Table of contents:

1. Technical Data

2. Purpose of use

3. Operating limits

4. Necessary documentation

5. Mode of operation

6. Control and inspection of the parachute

7. Behaviour in case of damage

8. Storage

9. Maintenance

10. Cleaning

11. Repairs

Warning

It´snotallowedtousethisrescue-parachuteforskydiving!

AccordingtoEN12491:Notsuitableforuseatspeedsexceeding32m/s(115km/h).

Useofthisparachutewithanyalternative inner container: the speed of opening and opening shock test

hasbeencompletedusingtheinnercontainersupplied.

Useofanyotherinnercontainermayproducedifferentresults(includingfailure)

TherescuesystemsoftheNG/NGlightseriescomplywiththeGermantypeapprovalLTF2-565-20andEN12491:2015.

The manufacturer cannot be held liable for any personal injury or material damage, which may result from this rescue

systeminanyway.

1.TECHNICALDATA

Typeofrescueparachute: NG100,NG120,NG140,

NG100light,NG120light, NG140light

Manufacturer: FlymarketFlugsport-ZubehörGmbH&Co.KG

AmSchönebach3

D-87637Eisenberg

Tel.+49-8364-9833-0

12. Nature- and environment-friendly behaviour

13. Environmentally compatible waste disposal

14. Spare parts / changeable parts

15. Structure of the parachute

16. Packing instructions

17. Mounting in an optional frontcontainer

18. Mounting / integration to a harness

19. Specialities for paraglider´s winch-towing

20. Pre-flight check

2.Purposeofuse

Manually activated rescue system for single-seat paraglider pilots in emergency situations, as well as the HG version for

hanggliderpilots.

3.Operatinglimits

Maximumoperatingspeed:115km/h(32m/s)

Packing interval: 12 months, after which repacking is required. This must be noted in the Repack and inspection Log

book.Thepackingintervalmaybeshortenedbytheeffectsofmoisture,sand,saltorotherenvironmentalinfluences.

Re-inspection interval: 24 months, after which a complete inspection of the rescue system is required. This includes a

thorough and complete visual inspection of all components. The re-inspection must be noted in the epack and inspection

Logbook.

Maximumoperatingtime:10years,thereafterupto12yearswithannualre-inspectionbythemanufacturer.

4.Necessarydocumentation:

a)Owner´smanual

b)Repackandinspectionlogbook(withrecordedrepackandinspectionjobs)

5.Modeofoperation:

Incaseofemergency,thedeploymenthandleispulledopenwithafirmjerk.Thisopenstheoutercontainerandreleasesthe

rescue system. Then the parachute package (still packed in the deployment bag) is thrown into the free airspace with a

sweepingmovement.Thedeploymenthandleistherebythrownawaytogetherwiththerescuesystem!!!!

The deployment bag together with the bridle is designed in such a way that the lines and parachute canopy are released

onlyafterthethrowhasbeencompleted.

This prevents an unwanted, early opening. This minimises the risk of snagging on the paraglider / pilot or the reason

responsiblefortheairemergency(e.g.collisionwithanotherpilot,etc).

The maximum speed of the deployment bag, which is necessary for a quick opening, is only reached after the pilot's hand

hasleftthedeploymentbag..

Ingeneral:Thefastertherescueparachutepackageisthrownaway,thequickertheparachutewillopen.

Afterthethrow,thedeploymentbagopensandreleasesthelinesandcanopy.

Thepowerfulthrowand/ortheairflowstretchesthelines,thecanopyandtherescuesystemopens.

Whentherescuesystemisfullyopen,theremainingheightabovegroundmustbecheckedfirst.

If there is still enough height, the paraglider should, if possible, be rendered flightless according to the doctrines in order to

avoidaV-positionofrescuesystemandparaglider.

Ifthereisnotenoughheightleft,youshouldonlykeepaneyeonthegroundandprepareforalandingfall.

6.ControlandInspectionoftheparachute

Before repacking the rescue system it must be checked by the packer and must be sufficiently ventilated. If the parachute

has been opened by a rescue deployment, it must be subjected to a full inspection either by the manufacturer or by a

companyauthorisedbythemanufacturer.

After repacking, as well as before each flight, it must be ensured that the release force of the locking system of the outer

containerisbetween2daNand7daN.

Iftherescuesystemiscombinedwithanoutercontaineroraharnesswithanintegratedrescuesystemcontainerforthefirst

time,thefunctionalitymustbecheckedbyacompetentpersonandconfirmedintherepackand inspectionlogbook.

The inspection includes a complete visual check of all components (cloth, seams, lines, straps) for damage and wear.

Suitableaids(lighttable,packingtools)mustbeavailableforare-inspection,andtheworkcarriedoutmustbedocumented

inasuitablemanner.

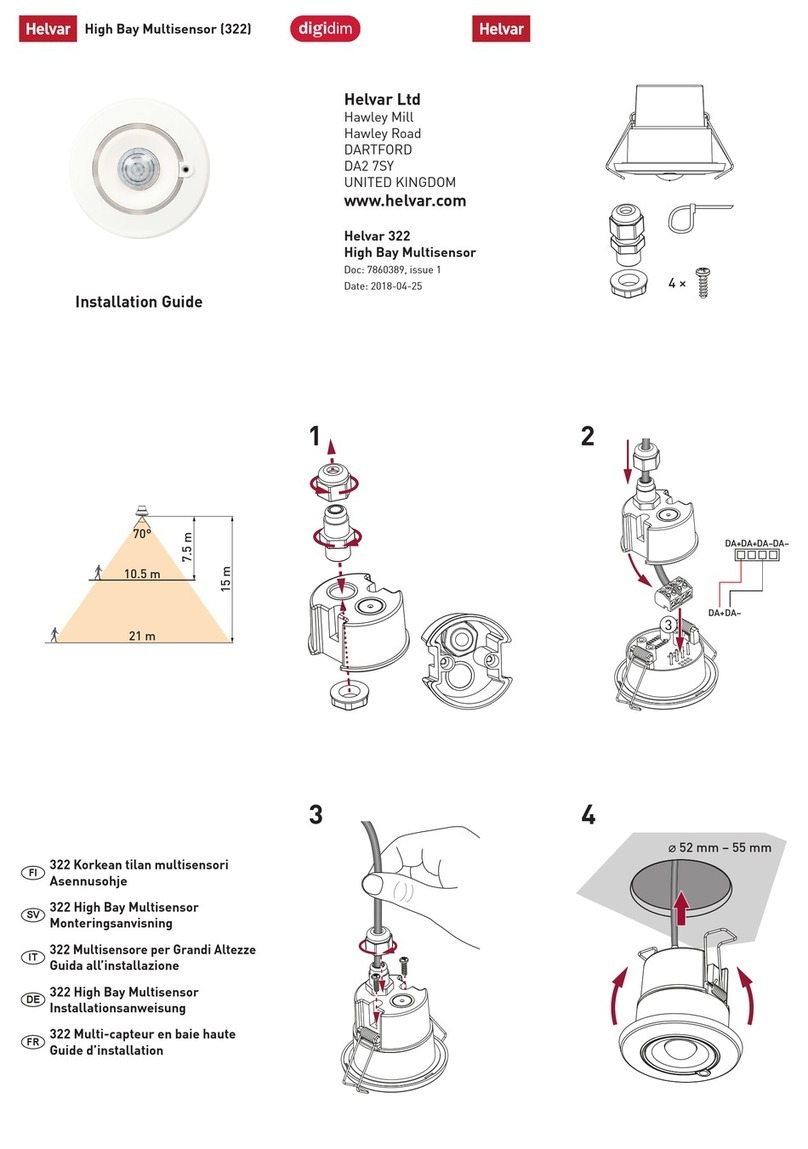

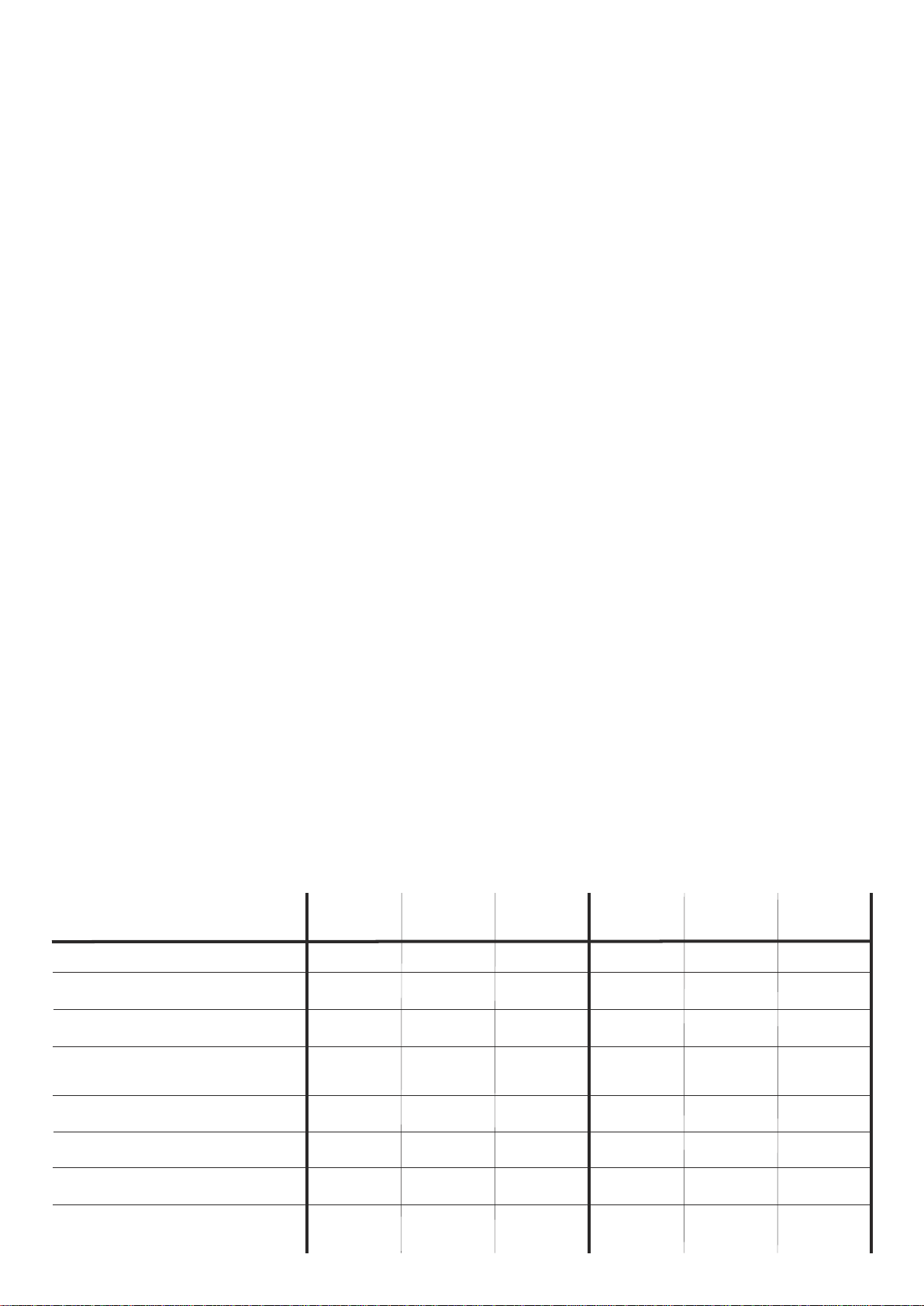

Rescuesystem:

Weight(kg):

Surface(m²):

Numberoflines/panels:

Total length packed:

(Bridle to packing loops)

Mn.load(kg):

Max.load(kg):

Sinkrateatmax.load:

VolumeinMilliliter

(withoutbridle)

NG

100

1,45

25

6,49

60

100

5,28 m/s

3600

20

NG

120

1,6

29

6,94

80

120

5,14 m/s

3800

20

NG

140

1,85

33

7,51

100

140

5,37 m/s

6300

20

NG 100

light

1,18

25

6,53

60

100

5,1 m/s

3300

20

NG 120

light

1,3

29

6,98

80

120

5,16 m/s

3500

20

NG 140

light

1,49

33

7,52

100

140

5,45 m/s

6000

20

2 3