2/3

Last Fault Management:

On starting the autotest sequence, after completing the autotest entry sequence:

The dishwasher shows the code of the last fault detected during a wash cycle.

This is displayed for 15/20 seconds, after which it indicates the start of the loads sequence.

Reset alarm:

During the autotest procedure, to reset the last alarm that occurred during a wash cycle, you must run an

autotest cycle right through until there are no more errors.

Autotest Sequence:

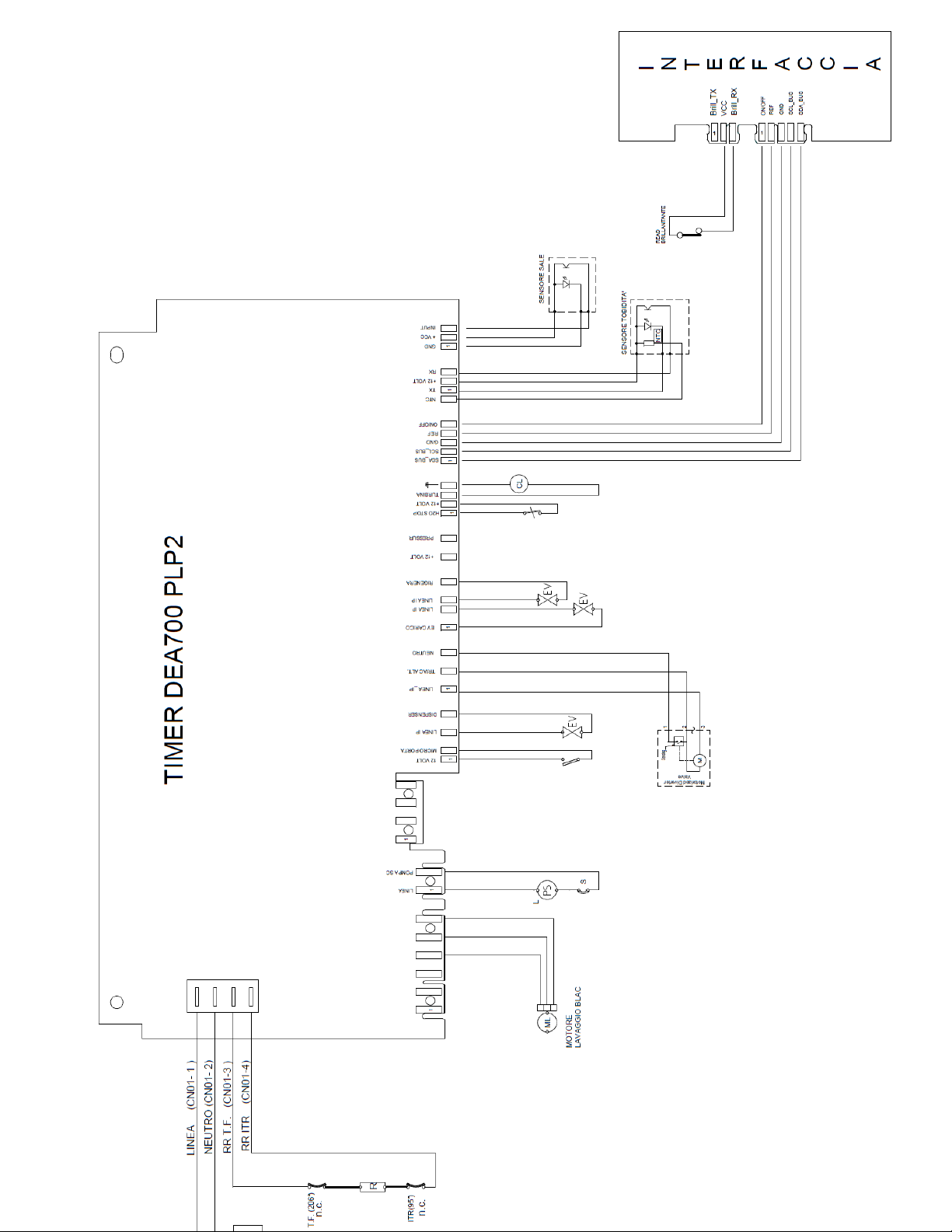

The autotest sequence in machines DEA 700 – PLP2 with“L”-shaped plumbing layout (BLAC Motor

with two sprayer arms) is as follows:

1. VDisplay of last fault (if any) for 15/20 seconds

2. The machine is drained to empty status + 15 seconds (D-Sensor); meantime the alternating wash

motor is repositioned to operate with the bottom delivery outlet open

3. Empty status is verified by the wash pump (W-sensor), running with the bottom delivery outlet open

at 1400 rpm for 40 seconds

4. The tub takes in 2 litres of water, with activation of the W-sensor to confirm full status

5. Another 2 litres are added in dynamic mode

6. The wash pump is activated for 30 seconds with the top delivery outlet open

7. The pump is switched to the bottom outlet for 30 seconds

8. The wash heating element is activated, with the wash pump running at 2500 rpm, and the tempera-

ture raised to 30 °C

9. The machine is drained to empty status (D_sensor) + 15 seconds

10. The dispenser is opened by activating the solenoid valve for 2 seconds

11. 10-second pause

12. Service action: once the dispenser has opened, open the door, remove the salt cover and insert

the door needle

13. The regenerate solenoid is activated for 5 seconds

14. The fill solenoid valve and regenerate solenoid valve are activated for 10 seconds. Check for outflow

of water from the salt container

15. The Turbo Dry Fan is activated (if installed)

16. Drain to empty status (D-Sensor) + 15 seconds

The autotest sequence in DEA 700 – PLP2 machines with “C”-shaped plumbing layout (BLAC

motor with two spray arms and showerhead) is as follows:

1. Display of LAST FAULT (if any) for 15/20 seconds

2. The machine is drained to empty status + 15 seconds (D_sensor); at the same time, the alternating

wash motor is repositioned to operate with the bottom delivery outlet open

3. Empty status is verified by the wash pump (W-sensor), running at 1400 rpm for 40 seconds

4. The tub takes in 2 litres of water, with activation of the W-sensor to confirm full status

5. Another 2 litres are added in dynamic mode

AUTOTEST EOS DEA 700 - PLP 2 - Synchronous and BLAC* Motor