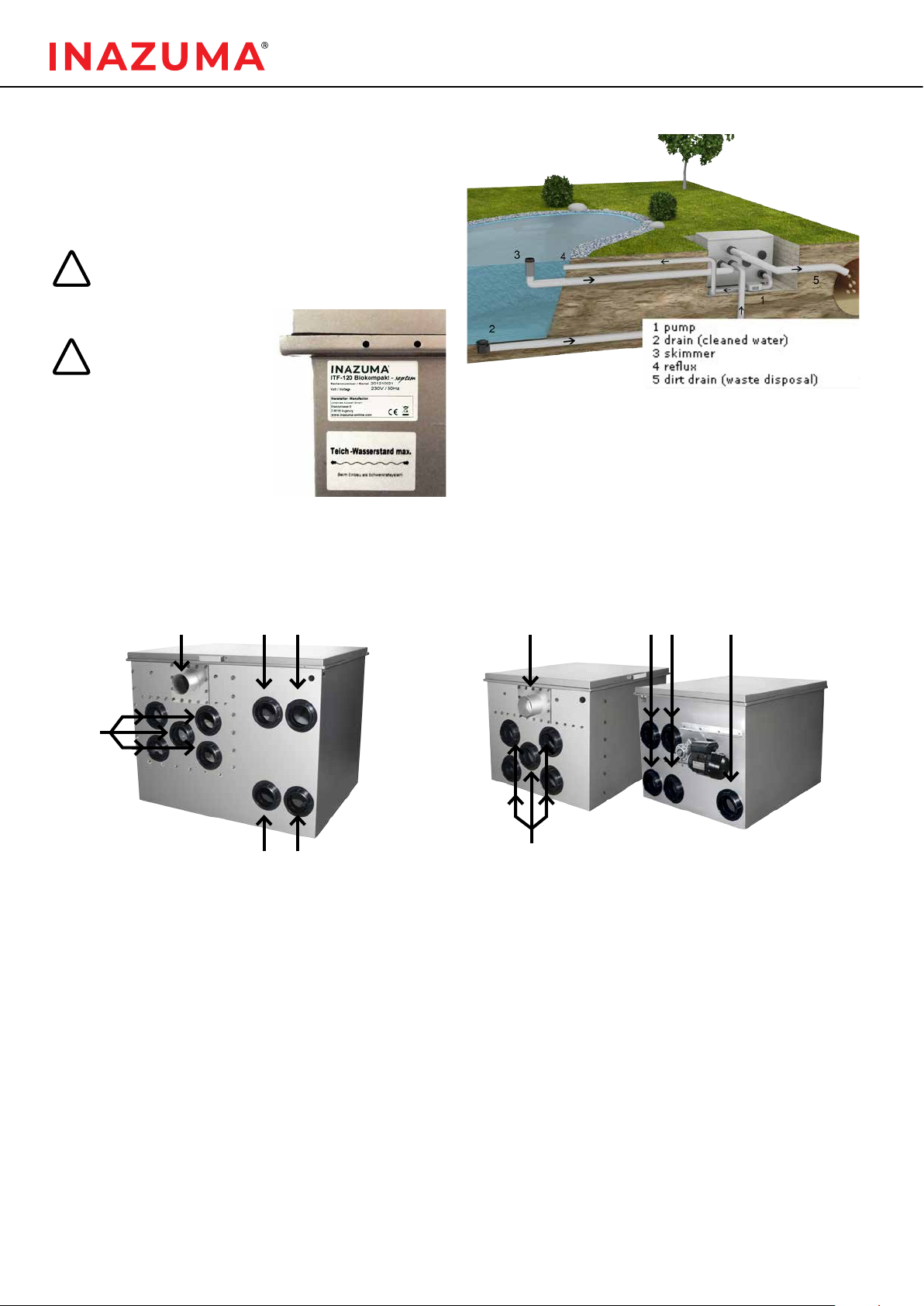

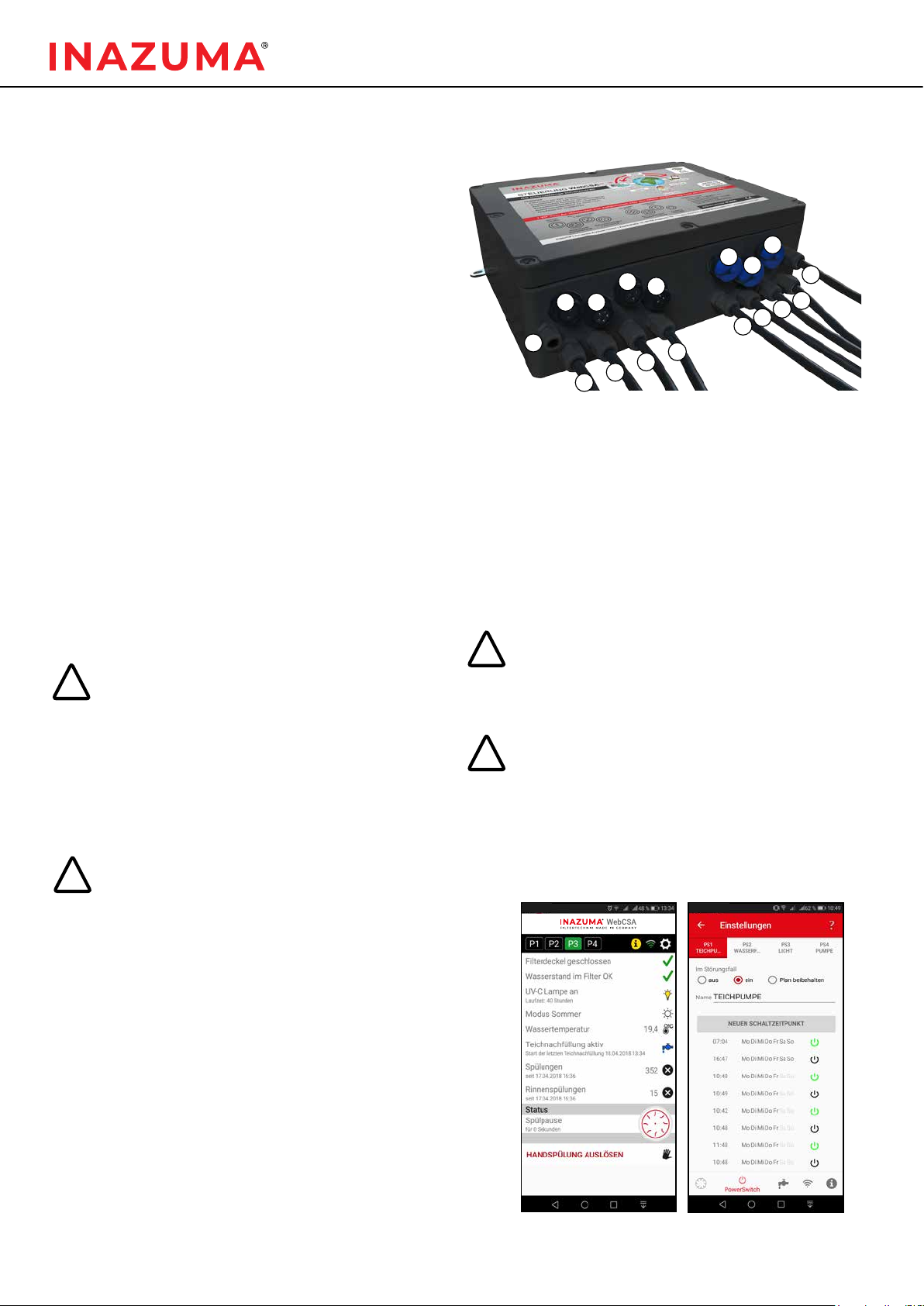

1. Mains Plug

2. Gear motor

3. High pressure pump

4. UVC

5. UVC

6. Power-Switch P4 (optional)

7. Power-Switch P3 (optional)

8. Power-Switch P2 (optional)

9. Power-Switch P1

10. Cable entry for W-LAN

antenna (optional)

11. Cover switch

12. Solenoid valve for gutter ush

13. Float switch 2 (2 oaters)

14. Float switch 1 (1 oater)

15. Temperature sensor (optional)

16. Solenoid valve for water level

regulator (optional)

1 7. water level sensor (optional)

2.5.1. Settings / conguration

The control is delivered without conguration. Before

commissioning, the control must be congured using

an app (available for Android and iOS). Please read the

operating instructions for the control WebCSA V2.

The rinsing process will start automatically depending on

the pollution level of the drum.

When the drum is soiled to a certain level, the oat switch

activates the rinsing process.

The drum lter control is equipped with a malfunction

detector. When a malfunction is detected, the control

reports a malfunction by sending out a beeping sound.

ATTENTION

You have to pay attention to the water level if

you have a pond without an automatic water

rell system. If the water sinks below the level

of the bottom oat switch, the lter will turn off

automatically, or else a continuous irrigation

would occur.

Inazuma offers an automatic pond level regulation

(item no. IK5001)

The drum lter control system should only be

opened by qualied personnel!

There is a danger of electric shock and risk of

injury, as the circuit board is live.

!

!

2.5. Installation Control WebCSA

V2 /

Initial commissioning of the lter

2.5.2. Connections

2.5.3. WebCSAV2 App

Before commissioning the lter, the system must be lled

with water and the cover must be closed.

• Control is splash proof (IP65)

• Protect from direct solar radiation!

• Do not drill any holes into the case, otherwise the

warranty will be lost.

A detailed operating manual for the WebCSA

V2

control, the app and the optional accessories for

the control (power switch, temperature sensor,

pond level regulation) can be downloaded from

our homepage www.inazuma-online.com.

The WebCSA

V2 app can be downloaded in the

google play store and apple app store.

!

!Always disconnect the power plug before

connecting / disconnecting components or

opening the control unit!

1

6

14

2

7

13

17

3

8

12

16

4

5

9

11

15

10

9

www. inazuma- online.com

2.6. Mounting of the two oat switches

The WebCSA

V2 control is supplied with two oat switches..

Mounting float switch 1

in the right area of the prechamber under the solenoid valve

2.6.1. Mounting oat switch 1 (gravity & pumped)

Float switch 2 (2 oaters) is responsible for ushing and

dry running protection.

Float switch 1 (1 oater) detects the water level in the

prechamber.

10

FILTER TECHNOLOGY MADE IN GERMANY

Position of the oat switch and its mounting

In the pump driven setup, the oat switch is already

installed in the waste water section in front of the drum.

The mounting is completely pre-assembled.Therefore,

there is no need to adjust its position.

Upper oat switch:

Responsible for the activation of the emergency shutdown

and protection of non-stop rinsing.

During normal operation of the drum lter it should be

always above the water level. If the upper oat switch gets

pushed upwards by water, the drum lter shuts down and

a fault signal occurs.

In pump mode, we recommend connecting the pond pump

to the Power Switch Outlet No. 1 of the control WebCSA

V2.

In this case, your pond pump (connected to the Power

Switch) will then be switched off in the event of a fault and

the pond will not be emptied.

Bottom oat switch:

Activates the rinsing-process. At the end of every rinsing-

cycle the top ring is supposed to oat towards the bottom

end.

2.6.3. Mounting oat switch 2 (pumped)

Waste water section in front of the drum

Upper oat switch:

Activates the rinsing-process. At the end of every rinsing-

cycle the top ring is supposed to oat towards the top end.

Bottom oat switch:

Activates the emergency shutdown in the event of non-

stop rinsing to prevent a drop of the water level in the

pond/pool.The bottom ring is always supposed to be

under water.

If it falls to the lower stop, the drum lter switches off,

because there is too little water in the pond.

The exact position of the oat switch must be

adjusted individually (slot holes in the mounting).

The height depends on the power of the pump.

Biokompakt-Models:

Pure water area outside the drum

2.6.2. Mounting oat switch 2 (gravity)

!

Filters without biochamber:

Mount float switch here.

Pure water area outside the drum

11

www. inazuma- online.com

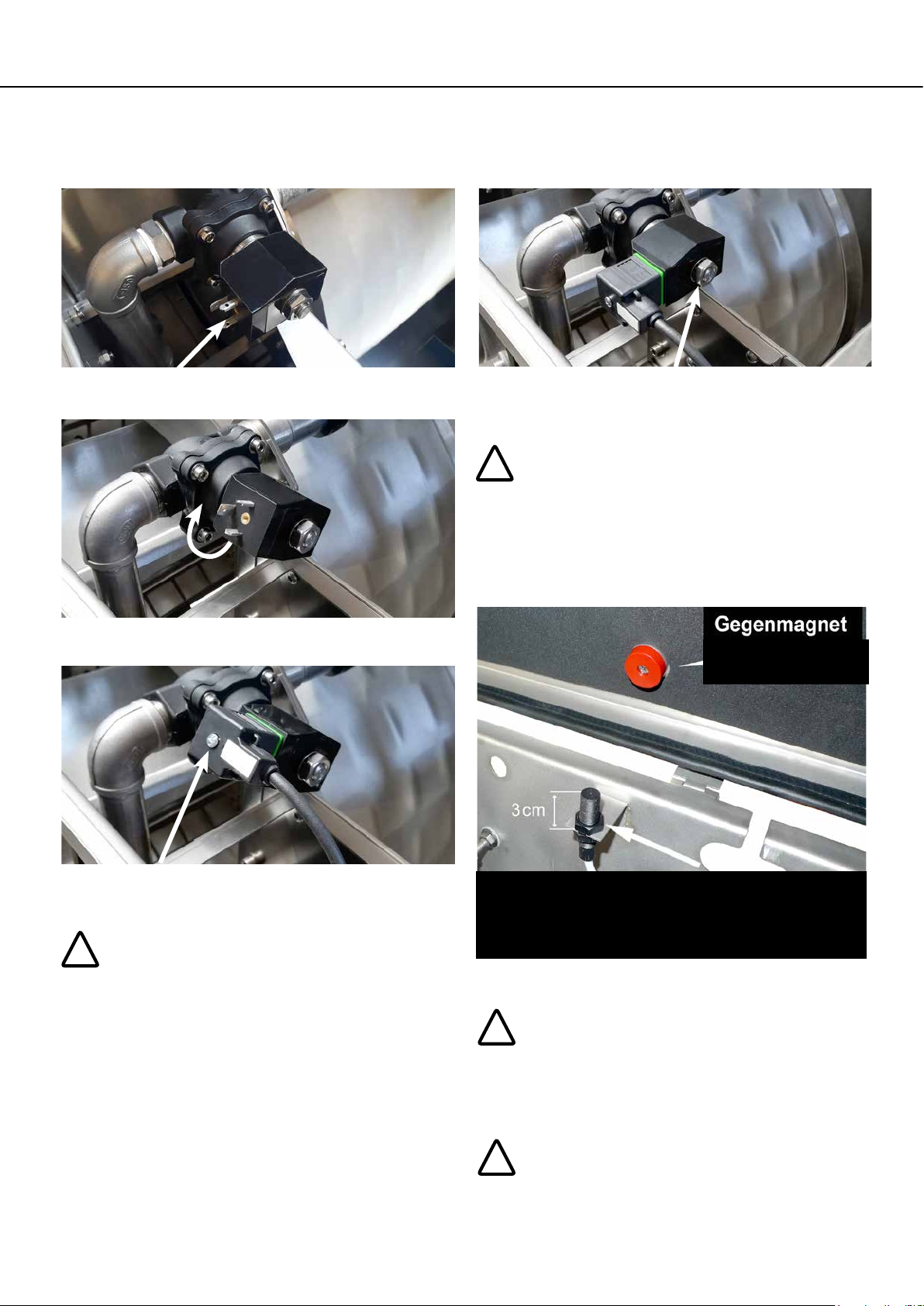

2.7. Installation of the magnetic valve

for the gutter ush

2.8. Cover switch

ATTENTION:

The manufacturer will not assume liability for

damages emerged by misuse of the product or

parts of it or by non-observance of rules, guides

and manuals provided in this document and

additional documents provided with the product.

During maintenance of the drum lter always

unplug the mains plug.

The system will also detect the opening of the

drum lter and will interject the power supply.

Never activate the cover-detection-switch

manually.

!

!

counter magnet

Cover switch

The cover switch must be in a position in which, when the

cover is closed, the gap between it and the counter-magnet is

at most 5 mm wide.

!

!

On delivery, the connection pins of the solenoid valve

head point towards the housing wall.

Loosen the nut on the solenoid valve head and turn it until

the pins point about 30 ° upwards.

Insert the plug of the solenoid valve onto the solenoid

valve head.Then tighten the screw on the back of the

connector.

Now turn the complete solenoid valve back to the starting

position until it is perpendicular to the lter wall.Tighten

the nut on the solenoid valve head rmly.

Make sure that the sealing washer of the screw

and the square housing seal are correctly attached.

IMPORTANT NOTE

Your drum lter is equipped with the Speed Flush

system (rinsing ush). In the default setting of the

controller, your lter performs a ush twice a day.

With the WebCSAV2 app, the number of ushes per

day can be changed.

12

FILTER TECHNOLOGY MADE IN GERMANY

2.9. Mounting of the immersion-UVC

2.9.1. Biokompakt models

All Inazuma drum lters of the septem series have one or more internal brackets for easy installation of immersion

UVC lamps suitable for the Inazuma high-performance duo lamp HD-PRO-50.000 V2.The UVC receptacles are sealed ex

factory with a sealing plug (see Fig. 1).

Assembly:

Depending on the number of UVC lamps, remove the sealing plugs. Insert the immersion UVC into the stainless steel

holder from above. Be careful not to damage the quartz tube.The lamp should now rest with the union nut on the top of

the bracket. Please keep the plugs after installing the UVC lamps (see g. 2).

g. 1 g. 2

2.9.2. Filters without biochamber

g. 1

g. 3

g. 2

All Inazuma septem drum lters have one or several UVC mountings on the inside (suitable for the HD-PRO 50.000 V2

immersion-UVC) (see g. 1)

Assembly:

Insert the immersion-UVC into the mounting until the device reaches the xture. Do this with caution to not damage the

quartz glass pipe.The union nut of the UVC-emmiter should now rest on the mounting (see g. 2)

Depending on the position of the immersion-UVC it might be necessary to remove the nut of the gas pressure absorber

(see g. 3)

13

www. inazuma- online.com

!

2.12. Factory settings operating

durations / ushes

rinsing duration: ca. 12 sec.

rinsing “Speed Flush”: 2 ushes within 24 hours

wave suppression: ca. 20 sec.

automated shutdown after non-stop rinsing

pump driven setup: ca. 10 min.

automated shutdown after non-stop rinsing

gravity driven setup: ca. 30 min.

Explanation of the rinsing process:

There are no guideline values for the number of rinses, this

always depends on the degree of soiling and the pumping

capacity.

In conjunction with the WebCSA

V2 app these and other

parameters can be changed or adjusted.

See also the operating instructions WebCSA

V2

www.inazuma-online.com.

Always unplug the power during any maintenance

work on the drum lter.

The system will also detect the opening of the

drum lter and will stop the power supply.

Never activate the cover switch manually.

2.11. Biological lter material Planet Bio

We recommended the use of biological lter material

Inazuma Planet Bio in following quantities:

ITF-30 BioKompakt septem 150 liters

ITF-50 BioKompakt septem 200 liters

ITF-80 BioKompakt septem 250 liters

ITF-120 BioKompakt septem 300 liters

ITF-160 BioKompakt septem 350 liters

ITF-240 BioKompakt septem 450 liters

Suggestion: At rst, put only half of the lter material into the

drum lter. Add the second half two weeks later.

The weight of the material is tared in such a way, that as soon

as the balls are canonicalized by microorganisms, they oat just

below the water level. In clean condition, just after putting them

into the lter, the balls push each other out of the water.

2.10. Assembly of the engine guard plate

The engine guard plate is inserted from the top of the

already pre-assembled bracket.

Dismantling the screws is not necessary!

14

FILTER TECHNOLOGY MADE IN GERMANY

2.13.2. Prelter

To protect the high-pressure

nozzles, a ne lter is

installed.

Simply rinse the disc lter

under running water. Please

also take care to remove any

contamination between the

individual panes.

2.13.4. Drum Seal

1. Once or twice a year,

especially after winter or a

longer standstill, the seal

of the drum should be

maintained.To do this, use an

ordinary silicone spray.This

prevents sticking of the seal on

the edge of the drum and an

easier startup of the drum.

1. Pull the mains plug of the the control unit, and the motor

connection cable leading to the control unit

2. Empty the lter completely

3. Plug the power plug from the motor into a socket (not

into the control unit)

Attention! Risk of injury due to rotating drum!

4. Spray some silicone spray on the edge of the drum until

it reaches about two turns

5. Disconnect the motor from the mains socket and

reconnect it to the control unit. Power the control unit.

6. Your lter is now ready for use again

!

2.13. Maintenance and care

During maintenance and before opening the lter it is necessary to turn it off and to unplug the power cable.

Otherwise, there will be a heavy risk of injury.

Maintenance: For optimal lter performance we recommend you to perform steps 1 to 5 once a year. Lime-water can

cause a poor cleaning of the mesh and shorter ushing intervals.To counteract that, please note point 2.13.7.

2.13.1. High pressure pump

To protect the high-pressure

pump, a lter sponge is

attached below the high

pressure pump.

To remove the lter sponge,

loosen the screw on the high-

pressure pump, lift it upwards

and remove the lter sponge

at the bottom.

Simply rinse the lter sponge

with clean water, put it back in

and retighten the screw.

2.13.3. High pressure nozzles

To decalcify the nozzles,

please disassemble them and

immerse them completely in

citric acid for about 30 minutes.

If the nozzles are clogged, you

can blow them out or clean

them with a toothbrush. Never

use hard or sharp objects,

such as Cutter knives or steel

brushes.These can damage the

spray nozzles.

2.13.5. Screen mesh and stripping brush

If the mesh is damaged, it can

be changed easily. Depending

on the load and water quality, it

may occasionally be necessary

to clean the mesh. For this see

chapter “Calcication / Fault”.

The stripping brush in the drum

should be checked occasionally

and replaced if necessary.

2.13.6. Waste ow trench

The gutter should, despite

regular gutter ushing, be

checked once a week for any

leftovers or adhering debris.

15

www. inazuma- online.com

2.13.7. Calcication / Fault

Depending on the degree of hardness of the water used in the

pond, there is usually no visible calcication of the mesh. A

common symptom is that the lter almost continuously rinses.

ATTENTION

This maintenance work should only be carried out by

qualied personnel!

ÎTo remove the calcication, we recommend cleaning the

mesh with citric acid.

1. Pull the mains plug of the the control unit, and the motor

connection cable leading to the control unit

2. Empty the lter completely

3. Apply the solution to the mesh with a brush

4. Leave the cleaning solution on for 10 to 15 minutes

5. Now plug the power plug of the engine into a socket (not on

the control) for a short time

Attention! Risk of injury due to rotating drum!

6. Repeat steps 3 to 5 until the entire mesh is treated

7. Rinse the mesh with clear water

8. Reconnect the motor connection cable to the control unit

and power the control unit.

ÎIf the above procedure does not lead to success, please

contact your dealer.

Do not place any tools such as brushes or containers

on the drum.The safety instructions of the cleaning

agent used must be observed!

2.14. Technical data

Materials in use

Stainless steel V4A: case, drum connections, trench etc.

Plastic: seal, rollers, anged housing unit

Motor and control

Power supply control 230 Volt / 50 Hz

Microfuse control 230 Volt / 10 A

Power supply sensor 12 Volt

Power supply cover switch 12 Volt

Power supply motor 230 Volt / 50 Hz

Motor power

0,18 KW (from ITF-30 to ITF-120)

0,36 KW (ITF-160 Biokompakt & ITF-240 Biokompakt)

Temperature range -10 °C – +50 °C

The case of the control elements must be

protected from direct sunlight and other heat

sources.

High pressure pump 230 Volt / 50 Hz

Power 0,6 kW

Hmax 42 m

Qmax 45 l/min

Flow rates (degree of pollution: max. ≤ 10 mg/ℓ)

!

!

!

!If the drum lters are operated with either a ow

rate, that is too high or with very heavily polluted

water, this can lead to extremely frequent rinsing

processes up to self-shutdown of the device

(continuous ushing protection, see factory setting

control times / ushing).

2.13.5. Winter operation

Generally, the operation of the

lter during winter is possible.

You have to make sure, that

the water temperature is

above 4°C (40°F).This can be

achieved by using appropriate

measures (e.g. immersion

heater).They prevent

damages and malfunctions of

the lter.

Ex works, a sealing plug is attached to the underside of

the rinsing drain. It must be unplugged when you are not

operating the lter in winter.

2.13.7. Operation in a swimming pond

Please follow your local guidelines for the operation of a

swimming pond.

Only run the drum lter, when no person is staying

in the water!

We recommend due to safety reasons to turn the

system off completely during bathing.

ITF-30 septem

Biokompakt ITF-50 septem

Biokompakt ITF-80 septem

Biokompakt ITF-120 septem

Biokompakt ITF-160 septem

Biokompakt ITF-240 septem

Biokompakt

pumped 20 m³ / h 30 m³ / h 45 m³ / h 60 m³ / h 80 m³ / h 120 m³ / h

gravity 15 m³ / h 25 m³ / h 35 m³ / h 45 m³ / h 65 m³ / h 100 m³ / h

ITF-30 septem ITF-50 septem ITF-80 septem ITF-120 septem ITF-160 septem ITF-240 septem

pumped 20 m³ / h 30 m³ / h 45 m³ / h 60 m³ / h 80 m³ / h 120 m³ / h

gravity 15 m³ / h 25 m³ / h 35 m³ / h 45 m³ / h 65 m³ / h 100 m³ / h

16

FILTER TECHNOLOGY MADE IN GERMANY

A ( 1 : 3 )

B ( 1 : 3 )

D ( 1 : 3 )

E ( 1:1 )

F ( 1:2 )

A

B

D

E

F

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

1

A1

Status Änderungen Datum Name

Gezeichnet

Kontrolliert

Norm

Datum Name

Zeichnungsnummer

Bezeichnung

Artikelnummer

Blechstärke

Bl.

mm

ISO 13715

Allgemeintoleranz

ISO 2768 mK

+0,50

+0,05

-0,50

-0,05

Material

12.05.2016 aplatzda

Projekt: Status:

Masse: -

1

3

2

46

5

14

13

12

10

17

11

15

19

16

7

8

9

Lagereinheit innenliegend

Lagereinheit und Antrieb

außenliegend

18

7

9

10

11

12

13

14

15

A ( 1 : 3 )

B ( 1 : 3 )

D ( 1 : 3 )

E ( 1:1 )

F ( 1:2 )

A

B

D

E

F

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

1

A1

Status Änderungen Datum Name

Gezeichnet

Kontrolliert

Norm

Datum Name

Zeichnungsnummer

Bezeichnung

Artikelnummer

Blechstärke

Bl. mm

ISO 13715

Allgemeintoleranz

ISO 2768 mK

+0,50

+0,05

-0,50

-0,05

Material

12.05.2016 aplatzda

Projekt: Status:

Masse: -

1

3

2

46

5

14

13

12

10

17

11

15

19

16

7

8

9

Lagereinheit innenliegend

Lagereinheit und Antrieb

außenliegend

18

E

A ( 1 : 3 )

B ( 1 : 3 )

D ( 1 : 3 )

E ( 1:1 )

F ( 1:2 )

A

B

D

E

F

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

1

A1

Status Änderungen Datum Name

Gezeichnet

Kontrolliert

Norm

Datum Name

Zeichnungsnummer

Bezeichnung

Artikelnummer

Blechstärke

Bl. mm

ISO 13715

Allgemeintoleranz

ISO 2768 mK

+0,50

+0,05

-0,50

-0,05

Material

12.05.2016 aplatzda

Projekt: Status:

Masse: -

1

3

2

46

5

14

13

12

10

17

11

15

19

16

7

8

9

Lagereinheit innenliegend

Lagereinheit und Antrieb

außenliegend

18

8

16

5

3

4

A ( 1 : 3 )

B ( 1 : 3 )

D ( 1 : 3 )

E ( 1:1 )

F ( 1:2 )

A

B

D

E

F

1

1

2

2

3

3

4

4

5

5

6

6

7

7

8

8

9

9

10

10

11

11

12

12

A A

B B

C C

D D

E E

F F

G G

H H

1

A1

Status Änderungen Datum Name

Gezeichnet

Kontrolliert

Norm

Datum Name

Zeichnungsnummer

Bezeichnung

Artikelnummer

Blechstärke

Bl. mm

ISO 13715

Allgemeintoleranz

ISO 2768 mK

+0,50

+0,05

-0,50

-0,05

Material

12.05.2016 aplatzda

Projekt: Status:

Masse: -

1

3

2

46

5

14

13

12

10

17

11

15

19

16

7

8

9

Lagereinheit innenliegend

Lagereinheit und Antrieb

außenliegend

18

6

A

1

2

1

2

Inazuma-Infohotline: (+ 49) 821 - 72 91 972

Bestellungen an: vertrieb@inazuma-online.de

Nr. Bezeichnung Art. Nr.

1 Nozzle kit (nozzle, union nut, seal) IK1564

2 Holder for high-pressure nozzle IK1000552

3 Drum tappet

4 Sealing set consisting of 2 x seals and 1 x pressure washer IK1000680

5 Flange bearing including shaft seals for ITF-30 to 240 IK1000679

6 Geared motor for ITF-30 to ITF-120 & Biokompakt models

Gear motor for ITF-160 & 240 Biokompakt

IK2039

IK1801

7 Guide roller set for ITF-30 to 120

Guide roller set for ITF-160 to 240

IK1000681

IK1000682

8 Magnet for lid switch IK1196

9 Gas Springs IK1731

10 Lid seal (sold by the meter!) IK1162

11 Cartridge lter for all drum lters from 2015 IK1577

12 Replacement cover for drum lter ITF-30 from MK V

Replacement cover for drum lter ITF-50 from MK V

Replacement cover for drum lter ITF-80 from MK V

Replacement cover for drum lter ITF-120 from MK V

Replacement cover for drum lter ITF-160 from MK V

Replacement covering for drum lter ITF-240 from MK V

IK1615

IK1616

IK1617

IK1618

IK1677

IK1619

13 Magnetic valve for trough ushing Speed Flush (black head /

actuator)

IK1845

14 Drum seal for all models 30 - 120

Drum seal for all models 160 - 240

IK1180

IK1786

15 Tank screw connection / bushing with thread & seal IK1466

16 Seal for gutter “Speed Flush” from MY 2016 IK1679

Feather key for keyway / drive shaft diameter 25 mm IK1702

Inazuma high pressure pump INA -TEC70c for all lters IK1607

Pre-lter for high pressure pump (blue foam) IK1668

4. Spare parts list

www. inazuma- online.com

Zertikat zur Qualitätssicherung

Certicate of quality

Trommellter

Drumlter

Endmontage / Final assembly:

Drehrichtung Motor geprüft

Direction of rotation of the engine

Düsen richtig montiert und positioniert

Position and mounting of the nozzles

Schrauben auf Festigkeit / Dichtigkeit geprüft

Tightness of the screws

Deckel schließt sauber

Lid closes clean and smooth

Gehäuse auf Verzug kontrolliert

Housing is without distortion

Filter von Produktionsrückständen gesäubert

Residues from production removed

Mechanic

Monteur:

Versand / Shipping:

Optische Sichtkontrolle des Filters durchgeführt

Visual inspection of the lter

Funktionstest ( Drehrichtung, Deckelschalter, Schwimmerschalter, Laufzeit)

Function test (direction of rotation, switch for lid, oat control, running time)

Einstellungen an der Steuerung überprüft

Settings of the control unit

Label „UVC –Typenschild – Logo“ angebracht

Labels „UVC-nameplate-logo“ attached

Label „Seriennummer“ angebracht

Label „serial number“ attached

Betriebsanleitung vorhanden

Manual for the drumlter included

Filter auf Sauberkeit geprüft

Filter checked for cleanliness

Warehouse

Lager:

FILTER TECHNOLOGY MADE IN GERMANY

www. inazuma- online.com

Make sure that the product is packaged with sufficient protection to prevent damage in transit.

Johannes Kurzweil GmbH | Eisackstrasse 16 | 86165 Augsburg | Telephone: (+49) 821 - 72 919 72 | Fax: (+49) 821 - 72 919 73

Service order / repair movement document

Please fill out this form legibly and completely. If you want a warranty repair, a copy of the proof of purchase as proof of the

existing warranty claim is mandatory. Send the form with proof of purchase in advance by fax to (+49) 821 - 7291973 or email

to info@inazuma-online.com

Customar data

First name, Last Name

Street, house number

Postcode, town

Phone

Email

Product data

Product name Serial number

Date of Purchase Date of commissioning

Installation carried out by the end customer

Installation carried out by specialized personnel Stamp / sign (authorized personnel)

Description oft he error / damage

Datum, Unterschrift

Order placement and confirmation

Chargable repair Preparation of a cost estimate (1) Warranty repair (2)

(1) I am informed that cost estimates are subject to a charge and are to be paid with a flat rate of € 49 plus VAT and shipping costs.

The flat rate does not apply if a repair order is placed.

(2) Warranty repair: If it turns out during the inspection that there is no warranty claim, the customer will in any case bear the inspection and return costs

incurred. In this case, a repair will only be carried out after the customer has approved the order based on a cost estimate.

Do not carry out any repair work on the device yourself.

This can make troubleshooting more difficult or invalidate the warranty!

Serial number

FILTER TECHNOLOGY MADE IN GERMANY

Inazuma®Drum Filters

Manufacturer:

Inazuma

Johannes Kurzweil GmbH

Eisackstraße 16

DE – 86165 Augsburg

Tel.: (+49) 821/ 72 91 97 2

Fax: (+49) 821 / 72 91 97 3

info @inazuma -online .com

www. inazuma-online .com

Technical modications and errors excepted

WEEE-Reg.-Nr. DE 19429673

Manual Version 2020-01

You will be amazed!

Edelstahl -Trommellter &High - End -Teichzubehör

This manual suits for next models

12

Table of contents

Popular Water Filtration System manuals by other brands

Sterling

Sterling IM Series Installation instructions & owner's manual

Intewa

Intewa SEPAMAT F 20 Installation and user manual

Schenker

Schenker SMART 80 Installation, use and maintenance manual

Whirlpool

Whirlpool WHELJ1 Installation and operation manual

GCTek

GCTek AlphaONE instructions

Veolia

Veolia Orion II 500 Operator's manual

DeWalt

DeWalt DXCM019-0352 quick start guide

Milli-Q

Milli-Q IQ Element user manual

Excalibur Water Systems

Excalibur Water Systems Sureflo SFLC Series Installation and user guide

Evince

Evince ELITE EV-ELT-948-1.0 owner's manual

Drop

Drop BX-20-201 operating instructions

AquaMaster

AquaMaster AMS700 Owner's manual and installation guide