Inbal Valves 700D Series Instruction manual

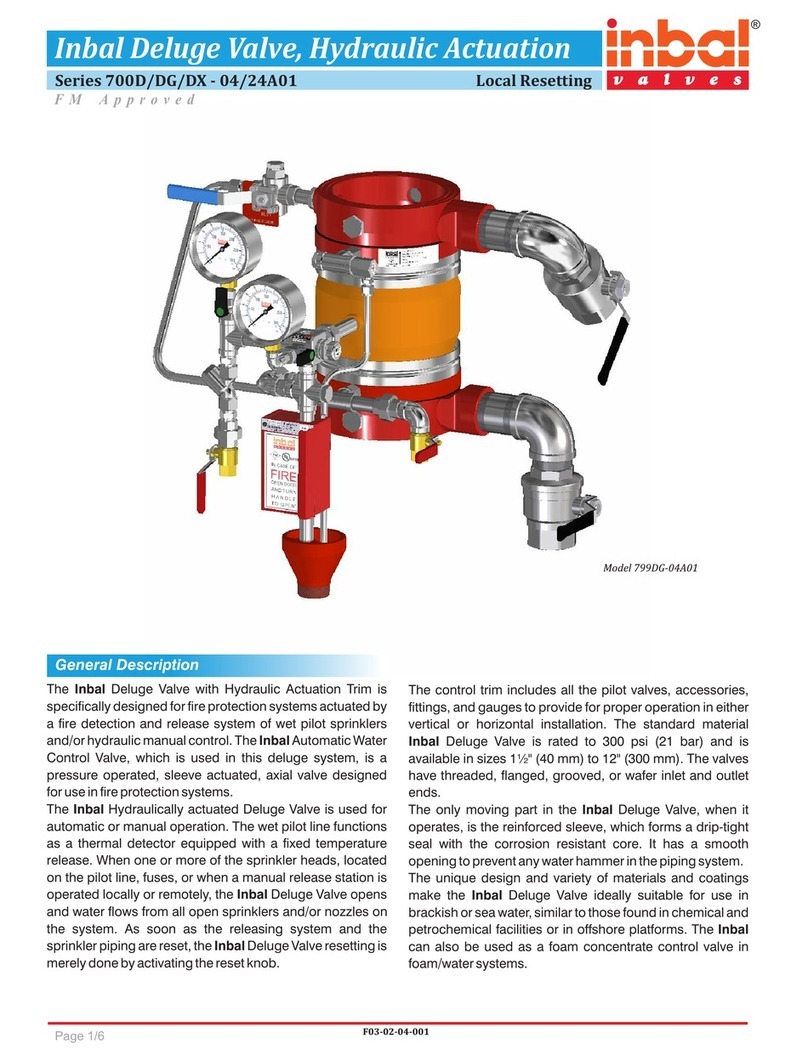

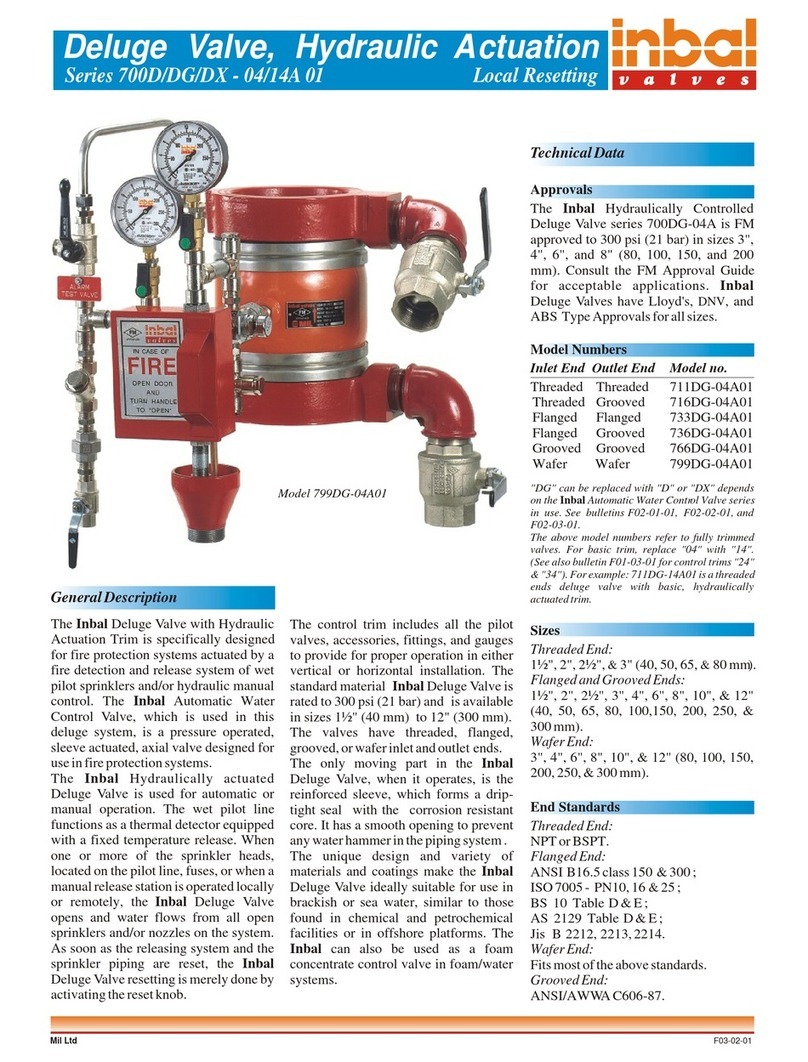

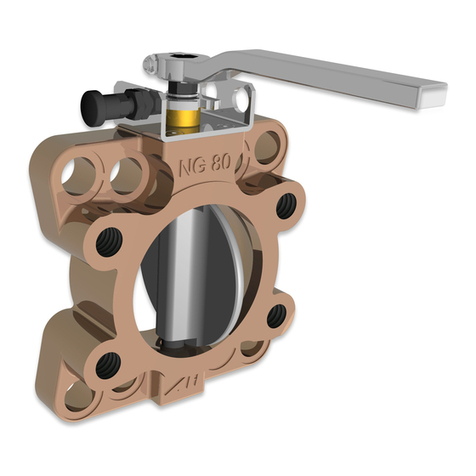

Model 799D

Automatic Water Control Valve

Series 700D

F02-01-02

General Description

The Inbal Automatic Water Control

Valve series 700D is a pressure operated,

sleeve actuated, axial valve, designed

from basic concepts, with a built-in

actuator to function as control valve in

fire protection system. The Inbal series

700D is used as deluge, preaction, dry

pipe, remote control, pressure reducing,

pressure relief, pump control, water level

control, and other types of control

valves. The standard material Inbal

Valve is rated to 300 psi (21 bar) and

requires a minimum line pressure of 20

psi (1.5 bar) for operation. Upon removal

of the control pressure the Inbal Valve

opens instantaneously, yet very

smoothly, to prevent any water hammer

in the piping system. The Inbal 700D

performance and ease of resetting are not

affected by vertical or horizontal

installation.

The Inbal Automatic Water Control

Valve utilizes the unique N.M.M.P. (No

Moving Mechanical Parts) design. The

only moving part when the Inbal Valve

operates, is the reinforced sleeve which

forms a drip-tight seal with the corrosion

resistant core. The Inbal design also

prevents false operation due to transient

surges in water supply pressure. The

N.M.M.P. design and variety of mater-

ials and coatings make the Inbal Auto-

matic Water Control Valve ideally

suitable for use with brackish or sea

water similar to those found in chemical

and petrochemical facilities or in

offshore platforms. It can also be used as

a foam concentrate control valve in

foam/water systems.

The Inbal Automatic Water Control

Valve series 700D is available in sizes

1½" (40 mm) to 12" (300 mm). The

valves have threaded, flanged, or wafer

inlet and outlet ends.

Technical Data

Approvals

The Inbal Automatic Water Control

Valve is FM approved to 300 psi (21 bar)

in sizes 3", 4", 6", and 8" (80, 100, 150,

and 200 mm). Consult the FM Approval

Guide for acceptable applications.

Inbal Deluge Valves have Lloyd's, DNV,

and ABS Type Approvals for all sizes and

most models.

Model Numbers

Inlet End Outlet End Model No.

Threaded Threaded 711D

Flanged Flanged 733D

Grooved Grooved 766D

Wafer Wafer 799D

Sizes

Threaded Ends:

1½", 2", 2½", & 3"(40, 50, 65, & 80 mm).

Flanged Ends:

2", 2½", 3", 4", 6", 8", 10", &12" (50, 65,

80, 100, 150, 200, 250, & 300 mm).

Wafer Ends:

3", 4", 6", 8", 10", & 12" (80, 100, 150,

200, 250, & 300 mm).

End Standards

Threaded End:

NPT or BSPT.

Flanged End:

ANSI B16.5 class 150 & 300 ;

ISO 7005 - PN10, 16 & 25 ;*

BS 10 Table D & E ;**

AS 2129 Table D & E ;**

Jis B 2212, 2213, 2214 ;**

Wafer End:

Fits all above standards.**

*Compatible with DIN 2501 and BS 4504.

** Exclude:

BS 10 Table E 6" (150 mm);

AS 2129 Table E 6" (150 mm);

Jis B2212 regular flange in sizes 4", 8", &12"

(100, 200, & 300 mm).

Grooved Ends:

2", 3", 4", 6", & 8", (50, 80, 100, 150, &

200 mm).

Grooved End:

ANSI/AWWA C606-87

F02-01-02-002

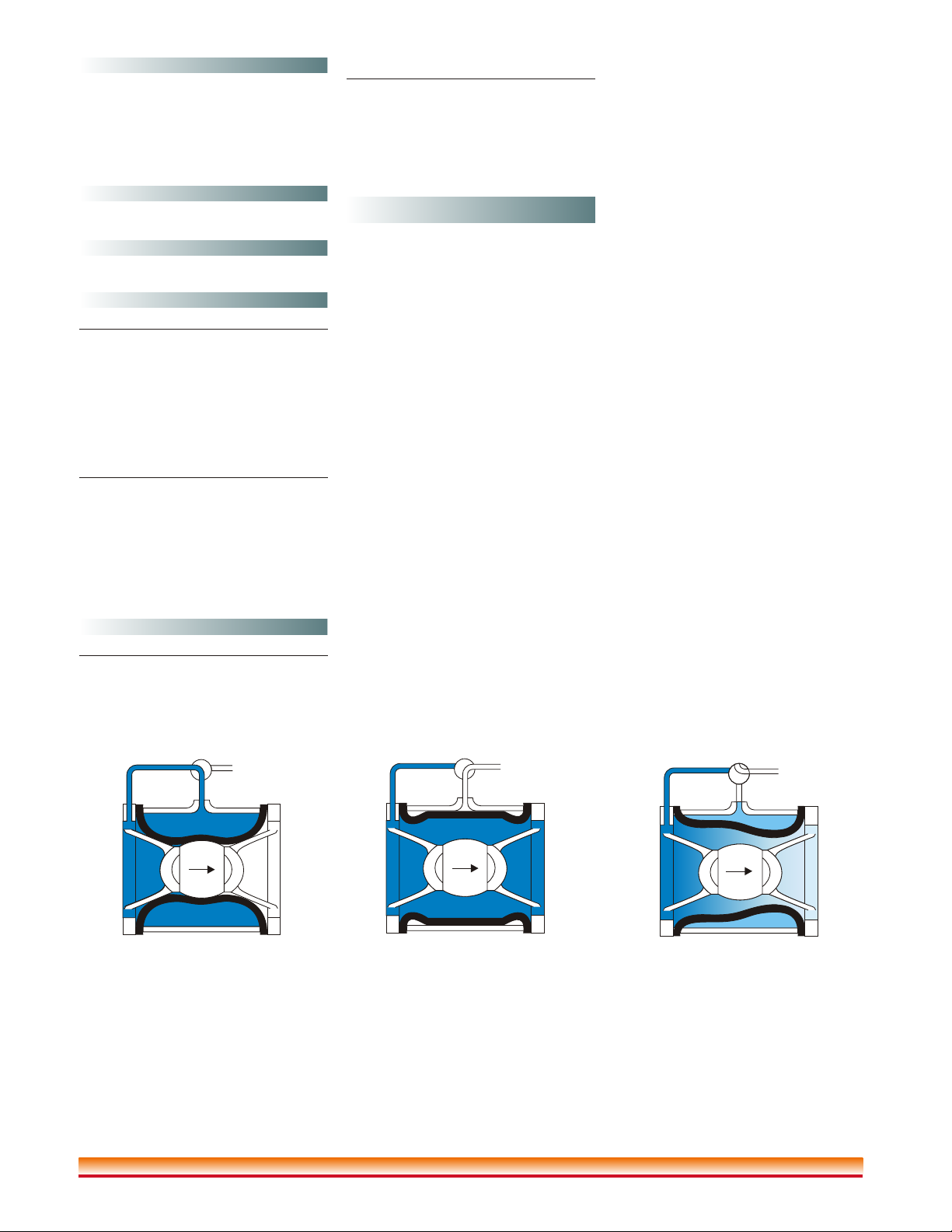

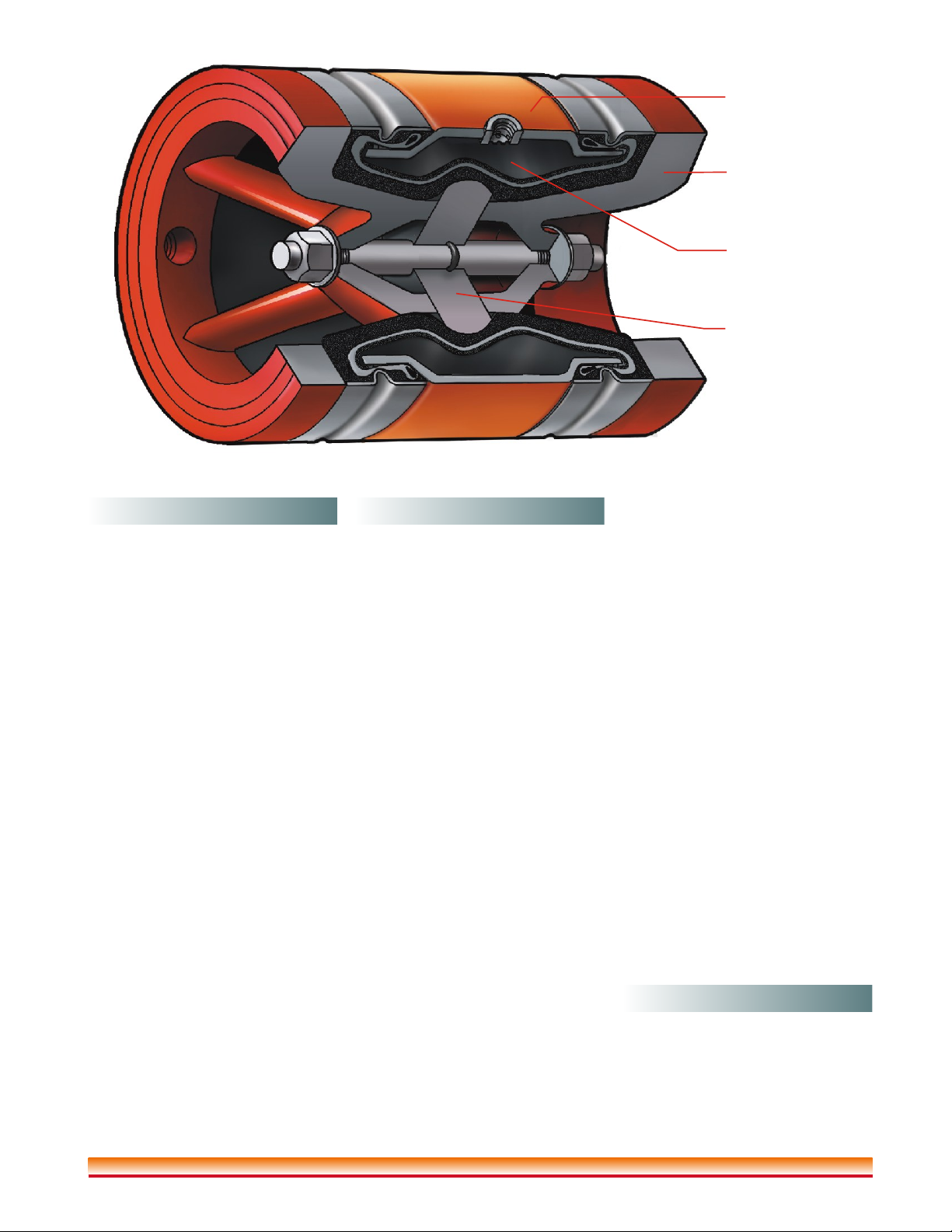

Full open operation

When pressure in the Control Chamber is

relieved to the atmosphere, the Inbal

Valve opens wide. The sleeve assembly

is safely enveloped by the housing.

Tight closing operation

When pressure from the valve inlet (or an

equivalent independent operating

pressure) is applied to the Control

Chamber, the Inbal Valve closes drip

tight. The fabric sleeve safely envelopes

the resilient sleeve giving full support.

Modulating action

A stable throttling position is obtained

when a quantity of pressurized fluid is

held in the Control Chamber. It is the

amount of fluid in the Control Chamber

that determines the position of the sleeve

assembly. The Control Chamber can be

alternately filled or exhausted to achieve

the desired operating condition.

Figure (1) Figure (2) Figure (3)

Pressure Rating

Maximum working pressure*: 300 psi

(21 bar). Minimum Working Pressure:

20 psi (1.5 bar).

*Standard material valve.

Temperature Range

oo

Water: Max. +150 F (+65 C).

Installation Position

Vertical or horizontal.

Materials

Standard

Valve Housing:

Carbon Steel (SAE 1021).

Valve Ends:

Ductile Iron (ASTM A536 65-45-12).

Sleeve:

SMR5 Elastomer reinforced with Poly-

ester and Kevlar.

Optional

Cast Steel ;

Bronze ;

NickelAluminium Bronze ;

Stainless Steel AISI 316 ;

SuperAustenitic Stainless Steel ;

Super Duplex Stainless Steel ;

Titanium.

Coating

Standard

Powder epoxy coated. Thickness: 0.004"

(0.1 mm) external and internal surfaces.

Optional

High built epoxy coated and polyure-

thane finish. Thickness: 0.01" (0.3 mm).

®

Halar coated. Thickness: 0.02"

(0.5 mm).

Halar ® is a registered trade mark of Ausimont USA Inc.

Features

!The Inbal Valve, designed for control

valve service from basic concepts,

utilizes a built-in sleeve actuator.

!No Moving Mechanical Parts

(N.M.M.P.) construction ensures a long

life of dependable operation, reducing

the cost of maintenance.

!The N.M.M.P. Design assures

frictionless operation. No sticking after

staying for prolonged periods in a

closed position. Suitable for brackish

and sea water.

!Quick, yet soft opening performance -

eliminates water hammer and conse-

quent damage.

!The line pressure or an equivalent

independent operating pressure, is

sufficient to close the Inbal Valve

tightly.

!Soft closure performance due to

inherent characteristics of the Inbal

Valve. Utilizes no spring to ensure

surge-free closing.

!Pressure rating of 300 psi (21 bar) for

standard materials valve due to rigid

construction.

!Suitable for vertical or horizontal

installation with no effect on Inbal

Valve performance.

!Lightweight - easy to be installed and

maintained.

!Available with threaded, flanged, and

wafer ends to various standards.

!Unique principle of operation prevents

false operations due to water surges.

!Wide range of sizes for an ideal system

design.

!Compact design - minimum space for

valve and trim. Enable installation in

confined spaces.

!Epoxy coating supplied as standard-

ensures excellent corrosion resistance.

!Variety of available materials - to

ensure corrosion-free service even

under severe conditions.

!Compatible with electric, pneumatic,

and/or hydraulic release.

!Excellent regulating performance in a

wide range of flows and line pressures.

!Wide selection of pilot valves,

actuators, and accessories to design the

ideal control valve for the purpose.

!A single Inbal Automatic Water

Control Valve can perform multi-

function controls.

!Every single valve is hydraulically

tested in real flow and pressure

conditions.

!Innovative design with a long record of

proven performance.

Operation

The Control Chamber of the Inbal

Automatic Water Control Valve is the

annular space between the valve

Housing and the Sleeve. The valve is

held in a closed position as long as inlet

pressure is maintained in the Control

Chamber.

In the set position, the water pressure is

transmitted from the upstream through

the valve trim to the Control Chamber,

and the Inbal Valve stays closed.

Actuation of the valve by a manual,

hydraulic, pneumatic, or electric release

system allows venting of the pressure in

the Inbal Valve Control Chamber, and

the valve opens wide, permitting a flow

of water to the piping system. When a

pressure or flow control is added, the

Control Chamber is monitored to

modulate a preset delivery pressure,

maximum inlet pressure, or flow rate.

The principle of operation is illustrated

in Figures (1) through (3). The nominal

pressure losses are shown in Graph (1).

Installation

Refer to the Trim Chart applicable to the

specific Inbal Valve model in use.

1. When the Inbal Valve is delivered,

carefully unpack and visually check

that there has been no damage to the

operating components, piping, and

fittings.

2. The Inbal Valve must be installed in

an area not subject to freezing

conditions.

3. Always flush the pipelines before

installing the valve.

4. Place the Inbal Valve in the piping in

the outlet of the Water Supply Valve.

Verify that the arrow on the valve

housing matches the actual flow

direction. The Inbal Valve may be

installed in any position. Determine

which side the valve will be accessed

from and locate all the components

accordingly.

5. Install the Inbal Valve in the piping

system. Refer also to the applicable

Installation Guide.

Threaded End Valve - connect the

female threaded ends of the Inbal

Valve to the male threads of the

piping. Use the pipe joint compound

sparingly on the male threads only.

Flanged End Valve - connect with

bolts and nuts, the valve flanges to

the existing flanges in the piping

system, using gaskets in between.

Complete bolting with uniform

tightening.

0

0

0

0

0

Wafer End Valve - Install the Inbal

Valve between the piping flanges.

Place gaskets between the valve ends

and the pipe flanges. Insert four of

o

the stud bolts, 90 apart around the

valve, through the bolt sleeves and

the pipe's flanges, and tighten with

nuts. Complete bolting with uniform

tightening.

6. Complete the trim assembly by

connecting the preassembled

sections, or assemble the trim if

ordered in loose component form.

Refer to the applicable Trim Chart

and Installation Guide.

7. The pressure supply to the trim must

always be sourced from either inlet

of Water Supply Valve or Inbal

Valve upstream, through a ½" pipe.

8. Exhaust tube must be free of any back

pressure. Provide an air gap between

the exhaust tube and drain facility.

9. Set the Inbal Valve by following the

applicable Resetting procedure.

10. Test the Inbal Valve, the trim, and

alarms according to the applicable

Testing procedure.

Resetting

The Inbal Automatic Water Control

Valve system must be reset and restored

to service as soon as possible after

automatic, emergency, or manual

actuation. Refer to the relevant bulletin

for detailed procedure.

0

0

0

0

F02-01-02-003

Core

Sleeve Assembly

Housing

End

January 2005 / F02-01-02

Automatic Water Control Valve

Series 700D

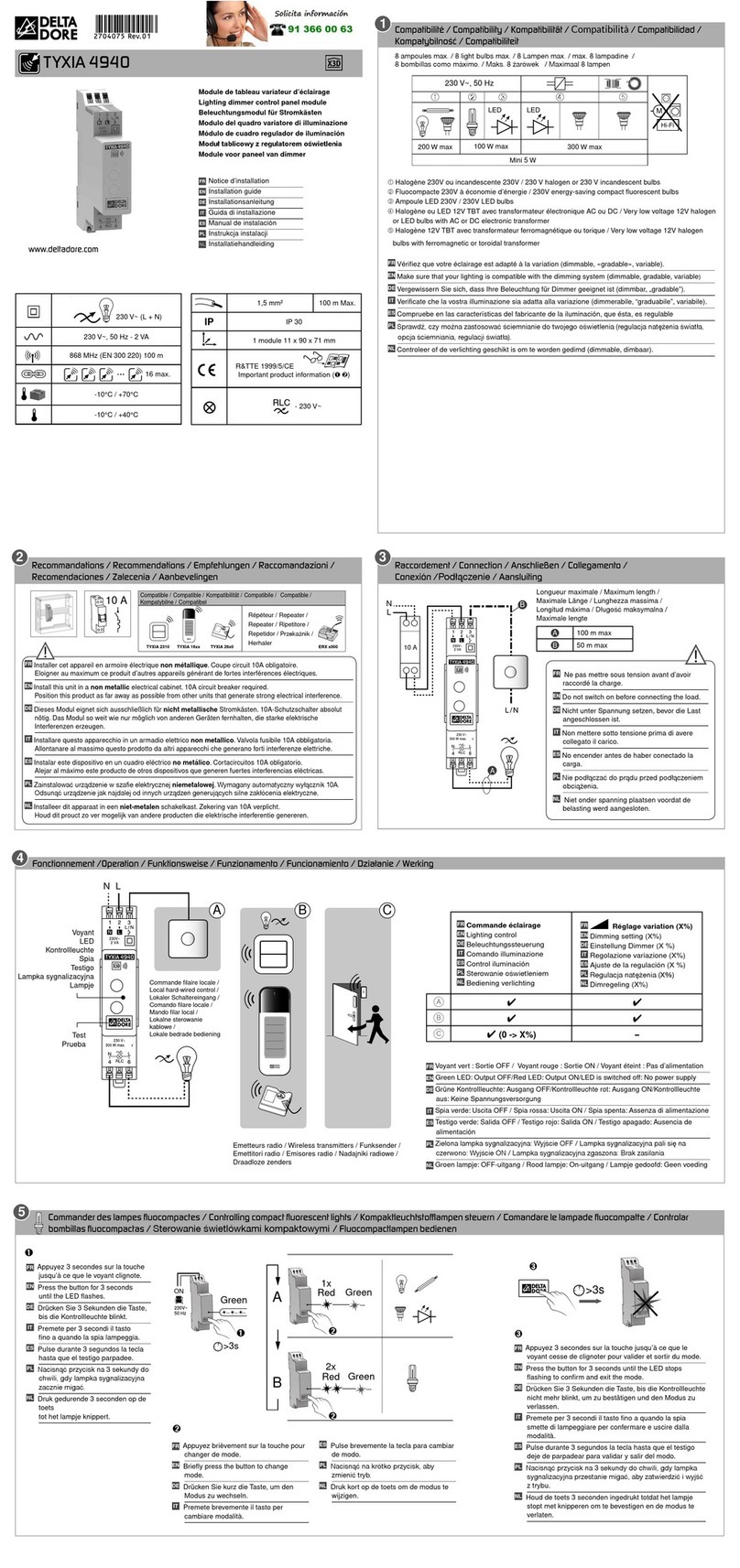

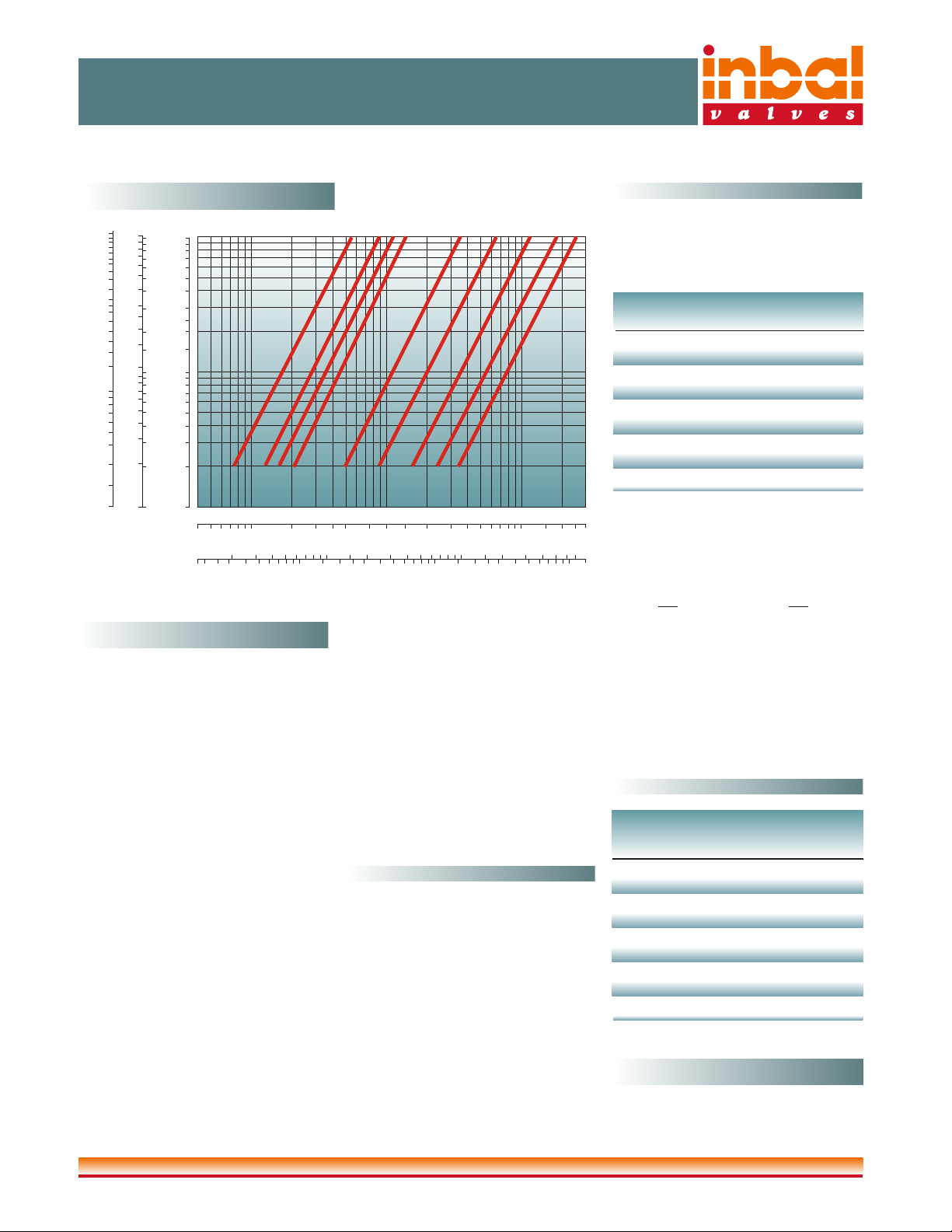

Flow Chart

Graph (1)

Flow Rate

45 6 710 20 30 40 50 75 100 200 300 500 1000150 2000 3000

2345 10 15 20 30 40 50 100 150 200 300

500

700

20 30 40 50 100 200 1000

2000

3000

5000 10000

300

500

6"

4"

3"

2"

1½” 12"

300

10"

250

8"

200150100805040

inch

mm

l/s

gpm

3

m/h

bar

0.10.98

0.2

0.3

0.4

0.5

3

10.1

0.01

0.02

0.03

0.04

0.05

1.5

2

2

3

4

5

10

10

15

20

30

40

50

100

5

4

0.15

0.2

0.3

0.4

0.5

1

psi

0.14

0.3

0.4

0.2

0.5

1

KPa m H O

2Inbal Valve Size

Head Loss

15

10

3

1.5

2

5

4Valve Size Flow Factor

mm inch Kv Cv

40 1½'' 60 70

50 2'' 90 105

65 2½" 115 133

80 3'' 140 162

100 4'' 330 383

150 6'' 610 708

200 8'' 1150 1334

250 10'' 1630 1891

300 12'' 2365 2743

Flow Factor

Q Flow rate in

=

3

m /h.

Kv = Flow factor.

Use Table (1)

Q

Kv

( )

2

DP =

DP = Head loss

i n b a r .

Table (1)

Table (2)

Valve Size Displacement

U.S.

mm inch liter gallon

40 1½" 0.3 0.08

50 2" 0.3 0.08

65 2½" 0.3 0.08

80 3" 0.3 0.08

100 4" 0.5 0.13

150 6" 1.7 0.45

200 8" 3.5 0.92

250 10" 8.1 2.1

300 12" 12.7 3.4

Control Chamber Displacement

To define the head loss through an Inbal

valve at a specific flow rate use the

following equation (for water only):

The Flow Factor Cv (Kv) is defined as

3

the flow rate in gpm (m /h) of liquid at

00

68 F (20 c), flowing at 1 psi (1bar) head

loss.

Q Flow rate in

=

gpm.

Cv = Flow factor.

Q

Cv

( )

2

DP =

DP = Head loss

in psi.

Trim Testing and/or Control Testing, as

well as a Quarterly Testing as listed in the

applicable data sheet of the specific

application in which the Inbal Auto-

matic Water Control Valve participates.

An Annual Testing shall include Trip

Testing, Semi-Annual Testing, and

Quarterly Testing as listed in the appli-

cable data sheet of the specific appli-

cation in which the Inbal Automatic

Water Control Valve participates.

Removal

To remove the Inbal Valve:

1.Close all the pressure supply valves:

a) Water Supply Valve

b) Trim Shutoff Valve.

2.Open the Emergency Release Valve to

release the water pressure from the

Inbal Valve Control Chamber.

3.Open the drain valves to allow all the

water to drain.

4.Remove the trim from the Inbal Valve.

5.Remove the Inbal Valve from the line

for inspection.

6.To reinstall, follow the Installation

procedure section (use new gaskets for

flanged or wafer valve).

Inquiries/Orders

The Data Sheet For Inquiries/Orders

(bulletin F01-05-XX) should be

submitted.

Maintenance, Inspection,& Testing

It is recommended that periodic

inspections and tests be conducted by

qualified personnel to ensure that the

Inbal Automatic Water Control Valve

and related equipment are in good

operating condition. The inspection and

testing activities should be done

according to NFPA Standards, the

guidelines and regulations of the

authorities having jurisdiction, and the

following instructions. It is recom-

mended that the Inbal Valve be tested,

operated, cleaned, and inspected on a

routine basis.

AWeekly Visual Inspection shall include

Water Supply Valve position, free

pressure access, and major trim compo-

nents as listed in the applicable data sheet

of the specific application in which the

Inbal Automatic Water Control Valve

participates.

AQuarterly Testing shall include Alarm

Testing, Strainer Cleaning, and major

components testing as listed in the

applicable data sheet of the specific

application in which the Inbal Auto-

matic Water Control Valve participates.

ASemi-Annual Testing shall include

2½"

65

Inbal Valves UK Ltd. 53 Limes Road, Tettenhall, Wolverhampton, W. Midlands, WV6 8RD England, Tel +44-1902-561111 Fax +44-1902-561113, E-mail: inbal @ inbalvl.com

This manual suits for next models

4

Other Inbal Valves Control Unit manuals

Popular Control Unit manuals by other brands

Littfinski Daten Technik

Littfinski Daten Technik RS-16-O-B Assembly instruction

Graco

Graco Gun Flush Box 570046 Instructions-parts list

ASA Hydraulik

ASA Hydraulik SDA Series manual

Automationdirect.com

Automationdirect.com HX-ECOM Series manual

Supermicro

Supermicro SBA-7121M-T1 user manual

Bosch

Bosch KTS 5a Series Original instructions