Independence paragliding Trigon User manual

Owner´s manual Fassung 1.0 vom 20.07.2018

Rescue system

Trigon

Fly market GmbH & Co. KG

Am Schönebach 3

D-87637 Eisenberg

Tel.: +49-8364-9833-0

Fax: +49-8364-9833-33

Mail: [email protected]

Inhaltsverzeichnis

1. Technical Data

2. Intended use

3. Operating limits

4. Necessary documentation

5. Mode of operation

6. usage of steering lines

7. Control and inspection of the parachute

8. Behaviour if damages are noticed

9. Storage

10. Maintanance

11. Cleaning

12. Repairs

13. Nature- and environment-friendly behaviour

14. Environmentally compatible waste disposal

15. Spare parts / changeable parts

16. Structure of the parachute

17. Packing the parachute

18. Mounting in a container

19. Mounting / integration to a harness

20. Specialities for winch towing

21. Preflight check

Warning

Itisnotallowedtousethisrescueparachuteforskydiving!

AccordingEN12491:Notsuitableforuseatspeedsinexcessof32m/s(115km/h)

The paragliding rescue systems of the Trigon series are certified according EN 12491 (European standard) and LTF

91/09(Germantypeapproval).

The manufacturer can not be made liable for any possible damages to persons or material damages, which may result

fromthisrescueparachutesinanyway.

1.TECHNICALDATA

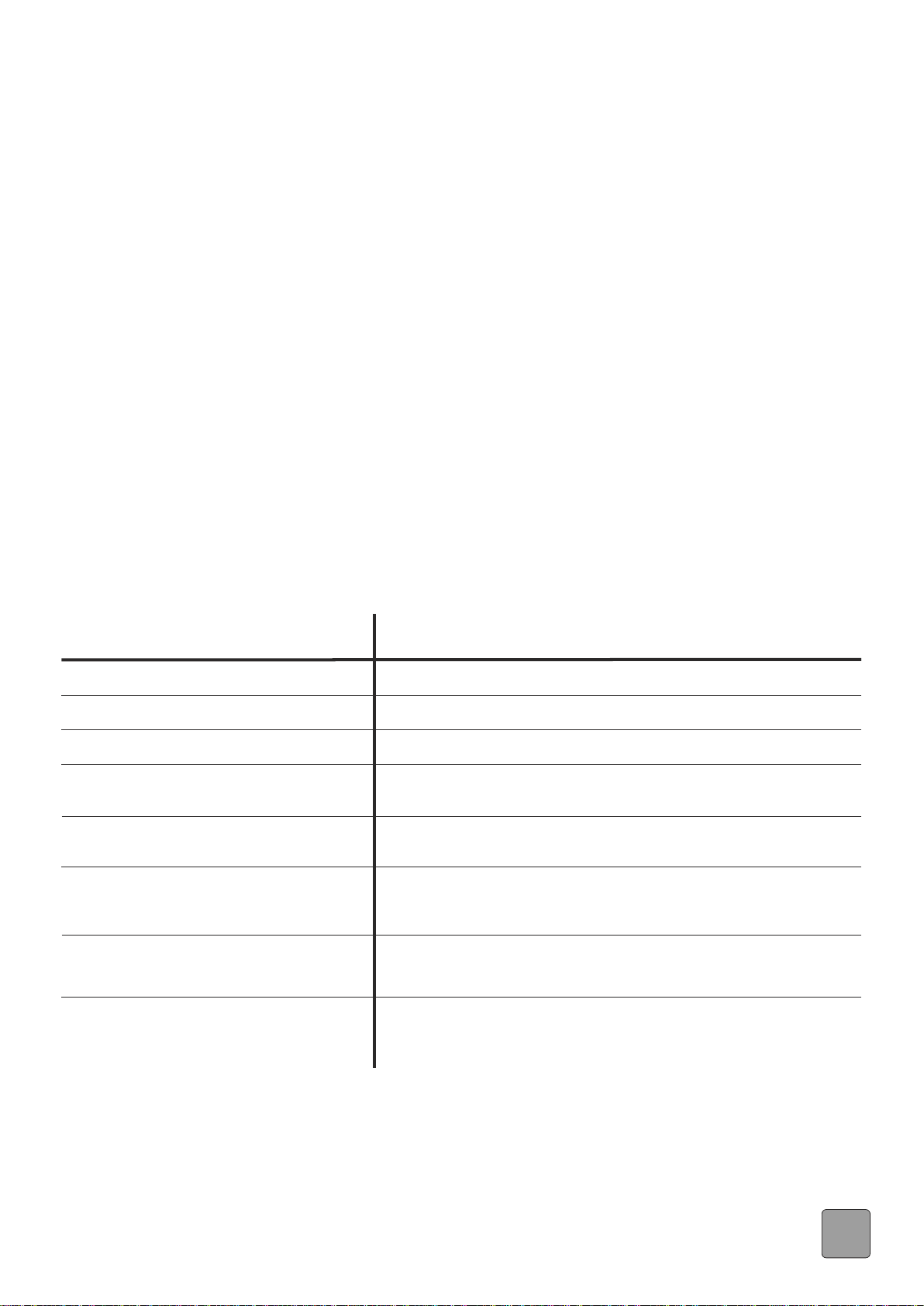

Typeofrescueparachute: paraglidingrescuesystem Trigon100,Trigon125

Manufacturer: FlymarketGmbH&Co.KG

AmSchönebach3

D-87637Eisenberg

Tel.+49-8364-9833-0

rescuesystem:

Weightoftherescuesystem(kg):

Surface(m²):

Numberofpanels:

Totallengthpacked:

(Bridletopackingloops)(m)

Minandmax.loadnotsteered(kg)

Minandmaxloadifsteered(kg)

SeePoint6.

Sinkrateatmax.load

VolumeinMilliliter

(withoutbridle)

Trigon 100

1,29

32

8,90

55 -100

55 -85

<5,5 m/s

3800

16

Trigon 125

1,45

37

9,40

70 - 125

70 - 100

<5,5 m/s

4300

16

2 3

Inhaltsverzeichnis

1. Technical Data

2. Intended use

3. Operating limits

4. Necessary documentation

5. Mode of operation

6. usage of steering lines

7. Control and inspection of the parachute

8. Behaviour if damages are noticed

9. Storage

10. Maintanance

11. Cleaning

12. Repairs

13. Nature- and environment-friendly behaviour

14. Environmentally compatible waste disposal

15. Spare parts / changeable parts

16. Structure of the parachute

17. Packing the parachute

18. Mounting in a container

19. Mounting / integration to a harness

20. Specialities for winch towing

21. Preflight check

Warning

Itisnotallowedtousethisrescueparachuteforskydiving!

AccordingEN12491:Notsuitableforuseatspeedsinexcessof32m/s(115km/h)

The paragliding rescue systems of the Trigon series are certified according EN 12491 (European standard) and LTF

91/09(Germantypeapproval).

The manufacturer can not be made liable for any possible damages to persons or material damages, which may result

fromthisrescueparachutesinanyway.

1.TECHNICALDATA

Typeofrescueparachute: paraglidingrescuesystem Trigon100,Trigon125

Manufacturer: FlymarketGmbH&Co.KG

AmSchönebach3

D-87637Eisenberg

Tel.+49-8364-9833-0

rescuesystem:

Weightoftherescuesystem(kg):

Surface(m²):

Numberofpanels:

Totallengthpacked:

(Bridletopackingloops)(m)

Minandmax.loadnotsteered(kg)

Minandmaxloadifsteered(kg)

SeePoint6.

Sinkrateatmax.load

VolumeinMilliliter

(withoutbridle)

Trigon 100

1,29

32

8,90

55 -100

55 -85

<5,5 m/s

3800

16

Trigon 125

1,45

37

9,40

70 - 125

70 - 100

<5,5 m/s

4300

16

2 3

2.Intendeduse

Manuallyreleased,steerablerescuesystemforsingleseatedparaglidersinanemergencysituationwhileflying.

3.Operatinglimits

Maximumspeedforusage:115km/h(32m/s)

Interval for repacking: 12 month, then the rescue system has to be repacked and this repacking has to be recorded in the

“Repackandinspectionlogbook”.

Duetotheeffectofwater,sand,saltorotherenvironmentalinfluencesmayreducetherepackinterval.

Interval of inspection: 24 month, then a complete inspection of the rescue system is necessary. The inspection has to be

recordedinthe“Repackandinspectionlogbook”.

Operational lifespan of parachute: 10 years. The lifespan can be extended for 2 more years if the rescue parachute is

inspectedyearlyduringthislasttwoyearsatthemanufacturer.Sothetotalmax.possiblelifespanis12years.

4.Necessarydocumentation

a)Owner´smanual

b)Repackandinspectionlogbook(withrecordedrepackandinspectionjobs)

5.Modeofoperation

During an emergency situation while flying the pilot pulls at the release handle with a firm tug. Thereby the outer container

opensandthedeploymentbagisreleased.Afterthattherescueparachutepackage(whichisstillpackedinit´sdeployment

bag)have tobethrownwithadynamicmove intothefree airspace.That meanstherelease handlehavetobethrown away

togetherwiththedeploymentbag!!!

The deployment bag and the bridle are designed in a way which releases the lines and canopy of the parachute not before

theparachutepackageisthrownaway.

Thispreventsanunintentionalortooearlyopeningoftherescueparachute.Thisisminimizingthedangeroftanglingupwith

the paraglider / hang glider / pilot or the reason which maybe causal for the emergency case (e.g. collision with another

paraglider).

Moreover the maximum throwing speed of the deployment bag should be reached when the deployment bag leaves the

pilothand.

Ingeneral:Thefastertherescuesystempackageisthrownaway,thequickerthesystemwillopen.

After the throw the deployment bag opens and releases lines and canopy. The powerful throw and/or the airstream

stretchesthelinesandcanopynowtherescueparachutesopens.

Whentherescueparachuteisopenedcompletely,youfirsthavetocheckthealtitudeaboveground.

If you have still enough height you should try to make the paraglider unable to fly according to the doctrine to avoid an V-

positionoftheparagliderandtherescuesystem.

Ifyoudonothaveenoughheightanymore,justfocusonthegroundandprepareyourselfforalandingfall.

6.Usageofsteeringlines

TheTrigonisequippedwithasystemthatpre-brakesthecanopyafteropeningbyshortenedsteeringlineswhichpreventsa

forwardspeed.

Theuseofthesteeringlinesrequiresafewconditionsthatmustallbemet:

After the rescue system has successfully opened in the pre-braked condition and is stable above the pilot, a sufficient

altitudemustbepresent.Inaddition,theparaglidermustbeinastable,incapableflyingposition(bestis,iftheparaglidergot

disconnectedbyaquickoutrelease).

If these conditions are all met, the pre-braked steering lines can be unlocked by pulling both control handles symmetrically

down.Therescuesystempicksupforwardspeedbydecreasingtheuseofthebrake.

Thecontrol handlesare attachedtothe rightandleftofthe bridle,rightabove thesuspension point.The steeringisworking

byincreasingthedragofthecanopy,sameasonaparaglider,butwithaslowanddampedreaction.

Attention:

Whenthepre-brakingisreleased,themax.takeoffweightisreduced(see1.Technicaldata).

Iftheparagliderisnotinareliable,incapableflyingpositionorseparatedthepre-brakedsteeringlinesmustbenot

releasedandused.IfreleasedinthisconditiontherewouldbeaveryhighpossibilityofaV-positionofparagliderto

rescue system (down plane), in combination with very high and dangerous sink rate and a without possibility of

steering.

The behaviour of the Trigon with non-activated steering lines is comparable with a conventional, not steerable

rescuesystem.

Withashouldersuspensionontheharness,dependingonthepositionofthesuspensionpoints,itcanbedifficulttoturnthe

headand seethe controlhandles.Veryoften, theserescuesystem suspensionare mountedonthe harnessfar intheback

areaand theposition ofthecontrolhandlescan thereforeonly befelt. Werecommendto testthe positionofthehandlesin

advancebyasuitablesimulation(hangintheharnessontheshouldersuspension).

The use of a front container is possible, but the bridle of the rescue system must be extended for the use on the main

carabiners.Otherwisethecontrolhandlesaremountedtoolowandasteeringisnotguaranteed.Theextensionisavailable

asanaccessory.

7.

A parachute must be controlled by a registered packer before it is repacked. After being opened during an emergency

rescue,theparachutemustbeinspectedbythemanufactureroraworkshopwhichisauthorizedbythemanufacturer.

A repackedparachuteshouldundergoareleasetestaftermountedintheoutercontainerorharness.Thisensuresthatthe

openingforcetoreleaseisbetween2kpand7kp.

Bythe firstassemblingof therescuesystem withanouter containerorharness withanintegrated rescuesystemcontainer

thefunctionalitymustbecheckedbyanexpertandmustbeconfirmedintheinspectionlogbook.

The inspection required after 24 months includes a complete visual examination of all components (cloth, seams, lines,

bridlesetc)fordamageandwear.Foraninspectionsuitabletoolsmustbeavailable(lighttable,repacktoolsetc).

Allworkmustbedocumentedappropriately.

8.Behaviourifdamagesarenoticed

If you notice any damage at the rescue parachute, which may affect the airworthy condition of the recue parachute, you

havetosendtherescueparachuteforinspection/repairtothemanufacturer.

Also, ifyouarenotsureabouttheairworthyconditioninanyway,youhavetosendtheparachutetothemanufacturer.

Attention:Chemicals,detergents, insects,mouldstainsor thelike canhavethesame negativeeffectstothestrength ofthe

partsasmechanicalinfluences.

9.Storage

Oil,grease,acidandpaintshouldnotbestoredneartheparachute.Thestoragespaceshouldbedry.Parachuteswhichwill

notbeusedforalongperiodshouldbeopenedandthecanopylooselyrolledandstoredinapermeablebag.

Avoidunnecessaryhightemperatureabove60°C(e.ginaparkingcar)!

10.Maintenance

Thelifespan andconditiondependslargely uponhowcarefully youhandleand maintainyourparachute.Out ofthisreason

werecommendtocontroltheparachuteregular,atthelatestifitisrepacked,ifthereareanywearsordamages.

Duringnormaluseyouhavetotakecareofthefollowingpoints:

If the parachute got wet, you have to open it and dry it at a well ventilated place as soon as possible (but avoid direct

sunlight!)Thefastdryingisimportanttoavoidmouldstains.Aftertheparachuteiscompletedryitcanberepacked.

Iftheparachuteisstrainedmorethannormal(forexample:acardroveovertheharnessinwhichtheparachuteisplaced,or

itmaybeisdamagedbyasharpobject,oranyotherpossibledamage),youhavetosendtheparachutetothemanufacturer

tocheckit.

Avoidcontactwithsaltwater,acidsorotheraggressivesubstances!

Alsoavoidunnecessaryexposuretosunlight,causetheUVraysmaydamagethemolecularstructureofthematerial.

11.Cleaning

Adirtycanopyandcontainercanbecarefullycleanedwithclearwaterandasoftsponge.

Attention: Never use detergents, chemicals, brushes or hard sponges to clean the parachute! Also a cleaning in the

washingmaschineisnotallowed.

Iftherescueparachute getsincontact withsaltwater,youhaveto washitwith freshwater.Atoooftencleaning accelerates

theageingofthesystem.

ControlandInspectionoftheparachute

45

2.Intendeduse

Manuallyreleased,steerablerescuesystemforsingleseatedparaglidersinanemergencysituationwhileflying.

3.Operatinglimits

Maximumspeedforusage:115km/h(32m/s)

Interval for repacking: 12 month, then the rescue system has to be repacked and this repacking has to be recorded in the

“Repackandinspectionlogbook”.

Duetotheeffectofwater,sand,saltorotherenvironmentalinfluencesmayreducetherepackinterval.

Interval of inspection: 24 month, then a complete inspection of the rescue system is necessary. The inspection has to be

recordedinthe“Repackandinspectionlogbook”.

Operational lifespan of parachute: 10 years. The lifespan can be extended for 2 more years if the rescue parachute is

inspectedyearlyduringthislasttwoyearsatthemanufacturer.Sothetotalmax.possiblelifespanis12years.

4.Necessarydocumentation

a)Owner´smanual

b)Repackandinspectionlogbook(withrecordedrepackandinspectionjobs)

5.Modeofoperation

During an emergency situation while flying the pilot pulls at the release handle with a firm tug. Thereby the outer container

opensandthedeploymentbagisreleased.Afterthattherescueparachutepackage(whichisstillpackedinit´sdeployment

bag)have tobethrownwithadynamicmove intothefree airspace.That meanstherelease handlehavetobethrown away

togetherwiththedeploymentbag!!!

The deployment bag and the bridle are designed in a way which releases the lines and canopy of the parachute not before

theparachutepackageisthrownaway.

Thispreventsanunintentionalortooearlyopeningoftherescueparachute.Thisisminimizingthedangeroftanglingupwith

the paraglider / hang glider / pilot or the reason which maybe causal for the emergency case (e.g. collision with another

paraglider).

Moreover the maximum throwing speed of the deployment bag should be reached when the deployment bag leaves the

pilothand.

Ingeneral:Thefastertherescuesystempackageisthrownaway,thequickerthesystemwillopen.

After the throw the deployment bag opens and releases lines and canopy. The powerful throw and/or the airstream

stretchesthelinesandcanopynowtherescueparachutesopens.

Whentherescueparachuteisopenedcompletely,youfirsthavetocheckthealtitudeaboveground.

If you have still enough height you should try to make the paraglider unable to fly according to the doctrine to avoid an V-

positionoftheparagliderandtherescuesystem.

Ifyoudonothaveenoughheightanymore,justfocusonthegroundandprepareyourselfforalandingfall.

6.Usageofsteeringlines

TheTrigonisequippedwithasystemthatpre-brakesthecanopyafteropeningbyshortenedsteeringlineswhichpreventsa

forwardspeed.

Theuseofthesteeringlinesrequiresafewconditionsthatmustallbemet:

After the rescue system has successfully opened in the pre-braked condition and is stable above the pilot, a sufficient

altitudemustbepresent.Inaddition,theparaglidermustbeinastable,incapableflyingposition(bestis,iftheparaglidergot

disconnectedbyaquickoutrelease).

If these conditions are all met, the pre-braked steering lines can be unlocked by pulling both control handles symmetrically

down.Therescuesystempicksupforwardspeedbydecreasingtheuseofthebrake.

Thecontrol handlesare attachedtothe rightandleftofthe bridle,rightabove thesuspension point.The steeringisworking

byincreasingthedragofthecanopy,sameasonaparaglider,butwithaslowanddampedreaction.

Attention:

Whenthepre-brakingisreleased,themax.takeoffweightisreduced(see1.Technicaldata).

Iftheparagliderisnotinareliable,incapableflyingpositionorseparatedthepre-brakedsteeringlinesmustbenot

releasedandused.IfreleasedinthisconditiontherewouldbeaveryhighpossibilityofaV-positionofparagliderto

rescue system (down plane), in combination with very high and dangerous sink rate and a without possibility of

steering.

The behaviour of the Trigon with non-activated steering lines is comparable with a conventional, not steerable

rescuesystem.

Withashouldersuspensionontheharness,dependingonthepositionofthesuspensionpoints,itcanbedifficulttoturnthe

headand seethe controlhandles.Veryoften, theserescuesystem suspensionare mountedonthe harnessfar intheback

areaand theposition ofthecontrolhandlescan thereforeonly befelt. Werecommendto testthe positionofthehandlesin

advancebyasuitablesimulation(hangintheharnessontheshouldersuspension).

The use of a front container is possible, but the bridle of the rescue system must be extended for the use on the main

carabiners.Otherwisethecontrolhandlesaremountedtoolowandasteeringisnotguaranteed.Theextensionisavailable

asanaccessory.

7.

A parachute must be controlled by a registered packer before it is repacked. After being opened during an emergency

rescue,theparachutemustbeinspectedbythemanufactureroraworkshopwhichisauthorizedbythemanufacturer.

A repackedparachuteshouldundergoareleasetestaftermountedintheoutercontainerorharness.Thisensuresthatthe

openingforcetoreleaseisbetween2kpand7kp.

Bythe firstassemblingof therescuesystem withanouter containerorharness withanintegrated rescuesystemcontainer

thefunctionalitymustbecheckedbyanexpertandmustbeconfirmedintheinspectionlogbook.

The inspection required after 24 months includes a complete visual examination of all components (cloth, seams, lines,

bridlesetc)fordamageandwear.Foraninspectionsuitabletoolsmustbeavailable(lighttable,repacktoolsetc).

Allworkmustbedocumentedappropriately.

8.Behaviourifdamagesarenoticed

If you notice any damage at the rescue parachute, which may affect the airworthy condition of the recue parachute, you

havetosendtherescueparachuteforinspection/repairtothemanufacturer.

Also, ifyouarenotsureabouttheairworthyconditioninanyway,youhavetosendtheparachutetothemanufacturer.

Attention:Chemicals,detergents, insects,mouldstainsor thelike canhavethesame negativeeffectstothestrength ofthe

partsasmechanicalinfluences.

9.Storage

Oil,grease,acidandpaintshouldnotbestoredneartheparachute.Thestoragespaceshouldbedry.Parachuteswhichwill

notbeusedforalongperiodshouldbeopenedandthecanopylooselyrolledandstoredinapermeablebag.

Avoidunnecessaryhightemperatureabove60°C(e.ginaparkingcar)!

10.Maintenance

Thelifespan andconditiondependslargely uponhowcarefully youhandleand maintainyourparachute.Out ofthisreason

werecommendtocontroltheparachuteregular,atthelatestifitisrepacked,ifthereareanywearsordamages.

Duringnormaluseyouhavetotakecareofthefollowingpoints:

If the parachute got wet, you have to open it and dry it at a well ventilated place as soon as possible (but avoid direct

sunlight!)Thefastdryingisimportanttoavoidmouldstains.Aftertheparachuteiscompletedryitcanberepacked.

Iftheparachuteisstrainedmorethannormal(forexample:acardroveovertheharnessinwhichtheparachuteisplaced,or

itmaybeisdamagedbyasharpobject,oranyotherpossibledamage),youhavetosendtheparachutetothemanufacturer

tocheckit.

Avoidcontactwithsaltwater,acidsorotheraggressivesubstances!

Alsoavoidunnecessaryexposuretosunlight,causetheUVraysmaydamagethemolecularstructureofthematerial.

11.Cleaning

Adirtycanopyandcontainercanbecarefullycleanedwithclearwaterandasoftsponge.

Attention: Never use detergents, chemicals, brushes or hard sponges to clean the parachute! Also a cleaning in the

washingmaschineisnotallowed.

Iftherescueparachute getsincontact withsaltwater,youhaveto washitwith freshwater.Atoooftencleaning accelerates

theageingofthesystem.

ControlandInspectionoftheparachute

45

This manual suits for next models

2

Table of contents

Other Independence paragliding Aircraft manuals