Inbal Valves 700D Series User manual

Deluge Valve, Hydraulic Actuation

Series 700D/DG/DX - 04/14A 01 Local Resetting

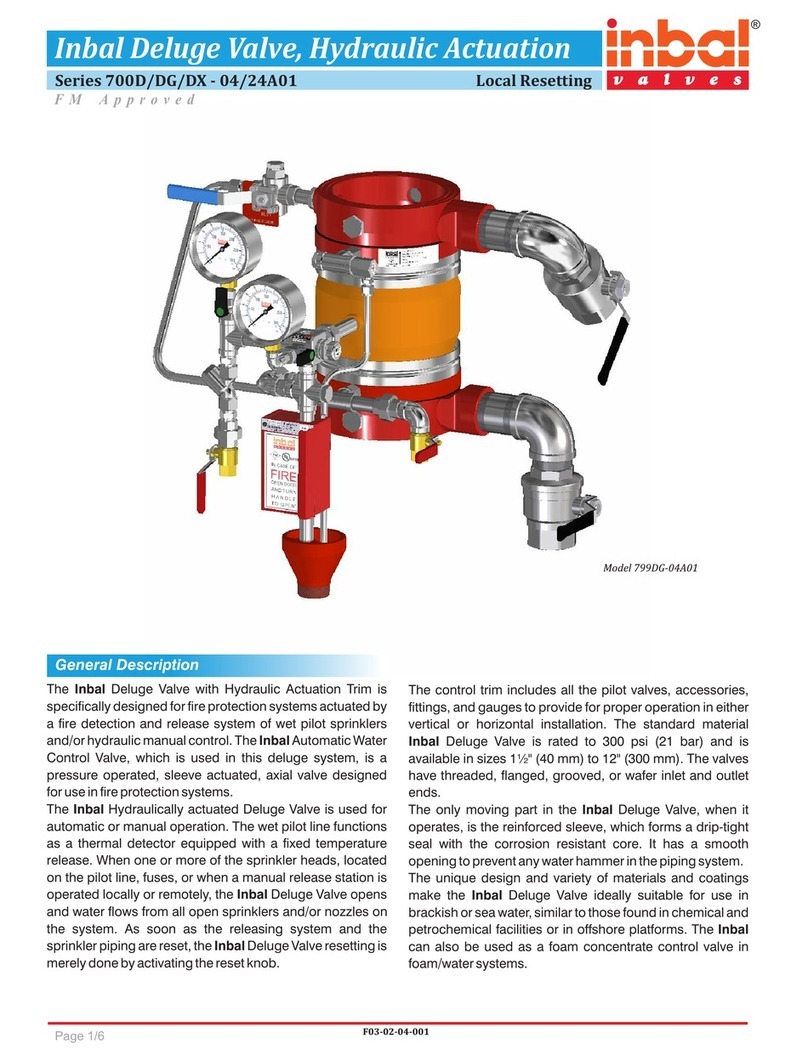

Model 799DG-04A01

Mil Ltd F03-02-01

GeneralDescription

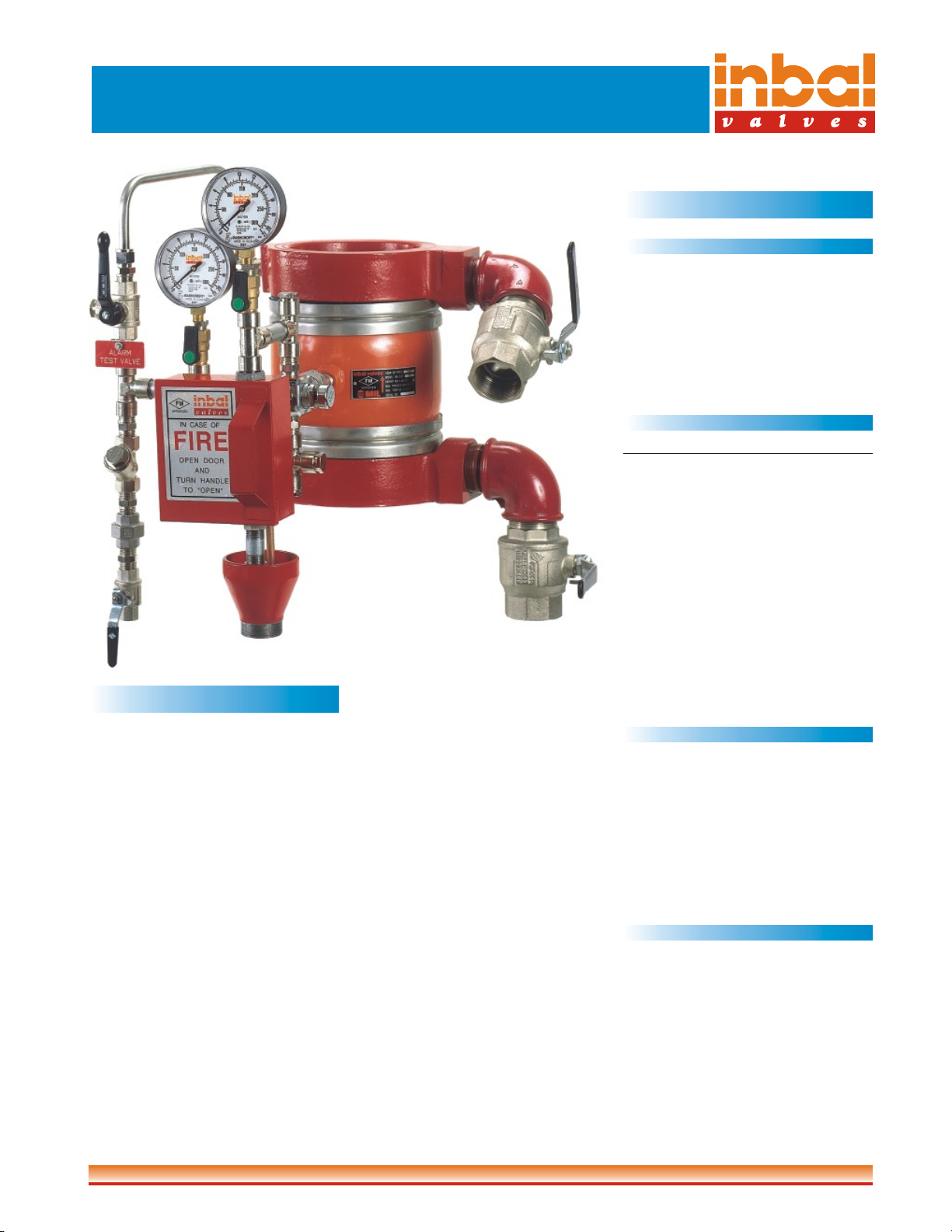

The Inbal Deluge Valve with Hydraulic

Actuation Trim is specifically designed

for fire protection systems actuated by a

fire detection and release system of wet

pilot sprinklers and/or hydraulic manual

control. The Inbal Automatic Water

Control Valve, which is used in this

deluge system, is a pressure operated,

sleeve actuated, axial valve designed for

useinfireprotectionsystems.

The Inbal Hydraulically actuated

Deluge Valve is used for automatic or

manual operation. The wet pilot line

functions as a thermal detector equipped

with a fixed temperature release. When

one or more of the sprinkler heads,

located on the pilot line, fuses, or when a

manualreleasestationisoperatedlocally

or remotely, the Inbal Deluge Valve

opens and water flows from all open

sprinklers and/or nozzles on the system.

As soon as the releasing system and the

sprinkler piping are reset, the Inbal

DelugeValve resetting ismerely done by

activatingtheresetknob.

The control trim includes all the pilot

valves, accessories, fittings, and gauges

to provide for proper operation in either

vertical or horizontal installation. The

standard material Inbal Deluge Valve is

rated to 300 psi (21 bar) and is available

in sizes 1½" (40 mm) to 12" (300 mm).

The valves have threaded, flanged,

grooved,orwaferinletandoutlet ends.

The only moving part in the Inbal

Deluge Valve, when it operates, is the

reinforced sleeve, which forms a drip-

tight seal with the corrosion resistant

core. It has a smooth opening to prevent

anywaterhammerinthepipingsystem.

The unique design and variety of

materials and coatings make the Inbal

Deluge Valve ideally suitable for use in

brackish or sea water, similar to those

found in chemical and petrochemical

facilities or in offshore platforms. The

Inbal can also be used as a foam

concentrate control valve in foam/water

systems.

TechnicalData

Approvals

The Inbal Hydraulically Controlled

Deluge Valve series 700DG-04A is FM

approved to 300 psi (21 bar) in sizes 3",

4", 6", and 8" (80, 100, 150, and 200

mm). Consult the FM Approval Guide

for acceptable applications. Inbal

Deluge Valves have Lloyd's, DNV, and

ABS TypeApprovalsforallsizes.

Model Numbers

Inlet End Outlet End Model no.

Threaded Threaded 711DG-04A01

Threaded Grooved 716DG-04A01

Flanged Flanged 733DG-04A01

Flanged Grooved 736DG-04A01

Grooved Grooved 766DG-04A01

Wafer Wafer 799DG-04A01

"DG" can be replaced with "D" or "DX" depends

on the Inbal Automatic Water Control Valve series

in use. See bulletins F02-01-01, F02-02-01, and

F02-03-01.

The above model numbers refer to fully trimmed

valves. For basic trim, replace "04" with "14".

(See also bulletin F01-03-01 for control trims "24"

&"34").Forexample: 711DG-14A01is athreaded

ends deluge valve with basic, hydraulically

actuatedtrim.

Sizes

ThreadedEnd:

1½", 2", 2½", & 3" (40, 50, 65, & 80mm).

FlangedandGroovedEnds:

1½", 2", 2½", 3", 4", 6", 8", 10", & 12"

(40, 50, 65, 80, 100,150, 200, 250, &

300mm).

WaferEnd:

3", 4", 6", 8", 10", & 12" (80, 100, 150,

200,250,&300mm).

End Standards

ThreadedEnd:

NPTorBSPT.

FlangedEnd:

ANSI B16.5class150 &300;

ISO7005- PN10,16 &25;

BS 10 Table D&E;

AS 2129 Table D&E;

Jis B 2212, 2213,2214.

WaferEnd:

Fitsmostoftheabovestandards.

GroovedEnd:

ANSI/AWWAC606-87.

F03-02-01-002

PressureRating

Maximum working pressure*: 300 psi

(21bar).

*standardmaterialvalve.

Temperature Range

00

Water: Max. +150F (+65 C).

Installation Position

Vertical or horizontal.

Materials

Standard

ValveHousing:

ForgedSteel(SAE1021).

Valve EndsandWafer FlowTest&Drain

Ends:

DuctileIron(ASTMA536 65-45-12).

Threaded, Flanged, and Grooved Flow

Test&Drain Ends:

CarbonSteel (SAE1020).

Sleeve:

SMR5 Elastomer reinforced with poly-

esterandKevlar.

ControlTrim:

Brass Nickel Chrome plated, Stainless

Steel,andGalvanizedSteel.

Optional

Cast Steel ;

Bronze ;

Nickel Aluminium Bronze ;

Stainless Steel AISI 316 ;

Super Austenitic Stainless Steel ;

Super Duplex Stainless Steel ;

Titanium.

Coating

Standard

Powderepoxy coated.Thickness:0.004"

(0.1mm)externalandinternalsurfaces.

Optional

High built epoxy coated and polyure-

thanefinish.Thickness:0.01"(0.3mm).

®

Halar coated. Thickness: 0.02"

(0.5mm).

®

Halar is a registered trademark of AusimontUSA Inc.

ControlTrim

On standard, the control trim is supplied

preassembled in sections. If self

assembly is required, all the trim

components are supplied in loose form.

The complete control trim includes the

followingcomponents:

!FlowReleasePilot(F.R.P.)withabuilt-

incheckvalve.

!Y-Strainerwithastainlesssteelscreen.

!Alarm Test Valve - 3 way, L-port,

quarter turn ballvalve.

!Trim Shutoff Valve, Flow Test Valve,

and Drain Valve are quarter turn ball

valves.

!Supply and System Pressure Gauges,

withdualscale(psiandbar).

!PressureGaugeValves- 3 way,quarter

turnball valves.

!DrainCupandDrainTubes.

!AutomaticDrainValves.

!EmergencyReleaseStation.

Features

!No Moving Mechanical Parts

(N.M.M.P.) construction ensures a long

life of dependable operation, reducing

thecostofmaintenance.

!Quick, yet soft opening performance -

eliminates water hammer and conse-

quentdamages.

!The line pressure is sufficient to close

the Inbal Valve tightly. Can perform

also, when water supply valve is not in

use.

!Optional opening and/or closing speed

controlisavailable.

!Anticolumning device is available for

longorhighelevationwetpilotline.

!Fast and easy reset by thumb activated

knob.

!Supplied as standard preassembled in

sections- saves the self assemblycost.

!Remoteemergency releasestationscan

beusedformanualoperation.

!Can be installed vertically or

horizontally.

!Compact design - minimum space for

valve and trim.

!Unique principle of operation prevents

falseoperationduetowatersurges.

!Pressure rating to 300 psi (21 bar) for

standardmaterial valve.

!Wide range of sizes for an ideal system

design.

!Control trim made of high grade

materialsasstandard.

!Epoxy coating supplied as standard -

ensuresexcellentcorrosionresistance.

!Variety of available materials - to

ensure corrosion-free service even

under severe conditions.

!Thesame basictrimis compatiblewith

electric, pneumatic, and/or hydraulic

release.

!Additional functions, such as pressure

control or another release system,

couldbeaddedonthesamevalve body.

Operation

The Control Chamber of the Inbal

Automatic Water Control Valve is the

annular space between the valve

Housing and the Sleeve. The valve is

held in a closed position as long as inlet

pressure is maintained in the Control

Chamber.

The wet pilot line, equipped with closed

sprinkler heads, is pressurized through

the valve trim and located over the

protected area. The wet pilot line serves

thedualpurposeofthermaldetectionand

releasesystem.

In the set position, water pressure is

applied to the Control Chamber of the

Inbal DelugeValve and to the hydraulic

release system from the upstream of the

Water Supply Valve. Consequently, the

Inbal DelugeValvestaysclosed.

The Inbal Deluge Valve opens wide

when one or more of the sprinklers

installed on the wet pilot line fuses and

water pressure is allowed to vent, or

when a hydraulic manual release opens.

Either one of these operations releases

water from the Inbal Control Chamber.

The Inbal Deluge Valve opens fully

introducing a flow of water to the system

while activating the system alarm

devices. Water will flow from any open

sprinklers and/or spray nozzles on the

system. The operation of the Inbal

Deluge Valve and the flow released from

the Control Chamber activate the Flow

Release Pilot (F.R.P) to latch in an open

position, isolating the Control Chamber

from the inlet water supply. The F.R.P

operation prevents the Inbal Deluge

Valve from closing even if the open

releasing wet pilot line closes. The Inbal

Valve will close only when the Resetting

procedureisfollowed.

The maximum elevations in which the

wet pilot sprinklers or manual release

stations can be installed are shown on

Graph (1).They are presented in relation

tothe various lengths ofpilotlines and to

thewatersupplypressure.

The Emergency Release Valve is used

for emergency actuation of the Inbal

DelugeValveand for routine testing.

F03-02-01-003

7a Supply Pressure Gauge

7b System Pressure Gauge

17 Alarm Test Valve

18a Flow Test Valve

18b Drain Valve

_

SchematicControl Diagram 700DG-04A01

50

100

300

0

50

100

300

0

2

18a

5

6

17 7b

3

4

18b

1

4

To Drain

To optional release

systems (hydraulic,

electric, or pneumatic)

To System

To Drain

To Drain

Drain

To Drain

Wet Pilot Line

To

To Alarm

Pressure

Switch

To Water

Motor

Alarm

OPEN

CLOSE

EMERGENCY

MANUALVALVE

Inspector's

Test Valve

Water

Supply

Valve

7a

1Inbal Automatic Water Control Valve

2 Emergency Release Station

3 Flow Release Pilot (F.R.P.)

4 Automatic Drain Valves

5 Trim Shutoff Valve

6 Y-Strainer

Installation

Refer to the Trim Chart applicable to the

specific Inbal Deluge Valve model in

use.

1.When the Inbal Deluge Valve is

delivered, carefully unpack and visu-

ally check that there has been no

damageto the operatingcomponents,

piping,andfittings.

2.Always flush the pipelines before

installingtheInbalValve.

3.Place the Inbal Valve in the piping at

the outlet of the Water Supply Valve.

Verify that the arrow on the valve

Housing matches the actual flow

direction. Determine which side the

system will be accessed from and

locate the Inbal Deluge Valve

accordingly.

.Install the Inbal Deluge Valve in the

pipeline. Use gaskets, bolts, stud

bolts, bolt sleeves, and nuts as

required bythe valve ends.

.Complete the trim assembly by

connecting the preassembled

sections, or assemble the trim if

ordered in loose component form.

Refer to the applicable Trim Chart

andInstallationGuide.

.The water pressure supply to the

control trim must always be sourced

from the inlet of the Water Supply

Valvethrougha½"pipe.

.Connect the wet pilot line to the Flow

Release Pilot (F.R.P.). Refer to Graph

(1) which shows the maximum

elevations above the Deluge Valve at

which the release line (pilot sprink-

lers or manual release) should be

installed. An Anticolumning Device

is required when the release line

elevation exceeds the figure corres-

ponding to the minimum water

supply system pressure in which the

Inbal Deluge Valve is planned to

perform.

.It is recommended to install an inspe-

ctor's test valve on the hydraulic

release system. The inspector's test

valve is a locked closed ball valve

with an outlet end orifice equivalent

tothesmallestorificeofthereleasing

device provided on the system. The

inspector's test valve may be used to

verify adequate operation of the

deluge system when a releasing

deviceoperates.

9.Set the Inbal Deluge Valve by

followingtheResettingprocedure.

10.TesttheInbalValve,thetrim,andthe

alarms according to the Testing

procedure.

0

0

0

0

0

0

0

0

0

4

5

6

7

8

Resetting

The Inbal Deluge Valve system must be

reset and restored to service as soon as

possible after automatic, emergency, or

manualactuation.

Theprocedureisasfollows:

1.Close the Water Supply Valve. Water

flowalarmsarereset.

2.ClosetheTrimShutoff Valve.

3.Open the Flow Test Valve and Drain

Valve,allowingallthewatertodrain.

4.Inspect and replace any portion of the

detection system subjected to fire

conditions.

5.Inspect the trim and alarm Y-

Strainers.Clean if necessary.

6.Verify that the Emergency Release

Valveisinaclosedposition.

7.Open the Trim Shutoff Valve. Push

and hold the reset knob on the F.R.P.

and allow water pressure to build up

in the trim and in the Inbal Valve

Control Chamber. Wait and verify

that the pressure readings on both

pressuregaugesareequal.

8.Release the reset knob on the Flow

ReleasePilot(F.R.P).

9.Close theFlowTest Valve.

0

0

0

0

0

0

0

0

0

10.Fully open the Water Supply Valve.

Verify that there is no flow from the

Drain Valve, downstream of the

Inbal Valve.

11.Closethe DrainValve.

Maintenance,Inspection,&Testing

It is recommended that periodic inspec-

tions and tests be conducted by qualified

personnel to ensure that the Inbal

Deluge Valve and related equipment are

in good operating condition. The

inspection and testing activities should

be done according to NFPA Standards,

the guidelines and regulations of the

authorities having jurisdiction, and the

following instructions. It is recom-

mended that the Deluge Valve be tested,

operated, cleaned, and inspected at least

onaroutinebasis.

Inspection

Aweekly Inspection is recommended:

1.Verify that the Water Supply Valve is

sealedinfullyopen position.

2. Verify that the required water

pressure is being applied to the Inbal

DelugeValveinlet and trim.

Mil Ltd.17 Moshe Beker Street, P.O.Box 15200, Rishon Lezion 75051, Israel. Tel: +972 3 966 4350, Fax: +972 3 966 4320, E-mail:inbalvl@ attglobal.net

March 2000 / F03-02-01

300 psi

120 140 160 180

WATER SUPPLY SYSTEM PRESSURE

821 bar

9 10 11 12

820 ft (250 m)

1475 ft (450 m)

660ft (200 m)

Up to575 ft(175 m)

990 ft (300 m)

1650 ft (500 m)

1310 ft (400 m)

1150 ft (350 m)

Based on ½'' (15 mm) Schedule 40 pipe

280

If the maximum elevation of hydraulic release piping exceeds the limits

shown on the graph, use anticolumning device model 395-08 (see bulletin F40-14-01).

Deluge Valve, Hydraulic Actuation

Series 700D/DG/DX - 04/14A01

20

MAX. ELEVATION OF WET PILOT LINE

m H O

2ft HO

2

0

10

20

30

40

0

30

60

90

120

150

604020 80 100

5

23467

Pilot Line

Equivalent

Length

Wet Pilot Line - Design Data

3.Close the Alarm Test Valve. All local

alarms should stop sounding and

pressureswitchisreset.

4.Verify that the supply piping to the

alarmdrainsproperly.

DelugeTrimTesting

Asemi-annual Deluge Trim Testing

is recommended. Testing of the control

trim is conducted with no flow of water

tothesystem.

1.Open the Flow Test Valve to flush

away debris or foreign particles

which may have accumulated in the

Inbal Deluge Valve inlet.

2.Close the Flow Test Valve.

3.Close the Water Supply Valve

installed in the inlet of the Inbal

DelugeValve.

4.Open the inspector's test valve in the

hydraulic release system. Water

should be drained from the deluge

trim. Verify that the pressure reading

on the System Pressure Gauge drops

to zero which simulates an open

positionoftheInbalDelugeValve.

5.Reset the valve by performing the

instructionsinResetting.

Trip Testing

AnannualTripTestingisrecommended.

Performing the Trip Testing will cause

water to flow from all open sprinklers

and/or nozzles. Prevent damage by

takingnecessaryprecautions.

1.Open the Flow Test Valve to flush

away any debris or foreign particles

which may have accumulated in the

Inbal Deluge Valve inlet.

2.Close the FlowTest Valve.

3.TriptheInbalValvetoopenbyeither:

a)Openingtheinspector’stestvalve.

b) Opening the Emergency Release

Valve.

The water in the Inbal Valve Control

Chamber is released to the atmos-

phere. The Inbal Deluge Valve will

open wide and water will flow to the

system. All the water flow alarms

should operate. Verify that the whole

systemisworkingproperly.

4.Close the inspector's test valve or the

EmergencyReleaseValve.

5.Reset the valve by performing the

instructionsinResetting.

Removal

ToremovetheInbalDelugeValve:

1.Closeallthepressuresupplies:

a) WaterSupplyValve.

b) TrimShutoff Valve.

2.Openthe EmergencyReleaseValveto

release the water pressure from the

InbalValveControlChamber.

3.Open the Flow Test Valve and Drain

Valvetoallowallthewatertodrain.

4.Disconnect the union and remove the

trimfromthevalve.

5. Remove the InbalValve from the line

forinspection.

6.To reinstall, follow the Installation

procedure (use new gaskets for

flangedor wafer valve).

Inquiries/Orders

The Data Sheet For Inquiries/Orders

(bulletin F01-05-01) should be

submitted.

Graph (1)

3.Verify that the Trim Shutoff Valve,

AlarmTest Valve,EmergencyRelease

Valve, Pressure Gauge Valves, Flow

TestValve,andDrainValve are in set

position.

4.The Supply and System Pressure

Gauges should be checked for

accuracy.

5.Visually inspect for broken or

missing parts, or other evidence

of impairedprotection.

StrainerCleaning

A quarterly Strainer Cleaning is

recommended:

1.Closethe TrimShutoffValve.

2. Remove the covers of the trim and

alarmY-Strainers.Cleanif necessary.

3.OpentheTrimShutoff Valve .

AlarmTesting

A quarterly Alarm Testing is

recommended:

1.Test the Water MotorAlarm or Alarm

Pressure Switch by opening the Alarm

TestValve.

2.Water Motor Alarm should be audible.

Alarm Pressure Switch should

activate.

This manual suits for next models

6

Other Inbal Valves Control Unit manuals

Popular Control Unit manuals by other brands

Sophos

Sophos SG 105wSG 105XG 105wXG 105SG 115SG 115wXG 115XG 115wSG 125SG 125wXG 125XG 125wSG 135SG 135wXG 135XG... Mounting instructions

Aaeon

Aaeon COM-TGUC6 user manual

Simatek

Simatek GFCD 16 manual

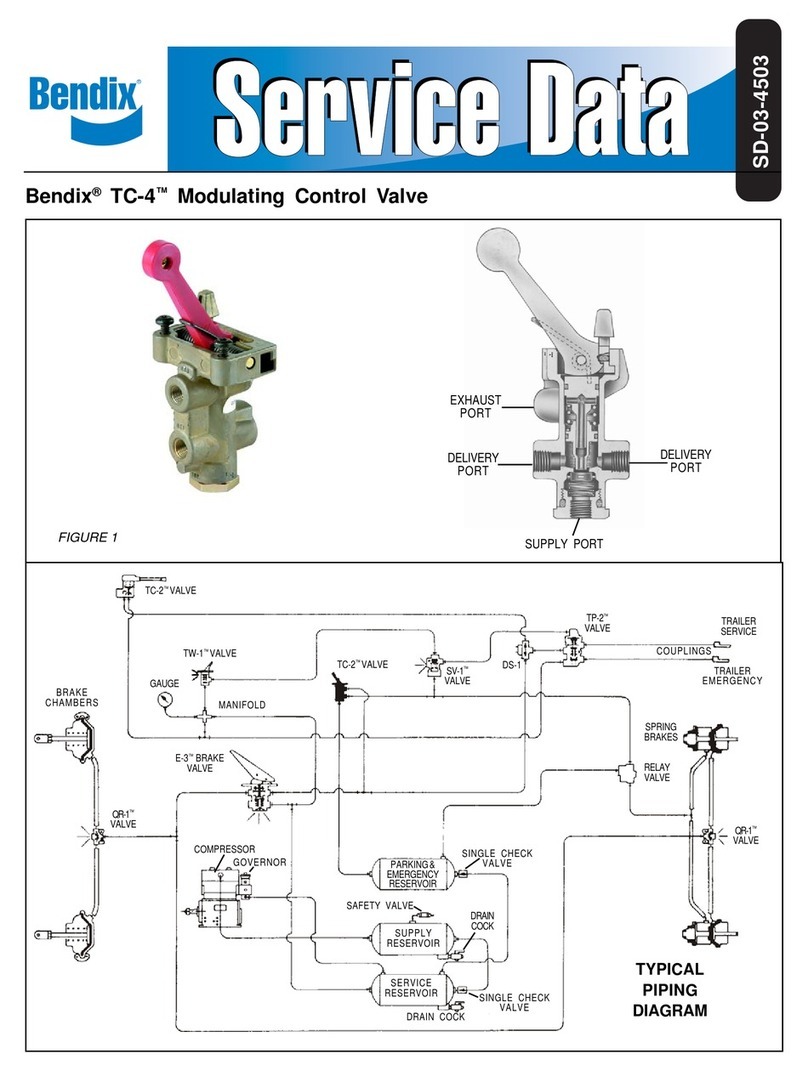

BENDIX

BENDIX TC-4 MODULATING CONTROL VALVE manual

HIMA

HIMA HIMax X-DO 12 51 manual

Wheelock

Wheelock ZC-3 installation instructions

Siemens

Siemens SINUMERIK 805 operating instructions

Toshiba

Toshiba nv Series instruction manual

infiniDome

infiniDome GPSdome 1.01 installation manual

Quectel

Quectel EG91 Series Hardware design

Telit Wireless Solutions

Telit Wireless Solutions GainSpan GS2K Series Hardware user's guide

Berker

Berker 751616 Series Technical documentation