Inbal Valves 700D Series User manual

General Description

The Inbal Deluge Valve with Hydraulic Actuation Trim is

specifically designed for fire protection systems actuated by

a fire detection and release system of wet pilot sprinklers

and/or hydraulic manual control. The Inbal Automatic Water

Control Valve, which is used in this deluge system, is a

pressure operated, sleeve actuated, axial valve designed

for use in fire protection systems.

The Inbal Hydraulically actuated Deluge Valve is used for

automatic or manual operation. The wet pilot line functions

as a thermal detector equipped with a fixed temperature

release. When one or more of the sprinkler heads, located

on the pilot line, fuses, or when a manual release station is

operated locally or remotely, the Inbal Deluge Valve opens

and water flows from all open sprinklers and/or nozzles on

the system. As soon as the releasing system and the

sprinkler piping are reset, the Inbal Deluge Valve resetting is

merely done by activating the reset knob.

The control trim includes all the pilot valves, accessories,

fittings, and gauges to provide for proper operation in either

vertical or horizontal installation. The standard material

Inbal Deluge Valve is rated to 300 psi (21 bar) and is

available in sizes 1½" (40 mm) to 12" (300 mm). The valves

have threaded, flanged, grooved, or wafer inlet and outlet

ends.

The only moving part in the Inbal Deluge Valve, when it

operates, is the reinforced sleeve, which forms a drip-tight

seal with the corrosion resistant core. It has a smooth

opening to prevent any water hammer in the piping system.

The unique design and variety of materials and coatings

make the Inbal Deluge Valve ideally suitable for use in

brackish or sea water, similar to those found in chemical and

petrochemical facilities or in offshore platforms. The Inbal

can also be used as a foam concentrate control valve in

foam/water systems.

F03-02-04-001

FM Approved

Inbal Deluge Valve, Hydraulic Actuation

Series 700D/DG/DX - 04/24A01 Local Resetting

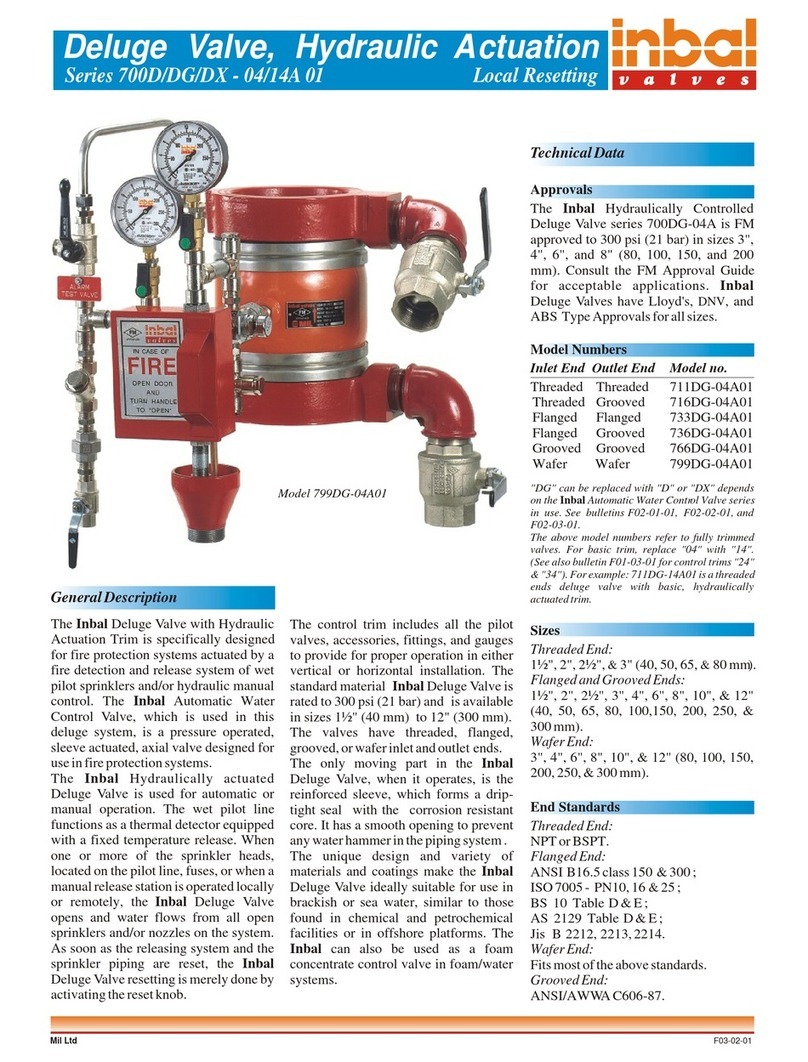

Model 799DG-04A01

Page 1/6

®

Technical Data

Approvals

The Inbal Hydraulically Controlled Deluge Valve models:

711D -24A01 733D -24A01 799D -24A01

711DX -24A01 733DX -24A01 799DX -24A01

711DX -04A01 733DX -04A01 799DX -04A01

711DG-24A01 733DG-24A01 799DG-24A01

711DG-04A01 733DG-04A01 799DG-04A01

are all FM approved to 300 psi (21 bar) in sizes 2", 3", 4", 6",

8", 10" and 12" (50, 80, 100, 150, 200, 250 and 300 mm) with

threaded, flanged and wafer ends. Consult the FM Approval

Guide for acceptable applications. Inbal Deluge Valves

▪

have Lloyd's, DNV GL, and ABS Type Approvals for all

sizes.

Inlet End Outlet End Model no.

Threaded Threaded 711DX-04A01

Threaded Grooved 716DX-04A01

Flanged Flanged 733DX-04A01

Flanged Grooved 736DX-04A01

Grooved Grooved 766DX-04A01

Wafer Wafer 799DX-04A01

”DX” can be replaced with ”D” or ”DG” depends on the Inbal

Automatic Water Control Valve series in use. See bulletins

F02-01, F02-02, and F02-03.

The above model numbers refer to potable water trimmed

valves. For sea / brackish control trim, replace ”04” with

”24” for sea water;”34” ─ for foam control trim. For example:

711DX-24A01 is a threaded ends deluge valve with sea

water, hydraulically actuated control trim.

Threaded Ends:

1½", 2", 2½" & 3" (40, 50, 65 & 80 mm).

Flanged Ends:

2", 2½", 3", 4", 6", 8", 10" & 12" (40, 50, 65, 80, 100,150, 200,

250 & 300 mm).

Grooved Ends:

2", 3", 4", 6" & 8" (50, 80, 100, 150 & 200 mm).

Wafer Ends:

3", 4", 6", 8", 10" & 12" (80, 100, 150, 200, 250 & 300 mm).

Threaded End:

NPT or BSPT.

Flanged End:

1

ANSI B16.5 class 150 & 300;

1

ISO 7005 - PN10, 16 & 25;

2

BS 10 Table D & E;

Model Numbers

Sizes

End Standards

AS 2129 Table D & E;

2

Jis B 2212, 2213, 2214.

Grooved End:

ANSI/AWWA C606-87.

Wafer End:

Fits most of the above standards.

(1) - On standard

(2) - On a special request

Maximum working pressure*: 300 psi (21 bar).

* Standard material valve.

o o

Water: Max. +150 F (+65 C).

Vertical or horizontal.

Standard

Valve Housing:

Forged Steel (SAE 1021).

Valve Ends and Wafer Flow Test & Drain Ends:

Ductile Iron (ASTM A536 65-45-12).

Threaded, Flanged, and Grooved Flow Test & Drain Ends:

Carbon Steel (SAE 1020).

Sleeve:

SMR5 Elastomer reinforced with polyester and Kevlar.

Control Trim:

Brass Nickel Chrome plated Stainless Steel, and

Galvanized Steel.

Optional

Cast Steel;

Bronze;

Nickel Aluminum Bronze;

Stainless Steel AISI 316;

Super Austenitic Stainless Steel;

Super Duplex Stainless Steel;

Titanium.

Standard

Powder epoxy coated. Thickness: 0.004" (0.1 mm) external

and internal surfaces.

Optional

High built epoxy coated and polyurethane finish. Thickness:

0.01" (0.3 mm).

®

Halar coated. Thickness: 0.02" (0.5 mm).

®

Halar is a registered trade mark of Ausimont USA Inc.

2

Pressure Rating

Temperature Range

Installation Position

Materials

Coating

F03-02-04-002

Page 2/6

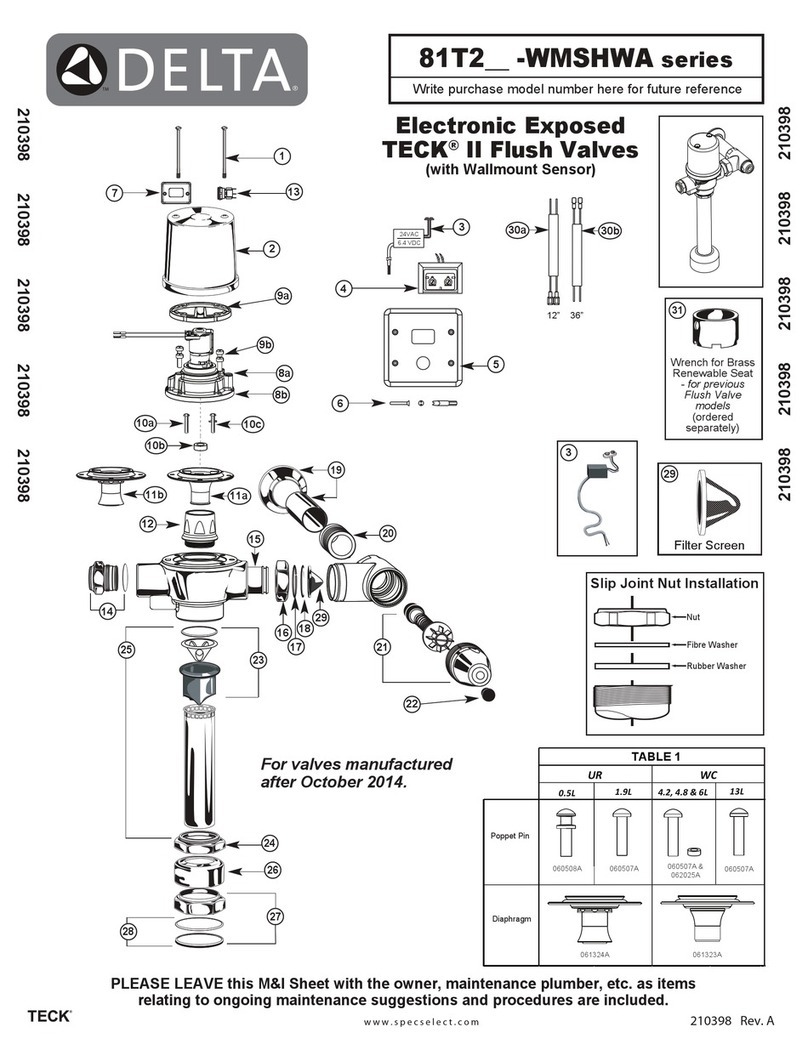

Water Line

To Deluge System

TO

DRAIN

TO

DRAIN

TO

DRAIN

Water

Supply

Valve

18

21a

29

32b

21b

3b

4

1

3a

1Inbal Automatic Water

Control Valve

2 Emergency Release Station

3a Test Valve

3b Trim Shutoff Valve

4 Y-Strainer

5 Flow Release Pilot (F.R.P.)

18 Automatic Drain Valves

21a Supply Pressure Gauge

21b System Pressure Gauge

29 Alarm Test Valve

32a Flow Test Valve

32b Drain Valve

Wet Pilot Line

Inspector's

Test Valve

To Water Motor

and/or Alarm Pressure Switch

Alarm

_

Schematic Control Diagram 700DG-04A01

5

18

TO

DRAIN

Control Trim

On standard, the Control Trim is supplied fully

preassembled. If self-assembly is required, all the trim

components are supplied in loose form. The complete

control trim includes the following components:

!Flow Release Pilot (F.R.P.) with a built-in check valve.

!Y- Strainer with a stainless steel screen.

!Alarm Test Valve ─ 3 way, L-port, quarter turn ball valve.

!Trim Shutoff Valve, Flow Test Valve, and Drain Valve.

!Supply and System Pressure Gauges, with dual scale (psi

and bar).

!Pressure Gauge Valves.

!Drain Cup and Drain Tubes.

!Automatic Drain Valve.

!Emergency Release Station.

Features

!No Moving Mechanical Parts (N.M.M.P.) construction

ensures a long life of dependable operation, reducing the

cost of maintenance.

!Quick, yet soft opening performance ─ eliminates water

hammer and consequent damages.

!The line pressure is sufficient to close the Inbal Valve

tightly. Can perform also, when water supply valve is not

in use.

!Optional opening and/or closing speed control is

available.

!Anti-columning device is available for long or high

elevation wet pilot line.

!Fast and easy reset by thumb activated knob.

!Supplied as standard preassembled in sections saves

the self-assembly cost.

!Remote emergency release stations can be used for

manual operation.

!Can be installed vertically or horizontally.

!Compact design ─ minimum space for valve and trim.

!Unique principle of operation prevents false operation

due to water surges.

!Pressure rating to 300 psi (21 bar) for standard material

valve.

F03-02-04-003

2

TO DRAIN

Page 3/6

32a

TO

DRAIN

!Wide range of sizes for an ideal system design.

!Control trim made of high grade materials as standard.

!Epoxy coating supplied as standard ─ ensures excellent

corrosion resistance.

!Variety of available materials ─ to ensure corrosion-free

service even under severe conditions.

!The same basic trim is compatible with electric,

pneumatic, and/or hydraulic release.

!Additional functions, such as pressure control or another

release system, could be added on the same valve body.

The Control Chamber of the Inbal Automatic Water Control

Valve is the annular space between the valve Housing and

the Sleeve. The valve is held in a closed position as long as

inlet pressure is maintained in the Control Chamber.

The wet pilot line, equipped with closed sprinkler heads, is

pressurized through the valve trim and located over the

protected area. The wet pilot line serves the dual purpose of

thermal detection and release system.

In the set position, water pressure is applied to the Control

Chamber of the Inbal Deluge Valve and to the hydraulic

release system from the upstream of the Water Supply

Valve. Consequently, the Inbal Deluge Valve stays closed.

Operation

The Inbal Deluge Valve opens wide when one or more of the

sprinklers installed on the wet pilot line fuses and water

pressure is allowed to vent, or when a hydraulic manual

release opens. Either one of these operations releases

water from the Inbal Control Chamber. The Inbal Deluge

Valve opens fully introducing a flow of water to the system

while activating the system alarm devices. Water will flow

from any open sprinklers and/or spray nozzles on the

system. The operation of the Inbal Deluge Valve and the

flow released from the Control Chamber activate the Flow

Release Pilot (F.R.P) to latch in an open position, isolating

the Control Chamber from the inlet water supply. The F.R.P

operation prevents the Inbal Deluge Valve from closing

even if the open releasing wet pilot line closes. The Inbal

Valve will close only when the Resetting procedure is

followed.

The maximum elevations in which the wet pilot sprinklers or

manual release stations can be installed are shown on

Graph (1).They are presented in relation to the various

lengths of pilot lines and to the water supply pressure.

The Emergency Release Valve is used for emergency

actuation of the Inbal Deluge Valve and for routine testing.

300 psi

120 140 160 180

WATER SYSTEM PRESSURESUPPLY

821 bar

9 10 11 12

820 ft (250 m)

1475 ft (450 m)

660 ft (200 m)

Up to 575 ft (175 m)

990 ft (300 m)

1650 ft (500 m)

1310 ft (400 m)

1150 ft (350 m)

Based on ½'' (15 mm) Schedule 40 pipe

280

If the maximum elevation of hydraulic release piping exceeds the limits shown on the graph, use anticolumning device model 395-08 (see bulletin F40-14-01).

20

MAX. ELEVATION OF WET PILOT LINE

m H O

2ft H O

2

0

10

20

30

40

0

30

60

90

120

150

604020 80 100

5

23467

Pilot Line

Equivalent

Length

Graph (1)

Wet Pilot Line - Design Data

F03-02-04-004

Page 4/6

F03-02-04-005

Installation

Refer to the Trim Chart applicable to the specific Inbal

Deluge Valve model in use.

1. When the Inbal Deluge Valve is delivered, carefully

unpack and visually check that there has been no

damage to the operating components, piping, and

fittings.

2. Always flush the pipelines before installing the Inbal

Valve.

3. Place the Inbal Valve in the piping at the outlet of the

Water Supply Valve. Verify that the arrow on the valve

Housing matches the actual flow direction. Determine

which side the system will be accessed from and locate

the Inbal Deluge Valve accordingly.

4. Install the Inbal Deluge Valve in the pipeline. Use

gaskets, bolts, stud bolts, bolt sleeves, and nuts as

required by the valve ends.

5. The Control Trim is supplied fully preassembled. Refer to

the applicable Trim Chart and Installation Guide.

6. The water pressure supply to the control trim must

always be sourced from the inlet of the Water Supply

Valve through a ½" pipe.

7. Connect the wet pilot line to the Flow Release Pilot

(F.R.P.). Refer to Graph (1) which shows the maximum

elevations above the Deluge Valve at which the release

line (pilot sprinklers or manual release) should be

installed. An Anti-columning Device is required when the

release line elevation exceeds the figure corresponding

to the minimum water supply system pressure in which

the Inbal Deluge Valve is planned to perform.

8. It is recommended to install an inspector's test valve on

the hydraulic release system. The inspector's test valve

is a locked closed ball valve with an outlet end orifice

equivalent to the smallest orifice of the releasing device

provided on the system. The inspector's test valve may

be used to verify adequate operation of the deluge

system when a releasing device operates.

9. Set the Inbal Deluge Valve by following the Resetting

procedure.

10.Test the Inbal Valve, the trim, and the alarms according

to the Testing procedure.

Resetting

Maintenance, Inspection, & Testing

The Inbal Deluge Valve system must be reset and restored

to service as soon as possible after automatic, emergency,

or manual actuation.

The procedure is as follows:

1.Close the Water Supply Valve. Water flow alarms are

reset.

2.Close the Trim Shutoff Valve.

3.Open the Flow Test Valve and Drain Valve, allowing all

the water to drain.

4.Inspect and replace any portion of the detection system

subjected to fire conditions.

5.Inspect the trim and alarm Y-Strainers. Clean if

necessary.

6.Verify that the Emergency Release Valve is in a closed

position.

7.Open the Trim Shutoff Valve. Push and hold the reset

knob on the F.R.P. and allow water pressure to build up in

the trim and in the Inbal Valve Control Chamber. Wait

and verify that the pressure readings on both pressure

gauges are equal.

8.Release the reset knob on the Flow Release Pilot (F.R.P).

9.Close the Flow Test Valve.

10. Fully open the Water Supply Valve. Verify that there is no

flow from the Drain Valve, downstream of the Inbal

Valve.

11. Close the Drain Valve.

It is recommended that periodic inspections and tests be

conducted by qualified personnel to ensure that the Inbal

Deluge Valve and related equipment are in good operating

condition. The inspection and testing activities should be

done according to NFPA Standards, the guidelines and

regulations of the authorities having jurisdiction, and the

following instructions. It is recommended that the Deluge

Valve be tested, operated, cleaned, and inspected at least

on a routine basis.

A weekly Inspection is recommended:

1. Verify that the Water Supply Valve is sealed in fully open

position.

2. Verify that the required water pressure is being applied to

the Inbal Deluge Valve inlet and trim.

3. Verify that the Trim Shutoff Valve, Alarm Test Valve,

Inspection

Page 5/6

Emergency Release Valve, Pressure Gauge Valves, Flow

Test Valve, and Drain Valve are in set position.

4. The Supply and System Pressure Gauges should be

checked for accuracy.

5. Visually inspect for broken or missing parts, or other

evidence of impaired protection.

A quarterly Strainer Cleaning is recommended:

1. Close the Trim Shutoff Valve.

2. Remove the covers of the trim and alarm Y- Strainers.

Clean if necessary.

3. Open the Trim Shutoff Valve.

A quarterly Alarm Testing is recommended:

1. Test the Water Motor Alarm or Alarm Pressure Switch by

opening the Alarm Test Valve.

2. Water Motor Alarm should be audible. Alarm Pressure

Switch should activate.

3. Close the Alarm Test Valve. All local alarms should stop

sounding and pressure switch is reset.

4. Verify that the supply piping to the alarm drains properly.

A semi-annual Deluge Trim Testing is recommended.

Testing of the control trim is conducted with no flow of water

to the system.

1.Open the Flow Test Valve to flush away debris or foreign

particles which may have accumulated in the Inbal

Deluge Valve inlet.

2.Close the Flow Test Valve.

3.Close the Water Supply Valve installed in the inlet of the

Inbal Deluge Valve.

4.Open the inspector's test valve in the hydraulic release

system. Water should be drained from the deluge trim.

Verify that the pressure reading on the System Pressure

Gauge drops to zero which simulates an open position of

the Inbal Deluge Valve.

5.Reset the valve by performing the instructions in

Resetting.

Strainer Cleaning

Alarm Testing

Deluge Trim Testing

Trip Testing

Removal

An annual Trip Testing is recommended. Performing the Trip

Testing will cause water to flow from all open sprinklers

and/or nozzles. Prevent damage by taking necessary

precautions.

1. Open the Flow Test Valve to flush away any debris or

foreign particles which may have accumulated in the

Inbal Deluge Valve inlet.

2. Close the Flow Test Valve.

3. Trip the Inbal Valve to open by either:

a) Opening the inspector's test valve.

b) Opening the Emergency Release Valve.

The water in the Inbal Valve Control Chamber is released

to the atmosphere. The Inbal Deluge Valve will open wide

and water will flow to the system. All the water flow alarms

should operate. Verify that the whole system is working

properly.

4. Close the inspector's test valve or the Emergency

Release Valve.

5. Reset the valve by performing the instructions in

Resetting.

To remove the Inbal Deluge Valve:

1. Close all the pressure supplies:

a) Water Supply Valve.

b) Trim Shutoff Valve.

2. Open the Emergency Release Valve to release the water

pressure from the Inbal Valve Control

Chamber.

3. Open the Flow Test Valve and Drain Valve to allow all the

water to drain.

4. Disconnect the union and remove the trim from the valve.

5. Remove the Inbal Valve from the line for inspection.

6. To reinstall, follow the Installation procedure (use new

gaskets for flanged or wafer valve).

The Data Sheet for Inquiries/Orders (bulletin F01-05) should

be submitted.

Inquiries/Orders

July 2016 / F03-02-04-006

FM Approved

Inbal Deluge Valve, Hydraulic Actuation

Series 700D/DG/DX - 04/24A01 Local Resetting

Page 6/6

®

The information contained in this document is subject to change without notice. Mil Inbal Valves Ltd shall not be liable for any errors, omissions or amendments contained herein

Copyright by Mil Inbal Valves Ltd. All rights reserved© Inbal Valves® is a registered trademark

This manual suits for next models

20

Table of contents

Other Inbal Valves Control Unit manuals