Indel GIN-AX4 User manual

Hardware Manual

Indel motion boards

Made in Switzerland

Rev 1.31 © Indel AG, 04/11/2013

Language: English

Table of contents Indel motion boards

Tabel of contents

1 Description ....................................................................................................................4

1.1 Position controller..........................................................................................................................4

1.2 Assembly groups............................................................................................................................5

2 Safety notes ...................................................................................................................6

2.1 General safety notes......................................................................................................................6

2.2 Safety requirements.......................................................................................................................7

2.2.1 Risk analysis.....................................................................................................................................7

2.2.2 24V DC power supply.......................................................................................................................8

2.2.3 48V DC power supply (motor supply)..............................................................................................8

2.2.4 EMV..................................................................................................................................................8

2.2.5 Commissioning.................................................................................................................................8

2.2.6 Intended use.....................................................................................................................................8

2.2.7 Plug-in connections..........................................................................................................................9

2.2.8 Responsibility...................................................................................................................................9

3 Technical details ..........................................................................................................10

3.1 Technical details for motion boards...........................................................................................10

3.2 Technical details for connector boards......................................................................................17

3.2.1 MAX-DBIT......................................................................................................................................17

3.2.2 MAX-DBMT....................................................................................................................................18

3.3 Dimensions, pin assignment.......................................................................................................19

3.3.1 Dimensions of AX4.........................................................................................................................19

3.3.2 Pin arrangement for AX4 board......................................................................................................20

3.3.3 Pin assignment for digital inputs and outputs in AX4.....................................................................21

3.3.4 Pin assignment for supplies and interfaces in AX4........................................................................22

3.3.5 Pin assignment for AX4 encoder systems.....................................................................................23

3.3.6 Pin assignment for motors in AX4..................................................................................................26

3.3.7 Dimensions of MAX boards............................................................................................................28

3.3.8 Pin assignment for MAX-2,4...........................................................................................................35

3.3.9 Pin assignment for MAX-2..............................................................................................................36

3.3.10 Pin assignment for MAX-4..............................................................................................................37

3.3.11 Supplies to MAX boards.................................................................................................................38

4 Serial interface ............................................................................................................39

5 Connection examples..................................................................................................40

5.1 Motors on MAX2 board................................................................................................................40

5.2 Wiring of digital inputs and outputs...........................................................................................42

6 Installation....................................................................................................................43

6.1 Cooling and ventilation................................................................................................................44

6.1.1 Notes on UL directive.....................................................................................................................45

6.1.2 Braking resistance..........................................................................................................................45

7 Operation .....................................................................................................................46

Page 2/54 Rev 1.31 © 04/11/2013

Table of contents Indel motion boards

7.1 Braking resistor............................................................................................................................46

7.2 Motion boards with an ethernet interface..................................................................................46

8 Fieldbus systems.........................................................................................................47

8.1 GinLink ..........................................................................................................................................47

8.2 INFO-Link.......................................................................................................................................48

8.3 Error messages ............................................................................................................................49

8.4 Warnings........................................................................................................................................49

9 Sales and service.........................................................................................................50

9.1 Manufacturer ................................................................................................................................50

9.2 Maintenance, cleaning, repair.....................................................................................................50

9.3 Transport and storage..................................................................................................................50

9.4 Disposal.........................................................................................................................................50

9.5 Declaration of conformity............................................................................................................51

10 List of figures...............................................................................................................53

11 Document status..........................................................................................................54

Page 3/54 Rev 1.31 © 04/11/2013

Description Indel motion boards

1 Description

MAX boards offer extremely flexible possibilities for motor control. There are various versions with 2 ...

10 motor output stages, PWM outputs, encoder, resolver, SinCos inputs, etc. available.

The units feature various analogue and digital inputs and outputs alongside the motor output stages.

The MAX boards are capable of controlling entire machines.

1.1 Position controller

PID controller

The user has access to 3 different PID2 parameter sets (forwards, backwards,

stand-by). This allows changes in load to be dealt with

in the best possible way.

Filter

Up to 4 bi-quad filters can be configured per axis.

Computational power

The PowerPC 405-300MHz assumes the following tasks in a 8 ... 32kHz cycle:

●PID position controller, speed regulation, active current regulation

●2. Target value: torque regulation

●Measuring wheel correction (inc encoder)

●Limitation for: IMAX, I2t , controller, motor temperatures

●Logger for 64 freely selectable parameters

●Customer-specific application

●Filter calculation

Position detection

●Resolver: single or multi-pole, 16-bit resolution per resolver revolution

●SinCos encoder: 4096 periods per revolution, 16-bit resolution

●Incremental encoder: up to 20,000 increments (incl. 4Q resolution)

●SSI, Endat, Hiperface interface

Operational safety

Page 4/54 04/11/2013; Rev 1.31

Figure 1.1: Block wiring diagram, MAX4 motion board

Full bridge 2

Full bridge 4

Full bridge 3

Full bridge 1

16 digital

Inputs

16 digital

Outputs

14 analog

Inputs

4 analog

Outputs

PowerPC

405

FPGA

Motor

Power

Supply

24 ... 48V

Peripherie

Power

Supply

24V

Logic

Supply

24V

Serial

Interface

Indel motion boards Description

A number of variables are continually monitored within the motion boards: short-circuit monitors switch

off the controller in the case of motor or ground short-circuit.

Rapid overcurrent cut-outs protect the motor and output stage within the individual phases. These

intervene when the drive is stuck or is stopped suddenly.

The motor and output stage are monitored for overheating.

1.2 Assembly groups

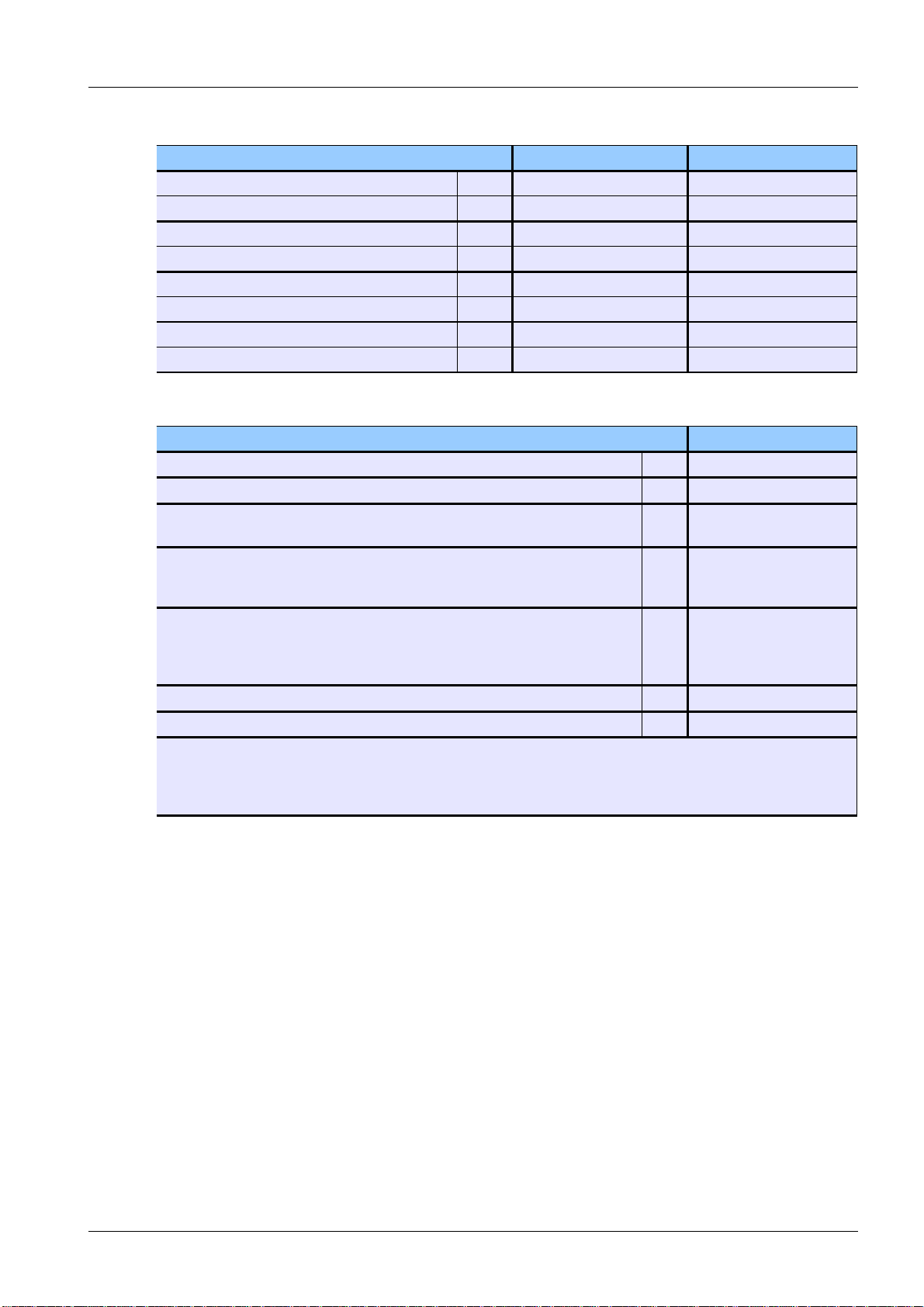

Order no. Type Description

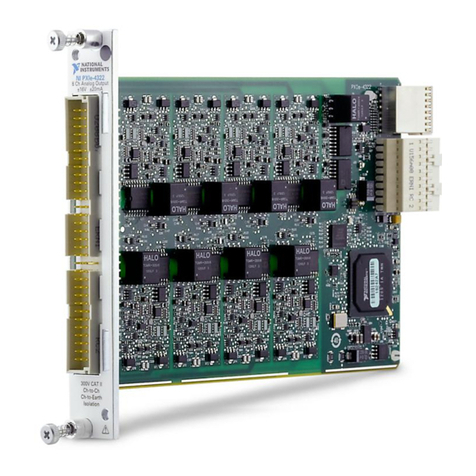

611041900 GIN-AX4 4/2 Axis Board with C96-PPC-Card4, 16 Input, 16 Output

610838600 GIN-MAX10 Multiaxis DC-Motor Module, 6x2.5A, 4x1.25A,

16 Out 24V 2A, 16 Inp 24V, 4 Analogue Input

610636340-4x2.5A GIN-MAX4 Multi-Axes Board, 4 x 3-Phase 48V/2.5A, 16x24V/2A IO,

14 x Analog Input +-10V, 4 x Analog Out +-10V

610636341-2x5A GIN-MAX4 Multi-Axis Board, 2 x 3-Phase 48V/5A, 16x24V/2A IO,

14 x Analog Input +-10V, 4 x Analog Out +-10V

610636300-4x2.5A INFO-MAX4 Multi-Axes Board, 4 x 3-Phase 48V/2.5A, 16x24V/2A IO,

14 x Analog Input +-10V, 4 x Analog Out +-10V

610636301-2x5A INFO-MAX4 Multi-Axis Board, 2 x 3-Phase 48V/5A, 16x24V/2A IO,

14 x Analog Input +-10V, 4 x Analog Out +-10V

610535700 MAX2-DBIT Distribution Board for MAX-2

610636400 MAX4-DBIT Distribution Board for MAX-4

610636501 MAX-DBMT Distribution Board for MAX Boards with 2 Resolvers

Inputs and 2 PWM 48V/3Aoutputs resistant to short-circuiting

Rev 1.31; 04/11/2013 Page 5/54

Safety notes Indel motion boards

2 Safety notes

Questions

These safety notes do not claim to be exhaustive. Please call us if you have any questions or

problems. (Tel. +41 44 956 20 00)

2.1 General safety notes

Documentation

Please read this documentation fully before installation and commissioning. Incorrect handling of the

modules can lead to personal injury or property damage. Ensure that the technical details and

information on connection conditions are complied with.

Qualified personnel

Only qualified specialist personnel may carry out work such as transport, assembly, installation,

commissioning, servicing and maintenance.

National accident prevention regulations must be observed.

ESD protection

The modules contain components that are sensitive to static charge, and that can be damaged

through improper handling. Discharge the static from your body before touching the modules. Avoid

contact with highly insulating materials (artificial fibres, plastic film, etc.). Place the modules on a

conductive surface in a voltage-free state.

Do not touch the plug connector contacts on the drive and the connected cables, or contact pins on

conductors.

Page 6/54 04/11/2013; Rev 1.31

Indel motion boards Safety notes

2.2 Safety requirements

2.2.1 Risk analysis

The machine manufacturer must compile a risk analysis for the machine and take suitable measures

to ensure that unforeseen movements do not cause damage to persons or property.

Notes on possible risks are also provided in other places throughout this document. All notes on risks,

warnings, precautions and information must be observed.

Run-on

If application-dependent risks arise due to run-on, additional protective measures (e.g. moveable

covers with locking) must be taken to cover the danger zone until such a time that the risk to persons

or property no longer exists.

It must be noted that run-on of the drive is possible without a mechanical brake or defective brake. The

securing brake is not safely controlled by the Indel servo drives. (Active output)

Braking resistance

The braking resistor is not safely controlled by the Indel servo drives. Adefective or incorrectly

connected braking resistor will result in the motor not stopping within the expected time span. In

unfortunate cases, this can lead to personal injury or property damage.

Protection from dangerous movements

Incorrect control of motors can trigger unwanted and dangerous movements.

Such behaviour may be caused by, for example:

●Faulty installation

●Faulty configuration

●Faulty or incomplete wiring

●Defective devices or cables

●Faulty control by the software

Essentially, movement of the motor should be expected as soon as the motion board is switched on.

Protection of persons and the machine can only be guaranteed by means of overarching safety

measures.

Suitable measures must be taken to ensure that the movement zone of machines are protected

against unintentional access by persons.

Removing, bypassing or circumventing the safety mechanisms is strictly prohibited.

Plenty of easily accessible emergency stop switches must be available in and around the machine.

Suspended loads

In the case of suspended loads, additional measures must be taken to ensure that the axis stays in

place. The Indel servo drives do not offer outputs that allow you to safely control securing brakes.

Holding brakes do not offer any protection when slowing down the motor.

Rev 1.31; 04/11/2013 Page 7/54

Safety notes Indel motion boards

Further notes

The emergency stop function may not necessarily lead to the energy supply being switched off. Drives

may remain in operation. Protection against touching live parts is therefore not necessarily

guaranteed.

Position switches and actuating controls must be secured against shifting in accordance with EN1088.

The reaction in the event of a power cut must be considered.

2.2.2 24V DC power supply

The motor may spin out in the event of loss of the 24V power supply to the motion board. If this is not

permissible, external measures must be taken to prevent the axis from spinning out.

2.2.3 48V DC power supply (motor supply)

The motor may spin out in the event of loss of the 48V DC power supply to the motors. If the

intermediate circuit voltage UCC falls below the configured limit UCC MIN, the motor control will go into

error mode and the motor will be switched off.

2.2.4 EMV

For EMC-compliant wiring, see the Indel wiring guidelines, as well as the wiring instructions in this

document.

The manufacturer of machines or systems must take additional EMC safety measures

if the product standard applicable to their machine stipulates lower limit values. Additional EMC safety

measures may be required for machines that contain a large number of Indel servo drives. In such

cases, the installation of a central mains filter is usually sufficient.

When using Indel motion boards in residential areas or when connecting Indel motion boards to a low-

voltage network that will supply buildings in residential areas without intermediate transformers,

additional measures must be implemented in order to filter out interference.

2.2.5 Commissioning

Before switching on a motion board, it must be ensured that the unit is correctly connected to the earth

potential. The earth connections must always be put in place, even if the motion board is only being

operated for testing purposes.

The commissioning must be documented and proof of the safety functions must be kept.

2.2.6 Intended use

The Indel motion boards must only be used within the framework specified in this document and other

documents to which it refers.

Intended use is prohibited until it has been established that the machine complies with the provisions

of EC Directive 2006/42/EC (Machinery Directive) and Directive 2004/108/EEC (EMC Directive), or the

relevant current version of said directives. Otherwise, the Indel motion board cannot be marketed.

Additional measures must be taken for use in areas at risk of explosion, such as flame-proof enclosure

in accordance with EN 50014 and EN 50018.

Page 8/54 04/11/2013; Rev 1.31

Indel motion boards Safety notes

2.2.7 Plug-in connections

Plug-in connections must never be plugged in or unplugged when the unit is switched on.

2.2.8 Responsibility

The motion boards are not completely safe from failure, particularly the safety functions. In the event

of failure, the operator is responsible for ensuring that the machine/system is put into a safe condition.

Rev 1.31; 04/11/2013 Page 9/54

All diagnosis and monitoring functions can only interrupt the control of the motor. This

means that the motor becomes currentless and can no longer be controlled or slowed down!

Depending on the application, additional measures are required to slow down or stop the

motor.

The operator is responsible for safety.

Technical details Indel motion boards

3 Technical details

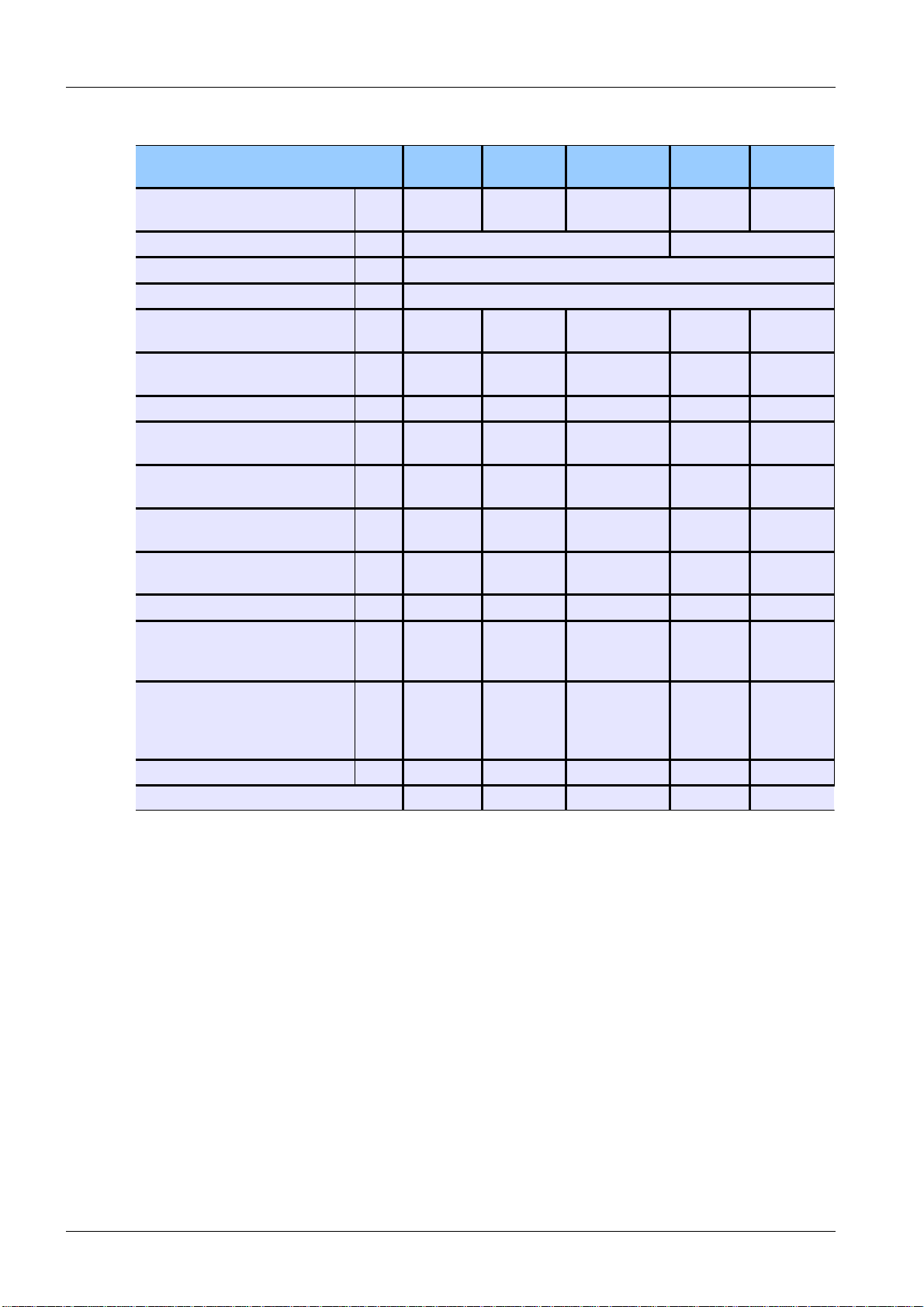

3.1 Technical details for motion boards

Ambient conditions Motion boards

Switch-on interval s > 10

Ambient temperature: Storage °C -20 … 80

Ambient temperature: Operation 1) °C 0 … 45

Heat sink temperature max. °C 80

Relative humidity, no condensation °C 80%

Protection class IP-20

Degree of contamination 2 (EN 50178)

Installation position MAX-Boards(sufficient cooling re-

quired, possibly with fan) any

Installation position GIN-AX4(sufficient cooling requi-

red, possibly with fan) vertical, upright

Vibration as per IEC 68-2-6

Amplitude, frequency response mm

Hz 0.35

10 … 120

Shock g 1

Interference emission, industrial zone EN 61000-6-4

Interference resistance, with mains filter, industrial

zone EN 61000-6-2

1) To keep the ambient temperature below 40°C you m ay need to install additional cooling measures

24V logic supply

Logic supply INFO-MAX4

2x5A INFO-MAX4

4x2.5A GIN-MAX4

2x5A GIN-MAX4

4x2.5A GIN-MAX10 GIN-AX4

Operating voltage VDC 24V -5% +15%

Galvanic

isolation no

External fusing,

fast A 8

Max. potential bet-

ween earth and 0V VDC 50

Power consumption at

24V mA 250 250 300 300 300 300

Page 10/54 04/11/2013; Rev 1.31

Indel motion boards Technical details

On-board supplies

Supplies MAX-2,4,10 AX4

Voltage V ± 15 / ± 15%

Power (± 15V supply) mA 50

Voltage V ± 5 / ± 5%

Power (± 5V supply) mA 100

Supply for encoders; voltage V 5 / ± 5% 5 / ± 5%

Power (5V supply) mA 600 600

Supply for logic; voltage V 3.3 / ± 5%

Power (3.3V supply) mA 50

Motors

Motor Motion boards

Minimum inductance mH 1

Minimum resistance Ohm 0.2

Max. Cable length

in the case of cable lengths > 20m use choke 0.5 … 1mH m 20

Min. Cable length in parallel operation of GIN-AX4

Minimum length of the parallel strands of the motor

connections.

m 0.12

Motor temperature monitoring

Bi-metal sensor must be in motor cable

Motor temperature monitoring only for AX4

Bi-metal

KTX-84 100 / 110

PTC

10k GT2

Accuracy of analogue temperature sensors °C ± 2

Motor cable shielded

Motor types:

- Synchronous servo motors and brushless asynchronous motors

- DC motors, linear motors, stepper motors (two coils)

The motors must be designed for operation using digital servo drives

Rev 1.31; 04/11/2013 Page 11/54

Technical details Indel motion boards

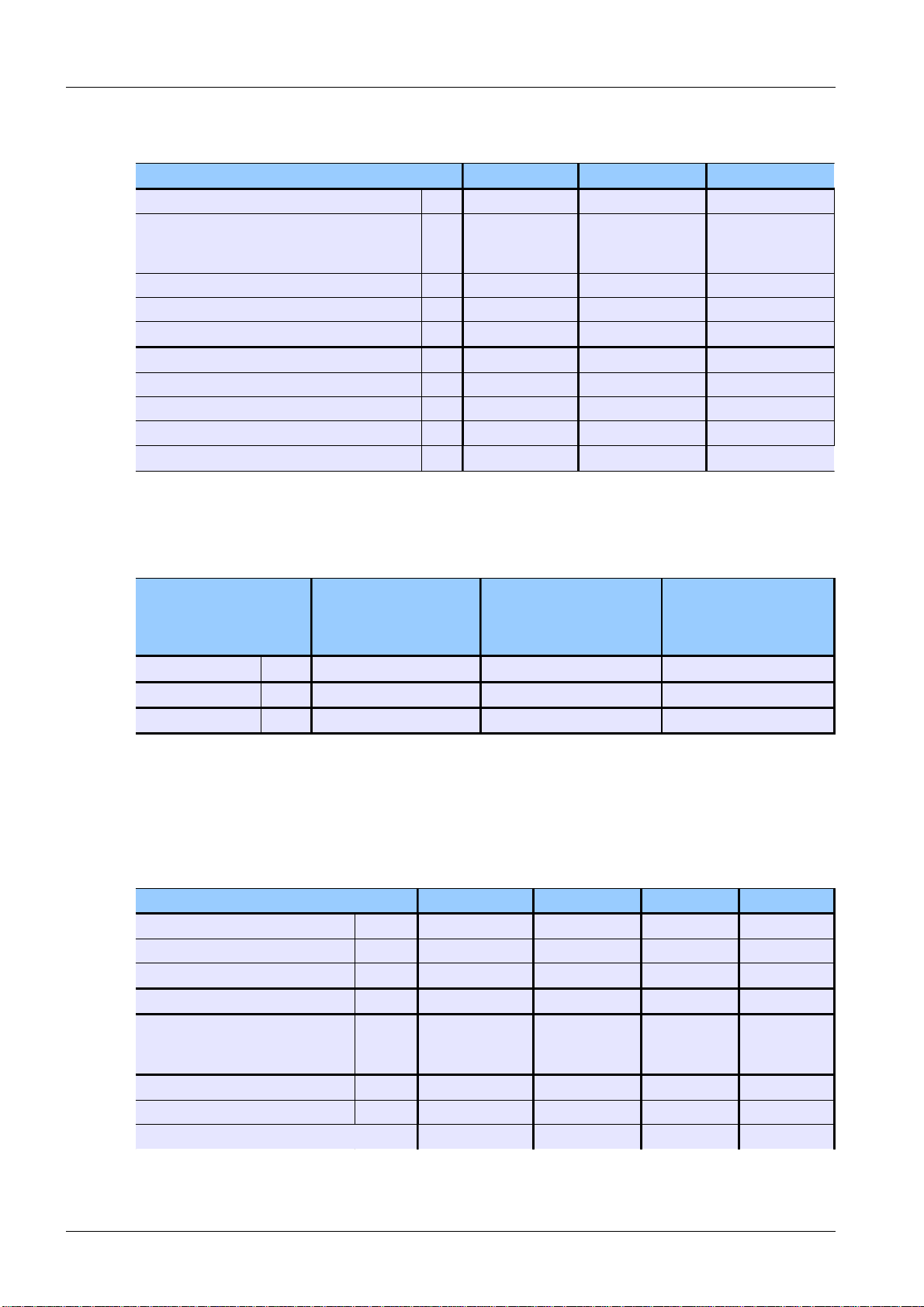

MAX boards output stages

Nominal values MAX4

4x2.5A MAX4

2x5A MAX10 AX4

4x5A AX4

2x10A

Number of output stages

(MAX-10 only DC motors) 4 2 10 4 2

Motor supply voltage VDC 15 … 48 0 … 48

Overvoltage cut-off VDC 54

Overheating cut-off °C 80

Max. Output per motor W 100 200 4 x 50

6 x 100 200 400

Irated at 8kHz sampling

rate Arms 2.5 5.0 1.25 / 2.5 5.0 10.0

IMAX at 8kHz sampling rate Arms 2.5 5.0 1.25 / 2.5 5.0 10.0

Irated at 12kHz sampling

rate Arms 2.5 5.0 1.25 / 2.5 5.0 10.0

IMAX at 12kHz sampling

rate Arms 2.5 5.0 1.25 / 2.5 5.0 10.0

Irated at 16kHz sampling

rate Arms 5.0 5.0 10.0

IMAX at 16kHz sampling

rate Arms 5.0 5.0 10.0

IMAX brake FET ADC 5 5 - 10 10

Minimum external braking

resistance

(48V supply)

Ohm 10 10 10 10

External fusing,

triggering characteri-

stic:

Slow, C

A 10 10 10 20 20

Power dissipation W 25 25 25 35 25

Weight Kg

PWM oversampling for motor drive: Sampling rate x2, x3, x4

Iron-less motors run better with PWM oversampling.

Feedback systems

MAX-2/4

total of 4 encoder inputs: 2 incremental encoder inputs, as well as 2 inputs that can be configured as

either an incremental encoder input or a SinCos input.

MAX-10

10 x incremental encoder inputs

AX4 (SinCos)

4 encoder inputs: each encoder input can be configured as an incremental encoder or SinCos

encoder.

Plus 2 digital interfaces for Hiperface, Endat, SSI (motor 1, 3)

Page 12/54 04/11/2013; Rev 1.31

Indel motion boards Technical details

Absolute feedback systems

Digital absolute feedback systems AX4

Number of dig. feedback systems (motor 1, 3) 2

Endat 2.1

Endat 2.2 a.A.

Synchronous serial interface, max. Telegram length Bit 32

Hiperface

Biss a.A.

An incremental encoder can also be connected to the absolute feedback inputs.

See section 3.3.5 Pin assignment for AX4 encoder systems

Resolver

Resolver inputs MAX-Boards

with DBMT

connector board

Resolution Bit 16

Reference, bridge circuit Vrms 2

Sine/cosine input Vrms 1

Multi-pole resolvers

Resolver cable Pair-twisted, double shielded

Number of channels per board 2

Rev 1.31; 04/11/2013 Page 13/54

Technical details Indel motion boards

Incremental encoder

Incremental encoder inputs MAX2,4 AX4 MAX-10

Level RS422 6)

Max. Counting frequency of incremental enco-

der track 1) MHz 2.5 2.5 2.5

Max. Counting frequency for incremental enco-

der at SinCos input 2) kHz 250 -

Max. Counting frequency for incremental enco-

der at absolute feedback system inputs 3) MHz - 2.5 -

Voltage supply for encoders V 5

Power, total for all encoders mA 200 800 200

Encoder cable shielded

Number of channels per board 4 4) 4 5) 10

SinCos encoder

Sin/Cos inputs GIN-MAX2,4

INFO-MAX2,4 AX4

Level: Sine, cosine, reference Vrms 1 1

Differential input resistance Ohm 120 120

Max. Periods / s 1), 2) kHz 200 200

Voltage supply for encoders 5V + 10% / 200mA 5V + 10% / 200mA

Voltage supply for encoders 10V + 10% / 100mA 10V + 10% / 100mA

Encoder cable pair-twisted

double shielded pair-twisted

double shielded

Number of channels per board 3) 2 4

Page 14/54 04/11/2013; Rev 1.31

1) Example: Incremental encoder with 0.1µm resolution (with 4-quadrant resolution) can be moved at 10m/s. A safety factor

of 2 has already been included.

2) Example: Incremental encoder with 1µm resolution (with 4-quadrant resolution) can be moved at 10m/s. A safety factor of

2 has already been included.

3) On theAX board, rapid digital encoders can be connected to the absolute feedback system inputs. Also see section 3.3.5

Pin assignment for AX4 encoder systems.

In the case of AX4 boards, this function is available from HW Rev. B.

4) The MAX2, MAX4 boards are each equipped with two pure digital encoder inputs and two combined digital encoder /

SinCos inputs.

5) The AX4 board is equipped with four combined digital encoder / SinCos inputs. Also see section 3.3.5 Pin assignment for

AX4 encoder systems

6) In accordance with the RS422 standard, each input is equipped with 120 Ohm resistance. The encoder must be able to

handle this load

1) Analogue inputs: The maximum sampling rate for analogue inputs is 450kHz, or 250kHz with a multiplexer.

2) For incremental encoder to Sin/Cos input see “Incremental encoder” table.

3) The MAX2, MAX4 boards are each equipped with two pure digital encoder inputs and two combined digital encoder /

SinCos inputs. Also see section 3.3.5 Pin assignment forAX4 encoder systems

Indel motion boards Technical details

Digital inputs and outputs

Digital inputs and outputs MAX-2,4 MAX-10 AX4

Number of digital outputs 16

24V outputs (resistant to short-

circuiting) VOUT 18 … 32

Constant current of 24V outputs A 1

Switching delay of outputs ms 0.5

Number of digital inputs 16

Digital inputs UIN V 18 … 32

Digitale Eingänge ION @ 24V mA 1

Input filter us 250

Level for logic 1 VON 13.2

Level for logic 0 VOFF 5.4

Input impedance Ohm 26.7k

Galvanic isolation of inputs and

outputs

Number of trigger inputs - 4 -

Trigger inputs UMAX V - 5 -

Pulsators (optional)

TTL outputs AX4

TTL outputs (74ABT245) VOUT MAX 5V/3.3V

Constant current of TTL outputs IMAX mA 10

PWM frequency kHz 20

Shortest ∆tns 20

Number of TTL outputs 8

PWM outputs

PWM outputs MAX2,4 MAX-10 AX4

PWM outputs, resistant to short-circui-

ting, open drain VOUT MAX 0 … 36 0 … 36 0 … 48

Constant current of PWM outputs IMAX A 2.5 2.5 5

PWM frequency kHz 20 20 20

Shortest ∆tns 20 20 20

Number of PWM outputs, incl. brake 3 6 1

Rev 1.31; 04/11/2013 Page 15/54

Technical details Indel motion boards

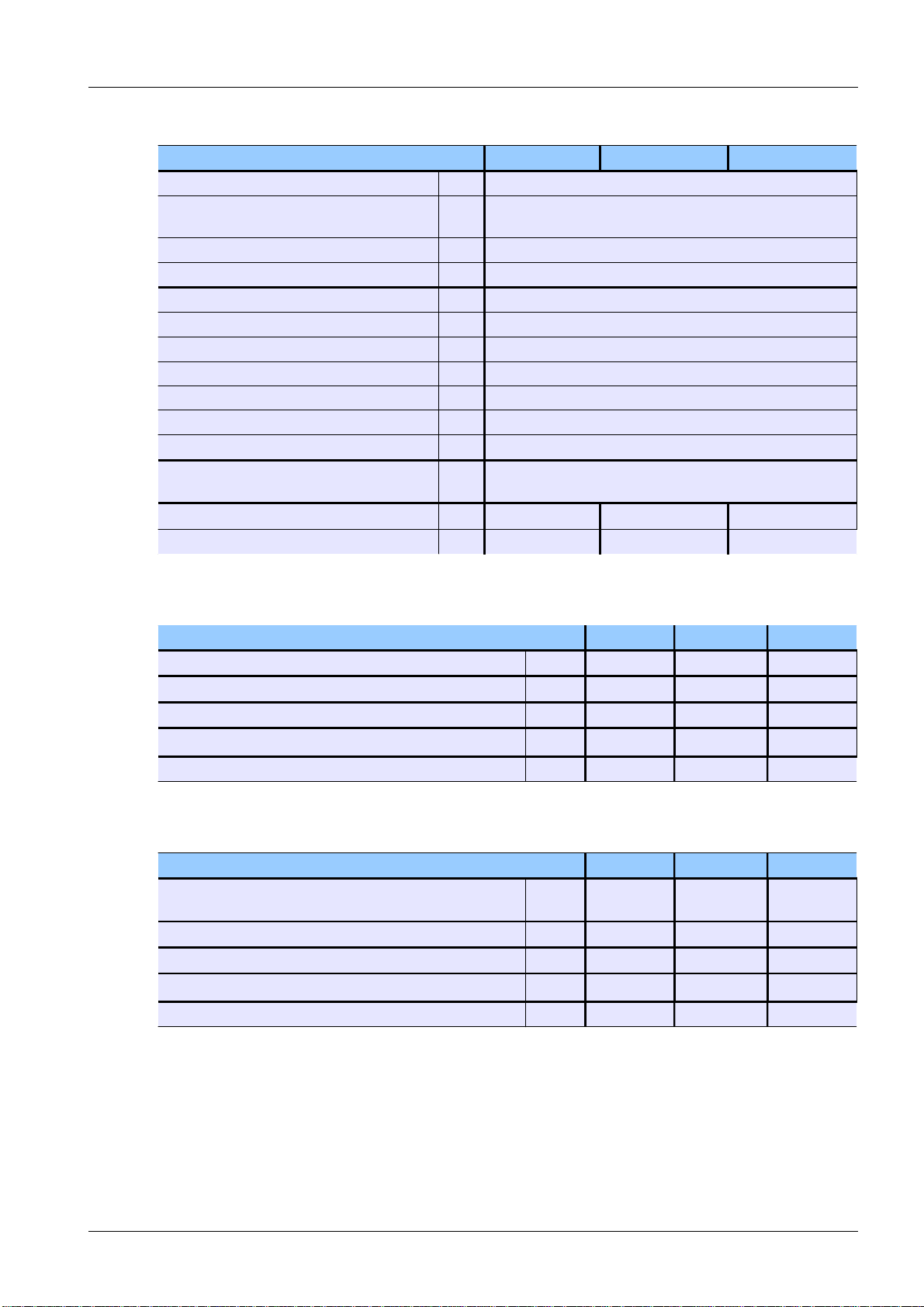

Analogue inputs and outputs

Analogue inputs and outputs MAX2,4 MAX-10 AX4

Number of analogue inputs 14 4 -

Ranges V ± 10

± 1

± 0.1

± 5

Converter time / channel Khz 4 8 … 12

Resolution Bit 16 16

Average filter 1 … 256 1 … 256

Number of analogue outputs 4 - -

Range V ± 10

Power per channel IMAX mA 5

Resolution Bit 16

Accuracy 1 ‰

Once switched on, the output of the analogue outputs is -12V over 300ms.

Accuracy of analogue inputs

Accuracy of ana-

logue inputs

Measuring range

Relative

accuracy of

individual measure-

ment

Relative accuracy

averaged for 100

values

Absolute

accuracy

± 10 V Bit 14 15 14

± 1 V Bit 13 14 13

± 0.1 V Bit 12 14 12

Optimum stability of measurement values is achieved once the unit has been switched on for 15min.

The accuracy specifications apply at the operating temperature.

Interfaces

Interfaces INFO-MAX2,4 GIN-MAX2,4 GIN-MAX10 GIN-AX4

Serial interface RS232 1 1 1 1

Baud rate RS232 115'200 115'200 115'200 115'200

Protocols: Modbus

INFO-link interface 11MBit

Ethernet interfaces

2 x GinLink or 1 x Ether-

net, 1x GinLink

1GBit - 2 2 2

IMP interface

Number of participants - - - 1

5V supply (IMP bus) mA - - - 800

Page 16/54 04/11/2013; Rev 1.31

Indel motion boards Technical details

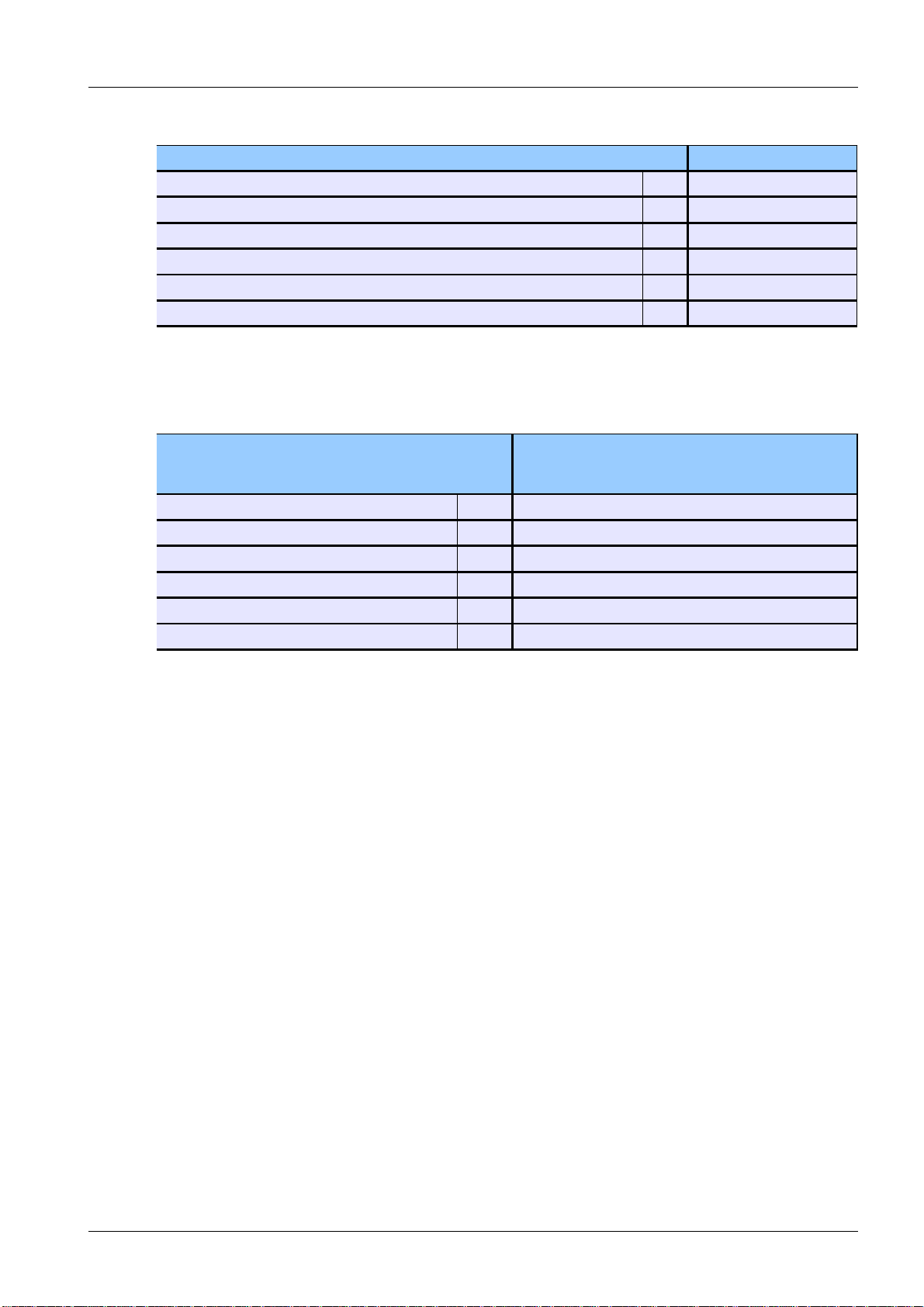

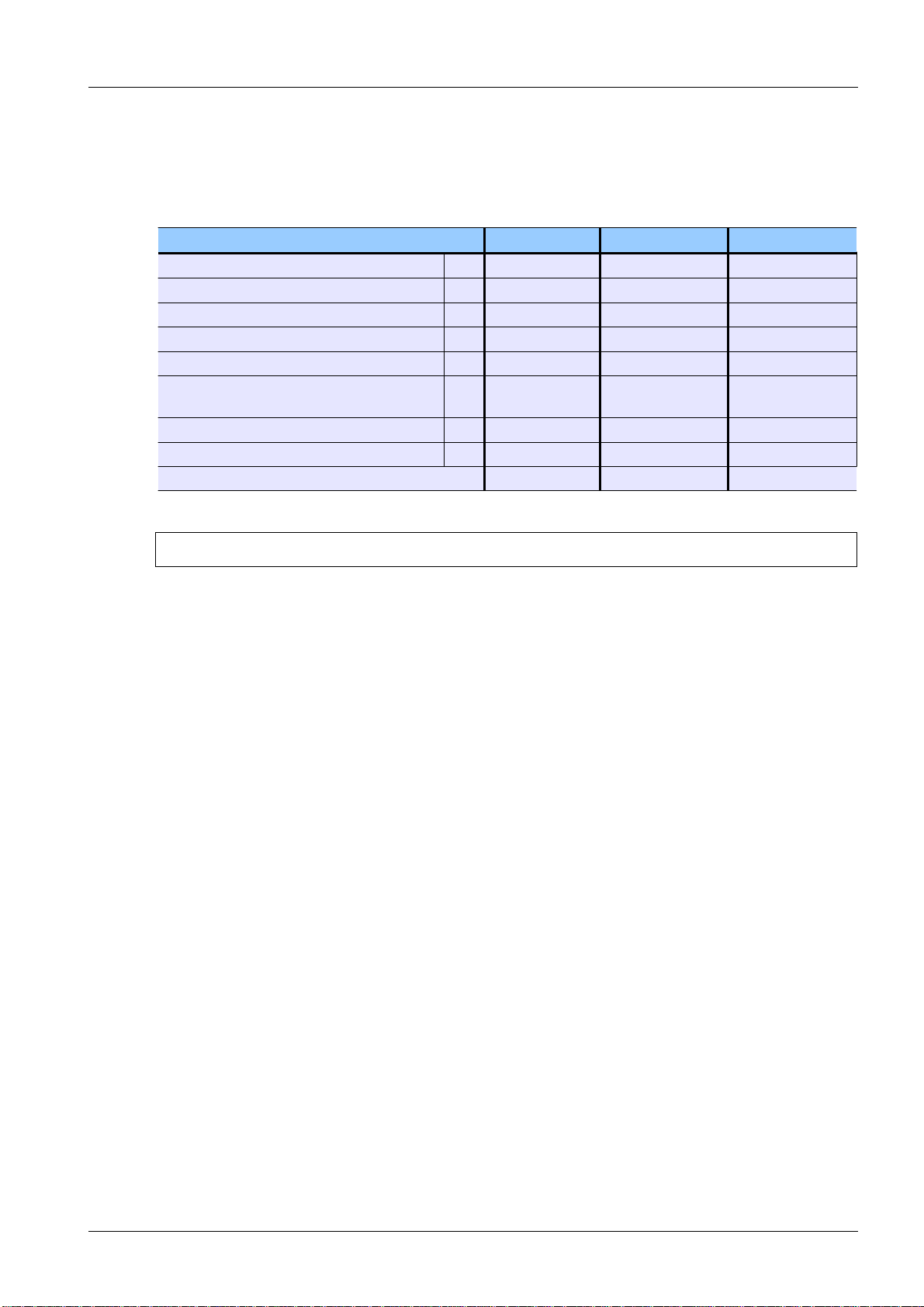

3.2 Technical details for connector boards

3.2.1 MAX-DBIT

Analogue inputs

Analogue inputs Channel no. Pin MAX-DBIT

Vacuum sensor 1) 0 On Board

Analogue inputs 1 … 3 X19, X20

Potentiometer input 3 X38

Potentiometer voltage V 10

PT-100 inputs 4 … 7 X20, X21, X22

Measuring current for PT-100 re-

sistance mA 3.333

Thermocouple inputs 8 … 12 X11 … X15

PT-100 balancing point 13 On Board

PT-100 references 14 … 15 On Board

Rev 1.31; 04/11/2013 Page 17/54

1) For specifications for the analogue inputs see section 3.1 Technical details for motion boards

Technical details Indel motion boards

3.2.2 MAX-DBMT

Analogue inputs

Analogue inputs Channel no. Pin MAX-DBMT

Analogue inputs 1) 0 … 11 X16, 17, 18

PT-100 inputs 12 … 13 X13

PT-100 references 14 … 15

Measuring current for PT-100 re-

sistance mA 3.333

Analogue outputs

Analogue outputs Channel no. Pin

Analogue outputs 1) 0 … 1 X14

Resolver reference 2) 2 … 3 X13

PWM outputs

PWM outputs MAX-DBMT

Number of PWM outputs, open collector

Pins X27, X28: PDOUT-0, PDOUT-1 2

Maximum PWM frequency kHz 4

Maximum voltage VDC 50

Maximum power A 5A

RDS ON mOhm 0.1

Page 18/54 04/11/2013; Rev 1.31

1) For specifications for the analogue inputs and outputs see section 3.1 Technical details for motion boards

2) For resolver specifications see section 3.1 Technical details for motion boards Resolver

Indel motion boards Technical details

3.3 Dimensions, pin assignment

3.3.1 Dimensions of AX4

A minimum distance of 50mm must be maintained between the individual motion boards.

Rev 1.31; 04/11/2013 Page 19/54

Fig. 2: AX4 front Fig. 1: AX4 side

Fig. 3: Drill plan, AX4

Technical details Indel motion boards

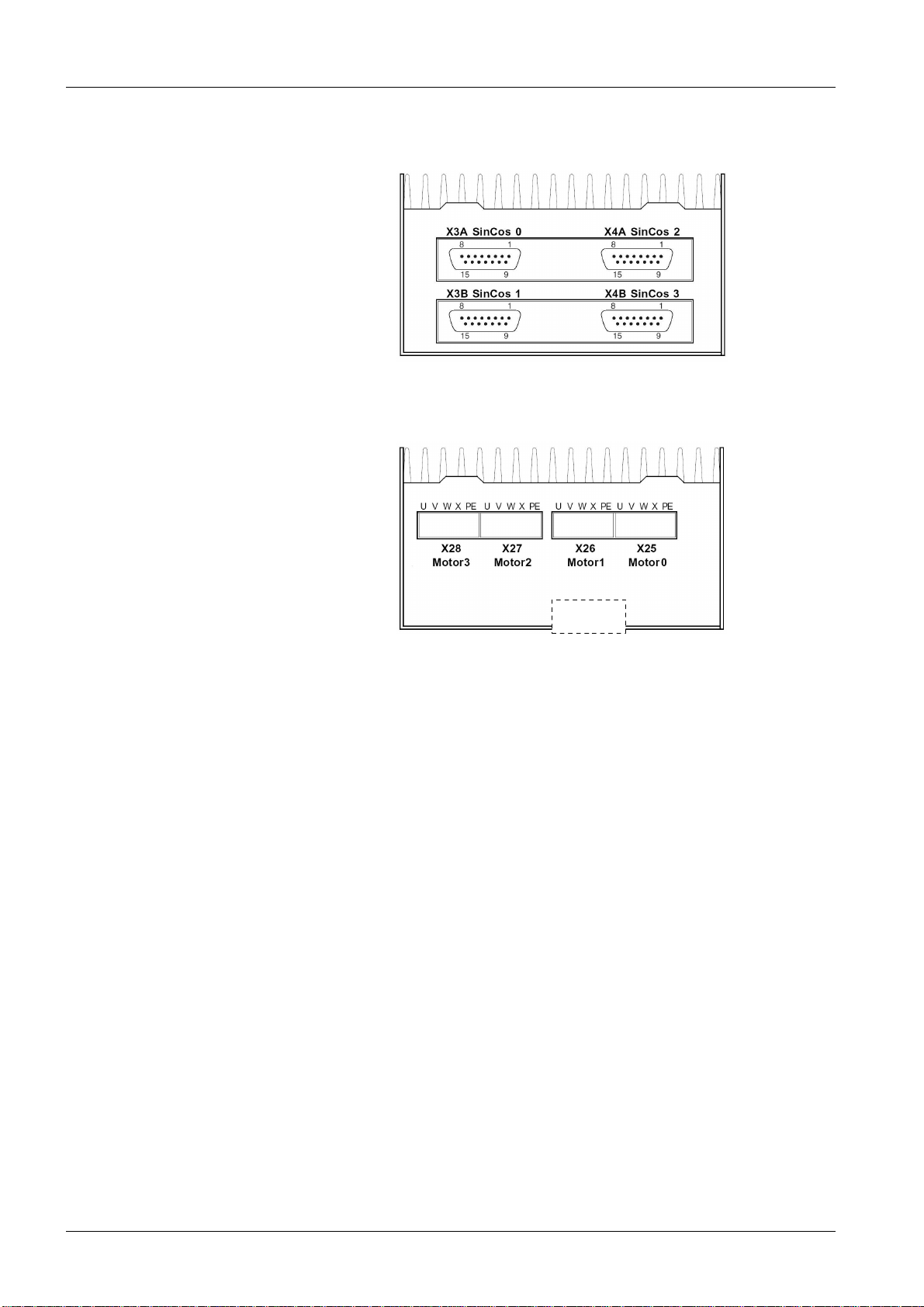

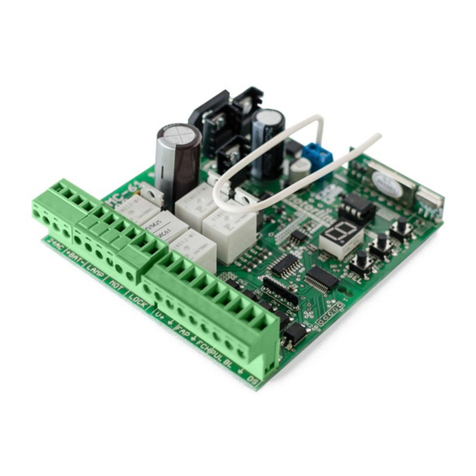

3.3.2 Pin arrangement for AX4 board

Absolute feedback systems can be connected to pins X3B, X4B; SinCos 1, 3.

Page 20/54 04/11/2013; Rev 1.31

Fig. 6: Motor pins

Fig. 5: Encoder pins

Fig. 4: Front pins

X30

(optional)

This manual suits for next models

14

Table of contents

Popular Control Unit manuals by other brands

Advantech

Advantech AIW-357 DK-G1P user manual

KWC

KWC F3SV2001 Installation and operating instructions

Motorline professional

Motorline professional MC61PL User& installer's manual

Conel

Conel CLEAR BOX operating instructions

Honeywell

Honeywell SLATE R8001S9001 installation instructions

CLA-VAL

CLA-VAL 40-01/640-01 Installation, operation and maintenance