Page 2

INCRA PUSHGUARD OWNER’S MANUAL

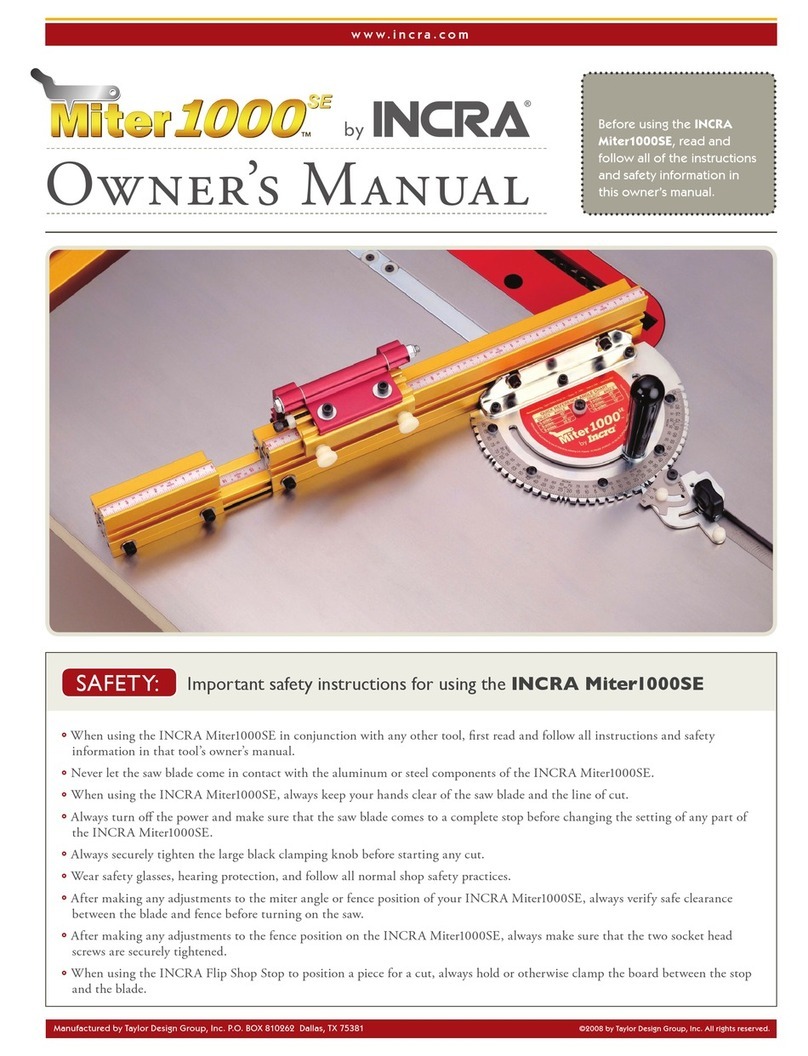

Fig. 2 Attach Deector Shield

Deector

Shield

OPER ATION

Attach Deflector Shield

Use ONLY the washers, screws,hex nuts and rectangular

nuts supplied with this product during assembly. DO

NOT use substitutes. Add a lock washer followed by a

flat washer to each of the (2) 1/4-20 x 1-1/2” Phillips Pan

Head screws and insert into the holes located on the

top of the Hand Guard, Fig 2. Loosely thread a 1/4-20

rectangular nut onto each of the fasteners. The raised

rim around the hole on the rectangular nuts should

be facing up. Now slide the Deflector Shield between

the rectangular nut and the underside of the recess in

the Hand Guard. Tighten the fasteners to secure the

Deflector Shield.

To Remove the Deflector Shield

The Deflector Shield is designed for use during free-form

edge cuts made using bearing or template guided router

bits. If you are performing more common cuts using a

fence system, the Deflector Shield should be removed.

Just loosen the (2) Phillips Pan Head screws and slide

the Deflector Shield off, Fig 3. Always securely

re-tighten the fasteners before making any

cuts.

Fig. 3 Removing Deector Shield

Loosen

Phillips

Screws

Slide Deector Shield Off

Then Re-tighten Fasteners

1/4-20 Rectangular Nut

Common Fence Guided Cuts

For fence guided cuts, the Deflector Shield should be

removed. ALWAYS CONFIRM YOUR SAFE

CUTTING ROUTINES! With the router turned off

and the bit below the table surface, perform a “dry run”

with your workpiece to make sure you are comfortable

with the routine and your safety equipment usage

before making any cuts. Leave space between the fence

and PushGuard to avoid drag and provide clearance for

your cutter guard.

Free-form Cutting with Bearing and Template

Guided Cutters

For this type of cut the addition of the Deflector Shield

provides additional eye protection from chips generated

during the cut. You should still always wear

Safety glasses and again, confirm your safe

cutting routines. Perform a dry run to make

sure that the Deflector Shield safely clears

the cutter.

1/4-20 x 1-1/2”

Phillips Pan Head

1/4” Split Lock

Washer

1/4” Washer

MADE IN THE

USA

Manufactured by:

Taylor Design Group, Inc.

P.O. Box 810262 Dallas, TX 75381

www.incra.com

P: 972-242-9975/F: 972-242-9985

INCRA is a Registered Trademark of Taylor Design Group, Inc.

You can also register your INCRA product

online at www.incra.com

Scan this QR code to register your product online

It’s quick and easy!

ONLINE WARRANTY REGISTRATION