3

Product note

Base holder for boring slide

W9800029EN-02.02.18

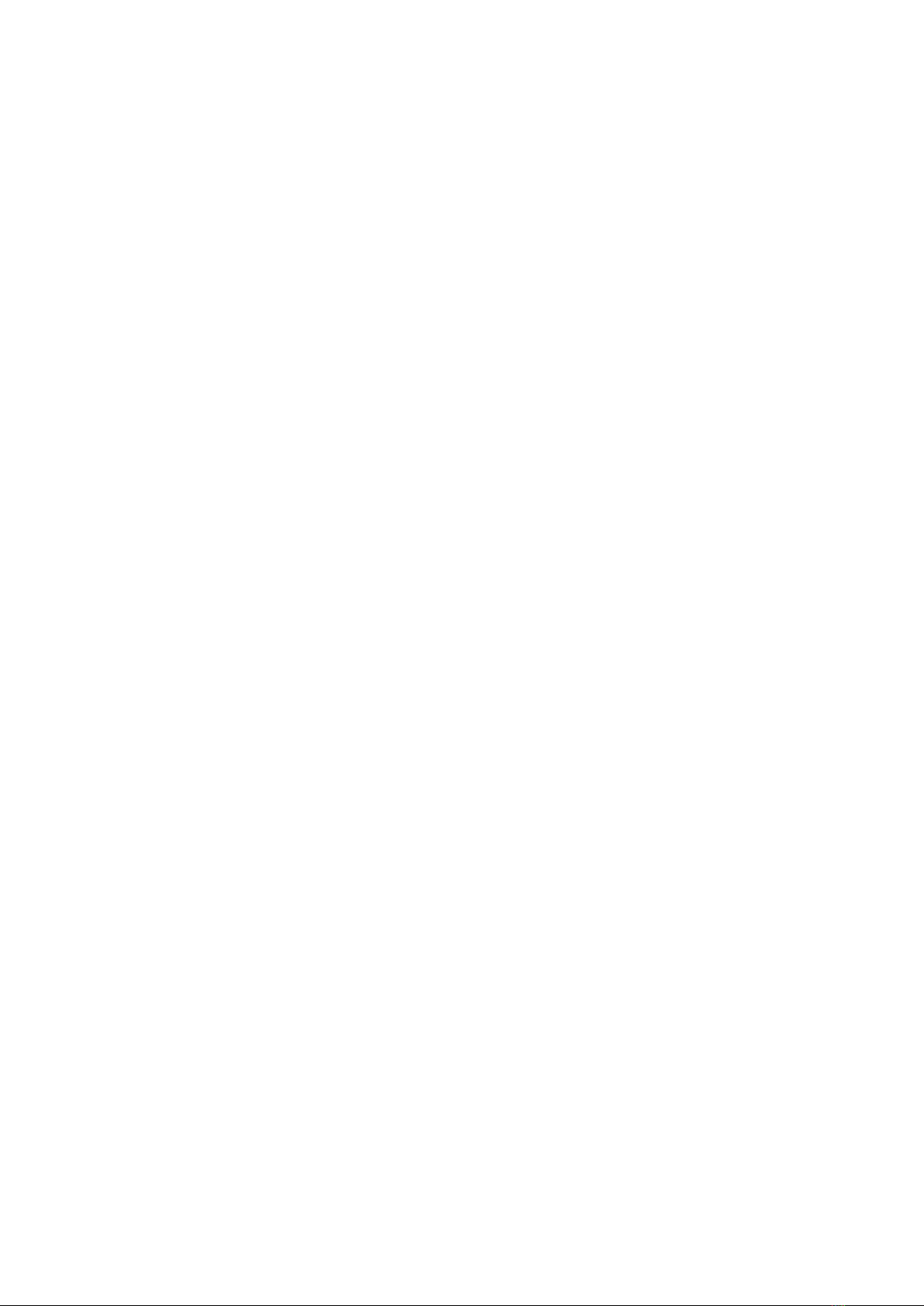

Setup options on boring slide

Z+ orientation ................................................................................................................................................................ 5

Z- orientation.................................................................................................................................................................. 5

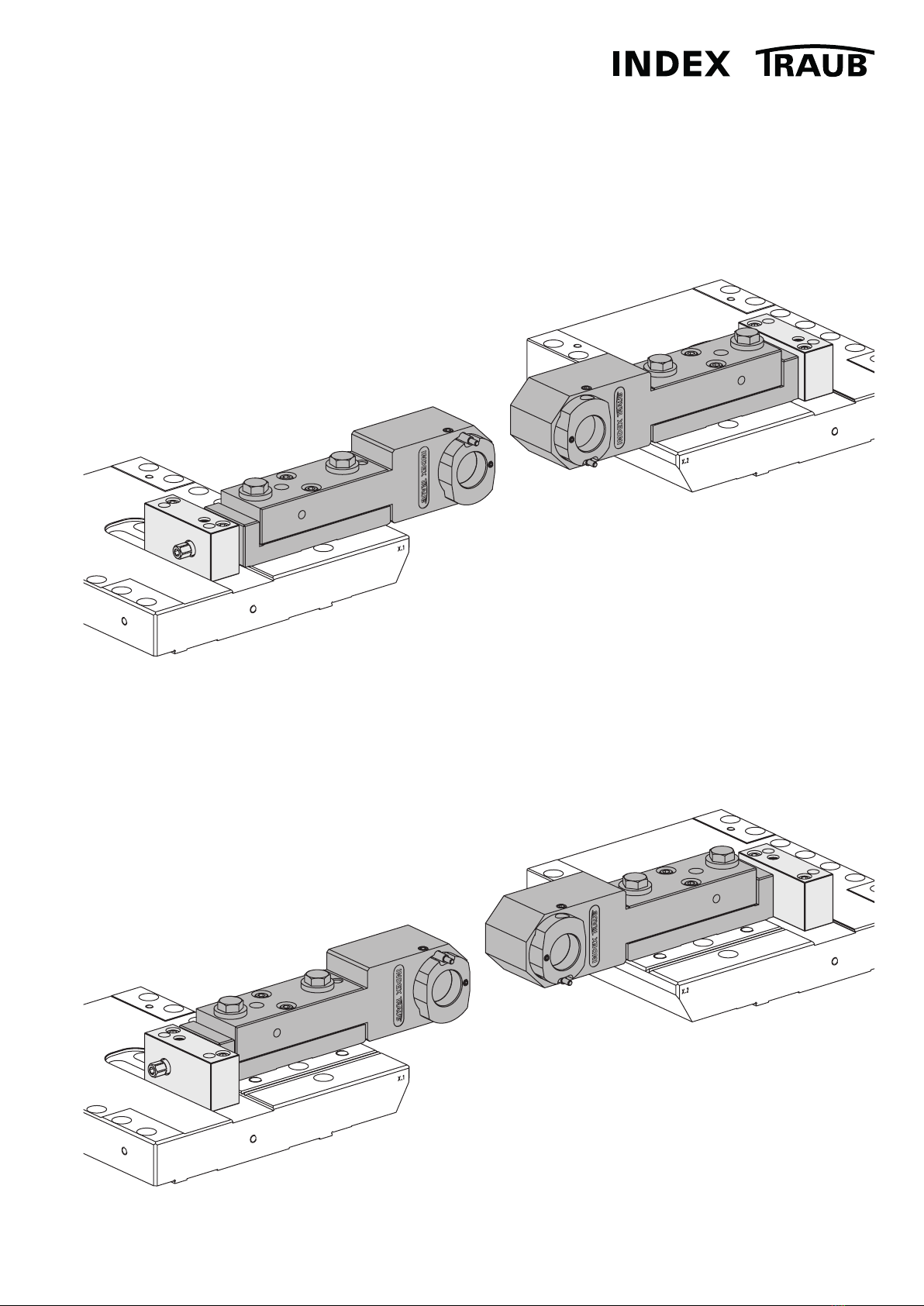

Base holder 10156937

Position X.2, delivery state .......................................................................................................................................... 6

Position X.1, conversion................................................................................................................................................ 7

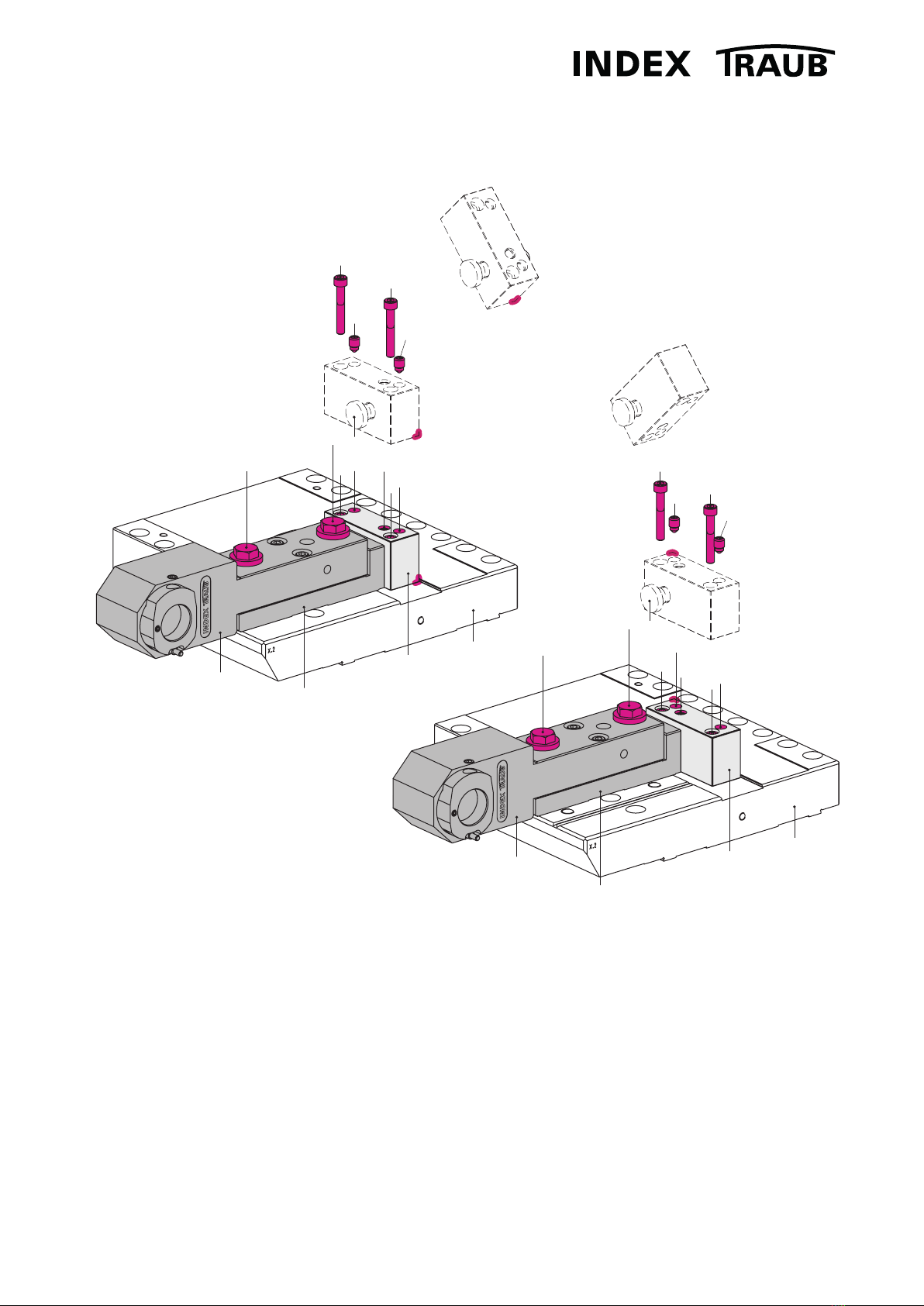

Setup on boring slide

Position X.2, Z+ orientation ......................................................................................................................................... 8

Position X.1, Z- orientation............................................................................................................................................ 9

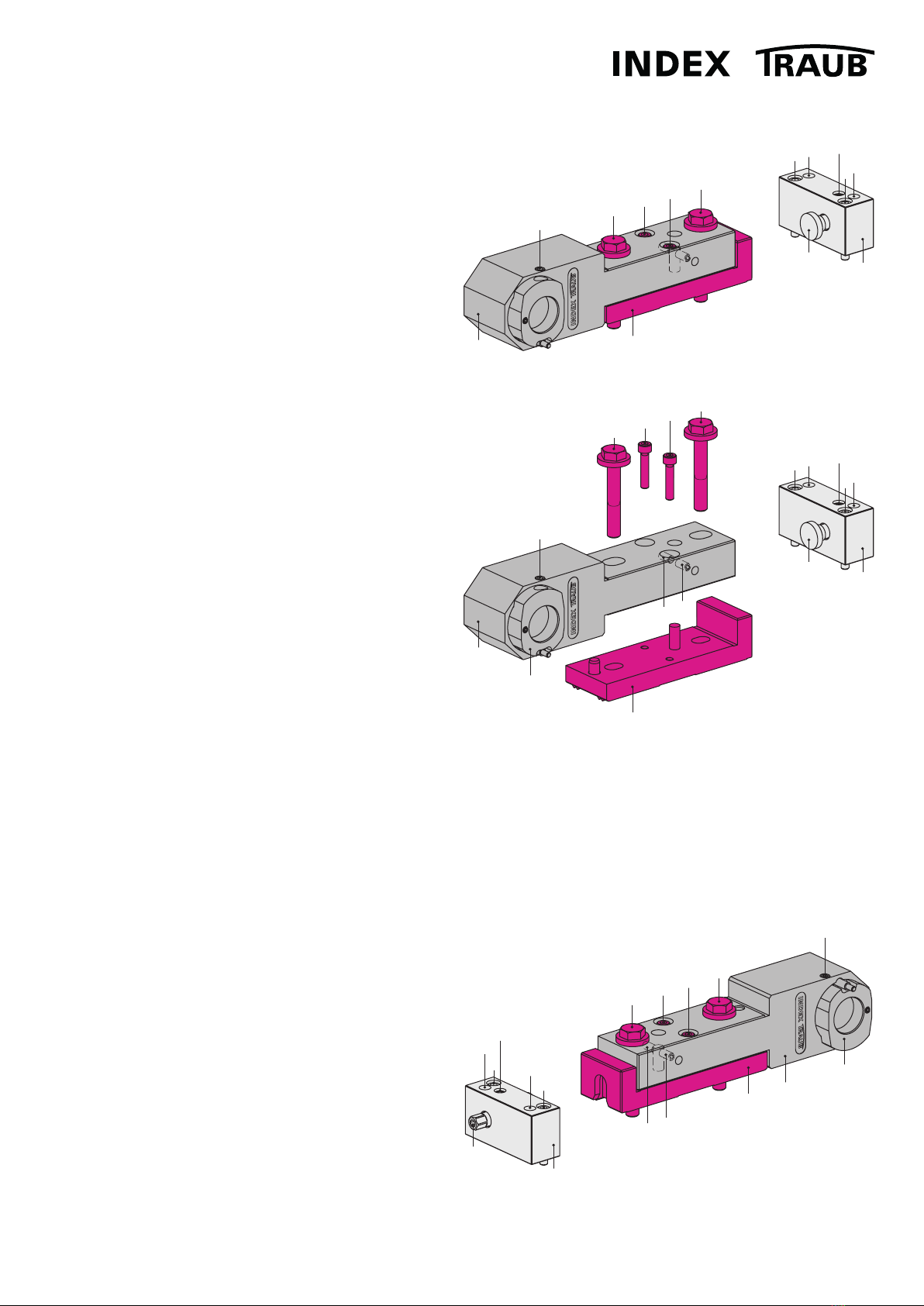

Conversion Z orientation, 30 mm offset .................................................................................................................... 10

Inserting the drill holder................................................................................................................................................ 11

Axis orientation................................................................................................................................................................ 12

Y orientation by hydraulic expansion clamping sleeve

Optimum conditions ..................................................................................................................................................... 13

Cleaning.......................................................................................................................................................................... 13

Clamping ........................................................................................................................................................................ 13

Temperature................................................................................................................................................................... 13

Storage ........................................................................................................................................................................... 13

Adjustment..................................................................................................................................................................... 14

Adjusting concentricity.................................................................................................................................................. 15

Adjustment to below 0.005 mm ............................................................................................................................... 16

Alignment in X- spindle center .................................................................................................................................... 17

TABLE OF CONTENTS