3

Transportation, Installation, Commissioning

LL1602.10043 - 04.08.2014

ABC

CONTENTS

Contents............................................................................................................................................................................. 3

Safety Instructions .......................................................................................................................................................... 5

Instructions for shipment, installation, commissioning .................................................................................................. 5

General sources of danger during in-house transportation...................................................................................... 5

Dimensions and masses.............................................................................................................................................. 6

Shipping- and lifting equipment................................................................................................................................... 6

Transport equipment, ropes......................................................................................................................................... 6

Preparations ...................................................................................................................................................................... 7

Suitable transport- and lifting equipment........................................................................................................................ 7

Space requirements .......................................................................................................................................................... 8

Foundations ........................................................................................................................................................................ 8

Environmental Conditions ................................................................................................................................................. 8

Power supply ..................................................................................................................................................................... 9

Compressed Air Supply .................................................................................................................................................... 9

Main fuse ........................................................................................................................................................................... 9

External data transfer........................................................................................................................................................ 10

Media to be provided ....................................................................................................................................................... 10

Pumps and Tanks.............................................................................................................................................................. 11

Chip disposal...................................................................................................................................................................... 11

Disposal of used media.................................................................................................................................................... 11

Compliance with waterbalance regulations .................................................................................................................... 11

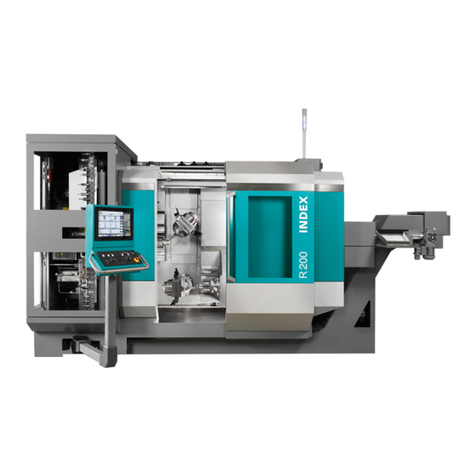

Transport ............................................................................................................................................................................ 12

Delivery............................................................................................................................................................................... 12

Machine ......................................................................................................................................................................... 12

Pressure accumulator ................................................................................................................................................... 12

Other separate units..................................................................................................................................................... 12

Transportation equipment............................................................................................................................................. 12

Unloading the machine with a crane .............................................................................................................................. 14

Quick start manual for Transport ABC ...................................................................................................................... 15

Preparations ...................................................................................................................................................................... 17

Transportation with a fork lift ........................................................................................................................................... 17

Transportation with casters .............................................................................................................................................. 18

Placing the machine.......................................................................................................................................................... 20

...with a crane or a mobile crane .......................................................................................................................... 20

...with hydraulic jacks (Fig.)..................................................................................................................................... 20

Unloading and transporting separate units ..................................................................................................................... 22

Unpacking the accessories and checking them for completeness ............................................................................. 22