Incra Twin Linear User manual

OWNER’S MANUAL

Please read this Ownerʼs Manual before

use and keep it at hand for reference.

NOTE

If you are setting up the TWIN at your

table saw, follow the mounting instructions

included with the TSII Base Mount Kit

6

-1

1

0

2

3

4

5

11

13

14

15

16

17

18

19

12

10

6

0

2

3

4

5

1

9

11

12

13

14

15

16

10

8

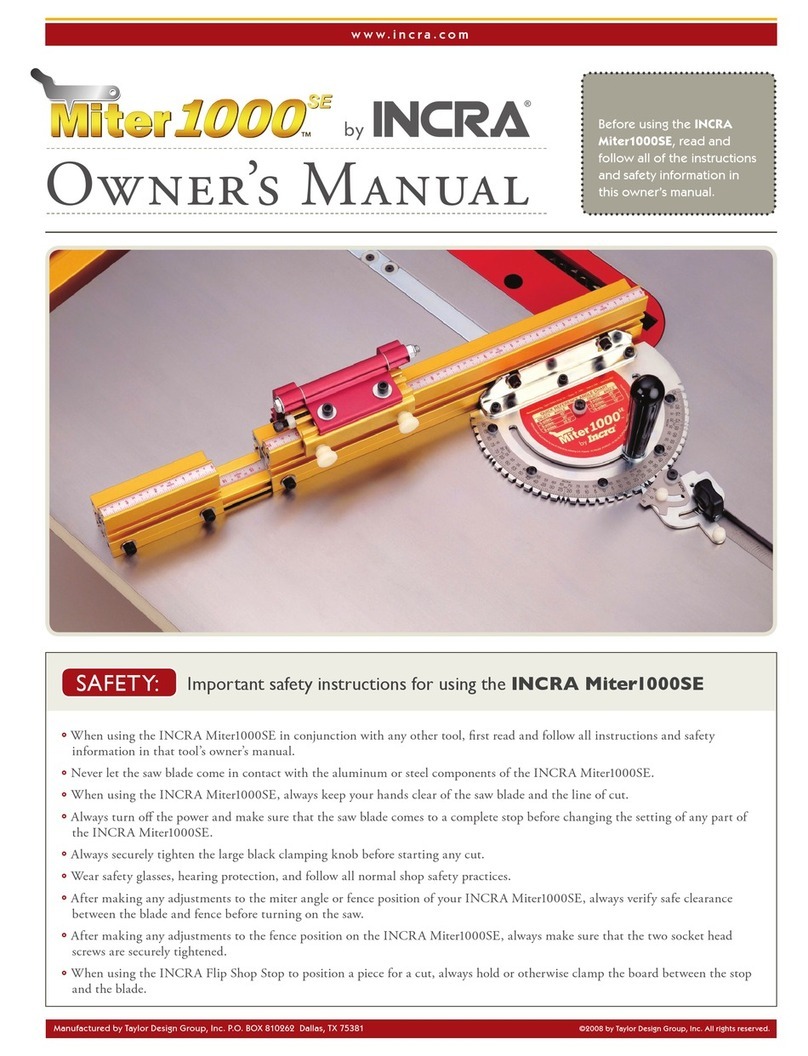

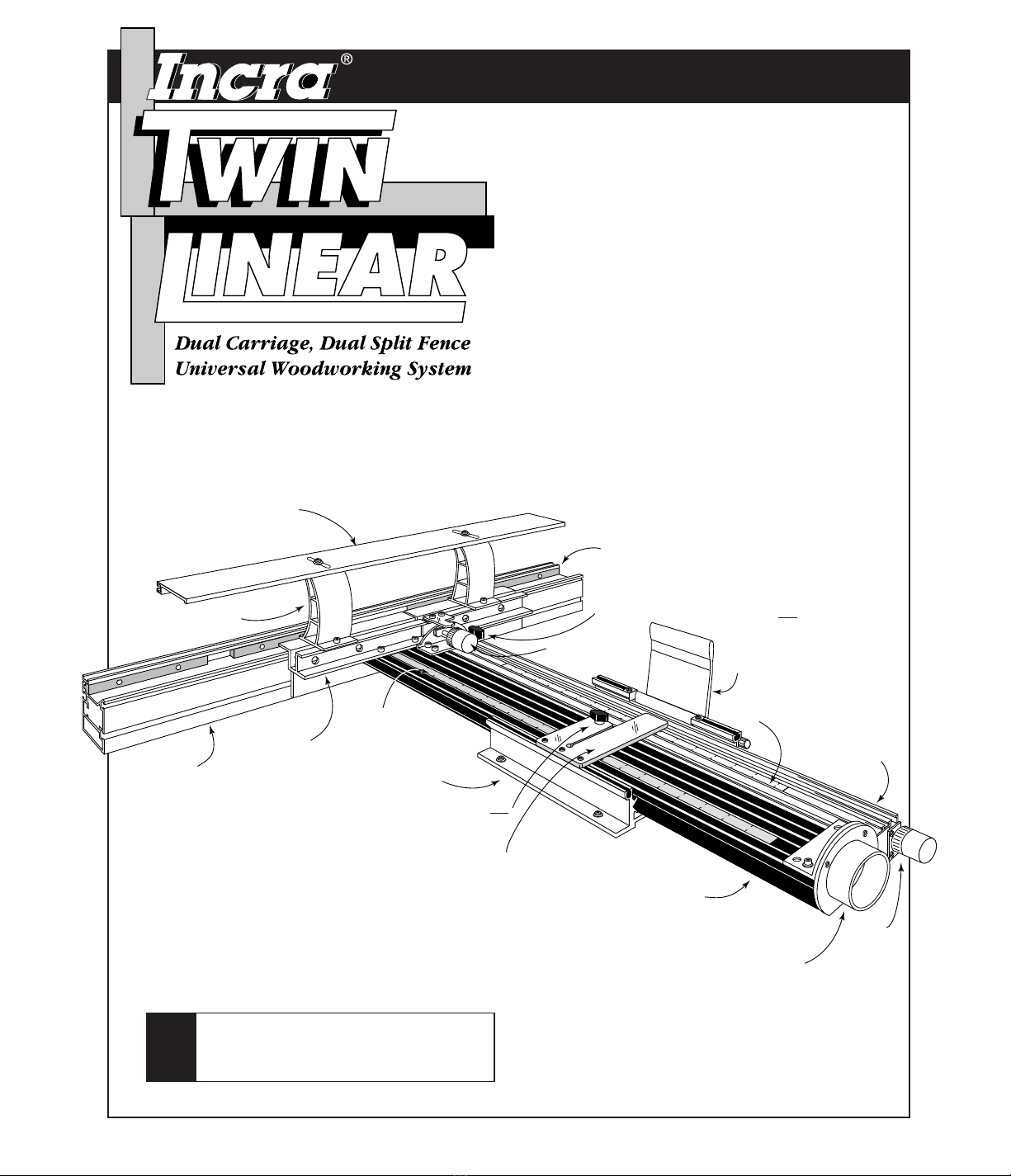

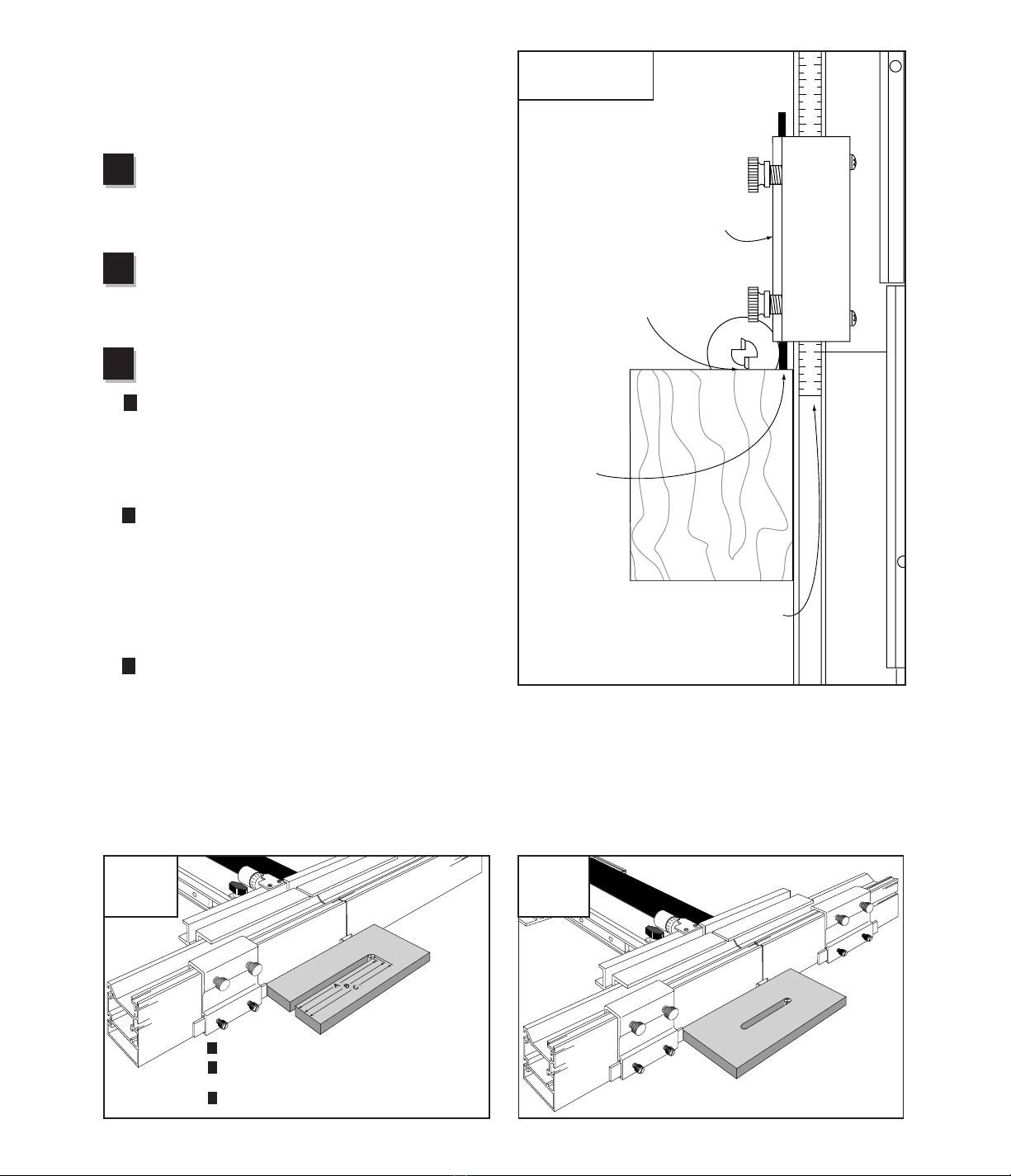

Hi-Rise fence cap

Infeed carriage

(black)

Carriage clamp

Outfeed fence

Red

micro adjust

knob

Dust

collection

port

Rear black thumbscrew (Tighten only

during outfeed fence offset adjustments)

Fence cap braces

Stainless steel

primary scale

Black infeed fence

adjustment knob

Infeed fence

Forward black thumbscrew (Loosen only during fence

offset adjustments

Outfeed carriage

(gold)

Lexan®“floating” scale

Hairline cursor

Fence mounting

bracket

Base

Please take just a few minutes of your time to read

your new INCRA TWIN LINEAR ownerʼs manual.

Youʼll find it full of interesting and useful information

about safety, setting up, and putting to use the many

wonderful features of the TWIN. And itʼs all written

by someone who continues to use every INCRA

product from the very first INCRA Jig all the way up

to our best offering ever — the INCRA TWIN LINEAR!

In eight years of using one INCRA Jig or another

virtually every weekend (and some week nights) Iʼve

come to know these tools inside out. In writing this

manual I want to share this experience with you. Iʼve

attempted to make everything as clear as possible,

but if you are in doubt, weʼll be here to help. See

you in the shop!

—

Perry

SAFETY

. . . . . . . . . . . . . . . . . . . . . . . . 2

TWIN LINEAR SETUP

Accessories . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

Hi-Rise

™

Fence Cap . . . . . . . . . . . . . . . . . . . . . 5

Installing the Extender Bar . . . . . . . . . . . . . . . . . 6

Extender Bar and Stop . . . . . . . . . . . . . . . . . . . . 6

Incra Stop Assembly . . . . . . . . . . . . . . . . . . . . . 6

OPERATION

Moving to a New Scale Setting . . . . . . . . . . . . . . . . 8

Micro Adjusting . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Offset Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . 10

Infeed Fence Adjustment . . . . . . . . . . . . . . . . . 10

Outfeed Fence Adjustment . . . . . . . . . . . . . . . . 11

Gap Adjustment . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

Zero Clearance Subfence . . . . . . . . . . . . . . . . . . . . 12

IN-LINE FENCE APPLICATIONS

General Purpose Router Fence . . . . . . . . . . . . . . . .14

Vertical Panel Raising . . . . . . . . . . . . . . . . . . . . . . 15

Joint Making . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 15

OFFSET FENCE APPLICATIONS

Jointing . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

Shaping . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

ADJUSTMENTS

Adjusting the Clamping Pressure . . . . . . . . . . . . . . 18

Realigning Carriage and Fence Racks . . . . . . . . . . 19

Realigning Infeed and Outfeed Fences . . . . . . . . . . 19

Parts and Optional Accessories . . . . . . . . . . . . . . . 20

SAFETY

2

Important safety instructions for using the INCRA

TWIN LINEAR. Before using, read and follow all of the

instructions and safety information in this manual.

❐When using the INCRA TWIN LINEAR in conjunction

with any other tool, first read and follow all instructions

and safety information in that toolʼs ownerʼs manual.

❐Always turn off the power and wait until the bit or blade

comes to a complete stop before changing the setting of

any part of the INCRA TWIN LINEAR or INCRA Stop.

❐Always keep both hands behind the fence when moving

the INCRA TWIN LINEAR to a new setting.

❐Before making a cut, always make sure that the

carriage clamp is fully engaged and the jig is securely

locked in place.

❐When using the INCRA TWIN LINEAR with other

tools, make sure that all safety guards and other

safety equipment supplied by the manufacturer of that

tool are securely in place and functional. Never let

the INCRA TWIN LINEAR interfere with another toolʼs

safety equipment.

❐Use appropriate safety devices. Keep hands clear of the

bit or blade. Always use a push stick, rubber soled push

block, or other safety device to keep your hands safely

away from the cutting tool.

❐Wear safety glasses, hearing protection, and follow all

normal shop safety practices.

❐DO NOT modify the INCRA TWIN LINEAR in an attempt

to use it with non-INCRA accessories.

❐When adjusting the fence opening, never position the

infeed or outfeed fence ends closer than 1/8” from the

router bit.

❐After making adjustments to the fence opening, be sure

to tighten the four socket head cap screws that secure

the fences to the fence mounting brackets.

❐After making any offset adjustments to the fence, always

tighten the carriage tie (black clamping knob behind the

outfeed fence mounting bracket) and pull the carriage

clamp up into the locked position.

❐When using fence settings in which the router bit is

partially recessed in the fence opening, always insure

that the bit is centered within the opening.

❐Never let the router bit come into contact with any part

of the INCRA TWIN LINEAR, INCRA Stop, or INCRA

Right Angle Fixture.

❐When using large diameter vertical or horizontal panel

raising bits or any other large diameter bit, always

follow that router bit manufacturerʼs operation and

safety recommendations.

❐Whenever it is necessary to remove large amounts of

stock, always use multiple side-by-side passes to

achieve the final cut. Several shallow cuts are safer and

will yield better results.

CONTENTS

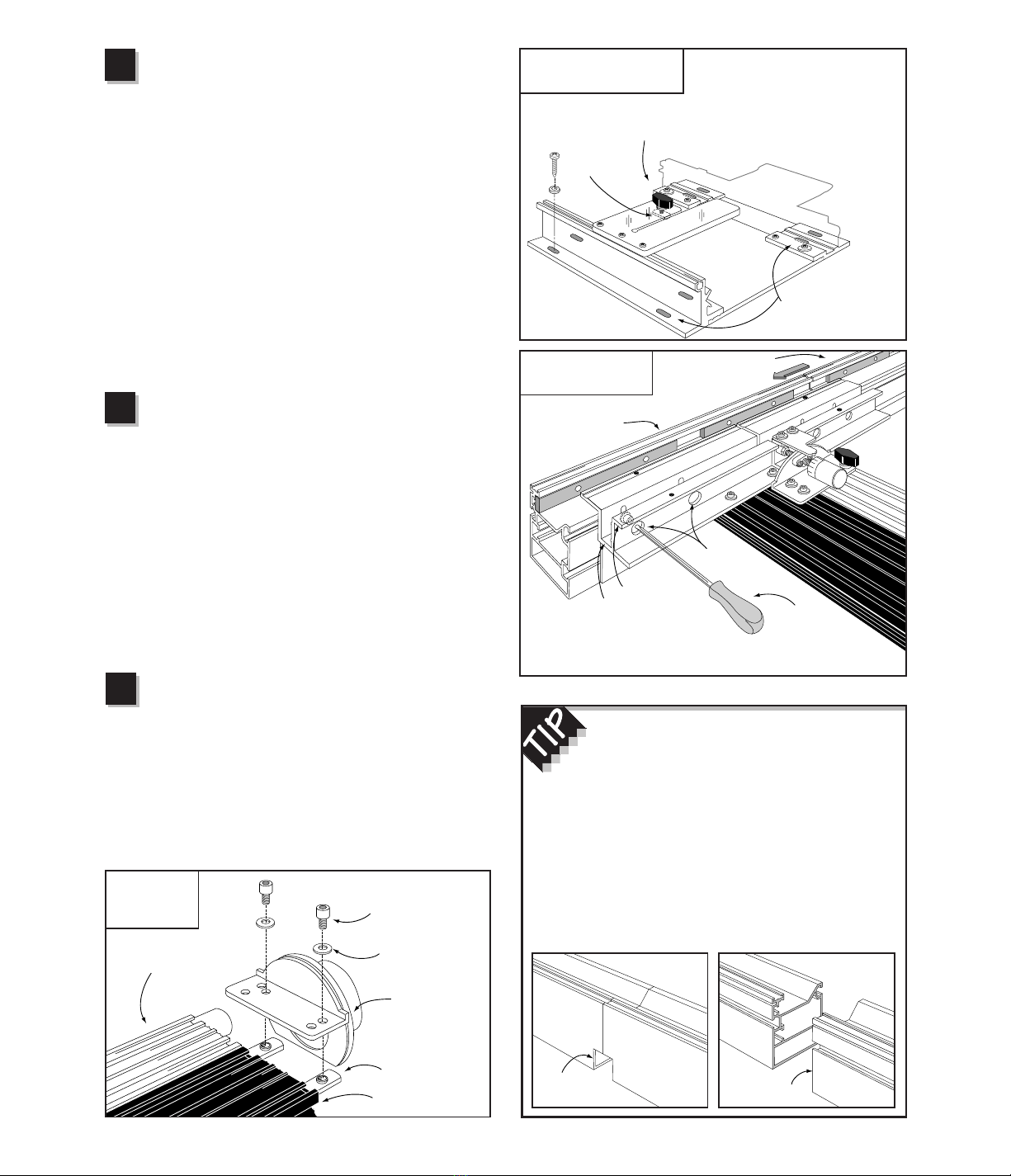

For those of you setting up the TWIN on an “INCRA

TWIN ready” router table, the mounting holes will be

predrilled with T-nuts installed. Skip to Step 2.

Suggested Router Table Dimensions

If you donʼt already own a router table, Fig. 1 gives minimum

dimensions for a table top designed around the TWIN and its

capabilities. If you have a router table top that is not long

enough to handle the full range of the TWIN, see the Tip at

right for an easy way to extend your table dimensions.

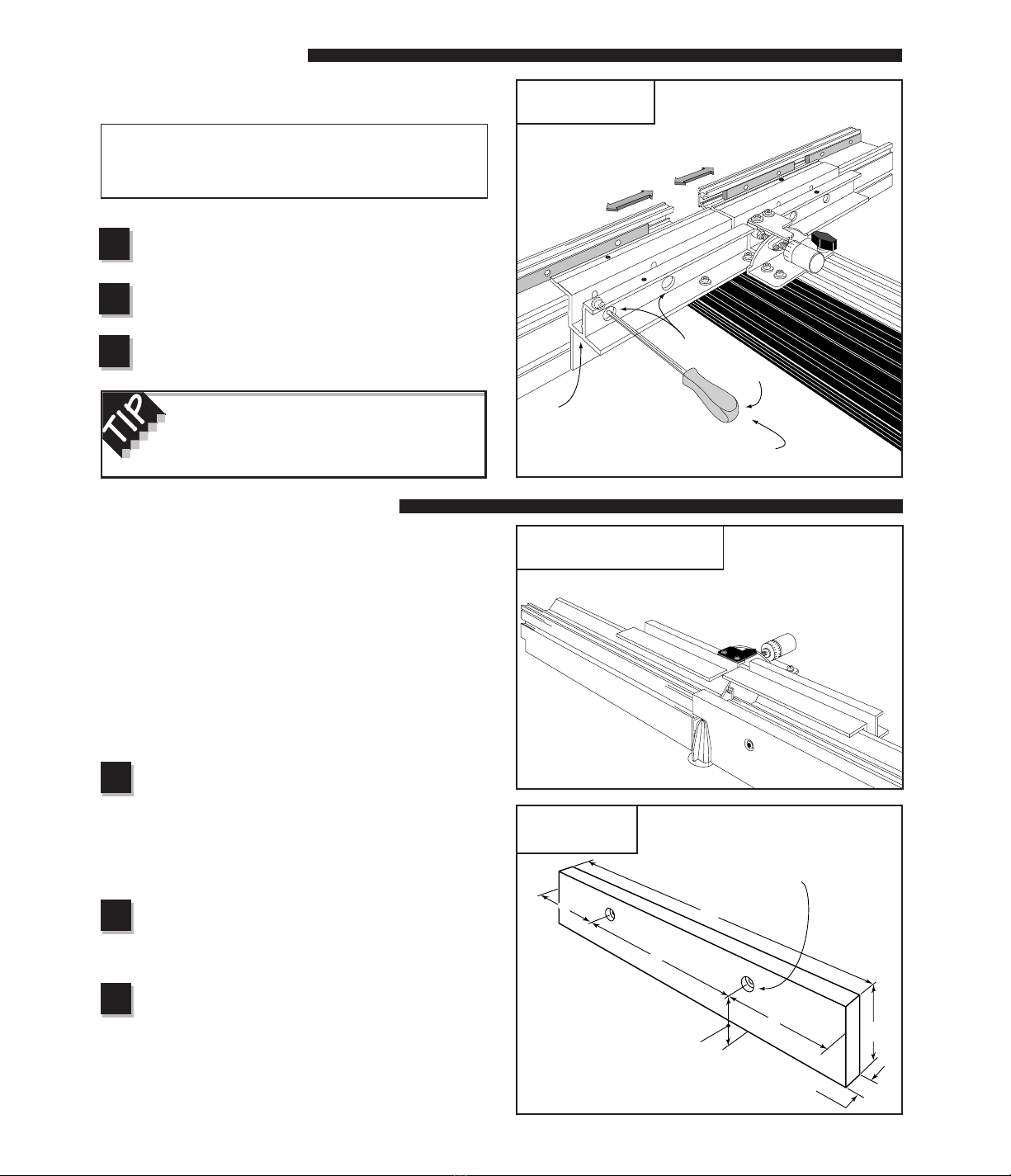

Drill Mounting Holes

Begin by drilling the (8) mounting holes in your router

table top. A paper pattern is provided to make locating the

holes easy. Draw a line extending from the center of the

hole in your router table toward the far edge of the table,

Fig. 2. This line needs to be parallel to the edges of the

table so take a few measurements at each end of the line to

make sure it is. Position the dark line on the pattern right on

top of the line you draw. Slide the pattern back until the

marked edge is 22" from the center of the hole in your table.

Tape the pattern in place.

3

Extending your router table length

Screw aluminum or steel angle to underside of

router table to provide support for table extension.

The extension needs to be flush and parallel to the

table top. Shim to alignment as necessary.

Fig. 1

Suggested router

table dimensions

Fig. 2

Drill mounting holes

NOTE

1

TWIN LINEAR SETUP

Extension wing

Wood screws

Aluminum or steel angle

Paper pattern

Drill 1⁄4" holes if you want to use the 10-24 x 13⁄4" machine

screws and hex nuts.

Drill 1⁄8" holes if you want to use the 10 x 7⁄8" wood screws.

NOTE

Placing the pattern 22" away from the center of the

hole will allow you the maximum usable range of the

TWIN. Moving the pattern closer to the hole on

smaller tables does not limit the full use of the many

features of the TWIN, it only decreases the distance

that the fence can be moved from the cutter later on.

The base mount hardware pack gives you a couple of

fastener options. You can mount the base with (8) 10 x 7⁄8"

wood screws with washers, in which case youʼll want to

predrill the (8) holes with a 1⁄8" drill bit. Or you can use the

(8) 10-24 x 1 3⁄4" phillips pan head machine screws and

predrill the (8) holes with a 1⁄4" bit. I prefer the machine

screws, but if you choose this option, make sure you have

clearance under the table for the washers and nuts at all eight

mounting hole locations.

Attach Base to Router Table

Slide the carriage out of the base. Depending on which

fastener option you selected in Step 1, attach the TWINʼs base

to your router table. Put a washer on the screw first and make

sure you place a screw in each of the eight slotted holes in the

base, Fig. 3. on the next page. If you are using the machine

screws, place a washer and hex nut on the screw from under

the router table. Tighten all (8) mounting screws.

24"

12" 12"

43"

31"

Existing router

table top

22"

2

FACT Infeed and Outfeed

Infeed refers to everything that is before the cutter,

while outfeed is everything that is after the cutter. Youʼll

hear about infeed and outfeed fences, of course, but

you also have an infeed and outfeed side to your router

table, and youʼll learn how to set an infeed or outfeed

stop later in this manual. Your INCRA TWIN LINEAR is

the only fence of its kind to offer separate infeed (black)

and outfeed (gold) carriages, each controlling its own

fence. The “twin” carriages can operate in tandem, or

independently for offset fence applications.

4

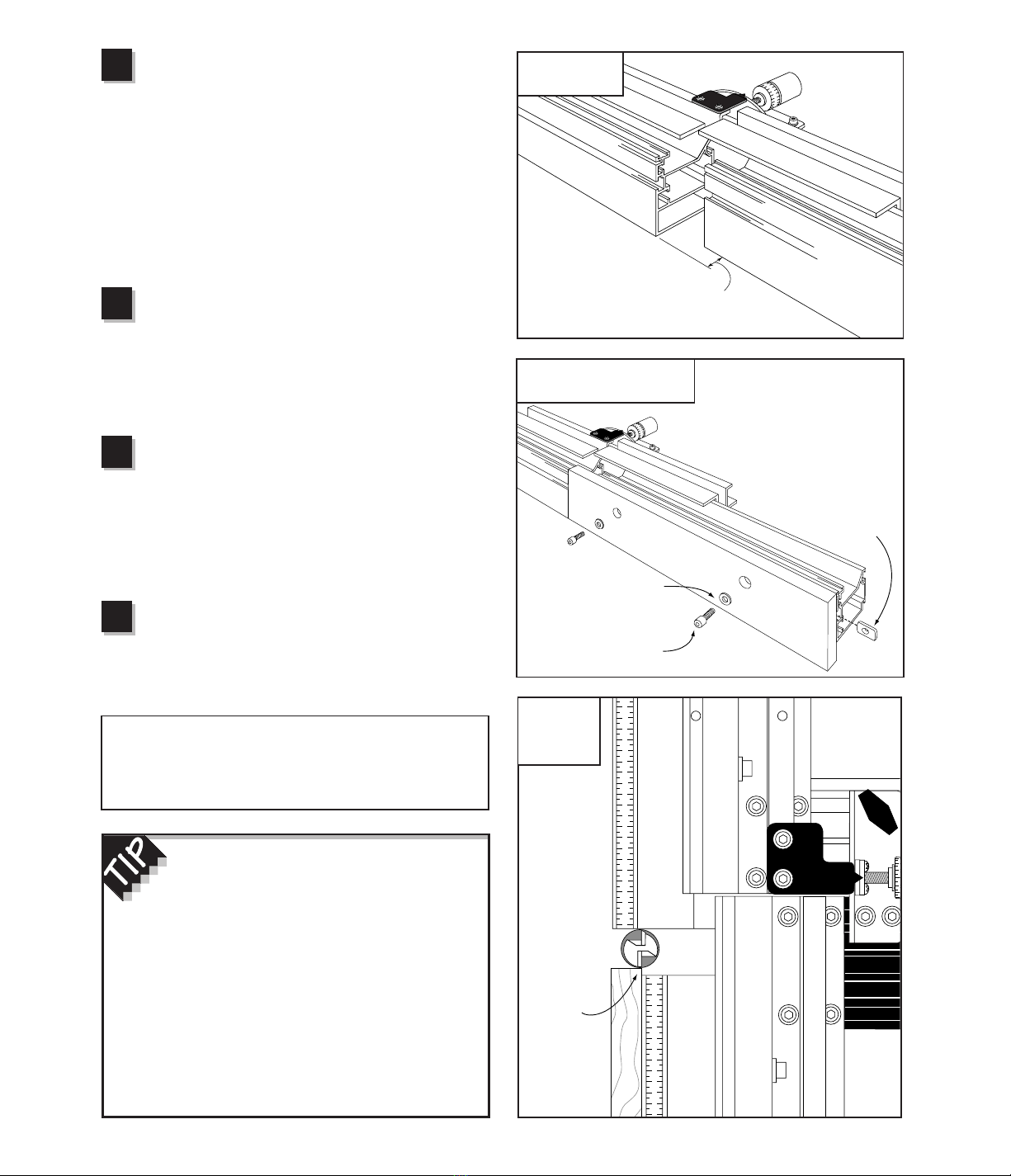

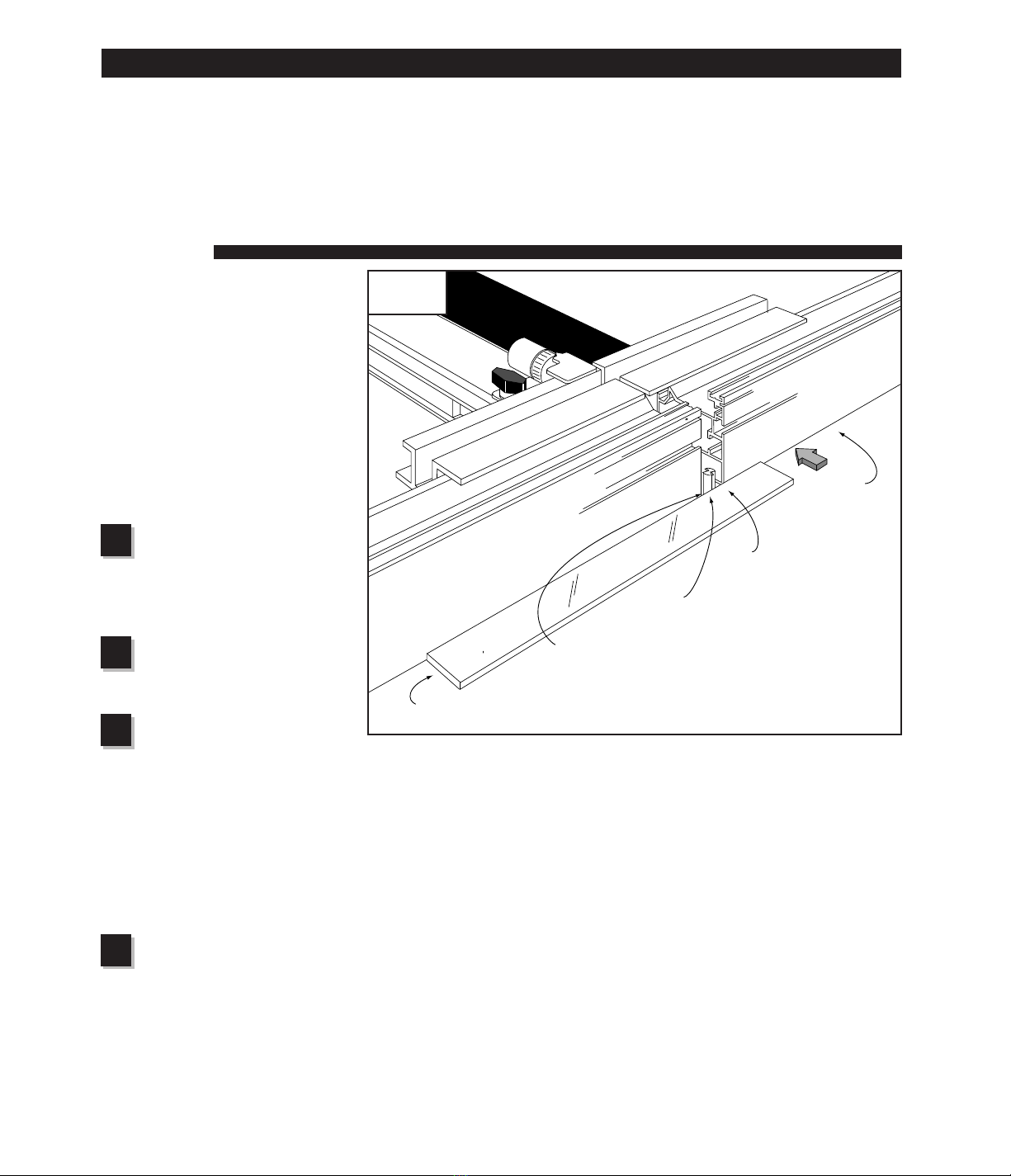

Attach Outfeed Fence

Before you slide the carriage back into the base, take

a look at the black thumbscrew that passes through the clear

acrylic hairline cursor on the base. Fig. 3. The thumbscrew

is screwed into a rectangular nut. Make sure that the

rectangular nut slides into the T-slot in the top of the infeed

carriage when you slide the carriage back into the base.

Now slide the carriage into the base and position the front of

the fence directly over the hole in your table top. Pull the

carriage clamp handle up into the locked position.

Using the supplied hex head tool, loosen the (4) socket head

cap screws about a half a turn through the access holes in

the rear of the fence mounting bracket. See Fig. 4. Place the

remaining fence half end-to-end with the half already

mounted and slide them both (as though they were one

continuous fence) until the notch at the front of the fence is

aligned directly over the hole in your router table. Retighten

the (4) socket head screws.

Initial Alignment for Primary Scale

With the carriage clamp locked in place, slide the

primary (stainless steel) scale to position the nearest scale

mark directly under the hairline cursor. The scale is held in

place by a magnetic strip. Lifting one end of the scale off of

the magnet will decrease the tension, allowing the scale to

slide more easily. Slide the Lexan plastic scale to position

the nearest scale mark under the cursor as well. You will

change the scale positions the first time you install a bit or

blade and “zero” to the cutter, but remember this: Since the

INCRA TWIN will only clamp every 1⁄32", you must always

make sure the carriage clamp is locked before positioning

any of the scales or joinery templates. If the clamp is

unlocked when the scales are positioned, it almost

guarantees inaccurate cut placement.

Install Dust Collection Port

Place washers on (2) 1⁄4-20 X 3⁄8" socket head cap

screws and place them through the holes as shown in Fig. 5.

Loosely attach (2) 1⁄4-20 rectangular nuts, then slide the nuts

into the T-slots on the top of the infeed (black) carriage. Slide

the port assembly forward until it stops, then tighten the

fasteners. Should you ever want to remove the carriage from

the base again, you must first remove the port by loosening

these same fasteners. The dust collection port accepts a

21⁄2" diameter hose.

Fig. 3

Attach base to router table Place mounting screw with washer

through each of the eight slotted holes

in the base. If using machine screws,

secure with washers and nuts from

beneath the table.

Fig. 4

Attach outfeed fence

Take a look at the TWINʼs fence. At one end

of each fence half youʼll find a flat cut, while on

the other end youʼll notice a small notch. Place the

two notched ends together whenever you want a

continuous fence surface above the cut area. Youʼll find

this especially useful when using the Right Angle

Fixture for joinery, since it tracks along the top surface

of the fence. Placing the two flat cut ends together is

perfect when you want to open or close the gap

between the fences for large or small diameter cutters.

4

5

Fig. 5

Install dust

collection port

3

Note: Mounting holes

are shaded in

illustration for clarity

Black

thumbscrew

Rectangular

nut

Socket head

cap screw

Fence mounting

bracket Hex tool

Access

holes

Infeed fence

Outfeed fence

Loosen (4) socket head cap screws that secure infeed fence and slide

outfeed fence onto fence mounting bracket. Retighten mounting screws.

Notched end Flat cut end

1/4– 20 x 3/8"

socket head cap screws

Stainless steel

washer

1/4– 20

rectangular nuts

Outfeed carriage

Infeed carriage

Port assembly

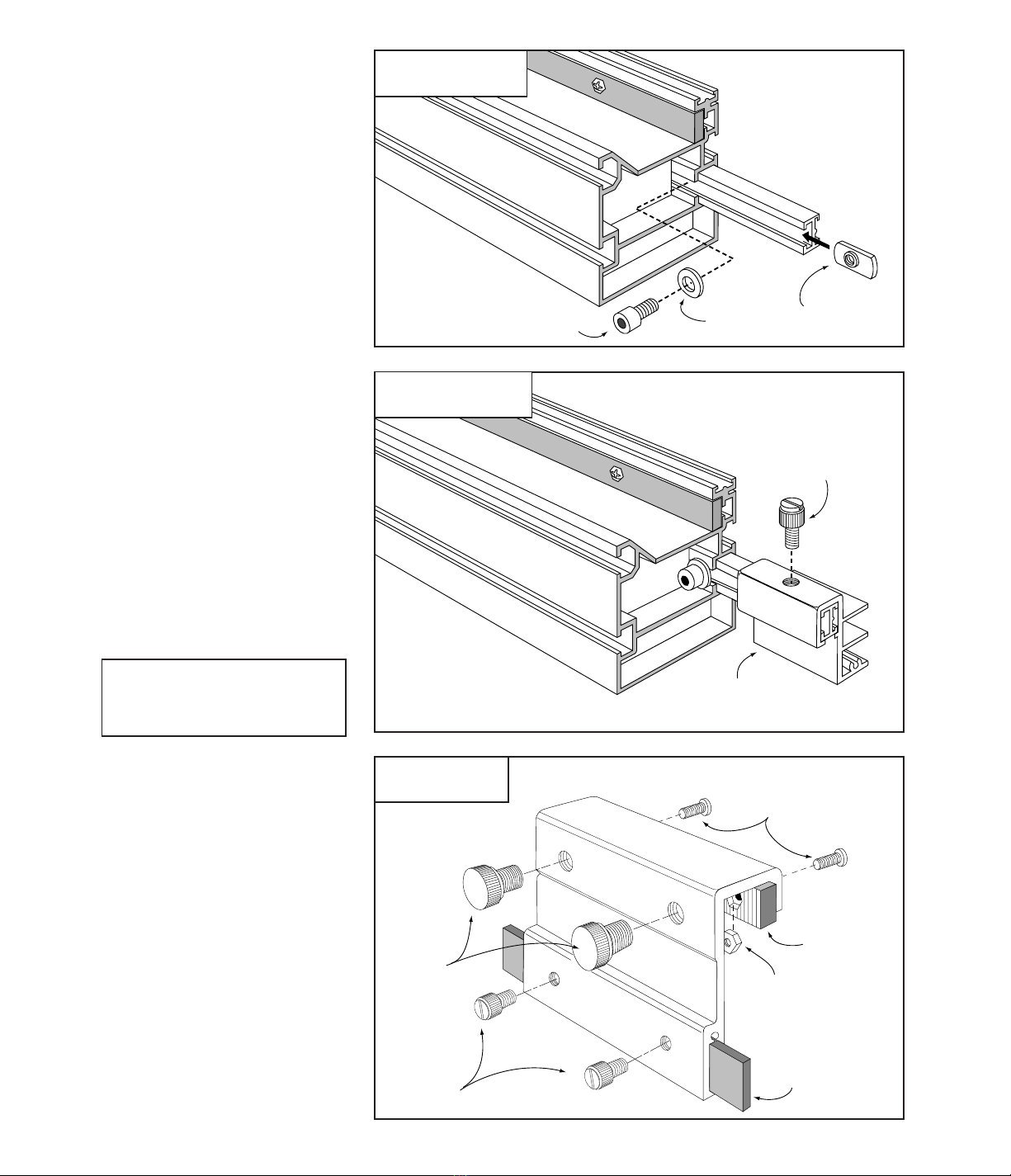

ACCESSORIES

Hi-Rise Fence Cap

Locate the (2) fence cap braces over

the threaded holes on top of the

fence mounting bracket and attach

with the 1⁄4-20 x 3⁄8" socket head

cap screws and washers from the

Hi-Rise hardware packet. Using the

(2) 10-32 x 1⁄2" phillips pan head

screws, nylon washers, and 10-32

hex nuts, attach the fence cap to the

two braces as shown in Fig. 6. The

slotted holes in the fence cap should

be aligned to provide access to the

front brace mounting screws. Use a

straightedge to align the leading

edge of the fence cap with the front

face of the infeed and outfeed fences

and tighten the two cap mounting

screws, Fig. 7. Though designed for

permanent residence on your INCRA

TWIN, you may prefer to take it off,

since it is not needed for most of the

things youʼll do with the TWIN. Just

remove the (4) socket head cap

screws and store the Hi-Rise

assembly for future use. Place the

fasteners back in the threaded holes

and tighten.

5

Fig. 6

Attach Hi-Rise fence cap

Fig. 7

Align fence cap with fence

The fence and Hi-Rise

fence cap provide the

low and high support

necessary for large

vertical panel work. If

you want to add an

auxiliary fence to

bridge the gap between

the two, use the drill

and counterbore

dimensions shown in

the illustration. Use

1⁄4– 20 x 3⁄4" machine

screws with washers

and hex nuts to attach

the auxiliary fence.

Hi-Rise fence cap

1/4– 20 x 3/8"

socket head cap screws

Nylon washer

Fence cap braces

10 – 32 hex nut

Stainless steel washer

Fence mounting

bracket

Threaded holes

Hi-Rise

fence cap

Straightedge

Fence

First: Place

straightedge

against fence

Second: Loosen screws

and slide fence cap to

straightedge. Retighten

screws.

Hi-Rise

fence cap

1/4– 20 x 3/4"

machine screw

Hex nut

captured in

T-slot

Fence

9/16" dia. x 3/8" deep counterbore

5/16" dia. through hole

7 15/32"

1 31/32"

10 – 32 x 1/2"

phillips pan head screw

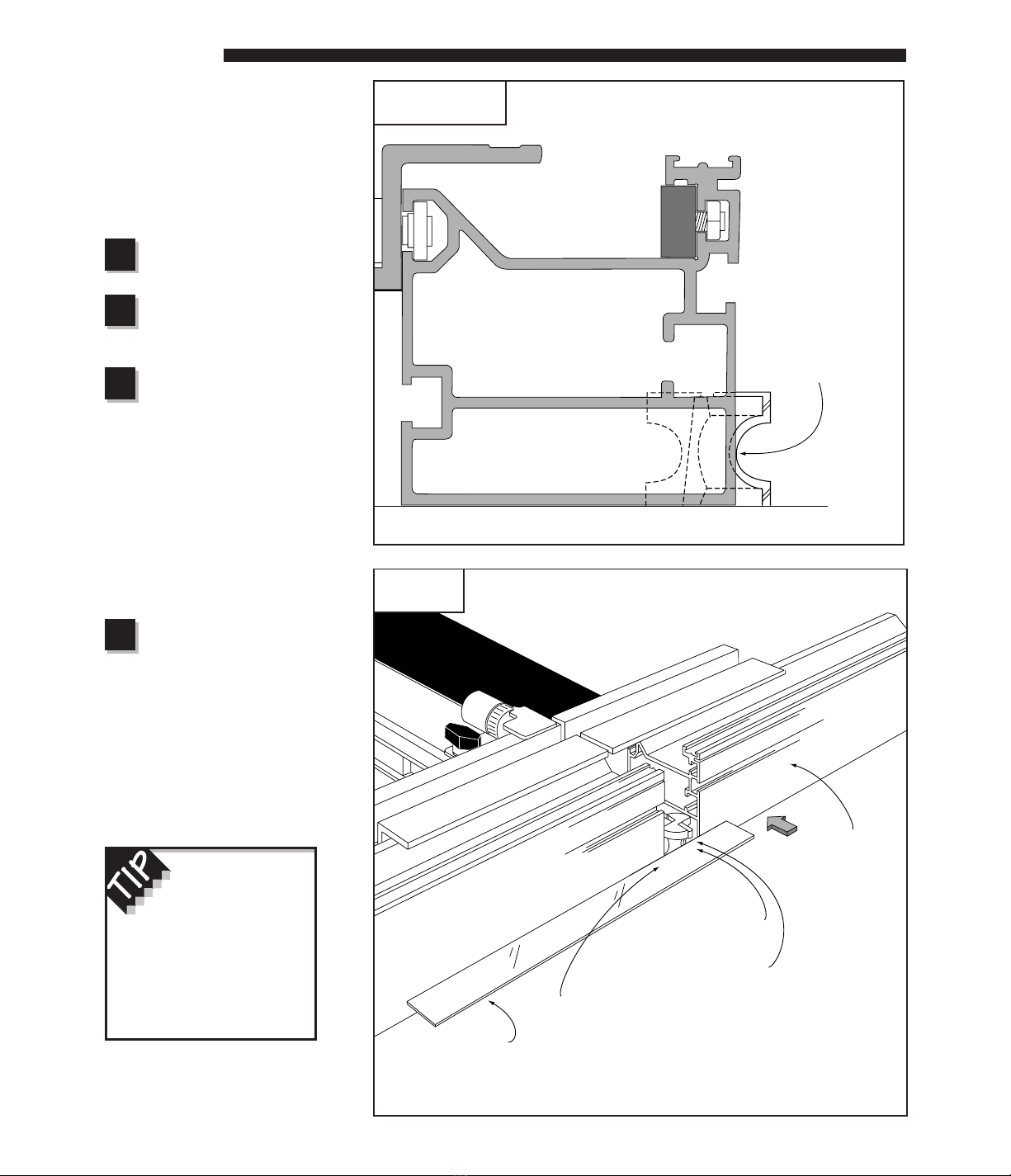

Installing Extender Bar

Hereʼs another accessory youʼll find

useful from time to time. The extender

bar will allow you to set its sliding stop

up to 16" beyond the end of either the

infeed or outfeed fence. Fig. 8 shows

the proper placement for the extender

bar. Insert the extender bar with the

scale facing forward and lock in place

with the 1⁄4-20 X 3⁄8" socket head

cap screw, stainless steel washer, and

rectangular nut as shown.

A second stop extender bar can be

purchased should you want to

increase the stop range beyond both

ends of your fence.

Extender Bar and Stop

Position the extender bar about 2"

beyond the fence end and using the

supplied 1⁄4"-20 X 1⁄2" nylon

thumbscrew, attach the extender bar

stop. See Fig 9. The stop can be

used on either end of the extender bar

to increase your stop range beyond

the ends of the fence. When not is

use, the stop can be turned around

and locked to the extender bar. This

storage position places the stop out of

the way, leaving the front face of the

fence uninterrupted for through cut

operations.

CAUTION: Never allow the

opposite end of the extender bar

to protrude into the cut area.

Incra Stop Assembly

Using the (2) 8-32 x 3/8" phillips

pan head screws and 8-32 hex

nuts, fasten the 4" long blue

INCRA rack to the INCRA Stop

and tighten the screws. Slide the

3/4" x 5" plastic strip into the slot

in the stop and secure with two

1/4"-20 x 1/2" nylon thumbscrews.

Thread the (2) 3/8"-16 x 1/2" nylon

thumbscrews into the INCRA

Stop. Fig.10. One or both of

these thumbscrews can be used

to clamp the INCRA Stop to the

fence. In use, the plastic strip

provides a non-metallic stop

surface which can be shaped for

special stop setups and can be

micro adjusted by loosening the

smaller thumbscrews.

6

Fig. 9

Attach extender bar stop

Fig. 10

Assemble INCRA Stop #8 – 32 x 3/8" phillips pan

head screws

1/4– 20 x 1/2"

nylon thumbscrews

3/8– 16 x 1/2"

nylon

thumbscrews

Plastic stop strip

INCRA rack

#8 – 32 hex nut

Fig. 8

Extender bar installation

1/4– 20 x 3/8"

socket head cap screw

Rectangular

nut

Stainless

steel washer

1/4– 20 x 1/2"

nylon thumbscrew

Extender bar stop

05

6

Zeroing INCRA Stop to the End of a Board

For most applications, you will be using your INCRA Stop on

the outfeed end of the INCRA Fence to control the length of a

cut relative to the front end of the board. Here is how to set

the initial scale position for this type of setup:

After installing the bit you wish to use, set the fence to

bit distance at about 1". Place a square cut piece of

scrap stock against the fence with the end of the board

against the infeed side of the bit. Turn the bit to find

the high spot.

Next, lock the INCRA Stop to the fence on the outfeed

side of the bit with the plastic stop strip as close as

possible to the end of the board. Adjust the position of

the stop strip until both the strip and the bit contact the

end of the board. Fig. 11.

You now have the choice of setting the sliding scale to

one of three initial positions:

In most cases, you will simply slide the scale to align

the 0" mark on the scale with the end of the INCRA

Stop nearest the bit. When set to this initial position,

the scale reading at any subsequent INCRA Stop

location will give you a direct readout of the total

length of the cut. (See Dimension “A”, Fig. 12.)

If you wish the subsequent scale readings to reflect

the distance from the front end of the board to the

center of the cut (Dimension “B”, Fig. 12), slide the

scale to an initial reading under the end of the INCRA

Stop equal to minus one half of the bit diameter.

Example:

If you are using a 1⁄2" diameter bit,

complete Steps 1 and 2 above then slide the scale to

read negative 1⁄4".

If you want the scale reading for future INCRA Stop

positions to reflect the distance between the end of

the board and the outfeed edge of the cutter

(Dimension “C”, Fig. 12), then slide the scale to an

initial reading equal to minus the bit diameter.

IMPORTANT: Some stop setups may require that some

portion of the fence scale be slid from the outfeed fence into

the infeed fence or visa versa. DO NOT offset the fence halves

with a scale in this position, as it may damage the scale.

7

Slide scale to 0" for a direct readout of Dimension “A”

Slide scale to “minus 1/2of the bit diameter” for a

direct readout of Dimension “B”

Slide scale to “minus diameter of the bit” for a direct

readout of Dimension “C”

C

Fig. 12

Initial scale

setting

Fig. 13

Dual stop

operations

B

A

Fig. 11

Top view of stop setup

First:

Slide the board up to contact

the “high spot” on the bit

Second:

Lock the INCRA

Stop to the fence

and adjust the

position of the

plastic stop strip

to contact the

end of the board

Third:

Slide the scale to read one of

the initial scale settings as

described in Fig. 12 below

INCRA

Stop

1

2

3

Dual INCRA Stop Operations

Using the same setup process described above and a

second INCRA Stop, you will find the precise positioning

of mortises on a board quite simple. The

INCRA Jig

Projects and Techniques Book

covers this technique fully

and includes several unique projects which feature dual

INCRA Stop operations. See Fig. 13.

A

B

A

C

A

6

-1

1

0

2

3

4

5

11

13

14

15

16

17

18

19

12

10

6

0

2

3

4

5

1

9

11

12

13

14

15

16

10

8

Fig. 14

Moving to any new scale setting

First:

Unlock carriage clamp

Second:

Slide fence as you view scale

through hairline cursor

Third:

Return clamp to

upright “locked”

position

OPERATION

8

Moving to a New

Scale Setting

Moving the fence to any new scale

setting is just as easy as moving any

other fence youʼve used before. Push

the carriage clamp down to unlock the

carriage, then slide the fence as you

sight through the hairline cursor.

When you see your measurement

under the hairline, pull the clamp back

up to the locked position, Fig. 14.

Remember that the INCRA TWIN will

only clamp every 1/32", so donʼt try to

clamp in between scale marks. It just

wonʼt work!

Although the clamping

pressure has been factory

adjusted, you may wish to

fine-tune the pressure to suit

your individual needs. If so, use

the thin plastic shims provided

and follow the instructions

shown on page 18.

CAUTION: For your safety, keep

your hands behind the fence

when moving to any new scale

position.

For more information on using

INCRA tools on the router table,

table saw and drill press,

pick up the

INCRA JIG Projects

and Techniques

, available from

you local INCRA dealer. This

148 page book contains detailed

plans with over 400 illustrations

and photos to build 14 of

Perry McDanielʼs intriguing

original projects.

Micro Adjusting

The micro adjust feature of your

INCRA TWIN allows for precise

positioning of the fence to any

location between the 1/32" tooth

spacing of the INCRA sawtoothed

racks. Youʼll find this feature

extremely handy the next time you

need to widen a mortise by a hair

for a great fitting mortise and tenon

joint. Use the micro adjuster for a

flawless fit when cutting grooves to

accept inlay strips or to loosen up a

tight-fitting box joint cut with an

undersized bit. Youʼll find it

especially useful for setup

operations like “zeroing” or

“centering”. Hereʼs a step-by-step

look at operating your INCRA

TWINʼs micro adjuster. See Fig. 15

as you follow the steps.

Pivot flip clip into

position under

carriage clamp

Micro adjustments are always made

with the carriage clamp halfway

between clamped and unclamped.

The spring-loaded flip clip will hold

the carriage clamp in this half-

clamped micro adjust mode position.

Use your right hand to quickly pivot it

in or out as necessary.

Unlock the carriage clamp

With the flip clip in place, the carriage clamp will

automatically spring to the micro adjust mode.

Micro adjust the fence position

Rotate the knob with the red dial located at the rear

end of the outfeed (gold) carriage. Turn the micro adjust

knob clockwise to move the fence toward the cutter, or

counterclockwise to move the fence away from the cutter.

Lock the carriage clamp

Pull the carriage clamp up to lock the carriage in

place, then pivot the flip clip back to its original position.

Gauging the distance moved when micro adjusting is easy.

A full turn of the knob equals 1/32" of movement, a half turn

equals 1/64". For smaller adjustments, the red dial is marked

in 1/1000" increments. After micro adjusting you can re-zero

the dial to the pointer by rotating the dial (not the knob) with

your fingers. See Fig. 16.

The micro adjust feature of the INCRA TWIN has an

adjustment range of +1/4" from mid-range. The range scale

decal on the carriage shows how much range remains in

either direction. To read the scale, just sight along the end of

the gold bar that overlaps the decal. Fig. 16.

9

NOTE

Do not continue to turn the micro adjust knob counterclockwise beyond the

minus

1

⁄

4

" range shown on the decal. If the knob is unscrewed beyond this

point, factory reinstallation may be required.

To avoid running out of micro adjustment

range in the middle of a project, you want to

remember two things: First, always micro adjust

back to mid-range before beginning a new project.

Second, whenever you need to micro adjust a

distance greater than 1⁄32", use the INCRA positioning

racks to get as close as possible before reaching for

the micro adjust knob.

6

0

Range

Scale

2

30

28

26

4

0

28

26

30

2

6

4

Fig. 16

Micro-adjust scale

Use the scale on the red dial

to accurately gauge the

distance moved. After micro

adjusting, dial can be

rotated to read zero

Gold bar Pointer

Range scale

0

30

2

Fig. 15

Micro adjusting

First:

Pivot flip clip into

position under

carriage clamp

Second:

Unlock carriage clamp Third:

Turn micro adjust knob

Fourth:

Lock carriage clamp

and return flip clip to

original position

Flip clip

Red micro

adjust

knob

2

3

4

1

Offset Adjustment

The infeed and outfeed fences of your INCRA TWIN

can be moved independently in two directions to

provide a variety of setup configurations. By making

the offset adjustments described below, you can

position the fences “in-line” for standard cutting

operations such as grooving, rabbeting, and joint-

making. You can “offset” the infeed and outfeed fences

for specialty cutting applications such as shaping or

jointing an edge.

Infeed Fence Adjustment

Though the INCRA TWIN design provides for both infeed

and outfeed fence adjustments, the infeed fence adjustment

is by far the more important of the two. In fact, all offset

fence operations can be set by adjusting only the infeed

fence and, since it is the easier of the two adjustments, this

is the adjustment you should memorize. See Fig. 17 as

you read through the steps.

Pivot flip clip into micro adjust position

Unlock the carriage clamp

With the flip clip in place, the carriage clamp will

automatically spring to the micro adjust mode.

Loosen the forward black thumbscrew

The thumbscrew is located at the forward end of the

outfeed (gold) carriage. It serves as a lock between the

infeed and outfeed carriages and must always be loosened

to make an offset adjustment. Loosen the thumbscrew

about 1/2turn.

Tighten the forward black thumbscrew

Tighten the thumbscrew loosened in Step 3. This

locks the infeed and outfeed carriages together.

Lock the carriage clamp back in place

Pull the carriage clamp up to lock the carriage in

place, then pivot the flip clip back to its original position.

Fig. 17

Infeed fence adjustment

Micro adjust the infeed fence position

Rotate the knob with the black dial (located at

the forward end of the carriage Turn the knob clockwise

to move the infeed fence backward. Once again, the

knob is calibrated so that one full turn equals 1/32" of

movement, 1/2turn equals 1/64" and, for smaller

adjustments, the knob is marked in 1/1000" increments.

To move the infeed fence forward, rotate the knob

counterclockwise as you pull forward on the infeed

fence. The infeed fence will not move forward by simply

turning the knob. You must pull the fence forward as the

knob is turned.

10

FACT:

Rotating the knob with

the black dial micro

adjusts the infeed (black)

carriage and its attached

fence, not the outfeed

fence. Because the knob

is located behind the

outfeed fence, it may

seem like the outfeed

fence is moving, but itʼs

not. Just remember

this: The knob with the

black dial adjusts the

fence with the black

carriage. Black dial,

black carriage.

Knob with black dial

adjusts black carriage

First:

Pivot flip clip

under carriage

clamp

Second:

Unlock carriage clamp

Third:

Loosen black thumbscrew 1⁄2turn

Fourth:

Turn knob with black dial

Fifth:

Retighten thumbscrew

Sixth:

Lock carriage clamp

2

3

4

1

When attaching an infeed zero clearance

subfence as described on page 12, you will

move the infeed fence backward as much as 3/4".

Instead of turning the micro adjust knob, simply

slide the fence backward the necessary distance.

5

6

Forward black

thumbscrew

Infeed fence

Tighten the forward black thumbscrew

Tighten the thumbscrew located at the forward end

of the outfeed gold carriage. This locks the infeed and

outfeed carriages together.

Lock the carriage clamp in place

Pull the carriage clamp up to lock the carriage in

place and pivot the flip clip back to its original position.

Loosen the rear black thumbscrew next

to the hairline cursor.

11

Outfeed Fence Adjustment

Most offset fence operations can be accomplished with an

infeed fence adjustment, but on occasion you may wish to

fine-tune the outfeed fence without altering the infeed

fence position. Hereʼs how it is done. See Fig. 18 as you

read the steps.

Tighten the rear black thumbscrew

Itʼs located next to the hairline cursor. This

thumbscrew locks the position of the infeed carriage.

Place carriage clamp in micro adjust

mode and loosen forward black

thumbscrew

Pivot the flip clip under the carriage clamp and unlock the

clamp. Now loosen the black thumbscrew located at the

forward end of the outfeed (gold) carriage.

Micro adjust the outfeed fence position

Set the red dial on the micro adjust knob located at

the rear end of the outfeed (gold) carriage to read zero.

Rotate the knob clockwise to move the outfeed fence

forward. If you find it necessary to micro adjust the fence

backward from the original zero scale reading you must

rotate both micro adjust knobs (black and red)

counterclockwise by the same amount.

2

3

4

1

Fig. 18

Outfeed fence adjustment

First:

Tighten rear black thumbscrew

Second:

Place carriage clamp in micro

adjust mode and loosen forward

black thumbscrew

Third:

Turn knob with

red dial

Fourth:

Tighten forward black thumbscrew

Fifth:

Lock carriage clamp

Sixth:

Loosen rear black thumbscrew

5

6

Rear black thumbscrew

Forward black

thumbscrew

Zero Clearance Subfence

The large fence offset range offered by the TWINʼS dual

carriage design provides an interesting approach to the use

of zero clearance subfences. Typically a zero clearance

subfence is a long piece of wood with the profile of a

particular router bit band sawn into the face. When attached

to the router table fence and moved into position the router

bit nestles into the cutout. This close fit around the router bit

provides both additional support and tearout protection for

the boards to be cut. By offsetting the TWINʼS infeed fence

an amount equal to the thickness of the subfence you can

quickly produce an infeed only subfence that offers perfect

tearout control and infeed support. Hereʼs how:

Prepare subfence blank

Begin with a smooth flat piece of wood 3/4" thick x 3"

wide x 16" long. I prefer medium density fiberboard. Itʼs

inexpensive and usually pretty flat. I donʼt recommend

plywood because it splinters too easily. Drill and

counterbore the subfence using the dimensions shown in

Fig. 21.

Adjust th fence gap

Install the cutter in your router and set the fence gap.

(see Gap Adjustment section above) so that the fence ends

are no closer than 1/8" from the cutter.

Offset infeed fence

Move the fence away from the cutter and offset the

infeed fence about 3/4" behind the outfeed fence (Fig. 22) on

the next page. Note: An infeed offset of 3/4" will move the

black adjustment knob beyond its working range, so instead of

turning the knob as described in Step 4 on page 10, just slide

the infeed carriage back by hand.

Gap Adjustment

Follow these steps to adjust the opening between the

infeed and outfeed fences (See Fig. 19)

Caution: When adjusting the fence opening or

gap, never position the aluminum fence ends

closer than 1/8” from the router bit.

Using the supplied hex tool, loosen the

(4) socket head cap screws that hold the

fences to the fence mounting bracket.

Open or close the fence gap by sliding

each fence to the desired position

Tighten the fence mounting screws

12

2

3

1

See Tip on page 4 for fence mounting

options to consider when adjusting the gap

in the fence.

Fig. 19

Adjusting the fence gap

First:

Loosen (4) socket head cap

screws through access holes

in fence mounting bracket

Second:

Adjust gap

Third:

Tighten fence mounting screws

Fig. 20

Zero clearance subfence on infeed fence

2

3

1

Fig. 21

Subfence dimensions

4" 16"

8"

4" 3"

1 31/32"

3/4"

Hex tool

Access holes

Fence

mounting

bracket

5/16" through hole with

3/4" dia. x 3/8"deep

counterbore

13

Attach subfence to infeed fence

Place the (2) 1/4- 20 x 3/4" socket head cap screws

with washers through the holes in the subfence and loosely

attach the 1/4- 20 rectangular nuts. (Fasteners supplied in

the auxiliary fence hardware pack) Slide the subfence onto

the infeed fence so the fasteners are captured in the T-slots.

Move the subfence forward until stopped by the outfeed

fence and tighten the fasteners, Fig. 23. Now fine-tune the

fence offset so that the subfence is flush with the outfeed

fence. Always make sure to tighten the black thumbscrew

that ties the two carriages together after making any offset

adjustment.

Position fence for initial profiling cut

Loosen the mounting screws that secure the

subfence about 1/2turn and slide the subfence back away

from the outfeed fence. Move the TWINʼS fence up to the

cutter and position it so the rear face of the subfence is in

line with the approximate center of the cutter. See

overhead view, Fig. 24.

Make the profiling cuts

Turn on the router and using a good rubber soled push

block advance the subfence forward into the cut. When the

subfence touches the outfeed fence, back the subfence out of

the cut and turn off the router. Unlock the carriage clamp and

move the Twinʼs fence back about 1/8". Relock the clamp,

then repeat the cut. Continue this process until you have cut

completely through the subfence.

Slide the subfence into final position

Now you can slide the completed subfence into its

final position on the infeed fence and tighten the mounting

screws. Final positioning should always be done with the

router turned off and the carriage clamp locked.

CAUTION: The nature of zero clearance places the

subfence very close to the cutter. NEVER attempt to

move your fence or make any adjustments to the setup

until the router bit has come to a complete stop.

5

6

7

If you want to add zero clearance to the

outfeed fence as well, make two of the

subfences as described above. Make the profiling

cuts on both pieces from the infeed side. NEVER

make the profiling cut by sliding the subfence into the

cut from the outfeed side.

When cutting what will later become the outfeed

subfence, either drill and counterbore after completing

the profiling cuts, or make sure the counterbore faces

the infeed fence during the cut. The end of the

subfences above the profile will need to be trimmed

off so they can close around the cutter.

4Fig. 22

Offset infeed fence

3/4"

Fig. 23

Attach subfence to infeed fence

1/4– 20 x 3/4"

socket head cap screw

1/4– 20

rectangular nut

Fig. 24

Position fence

for initial

profiling cut

Stainless steel washer

Rear face of

subfence in

line with

approx. center

of cutter

14

With the infeed and outfeed fences set in-line, your INCRA

TWIN can be used for a variety of typical fence applications

including grooving and dadoing, as well as edge forming

operations such as rabbeting, chamfering, and roundovers.

Youʼll also find the in-line position useful for many specialty

operations. With the Hi-Rise fence cap in place, youʼll be

able to use vertical panel raising bits to make raised panels

for cabinetry, and since its design is compatible with all

INCRA joint-making accessories, youʼll be able to cut

countless varieties of box joints and dovetails.

IN-LINE FENCE APPLICATIONS

Fig. 25

General purpose fence

General Purpose Fence

The essence of any INCRA JIG is its ability to accurately

position your board for a cutting operation. In a nutshell, it is

a precision fence system. Even when used as a joint maker,

the fact is that you are simply applying a particular method of

work to a very accurate fence system to produce the many

possible joints. Above all else, the INCRA TWIN gives you

the ability to make a cut exactly where you want it.

Using the TWIN as a general purpose fence is just as easy

as using any other fence in your shop. In fact, it shares in

common four things that all fences have: the straight edge or

fence that your board will be pushed along as you make a

cut, a scale, a hairline cursor, and a clamp. You will use your

INCRA fence as you would any fence. That is, first youʼll

unclamp the carriage clamp then youʼll look through the

hairline cursor as you move the fence. When you see your

measurement come under the hairline, youʼll clamp the

fence in place.

Of course, this is where the comparison ends, because unlike

other fences, when you clamp the TWIN in place, it is exactly

where you want it to be. Just get the mark on the scale close

to the hairline cursor and the Automatic Positioning Control of

the patented INCRA sawtoothed racks moves the fence to the

exact location as you pull the carriage clamp up to lock the jig

in place. It really is that easy. Youʼre sure to find many cutting

situations in the shop where the precision of the TWIN will

benefit you and your work.

“Zeroing” the Fence to Your Router Bit

In order to ensure accurate cutting results from any fence for

general purpose routing, the fence must first be “zeroed” to

the cutter. To zero your INCRA TWIN, unlock the carriage

clamp and slide the fence up to the edge of the cutter. Sight

down the length of the fence to check for a gap between the

fence and the cutter. Fine-tune any remaining distance by

micro adjusting the fence position. When the gap of light

disappears, the cutter will be “zero” distance from the fence.

Check to make sure that the router bit is safely centered in

the opening in the fence. Return the carriage clamp to the

locked position, then slide the 1/32" scale to read 0" under the

hairline cursor.

Fig. 26

Zeroing the fence to the cutter

For a truly precise “zeroed” setup, follow the

instructions above, then move the fence to a scale

reading of 1/4" and make a test cut on a piece of

scrap stock. (Make sure the scrap stock has a

square edge and that this edge is against the

fence during the cut.) Use a pair of machinist

calipers to measure the distance between the

groove and the edge of the board. If it does not

measure exactly .250", just use the micro adjuster

to accurately fine-tune the remaining distance.

Micro adjust fence until

gap of light between

fence and cutter

disappears

After positioning the fence at zero

distance from the cutter, slide the scale

to read 0" under the hairline cursor

15

Safety Reminder

❐Whenever using large diameter vertical or horizontal panel raising bits

or any other large diameter bit, always follow that router bit

manufacturerʼs operation and safety recommendations.

❐Whenever it is necessary to remove large amounts of stock, always

use multiple side-by-side passes to achieve the final cut. Several

shallow cuts are safer and will yield better results.

Vertical Panel Raising

The introduction of the vertical panel

raising bit has made cutting this all-

important component of frame and panel

construction a relatively simple operation

for the router table. Youʼll find your

INCRA TWIN with its built-in dust

collection, adjustable fence gap, and

Hi-Rise fence cap perfect for this

operation. The setup is as follows:

Install vertical panel

raising bit and set

appropriate depth of cut

Adjust fence gap as

necessary

See gap adjustment on page 12.

Attach the Hi-Rise fence

cap

Use a straightedge to adjust the cap in

line with the front of the fence. (see

Fig. 6 on page 5.)

Sneak up on the final

width of the cut

Do not make the full width of the cut in a

single pass. Instead, use several light

side-by-side passes, moving the fence

back 1/16" or so after each pass.

Fig. 27

Vertical panel raising

4

2

3

1

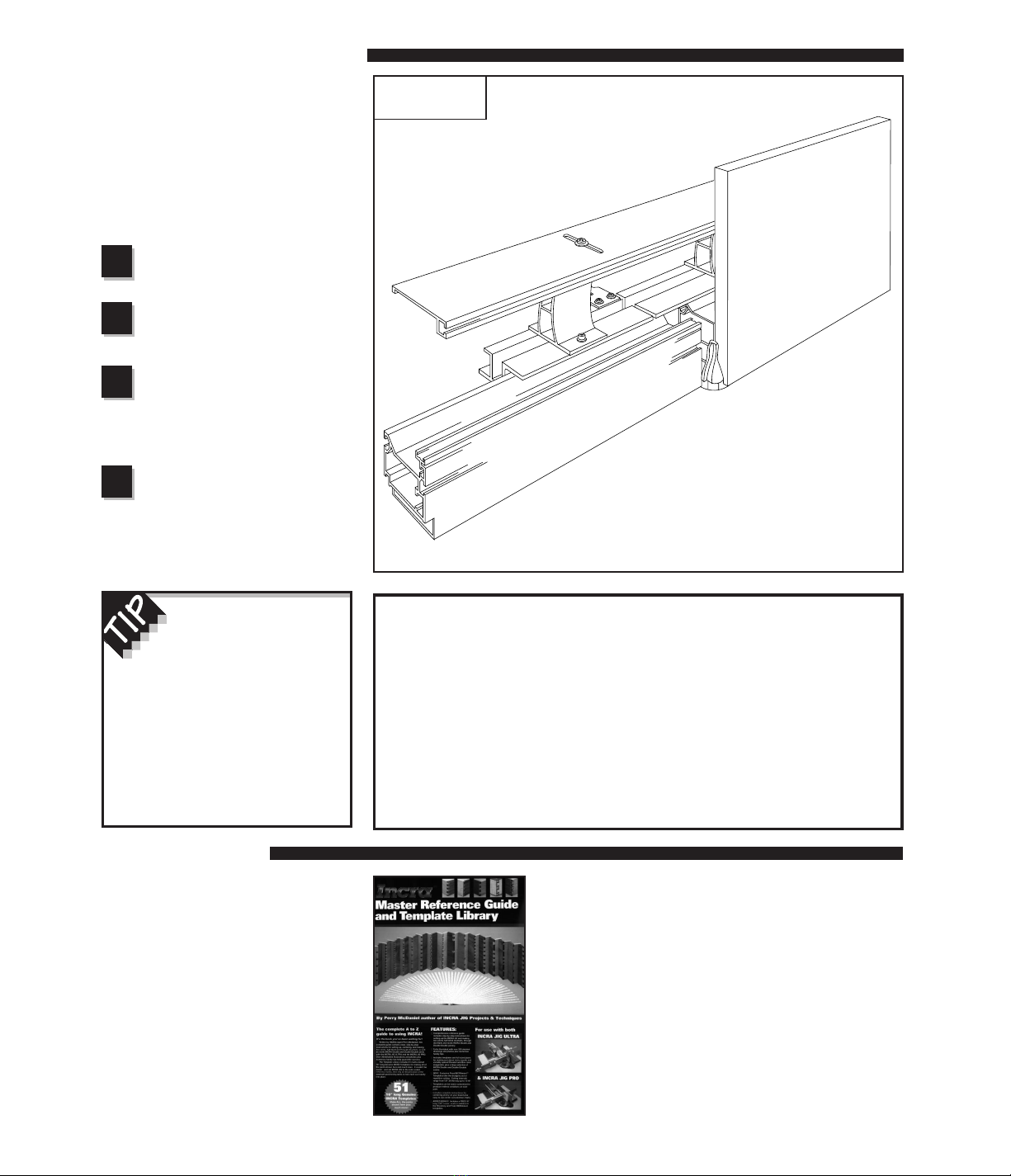

Joint Making

Joint making represents one of the

most exciting applications for your

INCRA TWIN. Just by applying a little

technique to the accuracy of the TWIN,

youʼll be able to add joinery for box

and drawer making to your list of shop

skills. The INCRA

Master Reference

Guide & Template Library

included in

the INCRA TWIN system package is a

complete source book for joinery,

including step-by-step instructions for

box joints, half-blind dovetails, through

dovetails, the INCRA double dovetail

and the double-double box joint.

A zero clearance

subfence will greatly reduce

tearout and increase support

for all cutting operations. See

page 12 for information on how to

make and use this handy item. To

use the fence cap in conjunction

with a zero clearance subfence,

mount the cap upside down with

the T-slot still facing forward.

16

Jointing

Most woodworking projects require

that your boards begin with at least

one straight edge. This one edge

then becomes the reference surface

for subsequent perpendicular or

parallel cuts. By using your INCRA

TWIN and the setup described below,

youʼll be able to put a perfectly

straight edge on your board at the

router table, and because of the

higher RPM of the router, youʼll find

the freshly jointed edge far smoother

than any jointer machine can produce.

Install a straight bit

Install a 1/2" diameter (or larger)

straight bit and set the depth of cut to

slightly greater than the thickness of

your stock.

Adjust fence gap as

necessary

See Gap Adjustment on page 12.

Set initial fence

position

Unlock the carriage clamp and slide

the fence up to the cutter. Adjust the

location of the fence to position the

outfeed fence in line with the

outermost cutting arc of the router bit.

A straightedge placed against the

outfeed fence can be used to help

align the fence with the cutter, see

Fig. 28.

Offset infeed fence

Set the desired infeed fence

offset by adjusting the infeed fence

backward. (See Infeed Fence

Adjustment on page 10.) Moving

the infeed fence back about .015"

(1/2turn clockwise with the black

micro adjust knob) should produce a

smooth cut.

OFFSET FENCE APPLICATIONS

4

2

3

1

Fig. 28

Jointing

One of the most valuable features of

the INCRA TWIN LINEAR is the ability

to offset the infeed and outfeed

fences. The offset fence adds a whole

new dimension to the router table,

allowing it to perform two new

operations: jointing and shaping.

First:

Install 1/2" dia. or larger straight bit

Second:

Adjust fence gap as necessary

Straightedge

Third:

Position TWIN to align fence with

the cutting wing on the router bit

Fourth:

Offset infeed

fence backward

about .015"

(1/64")

17

Shaping

Many shaping operations involve

the removal of the entire edge of a

square piece of stock as it is

moved past the cutter. With a

careful offset fence setup, a

shaping operation can

simultaneously straighten or joint

the shaped edge. Hereʼs how:

Install router bit

Set desired depth of cut

Adjust fence gap as

necessary

See Gap Adjustment on page 12.

Set initial fence

position

Unlock the carriage clamp and

slide the fence up to the cutter.

Adjust the location of the fence to

position the outfeed fence in line

with the outermost cutting arc of

the smallest diameter on the cutter,

Fig. 29. A thin straightedge held

against the outfeed fence can be

used to help align the fence with

the smallest diameter of the cutter.

Fig. 30

Set the desired fence

offset

Set the desired fence offset by

adjusting the infeed fence

backward. (See Infeed Fence

Adjustment on page 10.) Moving

the infeed fence back about .015”

(1/2turn clockwise with the black

micro adjust knob) should produce

a smooth cut.

4

2

3

1

Fig. 29

Set initial fence position

Fig. 30

Shaping

See page 12 for

information on how

to make a zero

clearance subfence

for your shaping

operations.

Align outfeed

fence with the

smallest diameter

on the cutter

Third:

Position TWIN to align with smallest diameter on the cutter

Fourth:

Offset infeed fence

backward about

.015" ( 1/64")

Thin straightedge

Note: View from outfeed side of table

First:

Install router bit

Second:

Adjust fence gap as necessary

18

ADJUSTMENTS

All of the components and features of

your new INCRA TWIN LINEAR have

been factory set and should require no

further attention. If, however, you wish

to adjust or recalibrate these

components, the following information

is provided to assist in performing the

adjustments.

NOTE

The INCRA TWINʼs base must be attached to the router

table with all eight mounting screws (see Fig. 3 on page 4.)

before adjusting the clamping pressure.

The INCRA TWIN LINEAR carriage

clamp was designed to make it easy

for the operator to adjust the clamping

pressure to his own individual

preferences using the supplied clamp

pad shims. Hereʼs how:

Unlock the carriage clamp. Remove

the small phillips head screw, washer,

and “L” shaped plastic clamp pad

retainer located just to the right of the

clamp (see Fig. 31). Leave the hex

nut in place in the T-slot below. Your

ownerʼs manual hardware pack

contains (3) .005 X 7/8" x 4" clamp

pad shims. If you want to increase

the clamping pressure, add one of the

shims into the clamp pad slot shown

in Fig. 32. Check the clamping

pressure and adjust further as

necessary. The shims should be

placed to the left of the 1/8" clamp pad

shown in Fig. 32 so that the clamp

always touches the 1/8" pad, not the

shims. To decrease the clamping

pressure, remove one of the existing

thin shims. When you are satisfied

with the clamping pressure, replace

the plastic clamp pad retainer and

secure with the screw and washer.

The screw is long enough to start into

the hex nut without removing the nut

from the T-slot.

CAUTION: Whenever making

clamping pressure adjustments,

always make sure that

adequate pressure remains to

hold the carriage rigidly in

place when clamped in the fully

extended position.

Fig. 31

Clamp pad retainer removal

Carriage clamp

unlocked

Fig. 32

Adjusting the clamping pressure

Add or remove shims to

the left of 1/8" clamp pad

Carriage not shown for clarity

1/8" clamp pad

Adjusting the Clamping Pressure

Clamp pad retainer

19

On the side of the outfeed (gold) carriage youʼll notice (4)

sawtoothed INCRA racks. To realign these racks, loosen

the phillips head screws that hold the forward (3) racks in

place. Do not loosen the screws on the rack at the rear

end of the carriage. Position the carriage in the base so

that when the carriage clamp is pulled up into the locked

position, the short clamping rack bridges the gap between

the already tightened rear rack and the second rack. See

Fig. 33. Tighten the one mounting screw you have access

to. Then unlock the carriage clamp and slide the carriage

Fig. 33

Realigning carriage racks

forward to tighten the other screw. Continue with this

bridging and tightening operation between racks #2 and

#3, then finally between #3 and #4.

Realign the fence racks in the same way that the

carriage racks are aligned. Leave one of the two racks

on each fence in place while loosening the screws on the

other. Bridge the gap between the loosened and

tightened racks using the INCRA Stop, then tighten the

two screws on the loose rack.

Loosen the (4) socket head cap screws that secure the

infeed fence mounting bracket to the infeed (black)

carriage, Fig. 34. Using a reliable straightedge, hold both

the infeed and outfeed fences against the straightedge and

tighten the (4) screws a little at a time until all are secure.

Adjusting the fences square to the table is done by

loosening the same (4) socket head cap screws and

placing shims between the fence mounting bracket and

carriage. Fence squaring adjustments may be performed

as necessary to one or both fences.

First:

Loosen screws on forward 3 racks

Second:

Position carriage so that short clamping rack bridges

ends of rear and second rack, then clamp in place

Approx. 5/16"

Do not loosen screws on rear rack

Fig. 34

Realigning

infeed and

outfeed fences

Infeed fence

Loosen (4)

socket head cap

screws on infeed

fence mounting

bracket

Realigning the Carriage and Fence Racks

Realigning Infeed and Outfeed Fences

NOTE

Before realignment, make sure to remove any offset

that may exist between the infeed and outfeed

fences and lock the carriage clamp in place.

Third:

Tighten screw then reposition

carriage to tighten other screw

Fourth:

Repeat bridging and tightening

operation for remaining racks

Use a reliable

straight edge

to realign

infeed fence

to outfeed

fence

Outfeed fence

20

Made in the U.S.A.

Taylor Design Group, Inc. • P.O. Box 810262 • Dallas, TX 75381

© 1997, Taylor Design Group, Inc. INCRA is a registered trademark of Taylor Design Group, Inc. 0997

PARTS AND OPTIONAL ACCESSORIES

PRODUCT INFORMATION

For a product information update on the complete Incra line

of tools, please see your nearest dealer. If you are unable to

locate a store nearby, or if you have trouble finding a

particular product, we will honor your order directly.

For a product information brochure, call, write or fax to:

Taylor Design Group, Inc.

P.O. Box 810262, Dallas, TX 75381

Tel: (972) 418-4811 Fax: (972) 243-4277

Web Site: www.incra.com

WARRANTY

Taylor Design Group, Inc. warrants this product for one year from date of purchase. We will repair any defects due

to faulty material or workmanship, or at our option, replace the product free of charge. Please return the failing

component only, postage prepaid, along with a description of the problem to the address below. This warranty does

not apply to parts which have been subjected to improper use, alteration, or abuse.

LIFETIME WARRANTY ON POSITIONING RACKS

If an Incra positioning rack in this tool becomes damaged for ANY reason, Taylor Design Group will replace it free of

charge for as long as you own your tool. Return the damaged rack, postage prepaid, and allow 1 to 2 weeks for delivery.

NOTE:

Replacement parts cannot be sent unless damaged racks have been received by Taylor Design Group.

Part # Part Description Price

TL-CURSOR Hairline Cursor (with mounting hardware) $ 7.95

ISTOP Stop Positioner (with mounting hardware) $22.95

IEXT18 18" Stop Extender Bar with auxiliary stop, scale and hardware $15.95

IJPT1

Incra Jig Projects & Techniques Book

$22.95

Features 14 original Incra projects, 4 exclusive new Incra joints,

and a wealth of tips and techniques that will help you master the Incra Jig

TL-SCALE16 16" long 1⁄32" Lexan®floating scale $ 2.95

TL-SCALE21 21" stainless steel primary scale $ 9.95

TL-SCALE31 31" stainless steel primary scale $14.95

Taylor Design Group, Inc.

P.O. Box 810262, Dallas, Texas 75381

Tel: (972) 242-9975 Fax: (972) 242-9985

www.incra.com

Table of contents

Other Incra Tools manuals

Popular Tools manuals by other brands

BGS technic

BGS technic 8716 instruction manual

Berner

Berner Tornador BPT-TG B011 instruction manual

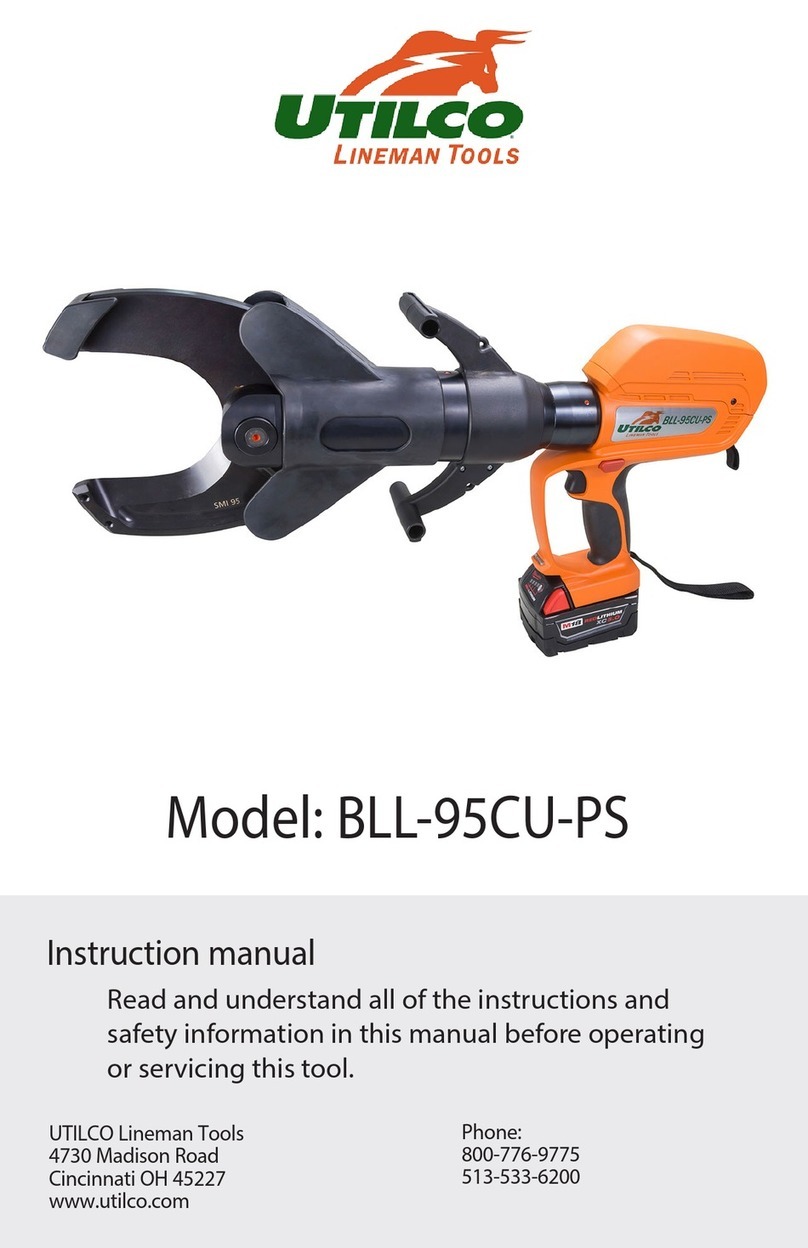

UTILCO

UTILCO UtilPro BLL-95CU-PS instruction manual

Schill

Schill FT 260 Installation and operating instruction

Harbor Freight Tools

Harbor Freight Tools 95878 Assembly and operation instructions

Cornwell Tools

Cornwell Tools blue POWER CAT851XLR operating instructions